oil MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 613 of 909

K2–198

TROUBLESHOOTING

NO.20 NOISE OCCURS AT IDLE WHEN VEHICLE IS STOPPED IN ALL POSITIONS/RANGESA6E578001030223

Diagnostic procedure

End Of SieNO.21 NOISE OCCURS AT IDLE WHEN VEHICLE IS STOPPED IN D RANGE, OR IN R POSITIONA6E578001030224

End Of SieNO.22 NO ENGINE BRAKING IN 1GR POSITION OF M RANGEA6E578001030225

Diagnostic procedure

20 Noise occurs at idle when vehicle is stopped in all positions/ranges

DESCRIPTION•Transaxle noisy in all positions and ranges when vehicle idling.

POSSIBLE

CAUSE•Malfunction is in pressure solenoid or oil pump which causes a high-pitched noise to be emitted from

transaxle at idle.

Note

•If a noise is emitted during shifting only, malfunction is in shift solenoid A, B, or C.

•If a noise is emitted during shifting at certain gears only or during deceleration only, it is gear noise.

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Inspect engine condition.

•Is any engine concern (e.g. Rough idle)?Yes Go to appropriate symptom troubleshooting.

(See F1–57 ENGINE SYMPTOM TROUBLESHOOTING.)

No Replace basic inspection and repair or replace any

defective parts according to inspection result.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

21 Noise occurs at idle when vehicle is stopped in D range, or in R position

DESCRIPTION•Transaxle noisy in driving ranges when vehicle idling.

POSSIBLE

CAUSE•Although the malfunction is basically the same as No.20 “Noise occurs at idle when vehicle is stopped

in all positions/ranges”, other causes may be selector lever position disparity or TR switch position

disparity.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

22 No engine braking in 1GR position of M range

DESCRIPTION•Engine speed drops to idle but vehicle coasts when accelerator pedal released during cruising at

medium to high speeds.

•Engine speed drops to idle but vehicle coasts when accelerator pedal released when in M range (1GR)

at low vehicle speed.

POSSIBLE

CAUSE•Clutch slipped, burned (Reduction brake)

—Line pressure low

•Malfunction of VSS

•Malfunction of input/turbine speed sensor

•Malfunction of sensor ground

•Malfunction of control valve body

—M range switch on not judged by TCM (short, or open circuit, poor operation)

•Malfunction of M range switch signal

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Inspect TR switch adjustment.

•Does TR switch adjusted properly?

•Select PNP PID.

•Is PNP PID reading okay when selecting

range?Yes Go to next step.

No Adjust TR switch as necessary.

(See K2–83 TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT.)

Inspect TR switch.

Repair or replace any defective parts.

Page 614 of 909

TROUBLESHOOTING

K2–199

K2

End Of SieNO.23 TRANSAXLE OVERHEATSA6E578001030226

Diagnostic procedure

End Of SieNO.24 ENGINE STALLS WHEN SHIFTED TO D RANGE, OR IN R POSITIONA6E578001030227

2•Do following symptoms concurrently occur?

—Engine flares up or slips during

acceleration

—Engine flares up or slips when shiftingYes Go to symptom troubleshooting No.14 “Engine flares up or

slips when upshifting or downshifting” or No.15 “Engine

flares up or slips when accelerating vehicle”.

No Go to next step.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM. STEP INSPECTION ACTION

23 Transaxle Overheat

DESCRIPTION•Burnt smell emitted from transaxle.

•Smoke emitted from transaxle.

POSSIBLE

CAUSE•Malfunction is restricted to hindrance of coolant at oil cooler. In addition, overheating of transaxle may

be caused by a malfunction of TFT sensor.

—Line pressure low

•ATF level low

•Incorrect throttle position signal

•Misadjustment of throttle cable

—Oil cooler malfunction (Foreign material mixed in with ATF)

—TFT sensor malfunction

—Excessive amount of ATF

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Is line pressure okay?

(See K2–72 Line Pressure Test.)Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

2•Is stall speed okay?

(See K2–74 Stall Speed Test.)Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

3•Inspect TFT sensor and related harness:

vibration, intermittent open/short circuit

•Is it okay?Yes Go to next step.

No Repair or replace part if necessary.

4•Inspect pressure control solenoid circuit.

•Is it okay?Yes Go to next step.

No•Inspect for pressure control solenoid mechanical stuck.

(See K2–88 SOLENOID VALVE INSPECTION.)

