coolant level MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 82 of 909

RADIATOR CAP

E–7

E

RADIATOR CAP INSPECTIONA6E361415201201MZR-CD (RF Turbo)

Warning

•Never remove the radiator cap while the engine is running, or when the engine and radiator are

hot. Scalding coolant and steam may shoot out and cause serious injury. It may also damage the

engine and cooling system.

•Turn off the engine and wait until it is cool. Even then, be very careful when removing the cap.

Wrap a thick cloth around it and slowly turn it counterclockwise to the first stop. Step back while

the pressure escapes.

•When you are sure all the pressure is gone, press down on the cap using the cloth, turn it, and

remove it.

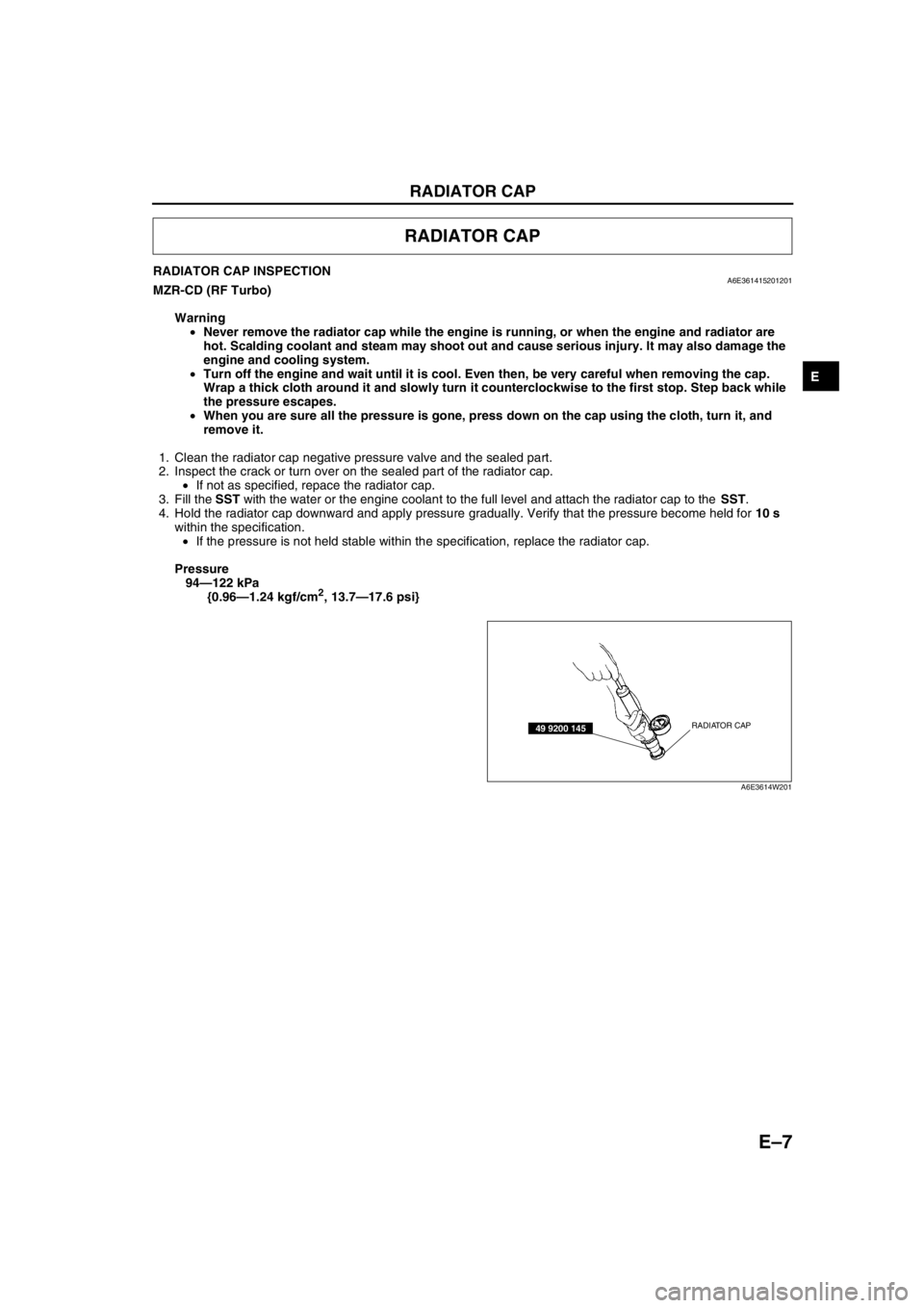

1. Clean the radiator cap negative pressure valve and the sealed part.

2. Inspect the crack or turn over on the sealed part of the radiator cap.

•If not as specified, repace the radiator cap.

3. Fill the SST with the water or the engine coolant to the full level and attach the radiator cap to the SST.

4. Hold the radiator cap downward and apply pressure gradually. Verify that the pressure become held for 10 s

within the specification.

•If the pressure is not held stable within the specification, replace the radiator cap.

