oil MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 710 of 909

M–80

ON-BOARD DIAGNOSTIC

End Of Sie

DTC U0100A6E637027100205

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

DTC U0101A6E637027100206

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

DTC U0121A6E637027100207

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

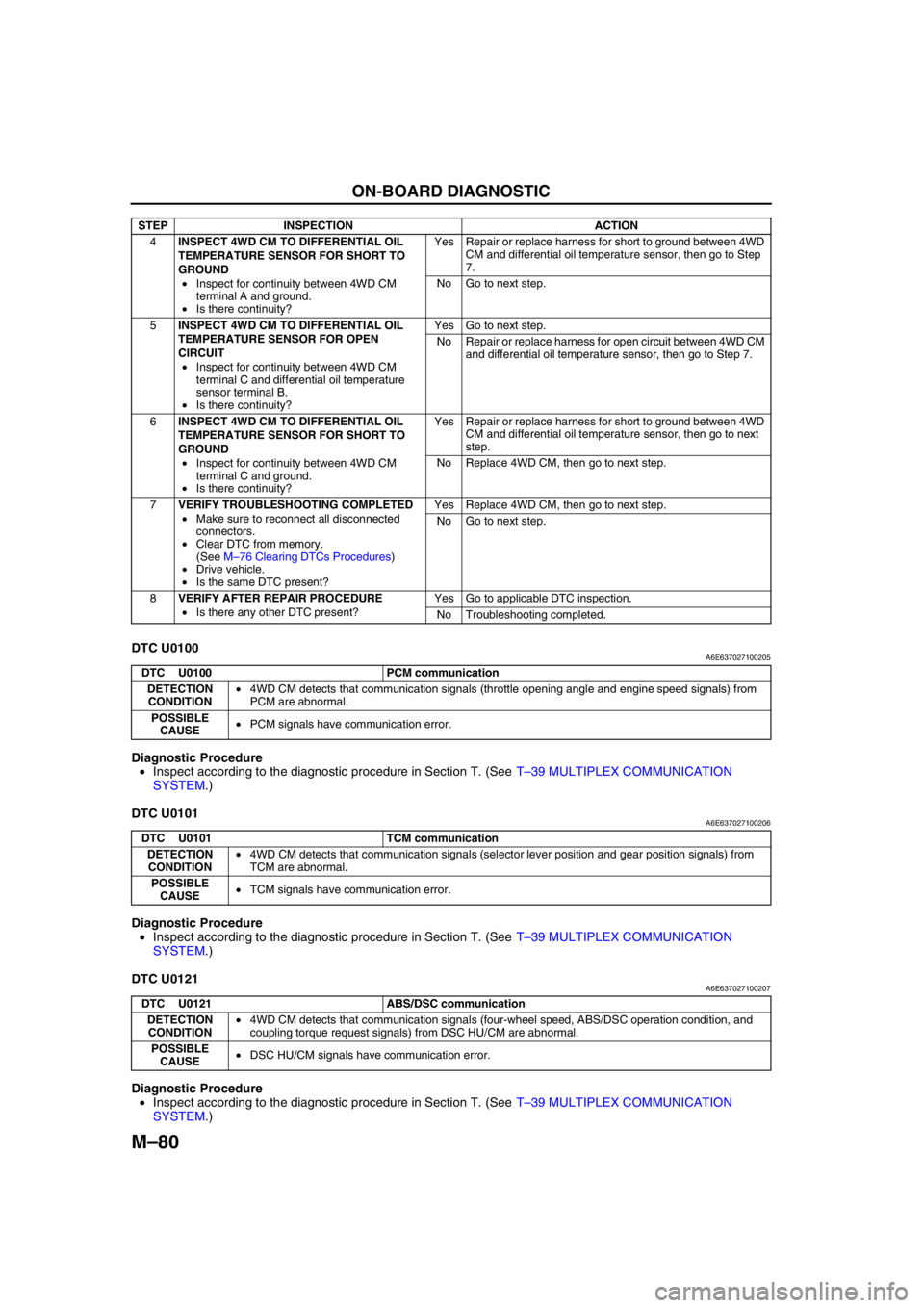

4INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal A and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and differential oil temperature sensor, then go to Step

7.