5•Inspect for bend, damage, corrosion or kinks

of oil cooler pipes.

•Are oil cooler pipes okay?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No Replace any defective parts.

6•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

24 Engine stalls when shifted to D range, or in R position

DESCRIPTION•Engine stalls when shifting from N or P position to D range or R position at idle.

POSSIBLE

CAUSE•Malfunction is on the engine control side (e.g. IAC system). Otherwise, malfunction is in input/turbine

speed sensor (engine sometimes starts) or TCC piston circuit (engine always stalls).

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic and

Automatic Transaxle Basic Inspection are conducted.

Page 615 of 909

K2–200

TROUBLESHOOTING

Diagnostic procedure

End Of SieNO.25 ENGINE STALLS WHEN DRIVING AT SLOW SPEED OR STOPPINGA6E578001030228

Diagnostic procedure

End Of SieNO.26 STARTER DOES NOT WORKA6E578001030229

End Of SieNO.27 GEAR POSITION INDICATOR LIGHT DOES NOT ILLUMINATE IN M RANGEA6E578001030230

Diagnostic procedure

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.4

“Engine stalls-after start/at idle”.

(See Section F.)

•Is engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

2•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Inspect for bend, damage or kinks of oil cooler line

pipes. If okay, overhaul control valve body and repair or

replace any defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No Replace torque converter.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

25 Engine stalls when driving at slow speeds or stopping

DESCRIPTION•Engine stalls when brake pedal depressed while driving at low speed or stopping.

POSSIBLE

CAUSE•Malfunction is on engine control side (e.g. Fuel injection control, IAC system)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.10 “Low

idle/stalls during deceleration”.

(See Section F.)

•Is engine control system okay?Yes Go to symptom troubleshooting No.24 “Engine stalls when

shifted to D range, or in R position”.

No Repair or replace any defective parts according to

inspection results.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

26Starter does not work

DESCRIPTION•Starter does not work even when P or N position.

POSSIBLE

CAUSE•Selector lever misadjustment.

•TR switch misadjustment.

•Open or short circuit in TR switch.

27 Gear position indicator light does not illuminate in M range

DESCRIPTION•Gear position indicator light in instrument cluster does not illuminate in M range and ignition switch at

on.

POSSIBLE

CAUSE•M range switch, gear position indicator light or related wiring harness malfunction.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Are other indicator lights illuminated with

ignition switch on? Yes Go to next step.

No Inspect meter fuse.