Pressure

94—122 kPa

{0.96—1.24 kgf/cm

2, 13.7—17.6 psi}

End Of Sie

RADIATOR CAP

RADIATOR CAP49 9200 145

A6E3614W201

Page 83 of 909

E–8

ENGINE COOLANT

ENGINE COOLANT LEAKAGE INSPECTIONA6E361215201201MZR-CD (RF Turbo)

Warning

•Never remove the radiator cap while the engine is running, or when the engine and radiator are

hot. Scalding coolant and steam may shoot out and cause serious injury. It may also damage the

engine and cooling system.

•Turn off the engine and wait until it is cool. Even then, be very careful when removing the cap.

Wrap a thick cloth around it and slowly turn it counterclockwise to the first stop. Step back while

the pressure escapes.

•When you are sure all the pressure is gone, press down on the cap using the cloth, turn it, and

remove it.

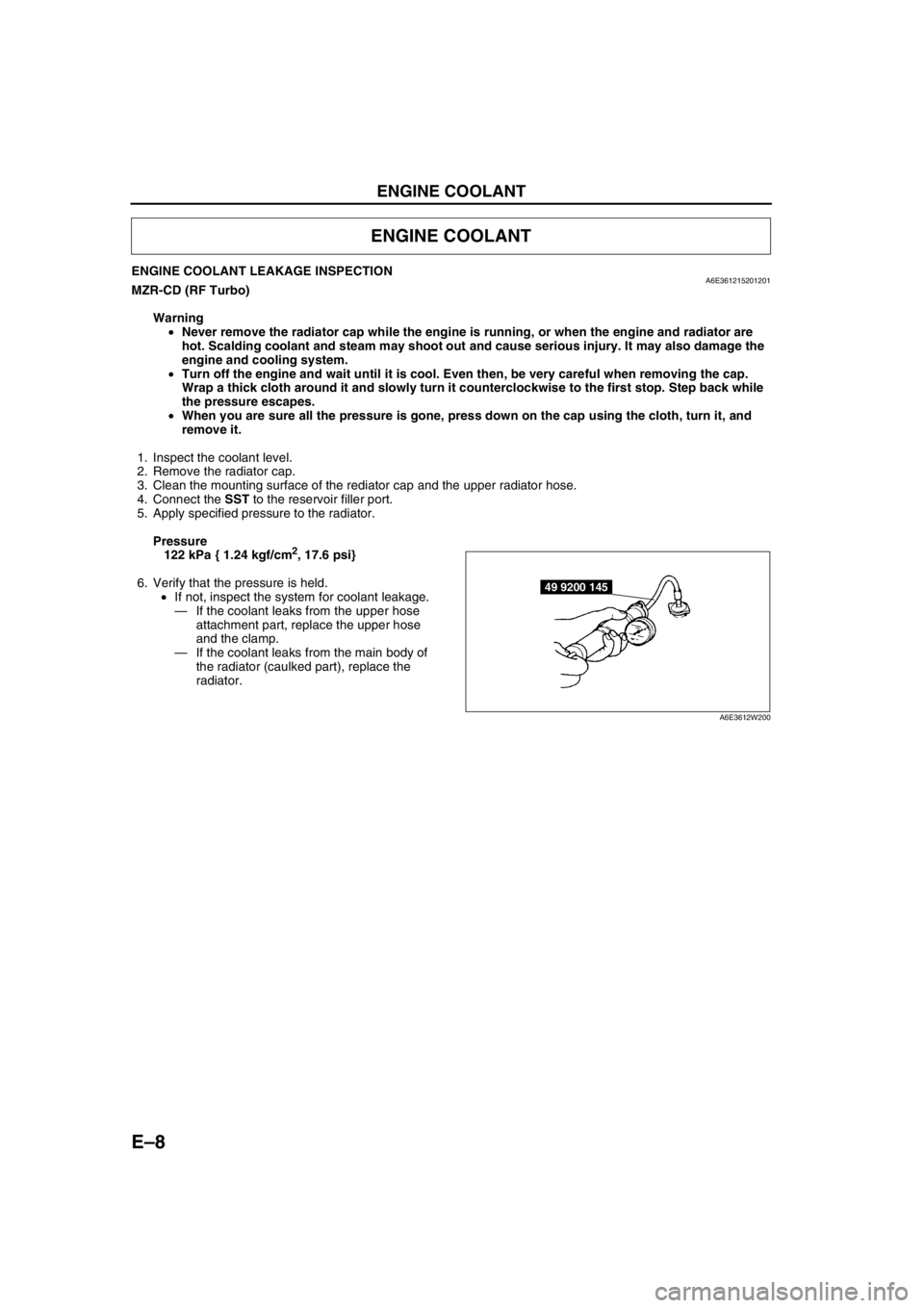

1. Inspect the coolant level.

2. Remove the radiator cap.

3. Clean the mounting surface of the rediator cap and the upper radiator hose.

4. Connect the SST to the reservoir filler port.

5. Apply specified pressure to the radiator.

Pressure

122 kPa { 1.24 kgf/cm

2, 17.6 psi}

6. Verify that the pressure is held.

•If not, inspect the system for coolant leakage.