No Go to next step.

5INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR OPEN

CIRCUIT

•Inspect for continuity between 4WD CM

terminal C and differential oil temperature

sensor terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and differential oil temperature sensor, then go to Step 7.

6INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal C and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and differential oil temperature sensor, then go to next

step.

No Replace 4WD CM, then go to next step.

7VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

(See M–76 Clearing DTCs Procedures)

•Drive vehicle.

•Is the same DTC present?Yes Replace 4WD CM, then go to next step.

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC U0100 PCM communication

DETECTION

CONDITION•4WD CM detects that communication signals (throttle opening angle and engine speed signals) from

PCM are abnormal.

POSSIBLE

CAUSE•PCM signals have communication error.

DTC U0101 TCM communication

DETECTION

CONDITION•4WD CM detects that communication signals (selector lever position and gear position signals) from

TCM are abnormal.

POSSIBLE

CAUSE•TCM signals have communication error.

DTC U0121 ABS/DSC communication

DETECTION

CONDITION•4WD CM detects that communication signals (four-wheel speed, ABS/DSC operation condition, and

coupling torque request signals) from DSC HU/CM are abnormal.

POSSIBLE

CAUSE•DSC HU/CM signals have communication error.

Page 711 of 909

TROUBLESHOOTING

M–81

M

SYSTEM WIRING DIAGRAMA6E638027100201

End Of Sie

TROUBLESHOOTING

IGNITION SWITCH

BATTERY

DIFFERENTIAL OIL

TEMPERATURE

SENSOR4WD CM4WD SOLENOID ELECTRONIC CONTROL

COUPLING

CAN DRIVERINSTRUMENT CLUSTER

CAN-H

CAN-LPCM DSC HU/CM KO

P I

A

C

NH G

TCM

A6E63702002

Page 712 of 909

M–82

TROUBLESHOOTING

FOREWORDA6E638027100202

End Of Sie

SYMPTOM TROUBLESHOOTINGA6E638027100203•Verify the symptoms, and perform troubleshooting according to the appropriate number.

End Of Sie

NO.1 FREQUENT FRONT WHEEL SLIPA6E638027100204

Warning

•During simulation driving, vehicle stability may decrease extremely and cause an accident. Be

sure to perform the simulation test driving in a safe area.

Malfunction vehicle delivered

Questionnaire

Verify malfunction symptoms

Symptom troubleshooting

Verify that malfunctions have been repaired

Troubleshooting completedConfirm all customer problems using a questionnaire.

Confirm malfunction on actual vehicle.

DTC inspection

Inspect for DTCs using WDS or equivalent.

Perform applicable troubleshooting inspection according to

diagnostic index.

A6E63802001

No. Symptom Description

1 Frequent front wheel slip Front wheels slip frequently during acceleration on low-friction road.

2

Tight corner braking effectBrakes seem to be applied during tight cornering while driving very

slowly on paved road.

3 Abnormal noise and/or vibration from

coupling unitThere is abnormal noise and/or vibration from coupling unit during

driving.

1 Frequent front wheel slip

[TROUBLESHOOTING HINTS]

•Tire traction performance is extremely poor for given road friction. (4WD system is normal.)

•Improper wheel alignment (4WD system is normal.)

•Rear differential oil temperature is extremely high (Fail-safe condition)

•Differential oil temperature sensor malfunction (Fail-safe condition)

•Compare slip frequency with another vehicle of the same model (under the same road conditions and tire traction

performance).

•Replace tires with others of the same model and perform test under the same road conditions to determine if the

malfunction was caused by tire traction performance.