Page 631 of 909

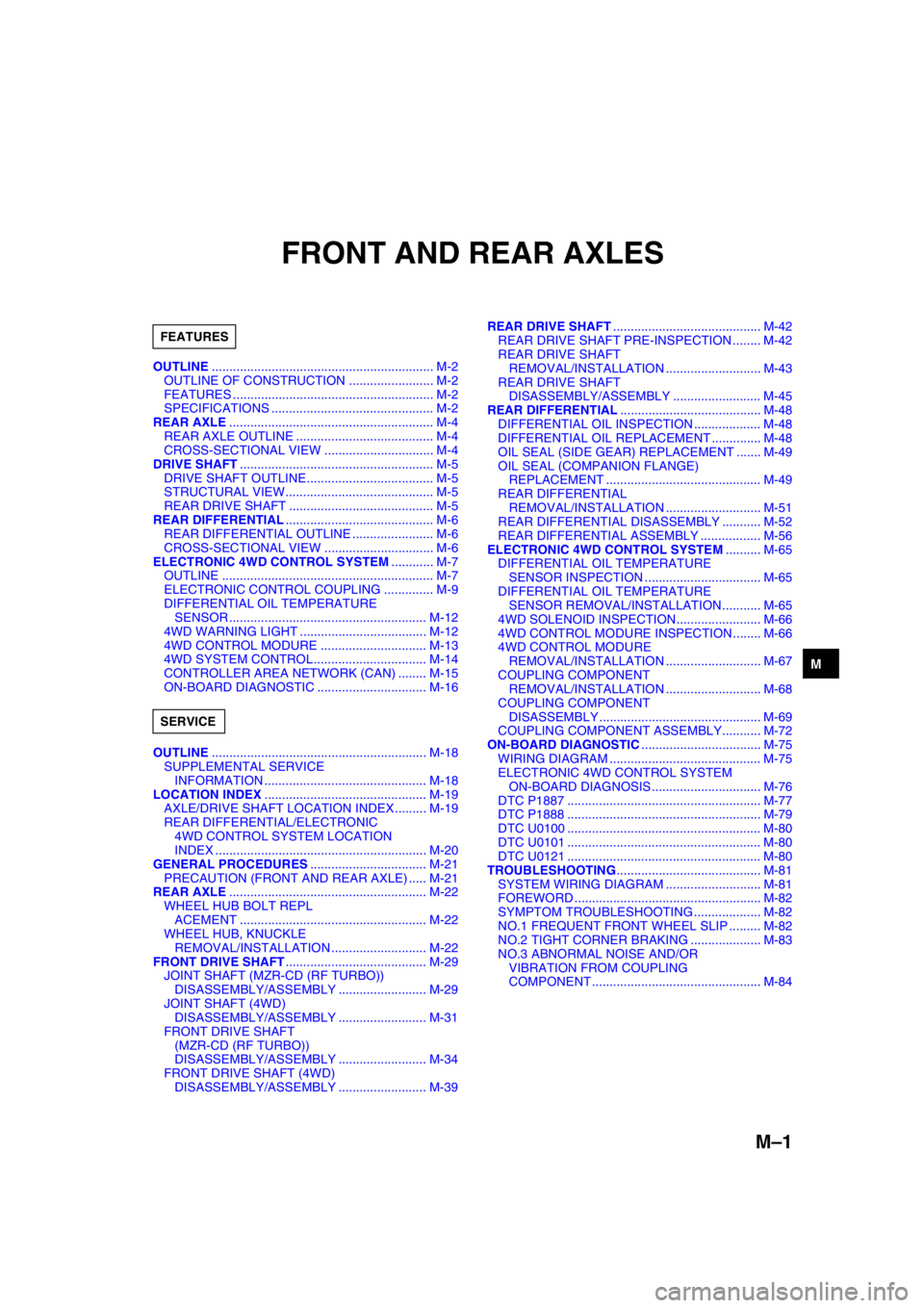

M–1

M

MFRONT AND REAR AXLES

OUTLINE............................................................... M-2

OUTLINE OF CONSTRUCTION ........................ M-2

FEATURES ......................................................... M-2

SPECIFICATIONS .............................................. M-2

REAR AXLE.......................................................... M-4

REAR AXLE OUTLINE ....................................... M-4

CROSS-SECTIONAL VIEW ............................... M-4

DRIVE SHAFT....................................................... M-5

DRIVE SHAFT OUTLINE.................................... M-5

STRUCTURAL VIEW.......................................... M-5

REAR DRIVE SHAFT ......................................... M-5

REAR DIFFERENTIAL.......................................... M-6

REAR DIFFERENTIAL OUTLINE ....................... M-6

CROSS-SECTIONAL VIEW ............................... M-6

ELECTRONIC 4WD CONTROL SYSTEM............ M-7

OUTLINE ............................................................ M-7

ELECTRONIC CONTROL COUPLING .............. M-9

DIFFERENTIAL OIL TEMPERATURE

SENSOR ........................................................ M-12

4WD WARNING LIGHT .................................... M-12

4WD CONTROL MODURE .............................. M-13

4WD SYSTEM CONTROL................................ M-14

CONTROLLER AREA NETWORK (CAN) ........ M-15

ON-BOARD DIAGNOSTIC ............................... M-16

OUTLINE............................................................. M-18

SUPPLEMENTAL SERVICE

INFORMATION .............................................. M-18

LOCATION INDEX.............................................. M-19

AXLE/DRIVE SHAFT LOCATION INDEX ......... M-19

REAR DIFFERENTIAL/ELECTRONIC

4WD CONTROL SYSTEM LOCATION

INDEX ............................................................ M-20

GENERAL PROCEDURES................................. M-21

PRECAUTION (FRONT AND REAR AXLE) ..... M-21

REAR AXLE........................................................ M-22

WHEEL HUB BOLT REPL

ACEMENT ..................................................... M-22

WHEEL HUB, KNUCKLE

REMOVAL/INSTALLATION ........................... M-22

FRONT DRIVE SHAFT........................................ M-29

JOINT SHAFT (MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY ......................... M-29

JOINT SHAFT (4WD)

DISASSEMBLY/ASSEMBLY ......................... M-31

FRONT DRIVE SHAFT

(MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY ......................... M-34

FRONT DRIVE SHAFT (4WD)