—If the coolant leaks from the upper hose

attachment part, replace the upper hose

and the clamp.

—If the coolant leaks from the main body of

the radiator (caulked part), replace the

radiator.

End Of Sie

ENGINE COOLANT

49 9200 145

A6E3612W200

Page 122 of 909

F1–34

CONTROL SYSTEM

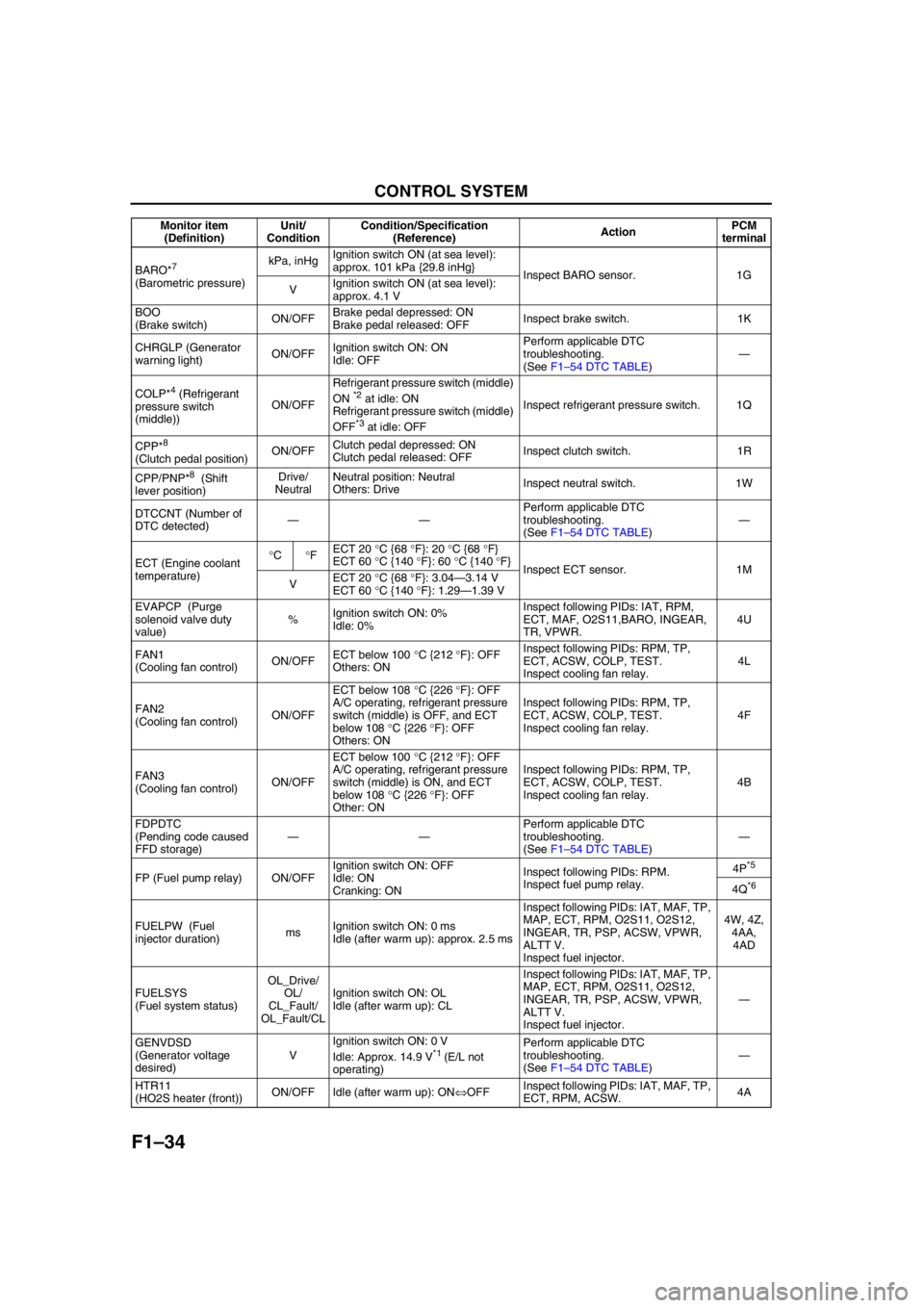

BARO*7

(Barometric pressure)kPa, inHgIgnition switch ON (at sea level):

approx. 101 kPa {29.8 inHg}

Inspect BARO sensor. 1G

VIgnition switch ON (at sea level):

approx. 4.1 V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Brake pedal released: OFFInspect brake switch. 1K

CHRGLP (Generator

warning light)ON/OFFIgnition switch ON: ON

Idle: OFFPerform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

COLP*

4 (Refrigerant

pressure switch

(middle))ON/OFFRefrigerant pressure switch (middle)

ON *2 at idle: ON

Refrigerant pressure switch (middle)