•Coupling component malfunction

•4WD solenoid malfunction

Page 715 of 909

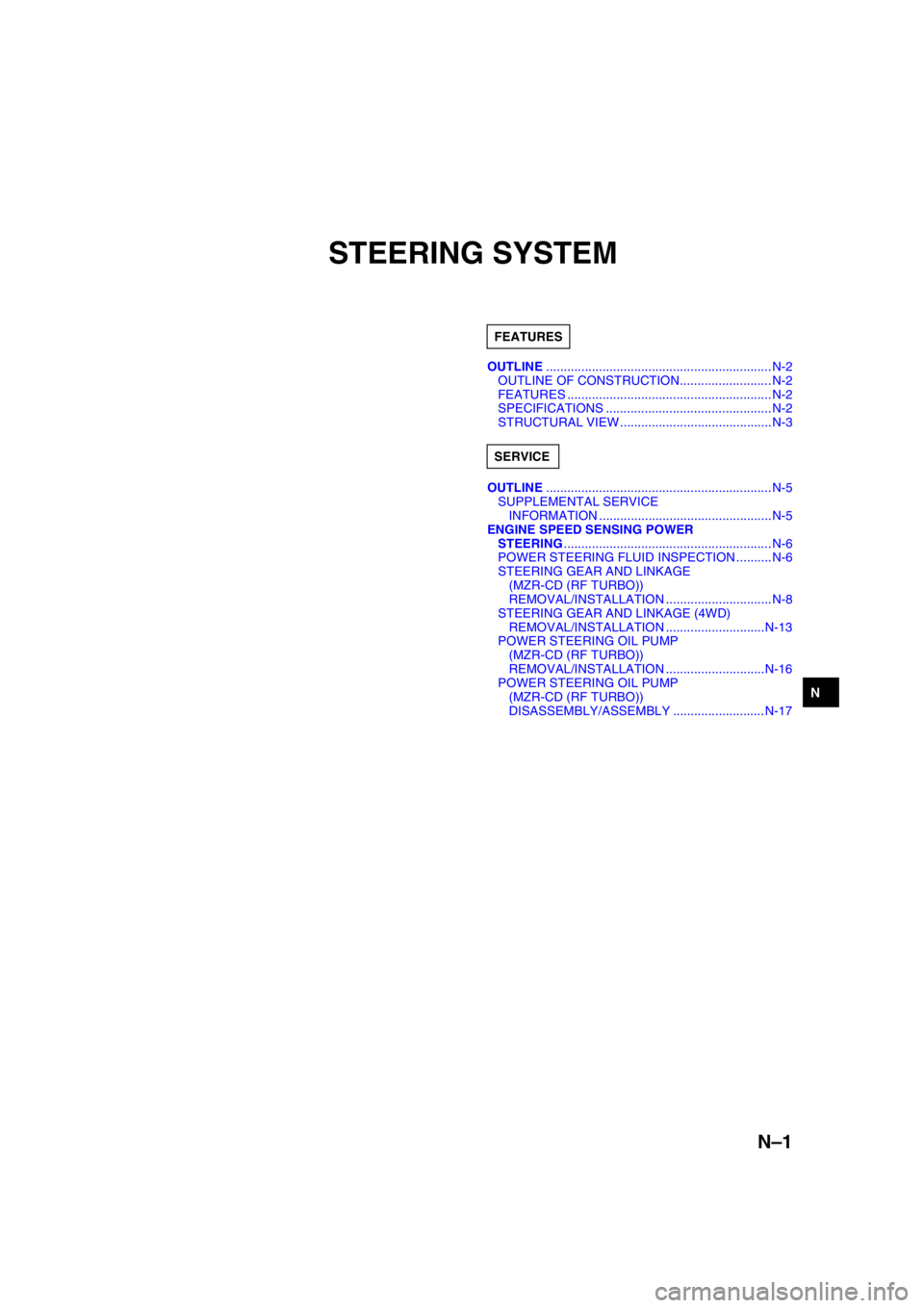

N–1

N

NSTEERING SYSTEM

OUTLINE................................................................ N-2

OUTLINE OF CONSTRUCTION.......................... N-2

FEATURES .......................................................... N-2

SPECIFICATIONS ............................................... N-2

STRUCTURAL VIEW ...........................................N-3

OUTLINE................................................................ N-5

SUPPLEMENTAL SERVICE

INFORMATION .................................................N-5

ENGINE SPEED SENSING POWER

STEERING........................................................... N-6

POWER STEERING FLUID INSPECTION ..........N-6

STEERING GEAR AND LINKAGE

(MZR-CD (RF TURBO))

REMOVAL/INSTALLATION ..............................N-8

STEERING GEAR AND LINKAGE (4WD)

REMOVAL/INSTALLATION ............................N-13

POWER STEERING OIL PUMP

(MZR-CD (RF TURBO))

REMOVAL/INSTALLATION ............................N-16

POWER STEERING OIL PUMP

(MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY .......................... N-17 FEATURES

SERVICE

Page 716 of 909

N–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E660201036201•The construction and operation of the steering system is essentially carried over from that of the current

Mazda6 (GG), except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

• Due to the addition of the MZR-CD (RF Turbo) engine, a gear-driven power steering oil pump has been

adopted. The operation of the oil pump is the same as that of the current Mazda6 (GG).

• The disassembly/assembly procedures for the steering gear and linkage of the newly equipped MZR-CD (RF

Turbo) engine, wagon and 4WD models are the same as that of the current Mazda6 (GG).

End Of Sie

FEATURESA6E660201036202Improved Steering Feel

• The fluid pressure characteristics of the power steering system has been optimized (MZR-CD (RF Turbo) and

4WD models).