DISASSEMBLY/ASSEMBLY ......................... M-39REAR DRIVE SHAFT.......................................... M-42

REAR DRIVE SHAFT PRE-INSPECTION ........ M-42

REAR DRIVE SHAFT

REMOVAL/INSTALLATION ........................... M-43

REAR DRIVE SHAFT

DISASSEMBLY/ASSEMBLY ......................... M-45

REAR DIFFERENTIAL........................................ M-48

DIFFERENTIAL OIL INSPECTION ................... M-48

DIFFERENTIAL OIL REPLACEMENT .............. M-48

OIL SEAL (SIDE GEAR) REPLACEMENT ....... M-49

OIL SEAL (COMPANION FLANGE)

REPLACEMENT ............................................ M-49

REAR DIFFERENTIAL

REMOVAL/INSTALLATION ........................... M-51

REAR DIFFERENTIAL DISASSEMBLY ........... M-52

REAR DIFFERENTIAL ASSEMBLY ................. M-56

ELECTRONIC 4WD CONTROL SYSTEM.......... M-65

DIFFERENTIAL OIL TEMPERATURE

SENSOR INSPECTION ................................. M-65

DIFFERENTIAL OIL TEMPERATURE

SENSOR REMOVAL/INSTALLATION ........... M-65

4WD SOLENOID INSPECTION........................ M-66

4WD CONTROL MODURE INSPECTION ........ M-66

4WD CONTROL MODURE

REMOVAL/INSTALLATION ........................... M-67

COUPLING COMPONENT

REMOVAL/INSTALLATION ........................... M-68

COUPLING COMPONENT

DISASSEMBLY .............................................. M-69

COUPLING COMPONENT ASSEMBLY........... M-72

ON-BOARD DIAGNOSTIC.................................. M-75

WIRING DIAGRAM ........................................... M-75

ELECTRONIC 4WD CONTROL SYSTEM

ON-BOARD DIAGNOSIS ............................... M-76