OFF

*3 at idle: OFFInspect refrigerant pressure switch. 1Q

CPP*

8

(Clutch pedal position)ON/OFFClutch pedal depressed: ON

Clutch pedal released: OFFInspect clutch switch. 1R

CPP/PNP*

8 (Shift

lever position)Drive/

NeutralNeutral position: Neutral

Others: DriveInspect neutral switch. 1W

DTCCNT (Number of

DTC detected)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

ECT (Engine coolant

temperature)°C°FECT 20 °C {68 °F}: 20 °C {68 °F}

ECT 60 °C {140 °F}: 60 °C {140 °F}

Inspect ECT sensor. 1M

VECT 20 °C {68 °F}: 3.04—3.14 V

ECT 60 °C {140 °F}: 1.29—1.39 V

EVAPCP (Purge

solenoid valve duty

value)%Ignition switch ON: 0%

Idle: 0%Inspect following PIDs: IAT, RPM,

ECT, MAF, O2S11,BARO, INGEAR,

TR, VPWR.4U

FAN1

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4L

FAN2

(Cooling fan control)ON/OFFECT below 108 °C {226 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is OFF, and ECT

below 108 °C {226 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4F

FAN3

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is ON, and ECT

below 108 °C {226 °F}: OFF

Other: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4B

FDPDTC

(Pending code caused

FFD storage)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

FP (Fuel pump relay) ON/OFFIgnition switch ON: OFF

Idle: ON

Cranking: ONInspect following PIDs: RPM.

Inspect fuel pump relay.4P

*5

4Q*6

FUELPW (Fuel

injector duration)msIgnition switch ON: 0 ms

Idle (after warm up): approx. 2.5 msInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.4W, 4Z,

4AA,

4AD

FUELSYS

(Fuel system status)OL_Drive/

OL/

CL_Fault/

OL_Fault/CLIgnition switch ON: OL

Idle (after warm up): CLInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.—

GENVDSD

(Generator voltage

desired)VIgnition switch ON: 0 V

Idle: Approx. 14.9 V

*1 (E/L not

operating)Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

HTR11

(HO2S heater (front))ON/OFF Idle (after warm up): ON⇔OFFInspect following PIDs: IAT, MAF, TP,

ECT, RPM, ACSW.4A Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 146 of 909