End Of Sie

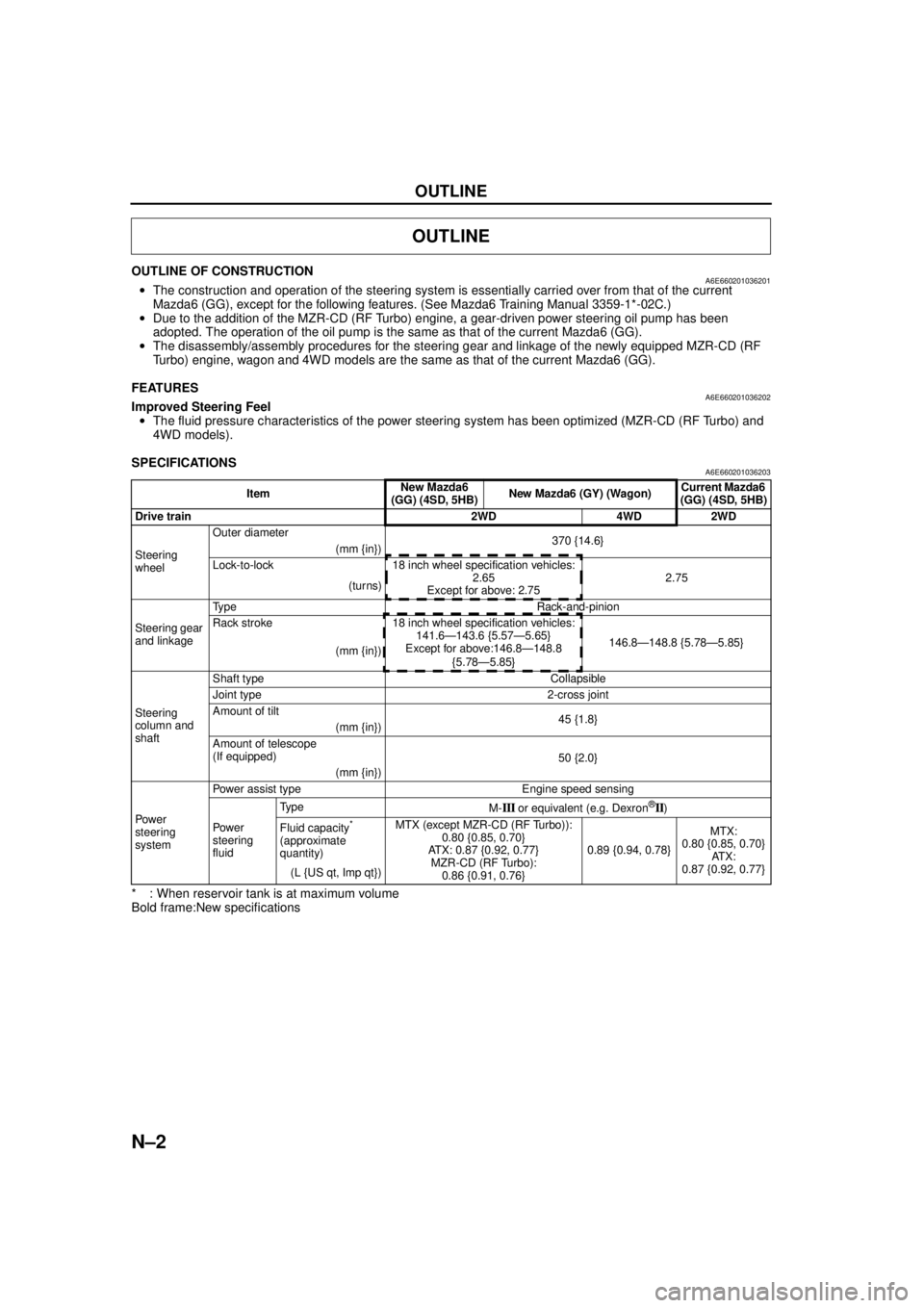

SPECIFICATIONSA6E660201036203

* : When reservoir tank is at maximum volume

Bold frame:New specifications

End Of Sie

OUTLINE

Item New Mazda6

(GG) (4SD, 5HB) New Mazda6 (GY) (Wagon) Current Mazda6

(GG) (4SD, 5HB)

Drive train 2WD 4WD 2WD

Steering

wheel Outer diameter

370 {14.6}

(mm {in})

Lock-to-lock 18 inch wheel specification vehicles: 2.65

Except for above: 2.75 2.75

(turns)

Steering gear

and linkage Type Rack-and-pinion

Rack stroke 18 inch wheel specification vehicles:

141.6—143.6 {5.57—5.65}

Except for above:146.8—148.8

{5.78—5.85} 146.8—148.8 {5.78—5.85}

(mm {in})

Steering

column and

shaft Shaft type Collapsible

Joint type 2-cross joint

Amount of tilt

45 {1.8}

(mm {in})

Amount of telescope

(If equipped) 50 {2.0}

(mm {in})

Powe r

steering

system Power assist type Engine speed sensing

Pow er

steering

fluid

Ty p e

M-

III or equivalent (e.g. Dexron®II)

Fluid capacity

*

(approximate

quantity) MTX (except MZR-CD (RF Turbo)):

0.80 {0.85, 0.70}

ATX: 0.87 {0.92, 0.77} MZR-CD (RF Turbo):

0.86 {0.91, 0.76} 0.89 {0.94, 0.78}

MTX:

0.80 {0.85, 0.70}

AT X :

0.87 {0.92, 0.77}

(L {US qt, Imp qt})

Page 717 of 909

OUTLINE

N–3

N

STRUCTURAL VIEWA6E660201036204MZR-CD (RF Turbo)

.

7

6

7

6

5

5

3

1

2

4

A6E63162001

1L.H.D.