DTC P1887 ....................................................... M-77

DTC P1888 ....................................................... M-79

DTC U0100 ....................................................... M-80

DTC U0101 ....................................................... M-80

DTC U0121 ....................................................... M-80

TROUBLESHOOTING......................................... M-81

SYSTEM WIRING DIAGRAM ........................... M-81

FOREWORD ..................................................... M-82

SYMPTOM TROUBLESHOOTING ................... M-82

NO.1 FREQUENT FRONT WHEEL SLIP ......... M-82

NO.2 TIGHT CORNER BRAKING .................... M-83

NO.3 ABNORMAL NOISE AND/OR

VIBRATION FROM COUPLING

COMPONENT ................................................ M-84 FEATURES

SERVICE

Page 633 of 909

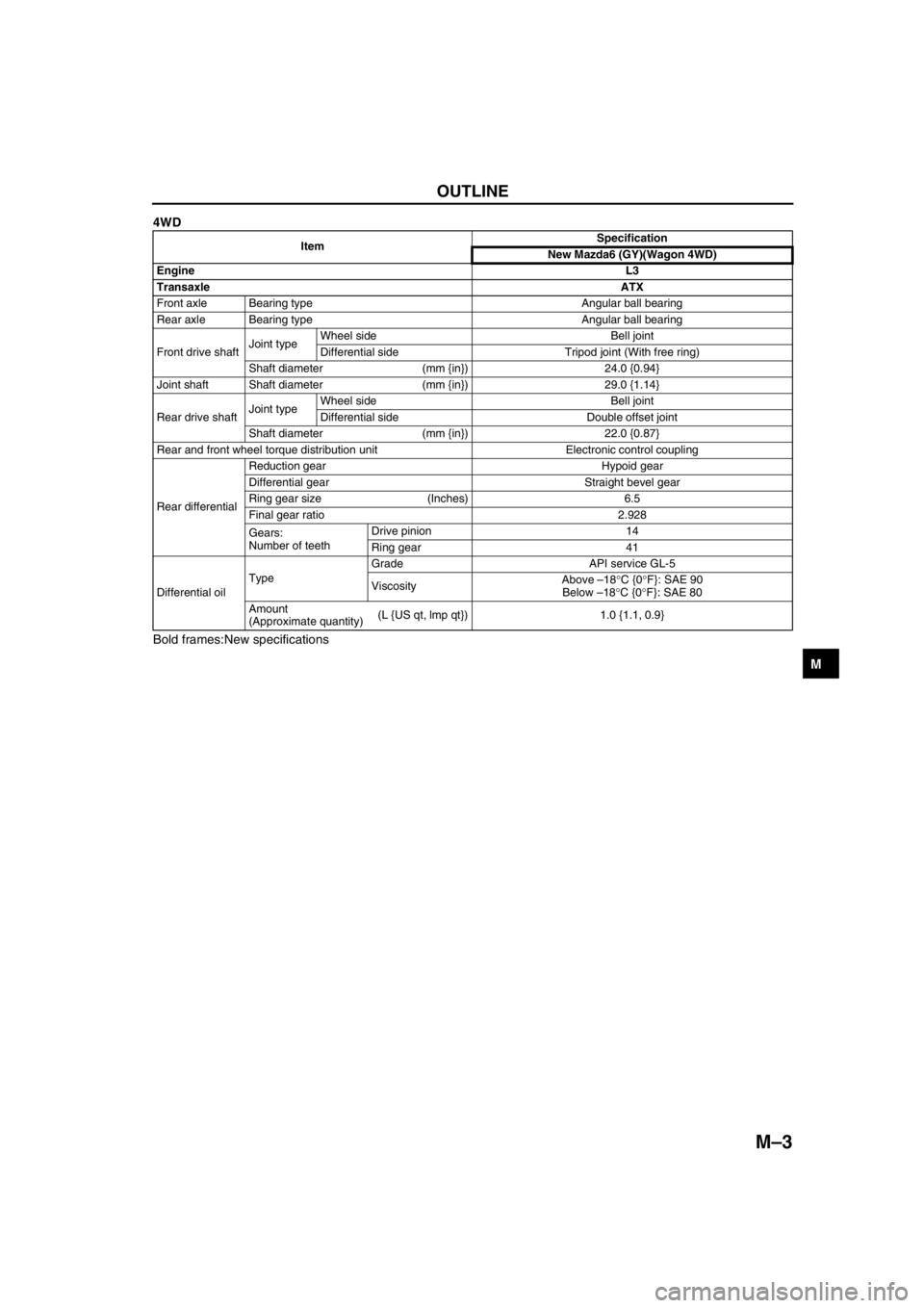

OUTLINE

M–3

M

4WD

Bold frames:New specifications

End Of Sie

ItemSpecification

New Mazda6 (GY)(Wagon 4WD)

EngineL3

TransaxleATX

Front axle Bearing type Angular ball bearing

Rear axle Bearing type Angular ball bearing

Front drive shaftJoint typeWheel side Bell joint

Differential side Tripod joint (With free ring)

Shaft diameter (mm {in}) 24.0 {0.94}

Joint shaft Shaft diameter (mm {in}) 29.0 {1.14}

Rear drive shaftJoint typeWheel side Bell joint

Differential side Double offset joint

Shaft diameter (mm {in}) 22.0 {0.87}

Rear and front wheel torque distribution unit Electronic control coupling

Rear differentialReduction gear Hypoid gear

Differential gear Straight bevel gear

Ring gear size (Inches) 6.5

Final gear ratio 2.928

Gears:

Number of teethDrive pinion 14

Ring gear 41

Differential oilTypeGrade API service GL-5

ViscosityAbove –18°C {0°F}: SAE 90

Below –18°C {0°F}: SAE 80

Amount

(Approximate quantity)(L {US qt, lmp qt}) 1.0 {1.1, 0.9}

Page 637 of 909

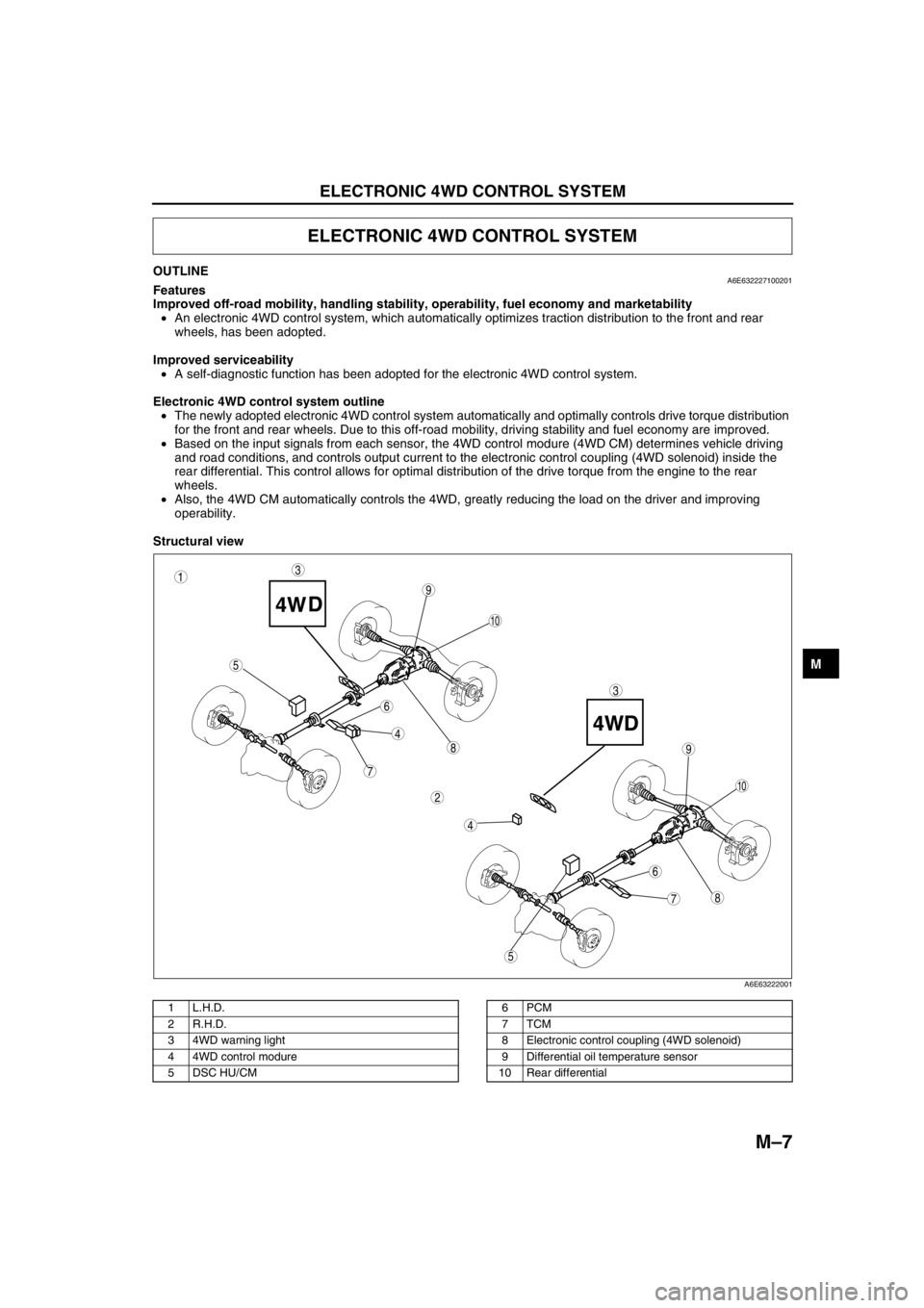

ELECTRONIC 4WD CONTROL SYSTEM

M–7

M

OUTLINEA6E632227100201Features

Improved off-road mobility, handling stability, operability, fuel economy and marketability

•An electronic 4WD control system, which automatically optimizes traction distribution to the front and rear

wheels, has been adopted.

Improved serviceability

•A self-diagnostic function has been adopted for the electronic 4WD control system.

Electronic 4WD control system outline

•The newly adopted electronic 4WD control system automatically and optimally controls drive torque distribution

for the front and rear wheels. Due to this off-road mobility, driving stability and fuel economy are improved.

•Based on the input signals from each sensor, the 4WD control modure (4WD CM) determines vehicle driving

and road conditions, and controls output current to the electronic control coupling (4WD solenoid) inside the

rear differential. This control allows for optimal distribution of the drive torque from the engine to the rear

wheels.

•Also, the 4WD CM automatically controls the 4WD, greatly reducing the load on the driver and improving

operability.

Structural view

.

ELECTRONIC 4WD CONTROL SYSTEM

87

5

4

3

6

9

8

7

5

4

3

10

6

1

2

9

10

A6E63222001

1L.H.D.