F1–58

TROUBLESHOOTING

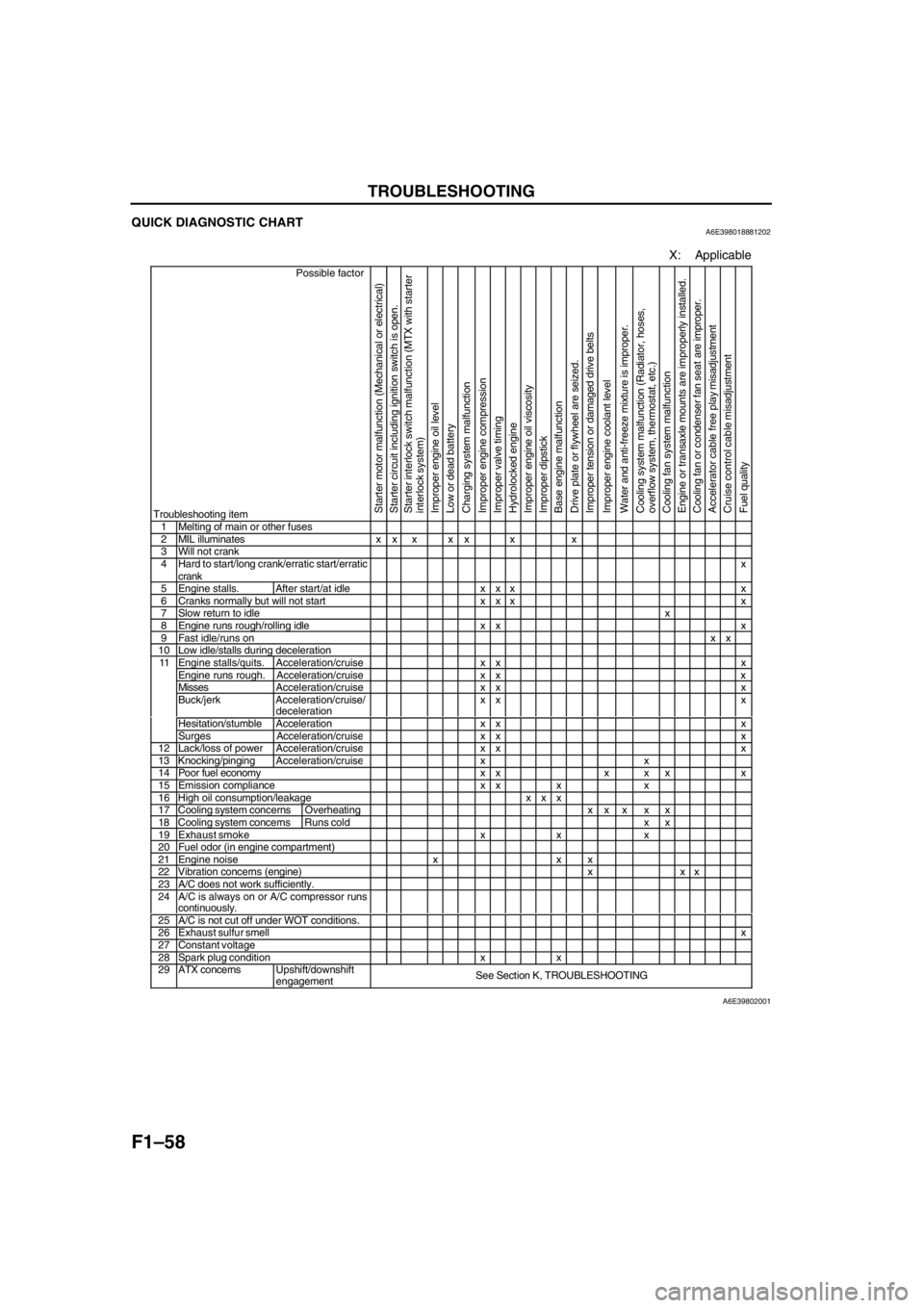

QUICK DIAGNOSTIC CHARTA6E398018881202

X: Applicable

Possible factor

Troubleshooting item

Starter motor malfunction (Mechanical or electrical)

Starter circuit including ignition switch is open.

Starter interlock switch malfunction (MTX with starter

interlock system)

Improper engine oil level

Low or dead battery

Charging system malfunction

Improper engine compression

Improper valve timing

Hydrolocked engine

Improper engine oil viscosity

Improper dipstick

Base engine malfunction

Drive plate or flywheel are seized.

Improper tension or damaged drive belts

Improper engine coolant level

Water and anti-freeze mixture is improper.

Cooling system malfunction (Radiator, hoses,

overflow system, thermostat, etc.)

Cooling fan system malfunction

Engine or transaxle mounts are improperly installed.

Cooling fan or condenser fan seat are improper.

Accelerator cable free play misadjustment

Cruise control cable misadjustment

Fuel quality

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crank4 Hard to start/long crank/erratic start/erratic

crankx

5 Engine stalls. After start/at idle x x x x6 Cranks normally but will not start x x x x7 Slow return to idlex8 Engine runs rough/rolling idle x x x9 Fast idle/runs onxx10 Low idle/stalls during decelerationEngine stalls/quits. Acceleration/cruise x x xEngine runs rough. Acceleration/cruise x x xMissesAcceleration/cruise x x xBuck/jerk Acceleration/cruise/

decelerationxx x

Hesitation/stumble Acceleration x x x

11

Surges Acceleration/cruis

exx x12 Lack/loss of powerAcceleration/cruisexx x13 Knocking/pingingAcceleration/cruisexx14 Poor fuel economy x x x x x x15 Emission compliance x x x x16 High oil consumption/leakage x x x17 Cooling system concerns Overheatingxx x x x18 Cooling system concernsRuns cold x x19 Exhaust smoke x x x20 Fuel odor (in engine compartment)21 Engine noise x x x22 Vibration concerns (engine) x x x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smellx27 Constant voltage28 Spark plug condition x x29 ATX concernsUpshift/downshift

engagementSee Section K, TROUBLESHOOTING

A6E39802001

Page 150 of 909

F1–62

TROUBLESHOOTING

NO.14 POOR FUEL ECONOMYA6E398018881203

Diagnostic procedure

14 POOR FUEL ECONOMY

DESCRIPTIONFuel economy is unsatisfactory.

POSSIBLE CAUSE•Contaminated air cleaner element

•VIS malfunction (if equipped)

•Engine cooling system malfunction

•Improper ATF level (ATX)

•Weak spark

•Poor fuel quality

•Erratic or no signal from CMP sensor

•Clutch slippage (MTX)

•VTCS malfunction

•Improper variable valve timing control system operation (if equipped)

•Improper coolant level

•Inadequate fuel pressure

•Spark plug malfunction

•PCV valve malfunction

•Brake dragging

•Improper valve timing due to jumping out of timing belt

•Contaminated MAF sensor

•Improper engine compression

•Exhaust system clogging

•Improper electrically controlled 4WD system operation

Warning

The following troubleshooting flow chart contains fuel system diagnosis and repair

procedures. Read following warnings before performing fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always

keep sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or

death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete

“BEFORE REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this

manual.

Caution

•Disconnecting/connecting quick release connector without cleaning it may possibly cause

damage to fuel pipe and quick release connector. Always clean quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Air cleaner element for contamination

•ATF level

•Fuel quality

•Coolant level

•Brake dragging

•Clutch slippage

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Connect WDS or equivalent to DLC-2.

Retrieve any continuous memory, KOEO and

KOER DTCs.

Are there any DTCs displayed?YesDTC is displayed:

Go to appropriate DTC test.

NoNo DTC is displayed:

Go to next step.

3 Access ECT PID.

Drive vehicle while monitoring PID.

(See F1–33 PCM INSPECTION (4WD).)

Is PID within specification?Yes Go to next step.

No Inspect for coolant leakage, cooling fan and condenser

fan operations or thermostat operation.