2 R.H.D.

3 Steering wheel

4 Steering column and shaft5 Steering gear

6 Power steering oil pump

7 Fluid reservoir

Page 718 of 909

N–4

OUTLINE

4WD

.

End Of Sie

8

7

5

4

3

1

2

6

5

6

8

7

A6E63162002

1 L.H.D.

2 R.H.D.

3 Steering wheel

4 Steering column and shaft5 Steering gear

6 Power steering oil pump

7 Fluid reservoir

8 Cooling pipe

Page 719 of 909

OUTLINE

N–5

N

SUPPLEMENTAL SERVICE INFORMATIONA6E660201034201•The following changes have been made since publication of the Mazda6 Workshop Manual (1730-1*-02C).

Power steering fluid

•Inspection procedure has been modified.

Steering gear and linkage (MZR-CD (RF Turbo))

•Removal/installation procedure has been added.

Steering gear and linkage (4WD)

•Removal/installation procedure has been added.

Power steering oil pump (MZR-CD (RF Turbo))

•Removal/installation procedure has been added.

•Disassembly/assembly procedure has been added.

End Of Sie

OUTLINE

Page 720 of 909

N–6

ENGINE SPEED SENSING POWER STEERING

POWER STEERING FLUID INSPECTIONA6E661432040201Fluid Level Inspection

1. Inspect the power steering fluid level.

•Add fluid to the specified level as necessary.

Fluid specification

ATF M-III or equivalent (e.g. Dexron

®II)

Fluid Leakage Inspection

Caution

•If the steering wheel is kept in the fully turned position for more than 5 seconds, the fluid

temperature will rise excessively and adversely affect the oil pump.

1. Start the engine and let it idle.

2. Turn the steering wheel fully to the left and right to apply fluid pressure.

Note

•The points where fluid leakage may occur are indicated in the figure.

3. Inspect for fluid leakage.

•If fluid leakage is found, replace the related pipe or hose.

ENGINE SPEED SENSING POWER STEERING

L.H.D.

ATX

MTX

R.H.D.

ATX

MTX MZR-CD (RF Turbo)

