cooling MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 2 of 279

Mazda 323

o Workshop

b Manual CONTENTS

r Title Section

IG eneral Information

Pre-Delivery inspection and

Scheduled Maintenance

Supplement

I Lubrication System

j Cooling System

FOREWORD

This is a supplement to the workshop manu-

a!(s) shown below. This supplement describes

service procedures of. new or modified me-

chanicat and/or ekctrical systems. For service

procedures and important safety notices not

contained in this supplement, please refer to

the previous workshop manual.

Workshop Manual:

Form No.1 203-l O-89F (vol. 1)

1206-1 O-89F (Vol.2)

1229-l O-89L

1275-l O-91 c

b

All information in this supplement was the

latest available at the time of printing, ail alter-

nations related to modifications will be notified

by Service Sulletin. Carburetor

m !I

Fuel and

Emission

Controt

System EGi unieaded Fuel BP (DOHC

and S

Diesel

-Electrica I System

I-- Clutch

Manual

Transaxie

1 Electronically Co Introlled

I

Automatic

Transaxle Hydraulicaf~y’Co~~~rull=;u

1 Transfer

Mazda Motor Corporation

HIROSHIMA, JAPAN [ Propefier Shaft

1 Front and Rear Axles

P ISteerIng System

APPLICATION:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (VIN)

shown on the following page. Braking System

IWheels and Tires

ISusiension

1 Bodv Electricat System

1 Heater and Air Conditioner System

1 Technical Data

Special Toots

Parts Index

/ Wiring Refer to the form No.

, Diagram 5232-l 0-92A

--

This manual explains onty the secticlns marked with shadows (-1

0 1992 Mazda Motor Corporation

PR1NTED tN JAPAN, JAN., ‘92 @I

1318010192A

Page 27 of 279

The following chart shows interchangeability of the main parts of the previous BP DOHC Turbo engine

and the new BP DOHC Turbo engine for 4WD models.

S ymiols: 0 _. lnterc hangeable X . . . Not Interchangeable

Part name tnterchangeability

Remark

Cytlnder head 0

Camshaft 011 seal 0

Cvllnder head bolt 0

CB :

Cyh nder

blcck

related

Crankshaft

related

Timing belt

related

Valve

related

Lubrication

system

related Cylrnder head gasket 0

Wnder head cover 0

Cylinder head cover gasket

Cylinder block

MaEn bearina cao 0

0

0

Ma+n bearino suo~oFt elate I

0 I ” ,I I

Oil pan

Timrno belt cover I X

0 I

Turbocharger oil return pipe hole increased from

13mm IO.51 in) to 17mm IO.67 in)

Seal elate

Front orl seal I 0 I

I I 0

1

Rear 011 seal 0

Crankshaft 0

Marn bearina 0

Thrust bearing

Connectmg rod

Connecting rod beartng

Piston 0

;J

X

Shape different

Piston skirt shortened

I Piston pm cl

Tw

X Sectional shape different

Piston rrng Piston ring end gap increased from 0:?5--0.30mm

Second

X ~0.006-0.011 in ) to 0.35-0.50mm IO.01 4-0.019

in ] (Measured In cylinder)

Crankshaft pulley Shape different

Rear cover ;5

Flywheel

I 0

Flywheel bolt 0

Tbmlng belt 0

Timing belt crank pulley 0

Camshaft pulley 0

Timing belt tensioner and spring

0

Idler 0

Camshaft 0

AA

Valve Intake

Exhaust

cl

0

X Metallic sodium-filled valve

Valve spring Intake

I 0

and seat

Exhaust 0

Vatve wide I 0

Valve seal

Oil pump 0

Oil pump gasket 0

oil strainer 0

Oil strainer gasket 0

Oil cooler

X Heat dissi patlon capacity increased

Oil jet

Oil filter Shape different

1 Water pump 0

Coohng Thermostat 0

system

related Radiator 0

Cooling fan 0

I 3EO32.304

BZ-3.

Page 28 of 279

![MAZDA 323 1992 Workshop Manual Suplement B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1 MAZDA 323 1992 Workshop Manual Suplement B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 1](/img/28/57055/w960_57055-27.png)

B2 OUTl1NE

COOUNG CHANNEL RtNG CARRtER

61.5mm i 2.42 in ] - 56.5mm (2.22 in

Piston diameter Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm and 11 .Omm

IO.650 in 1 below 10.433 in 1 below

oil rmg groove. oil ring groove.