Page 320 of 909

F2–168

TROUBLESHOOTING

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×××

5 Engine stalls After start/at idle×××

6 Cranks normally but will not start××

7 Slow return to idle×

8 Engine runs rough/rolling idle××××

9 Fast idle/runs on×

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××××

Engine runs rough Acceleration/cruise×××× ×

Misses Acceleration/cruise××××××

Buck/jerk Acceleration/cruise/ deceleration××××××

Hesitation/stumble Acceleration××××××

Surges Acceleration/cruise××××××

12 Lack/loss of power Acceleration/cruise×××××××

13 Knocking/pinging×××××

14 Poor fuel economy××××

15 Emissions compliance× ××××××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×× × ×

18 Cooling system concerns Runs cold××

19 Excessive black smoke××××

20 Fuel odor (in engine compartment)

21 Engine noise××

22 Vibration concerns (engine)×× ×

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Improper engine coolant levelWater and anti-freeze mixture is improperCooling system malfunction (Radiator, hose,

over-flow system, thermostat, etc.)Cooling fan system malfunctionEngine or transaxle mounts are improperly installedCooling fan No.1 or No.2 seat are improperFuel qualityEngine overheatingIntake-air system clogging or restrictionAir leakage from intake-air systemVSC system malfunctionVacuum leakage

Page 354 of 909

F2–202

TROUBLESHOOTING

NO.14 POOR FUEL ECONOMYA6E408018881216

Diagnostic Procedure

14 POOR FUEL ECONOMY

DESCRIPTION•Fuel economy is unsatisfactory.

POSSIBLE

CAUSE•Incorrect idle speed

•A/C system improper operation

•Intake -air system clogging or restriction

•Engine cooling system malfunction

•Poor fuel quality

•Improper coolant level

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•Fuel pressure sensor or related circuit malfunction

•ECT sensor or related circuit malfunction

•Boost sensor or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•Incorrect adjustment idle switch

•MAF/IAT sensor or related circuit malfunction

•IAT sensor No .2 or related circuit malfunction

•VSS or related circuit malfunction

•Turbocharger malfunction

•Charge air cooler malfunction

•Low engine compression

•Improper valve timing

•Exhaust system and/or catalyst converter clogging

•Incorrect fuel injection timing

•Fuel injector malfunction

•Supply pump malfunction

•Fuel leakage

•Fuel line clogging or restriction

•Fuel filter clogging or restriction

•Brake dragging

•EGR system malfunction

•Vacuum leakage

•Clutch slippage

•Variable boost control (VBC) system malfunction

•Coolant heater system malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Fuel quality (e.g.: including water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging and/or restriction

•Fuel line leakage

•Intake-air system restriction

•Exhaust system and/or catalyst converter

restriction

•Charge air cooler condition (restriction or

damaged)

•Vacuum leakage

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Is brake system functioning properly? Yes Go to next step.

No Inspect for cause.

Page 362 of 909

F2–210

TROUBLESHOOTING

End Of SieNO.17 COOLING SYSTEM CONCERNS-OVERHEATINGA6E408018881219

Diagnostic Procedure

17

COOLING SYSTEM CONCERNS-OVERHEATING

DESCRIPTION•Engine runs at higher than normal temperature/overheats.

POSSIBLE

CAUSE•Cooling fan No.2 malfunction

•Cooling fan No.1 malfunction

•Low drive belt tension

•Drive belt damage

•Improper coolant level

•Thermostat malfunction

•Radiator clogging

•Improper water/anti-freeze mixture

•Improper or damaged radiator cap

•Radiator hose damage

•Coolant leakage (engine internal, turbocharger, external)

•A/C system malfunction

•EGR system malfunction

•Coolant heater system malfunction

STEP INSPECTION RESULTS ACTION

1 Inspect following:

•Engine coolant level

•Coolant leakage (around heater unit in

passenger compartment, coolant hoses and/

or radiator, and around coolant heater unit.)