2 R.H.D.

3 4WD warning light

4 4WD control modure

5 DSC HU/CM6PCM

7TCM

8 Electronic control coupling (4WD solenoid)

9 Differential oil temperature sensor

10 Rear differential

Page 638 of 909

M–8

ELECTRONIC 4WD CONTROL SYSTEM

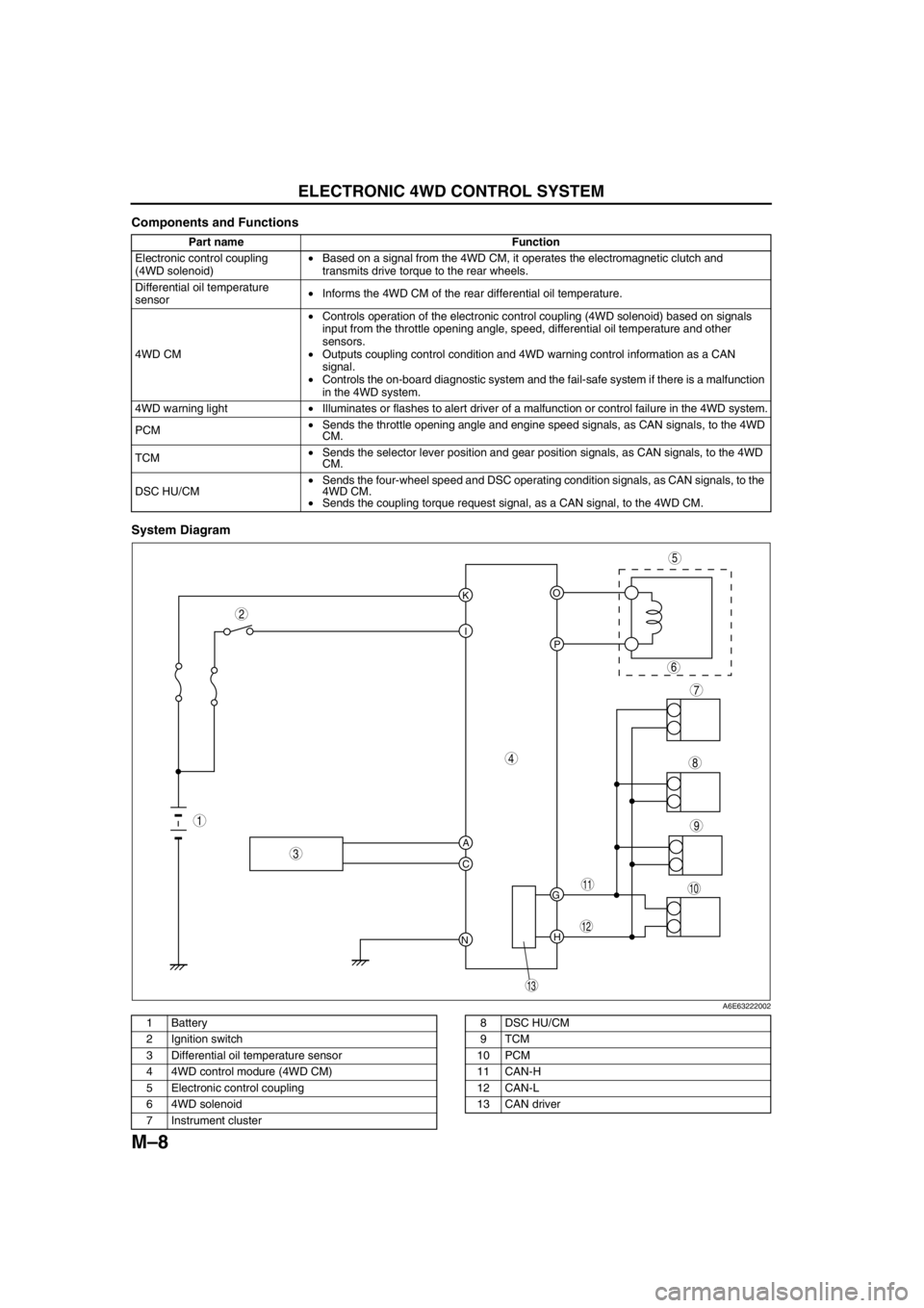

Components and Functions

System Diagram

.

Part name Function

Electronic control coupling

(4WD solenoid)•Based on a signal from the 4WD CM, it operates the electromagnetic clutch and

transmits drive torque to the rear wheels.

Differential oil temperature

sensor•Informs the 4WD CM of the rear differential oil temperature.

4WD CM•Controls operation of the electronic control coupling (4WD solenoid) based on signals

input from the throttle opening angle, speed, differential oil temperature and other

sensors.

•Outputs coupling control condition and 4WD warning control information as a CAN

signal.

•Controls the on-board diagnostic system and the fail-safe system if there is a malfunction

in the 4WD system.