COOLING CHANNEL

*IL YTLET

OIL t NiET

l The piston skirt is shortened for reduced weight and friction. l A cast iron ring carrier is installed in the piston to reduce piston-ring groove wear. l A cooling channel is incorporated in the body of the piston. The 011 jet squirts oil into this cootrng channel

and the or! absorbs

the heat from around the ring lands, reducing piston ring and cylinder wat! wear

Bz-4

Page 52 of 279

F3 TROUBLESHUOTING GUIDE

TROU8LESHOOTlNG GUIDE

RELATIONSHIP CHART

.

OUTPUT DEVICE

INPUT DEVICE

w

3

s

s

KNOCK SENSOR

0

0 0 0 DtAGNOStS CONNECTOR

(TEN TERMINAL)

0 0 0 IGNITION SWlTCH

(START POSITION) 0 0

0

0

0 0

0 0

0 0

0

0

0

0

0 0 0 0

E/L SIGNAL* 0

P/S PRESSURE SWITCH 0

0

A/C SWtTCH

NEUTRAL AND CLUTCH

SWITCHES

STOPLIGHT SWITCH

ATMOSPHERIC PRESSURE

SENSOR (IN ECU)

THROTTLE SENSOR

0 0 0 0

0

0

0 0’

0

0 0

0

0 0

0

’ 0

0

0 0 0 0 0 0 0

0 I

0 ~ INTAKE AIR THERMOSENSOR 0 0 0 0

0 -~

OXYGEN SENSOR

0 0 0 0 WATER THERMOSENSOR

A

0

* 0 0 0 c 0

13

3F3-32 IN, o . E/L SIGNAL: Blower fan control switch second position or higher, electric cooling fan operating, headlights

rear window defroster ON.

F3-19

i

Page 82 of 279

-. _.. . . . . . _ - ._.

-w

CONTROL SYSTEM F3

I .

-.

Ve: Battery voltaae I

Incorrect voltage

Atwafi below 1 .OV

Always VB

Always VS (foglight switch OK)

Always below 1 .OV

Always below 1 .OV

Always Vs

Always

below 23 (blower fan OK)

Always VB (blower fan OK)

Always below 1 .OV

(electric cooling fan OK) -

1-

Possible cause

l Throttle sensor mrsadjustment l Short circuit in wtrrng from throttle sensor to ECU terminal 1 N l ECU malfunction

l Throttle sensor mrsadjustment l Open circuit in wiring from throttle sensor to ECU terminal fN l Open circuit in mnng from throttle sensor to ECU terminal 20

l Foglight relay malfunctron

l Foglrght relay malfunction

l P/S pressure switch maltunctron l Short crrcurt In wrrlng from P/S pressure switch to ECU terminal 1 P l ECU malfunction

l P/S pressure switch malfunction l Open circuit in wlnng from P/S pressure switch to ECU terminal 7 P l Open circuit in wiring from P/S pressure switch to ground

l A/C switch malfunctron l Short circuit tn wiring from A/C switch to ECU terminal 1Q l Poor connection at ECU connector l ECU malfunction

l #C swatch malfunction l Open circuit in wiring from A/C switch to ECU terminal 1Q l Open circuit in wiring from A/C switch to blower control switch

l Open or short circuit in wiring from fan relay to ECU terminal 1R l ECU matfunction

Always below 1 .OV (blower fan OK}

Always Vs (btower fan OK)

Always betow illumination lamp

1 .ov ON when rear

window defroster

switch ON

Illumination lamp

never ON

Atways below 1 .OV (headttghts OK)

l Short circuit in wrrtng from blower control switch to ECU terminal IS l Poor connection at ECU connector l ECU m&function

l Open crrcuit in wrrrng from blower control switch to ECU terminal 1s

l Open or short crrcuit In wiring from rear window defroster switch to ECU

terminal t T

l Open circuit in wiring from ignitron switch to rear window defroster switch l Rear window defroster switch malfunction

l Open or short circuit in wiring from headlight relay to ECU terminal 1 U

Always below 1 .OV

l Neutral switch malfunction l Clutch switch malfunction l Short circuit in wiring from ECU terminal IV to neutral or clutch switch

Always VB

l Neutral switch malfunction l Clutch switch malfunction l Open circuit in wiring from ECU terminal 1V to neutral or clutch swdch l Poor connection at ECU connector

13FOl=3-36 .