•Water and anti-freeze mixture

•Radiator condition

•Collapsed or restricted radiator hoses

•Radiator pressure cap

•Drive belt tension

•Drive belt

•Fan rotational direction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

Page 487 of 909

K2–72

AUTOMATIC TRANSAXLE

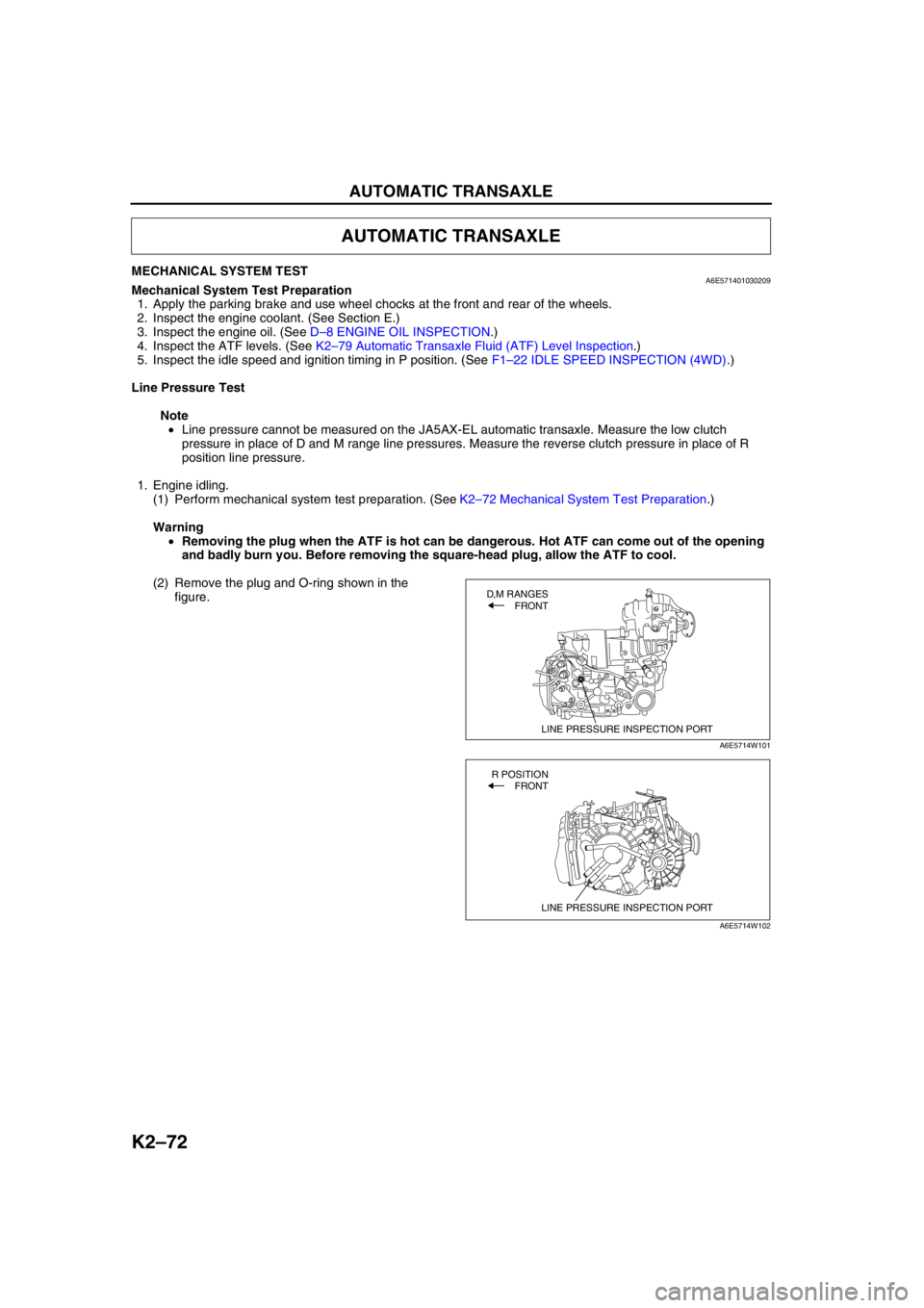

MECHANICAL SYSTEM TESTA6E571401030209Mechanical System Test Preparation

1. Apply the parking brake and use wheel chocks at the front and rear of the wheels.

2. Inspect the engine coolant. (See Section E.)

3. Inspect the engine oil. (See D–8 ENGINE OIL INSPECTION.)

4. Inspect the ATF levels. (See K2–79 Automatic Transaxle Fluid (ATF) Level Inspection.)

5. Inspect the idle speed and ignition timing in P position. (See F1–22 IDLE SPEED INSPECTION (4WD).)

Line Pressure Test

Note

•Line pressure cannot be measured on the JA5AX-EL automatic transaxle. Measure the low clutch

pressure in place of D and M range line pressures. Measure the reverse clutch pressure in place of R

position line pressure.

1. Engine idling.

(1) Perform mechanical system test preparation. (See K2–72 Mechanical System Test Preparation.)

Warning

•Removing the plug when the ATF is hot can be dangerous. Hot ATF can come out of the opening

and badly burn you. Before removing the square-head plug, allow the ATF to cool.

(2) Remove the plug and O-ring shown in the

figure.

AUTOMATIC TRANSAXLE

LINE PRESSURE INSPECTION PORT

D,M RANGES

FRONT

A6E5714W101

LINE PRESSURE INSPECTION PORT

R POSITION

FRONT

A6E5714W102

Page 490 of 909

AUTOMATIC TRANSAXLE

K2–75

K2

Time Lag Test

1. Perform mechanical system test preparation. (See K2–72 Mechanical System Test Preparation.)

2. Start the engine.

3. Warm up the engine until the ATF temperature reaches 60—70°C {140—158°F}. Shift the selector lever from N

position to D range.

4. Use a stopwatch to measure the time it takes from shifting until engagement is felt. Take three measurements

for each test and average the results using the following formula.