EXCEPT MZR-CD (RF Turbo)L.H.D

R.H.D

A6E66142001

Page 721 of 909

ENGINE SPEED SENSING POWER STEERING

N–7

N

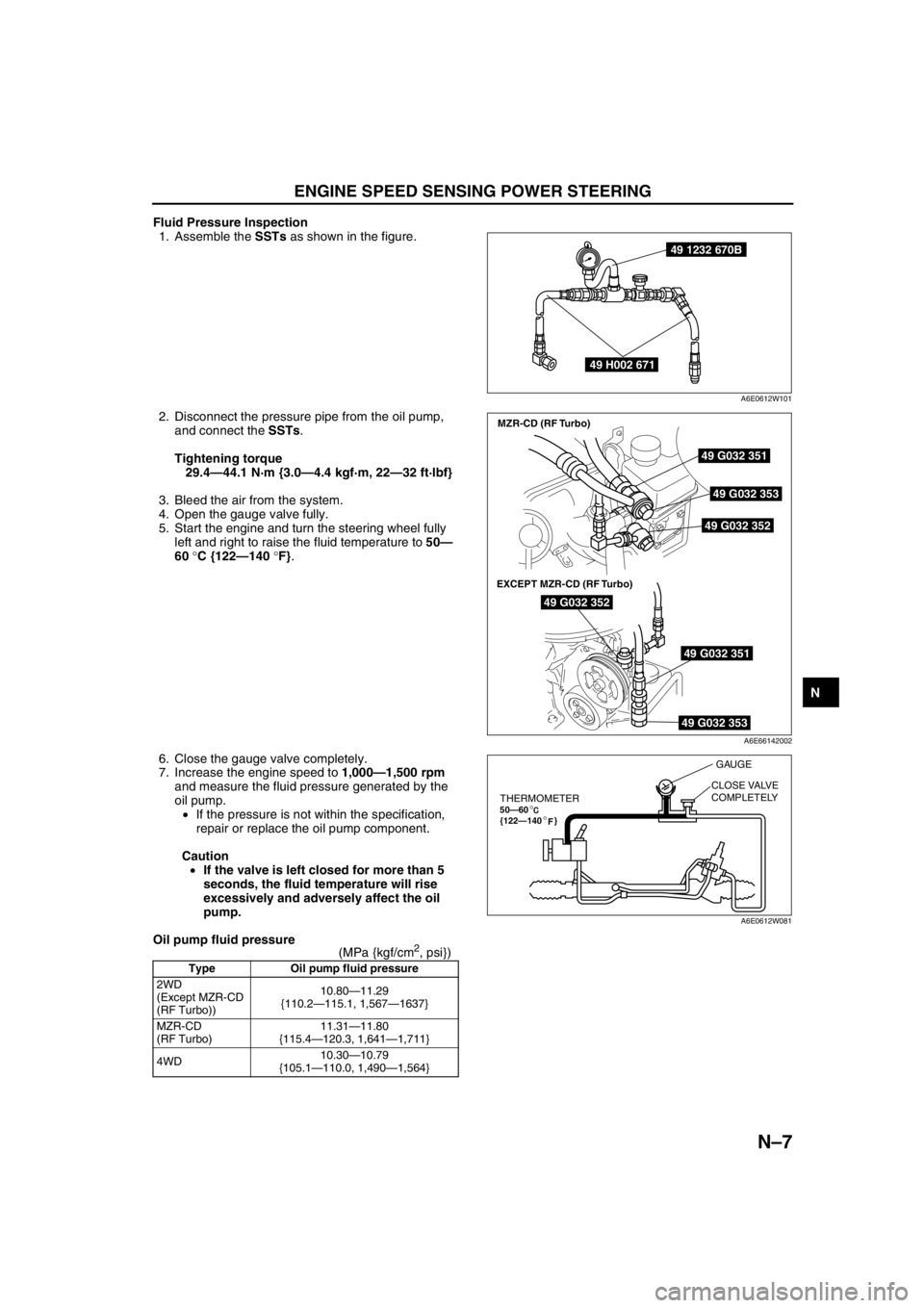

Fluid Pressure Inspection

1. Assemble the SSTs as shown in the figure.

2. Disconnect the pressure pipe from the oil pump,

and connect the SSTs.

Tightening torque

29.4—44.1 N·m {3.0—4.4 kgf·m, 22—32 ft·lbf}

3. Bleed the air from the system.

4. Open the gauge valve fully.

5. Start the engine and turn the steering wheel fully

left and right to raise the fluid temperature to 50—

60 °C {122—140 °F}.

6. Close the gauge valve completely.

7. Increase the engine speed to 1,000—1,500 rpm

and measure the fluid pressure generated by the

oil pump.

•If the pressure is not within the specification,

repair or replace the oil pump component.

Caution

•If the valve is left closed for more than 5

seconds, the fluid temperature will rise

excessively and adversely affect the oil

pump.

Oil pump fluid pressure

(MPa {kgf/cm

2, psi})

Type Oil pump fluid pressure

2WD

(Except MZR-CD

(RF Turbo))10.80—11.29

{110.2—115.1, 1,567—1637}

MZR-CD

(RF Turbo)11.31—11.80

{115.4—120.3, 1,641—1,711}

4WD10.30—10.79

{105.1—110.0, 1,490—1,564}

49 1232 670B

49 H002 671

A6E0612W101

49 G032 351

49 G032 353

49 G032 352

49 G032 352

49 G032 351

49 G032 353

MZR-CD (RF Turbo)

EXCEPT MZR-CD (RF Turbo)

A6E66142002

THERMOMETER50—60

{122—140 }°

°F

GAUGE

CLOSE VALVE

COMPLETELY

A6E0612W081