F3-49

.:i

Page 139 of 279

UUTLINE

RADfATOR GRfLtE

l The air inlet area of the radiator grille is enlarged for improved cooling efficiency.

FRONT BUMPER

l The large front bu,mper includes fog lights and bumper mesh to give the vehicle a dynamic appearance.

l tight and rigid polyurethane is used for the bumper fascia.

l The air inlet area is adopted for improved cooling efficiency.

s-4

REAR SKI

l The rear 5

l Light and

WHEEL AR4

l Wheel arc

Page 154 of 279

TD

TECHNICAL DATA

ENGtNE ..................................................

TD- 2

LUBRICATlON SYSTEM ...........................

TD- 4

COOLING SYSTEM ..................................

TD- 5

FUEt AND EMISSION CONTROL

SYSTEMS

.............................................

TD- 6

ENGINE ELECTRICAL SYSTEM

................ TD- 7

CLUTCH .................................................

TD- 7

MANUAL TRANSAXLE AND TRANSFER

.... TD- 8

PROPELLER SHAFT

................................

TD-l 0

FRONT AND

REAR AXLES ....................... TD-lU

STEERING SYSTEM ................................

TD-11

BRAKING SYSTEM

..................................

TD-11

WHEELS AND TIRES

...............................

TD-12

SUSPENSION

......................................... TD-13

BODY ELECTRICAL SYSTEM

................... TD-14

STANDARD BOLT AND NUT TIGHTENING.

TORQUE ..............................................

TD-f 4

13ETOX-301

I

m I

Page 157 of 279

![MAZDA 323 1992 Workshop Manual Suplement TD TECHNICAL DATA

LU8RlCATtON SYSTEM

Item

Lubricating method

011 pump Engine

BP DOHC turbo

Force-fed

6 . Trochoid gear

Relief pressure

kPa I kgf/cm’. psi] 343-441 [ 3.5-4.5, 50-64 1

Regula MAZDA 323 1992 Workshop Manual Suplement TD TECHNICAL DATA

LU8RlCATtON SYSTEM

Item

Lubricating method

011 pump Engine

BP DOHC turbo

Force-fed

6 . Trochoid gear

Relief pressure

kPa I kgf/cm’. psi] 343-441 [ 3.5-4.5, 50-64 1

Regula](/img/28/57055/w960_57055-156.png)