Formula

Average time lag = (Time 1 + Time 2 + Time 3) / 3

5. Perform the test for the following shifts in the same manner.

•N position → P position

Time lag

N → D range ... approx. 0.5—1.0 second

N → R position ... approx. 0.6— 1.0 second

Evaluation of time lag test

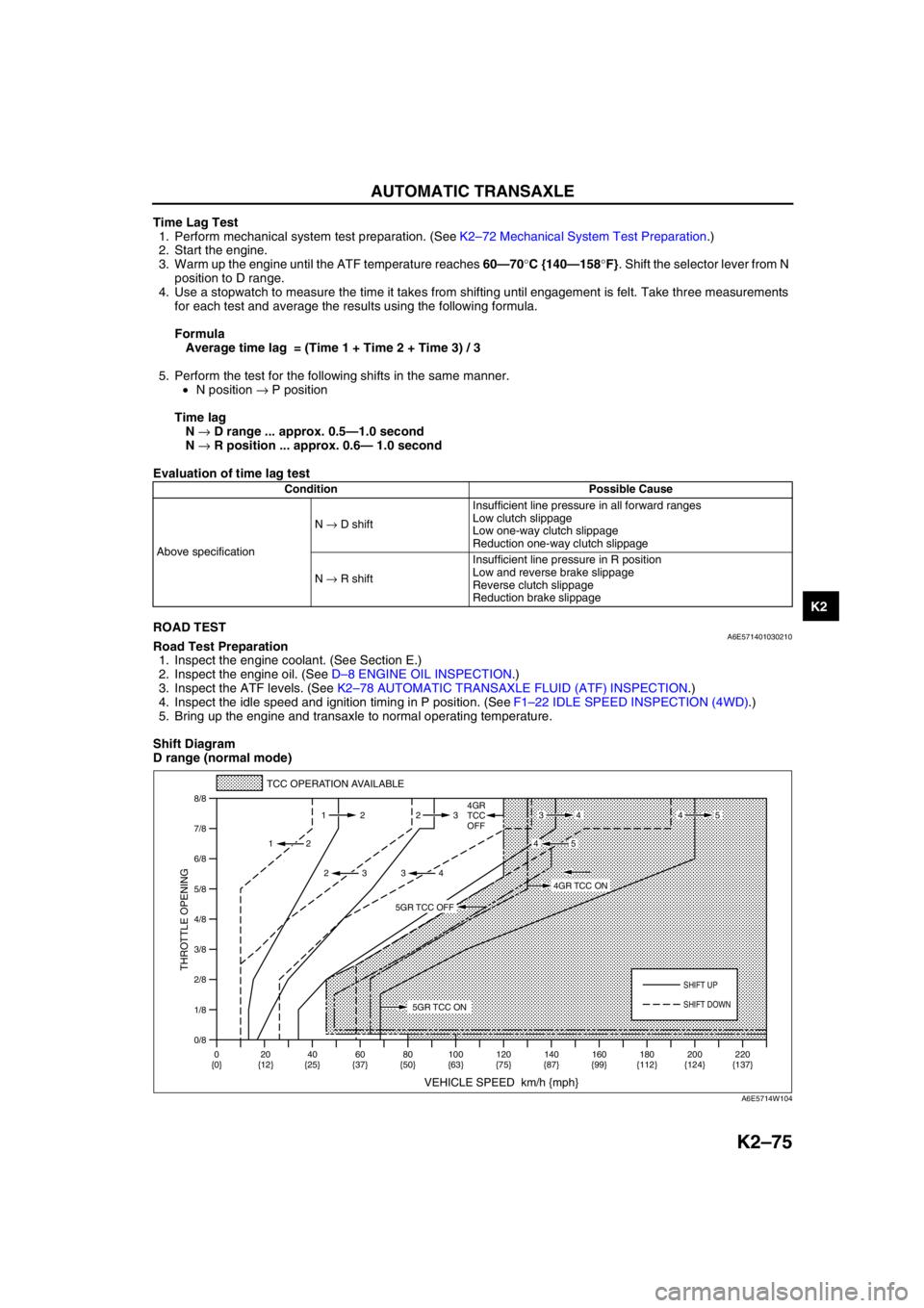

End Of SieROAD TESTA6E571401030210Road Test Preparation

1. Inspect the engine coolant. (See Section E.)

2. Inspect the engine oil. (See D–8 ENGINE OIL INSPECTION.)

3. Inspect the ATF levels. (See K2–78 AUTOMATIC TRANSAXLE FLUID (ATF) INSPECTION.)

4. Inspect the idle speed and ignition timing in P position. (See F1–22 IDLE SPEED INSPECTION (4WD).)

5. Bring up the engine and transaxle to normal operating temperature.

Shift Diagram

D range (normal mode)

Condition Possible Cause

Above specificationN → D shiftInsufficient line pressure in all forward ranges

Low clutch slippage

Low one-way clutch slippage

Reduction one-way clutch slippage

N → R shiftInsufficient line pressure in R position

Low and reverse brake slippage

Reverse clutch slippage

Reduction brake slippage

0/8 1/8

2/8

3/8

4/8

5/8

6/8

7/8

8/8

TCC OPERATION AVAILABLE

VEHICLE SPEED km/h {mph}

THROTTLE OPENING

SHIFT UP

4GR

TCC

OFF

SHIFT DOWN

0

{0}20

{12}40

{25}60

{37}80

{50}100

{63}120

{75}140

{87}160

{99}180

{112}220

{137} 200

{124} 112 23

2

2 232

34

4534

45

5GR TCC ON

4GR TCC ON

5GR TCC OFF

A6E5714W104