4WD warning light•Illuminates or flashes to alert driver of a malfunction or control failure in the 4WD system.

PCM•Sends the throttle opening angle and engine speed signals, as CAN signals, to the 4WD

CM.

TCM•Sends the selector lever position and gear position signals, as CAN signals, to the 4WD

CM.

DSC HU/CM•Sends the four-wheel speed and DSC operating condition signals, as CAN signals, to the

4WD CM.

•Sends the coupling torque request signal, as a CAN signal, to the 4WD CM.

KO

P I

A

C

NH G

9

8

7

5

4

3

10

13

11

12

6

1

2

A6E63222002

1 Battery

2 Ignition switch

3 Differential oil temperature sensor

4 4WD control modure (4WD CM)

5 Electronic control coupling

6 4WD solenoid

7 Instrument cluster8 DSC HU/CM

9TCM

10 PCM

11 CAN-H

12 CAN-L

13 CAN driver

Page 639 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–9

M

End Of SieELECTRONIC CONTROL COUPLINGA6E632227100202Outline

Features

•An electromagnetic clutch, which operates smoothly due to the lack influence from the front and rear wheel

traction force, has been adopted for the electronic control coupling system.

•The construction of the coupling enables the torque formed by the pilot clutch to be amplified by the cam

mechanism, thus allowing the main clutch to obtain a high degree of torque. Due to this, size and weight

reduction of the component parts has been achieved.

Construction

•The electronic control coupling basically consists of an electromagnetic clutch, a cam mechanism and a torque

transmission system.

•The electromagnetic clutch consists of a 4WD solenoid (electromagnetic coil), rear-housing that forms a

magnetic path, pilot clutch, and armature. The cam mechanism consists of a pilot cam, balls, and main cam.

The torque transmission system consists of a main clutch and hydraulic oil (ATF).

.

9

8

7

5

43

10

13

1112

6

12

A6E63222003

1 Front wheel side

2 Rear wheel side

3 Torque transmission system

4 Electromagnetic clutch

5 Rear housing

6 4WD solenoid (Electromagnetic coil)

7 Cam mechanism8Ball

9 Main clutch

10 Main cam

11 Armature

12 Pilot clutch

13 Pilot cam

Page 640 of 909

M–10

ELECTRONIC 4WD CONTROL SYSTEM

Operation

4WD solenoid control current is OFF

•When the 4WD solenoid control current is OFF, no torque is generated in the pilot clutch because there is no

current flowing to the 4WD solenoid. At the same time, the pilot cam and the main cam rotate in the same

direction via the balls, and the main cam does not exert any push force on the main clutch side. Therefore, the

traction from the front wheels is not transmitted to the rear wheels.

.

8

7

5

4

3

6

12

56

7

A6E63222004

1 Main clutch

2 Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)5Main cam

6Pilot cam

7Ball

8 Armature

Page 641 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–11

M

4WD solenoid control current is ON

•When the 4WD solenoid control current is ON, current flows from the 4WD CM to the 4WD solenoid, and the

coupling operates in the following manner.

1. Magnetic flux forms at the electromagnetic coil of the 4WD solenoid.

2. Due to the magnetic flux in the armature, the pilot clutch is suctioned towards the magnetic coil side and

made to engage. This causes frictional torque to generate in the pilot clutch.

3. The torque is transmitted to the pilot cam, which is engaged with the pilot clutch.

4. A rotational difference is created between the pilot cam and the main cam. Due to this relative torsion, the

cam mechanism operates, transmitting torque from the pilot cam to the ball and then to the main cam. In

this way, the push force exerted on the main clutch is amplified.

5. As the main clutch engages, the drive torque from the front wheels is transmitted to the rear wheels.

•The amount of push force exerted on the main clutch by the main cam (that is, the strength of the drive torque

transmitted to the rear wheels) changes in accordance with the proportion of the force acting upon the pilot

cam, engaged with the pilot clutch. Therefore, by changing the periodicity of the electric current from the 4WD

CM to the 4WD solenoid (ON/OFF rate of the 4WD solenoid = force acting on the pilot cam), the module

controls the transmission of drive torque to the rear wheels.

.

End Of Sie

98

75

4

3

10

11

6

12

56

7

12

A6E63222005

1 Main clutch

2Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)

5Main cam

6Pilot cam7Ball

8Armature

9 Drive torque

10 Magnetic flux

11 Input

12 Output