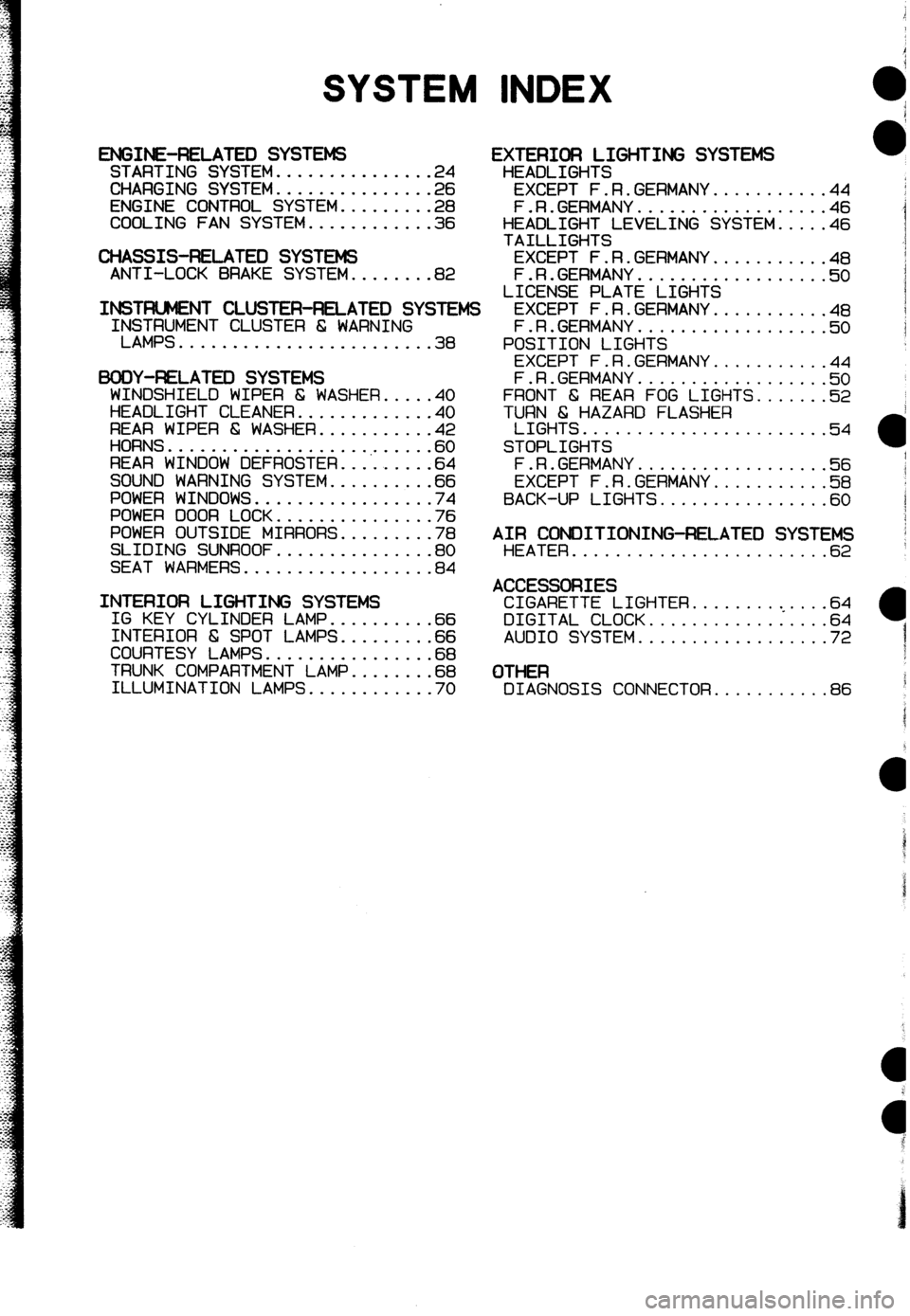

TD TECHNICAL DATA

LU8RlCATtON SYSTEM

Item

Lubricating method

011 pump Engine

BP DOHC turbo

Force-fed

6 . Trochoid gear

Relief pressure

kPa I kgf/cm’. psi] 343-441 [ 3.5-4.5, 50-64 1

Regulated pressure kPa { kgf/cm’ , psi ] -rpm

294-392 { 3.0-4.0, 43--57.1.3,000

Inner rotor tooth tip to outer. rotor Standard

0.02-0.16 (OJOOS-O.O063]

clearance

mm {in]

Maximum I

0.20 [ 0.0078 )

Outer rotor to body clearance

Side clearance

Oil fIl!er

, TYpe

Relief pressure differential . mm [in) Standard

Maximum

mm {in) Standard

Maximum 1

kPa’ f kgf/cm’, psi 1 0.09-0.18 ~0.00354.Ofl71]

0.22 { 0.0087 1

0.03-0.11 ~0.0012-0.0043~

0.14 {0.0055)

Full-flow, paper element

. 78-118 (0.8-1.2. 11-17) Srade

----l-in

Viscosity

num her

Item

Cooling metha

Water pump

, We

Impeller diame

Number of imf

Speed ratio -

Water seal !$

Thermostat

Jype. _

Opening terq

/Full-open

1 F&open lift

I

Antifreeze E

TD-4

Page 158 of 279

TECHNICAL DATA TD

Engine

Item BP DOHC turbo

Engine oii

Total (dry engine} 4.0 14.2, 3.5)

Capacity

L IUS qt, Imp qtl Ott pan 3.6 (3.8, 3.2)

011 filter 0.17 (0.18, 0.15)

Grade API Service SD, SE, SF or SG

Above 30°C (86*F) SAE 40

O*C-40*C ~32°F-1040F 1 SAE 30

-1 OOC--2O*C [ 14OF-68OF ] SAE 2OW-20

Viscosity Above -10% [14*Fj SAE ZOW-40 or 2OW-50

number -25*C--3O*C I-1 3OF-86OF ] SAE 1 OW-30

Above -25OC (-13*F1 SAE low-40 or low-50

Below O*C (32*F] SAE 5W-30

Below -2O*C I-4*F] SAE 5W-20

COOLING SYSTEM

L

item

Zooling method - 1 Engine

BP DUHC turbo

I Water-cooled, forced crrcutation

water pump

Type

mpeller diameter

Number of impeller blades

Speed ratio

tiater seal type

rhermostat

bfpe

Opening temperature

Full-open temperature

Full-open lift mm [in)

