fuel pressure MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 99 of 909

FUEL SYSTEM

F1–11

F1

Operation

•The fuel jet pump (venturi) is installed in the return passage from the pressure regulator, and fuel in the fuel

tank is pumped to the left side from the right side using the vacuum generated in the passage.

•When the return fuel pressure exceeds a specified value, the relief valve is opened. The relief valve delivers the

return fuel directly to the fuel tank. In this way, pressure of the return fuel passing through the fuel jet pump is

kept constantly below the specified value.

.

End Of Sie

9

8

7

54

3

10

14

13

11

12

6

1

2

:

:

2

15

A6E39122003

1 Fuel pump unit

2 Fuel pump (transfer)

3 Fuel injector

4 Fuel tank (left side)

5 Fuel tank (right side)

6 Relief valve

7 Discharge outlet

8 From pressure regulator9 From fuel tank (right side)

10 Fuel jet pump

11 To fuel tank (left side)

12 Fuel jet pump

13 From fuel tank (left side)

14 Fuel flow

15 Pumped fuel flow

Page 102 of 909

F1–14

CONTROL SYSTEM

OUTLINEA6E394018880201•The control system is essentially carried over from the current Mazda6 (GG), except for the following. (See

Mazda6 Training Manual 3359-1*-02C.)

Vehicle Adoption

4WD ATX model

•TCM has been adopted. Due to this the PCM terminal of ATX device has been replaced to TCM. The ATX

device information which is needed by the fuel and emission control systems is communicated to the PCM by

the controller area network (CAN).

Unleaded (RON 90 or above) model

•BARO sensor has been eliminated. Due to this the BARO factor for purge control has been eliminated.

Input Device

×:