OC (OF)

*C j*FJ

mm (in] Centrifugal, V-belt driven

75 12.95)

6

1 : 1.05

Unified mechanical seal

Wax, two-stage

Marn: 86.5-89.5 [ 788-I 93 1

Sub: 83.5-86.5 [182-i 88)

loo (212)

Main: 8.0 (0.31 1 min.

Sub: 1.5 IO.061 min.

Radbtor

Type

Cap valve opening pressure kPa { kgflcm2, psi)

Cooling circuit checkrng pressure kPa ( kgflcm2, psi 1

Cooling fan

Type

Number of blades

Outer diameter mm {in 1

Capacity w-v

Current A

Water thermoswitch

OFF-+ON “C 1°F) 1

Radiator thermoswitch

OFFdON OC (OF]

Coolant

Capacity LWS qt,

Imp qt) Coolant protection

Above -16*C (3OF]

Antifreeze solutron

.Above -26*C t-1 5*F ) -

Above -4UOC I-40°F) Corrugated fin

74-103 {0.75--1.05, 11-15)

103 11.05, 15)

Electric

5

340 (13.41

160-12

Hi: 13.3+ 10% max., Lo: 8.8+ 10% max.

97 f207)

105 [221)

6.0 16.3, 5.3)

Specific gravity at 20*C (68*f)

1.054

1.066

1.078 -.ep

1

Page 179 of 279

SYSTEM INDEX

ENGINE-RELATED SYSTEMS STARTING SYSTEM...............2 4

CHARGING SYSTEM...............2 6

ENGINE CONTROL SYSTEM.........2 8

COOLING FAN SYSTEM............3 6

CHASSIS-RELATED SYSTEMS ANTI-LOCK BRAKE SYSTEM........82

INSTFUJMENT CLUSTER-RELATED SYSIEMS IrS$;MENT CLUSTER 6 WARNING

........................ 38

BODY-F&LATEX) SYSTEMS

WINDSHIELD WIPER 6 WASHER.....4 0

HEADLIGHT CLEANER.............4 0

REAR WIPER & WASHER...........4 2

HORNS...................,......6 0

REAR WINDOW DEFROSTER.........6 4

SOUND WARNING SYSTEM..........6 6

POWER WINDOWS.................7 4

POWER DOOR LOCK...............7 6

POWER OUTSIDE MIRRORS.........7 8

SLIDING SUNROOF...............8 0

SEAT WARMERS..................8 4

INTERIOR LIGHTING SYSTEMS IG KEY CYLINDER LAMP..........6 6

INTERIOR 6 SPOT LAMPS.........6 6

COURTESY LAMPS................6 8

TRUNK COMPARTMENT LAMP........6 8

ILLUMINATION LAMPS............7 0

EXTERIOR LIGHTING SYSTEMS

HEADLIGHTS

EXCEPT F.R.GERMANY...........44

F.R.GERMANY..................46

HEADLIGHT LEVELING SYSTEM.....46

TAILLIGHTS

EXCEPT F.R.GERMANY...........48

F.R.GERMANY..................5 0

LICENSE PLATE LIGHTS

EXCEPT F.R.GERMANY...........4 8

F.R.GERMANY..................5 0

POSITION LIGHTS

EXCEPT F.R.GERMANY...........4 4

F.R.GERMANY..................!i? 0

FRONT 6 REAR FOG LIGHTS.......52

TURN 6 HAZARD FLASHER

LIGHTS.......................54

STOPLIGHTS

F.R.GERMANY.a................5 6

EXCEPT F.R.GERMANY...........5 8

BACK-UP LIGHTS................6 0

AIR CONDITIONING-RELATED SYSTEMS HEATER........................6 2

ACCESSORIES CIGARETTE LIGHTER.........<....64

DIGITAL CLOCK.................64

AUDIO SYSTEM..................72

OTHER DIAGNOSIS CONNECTOR...........86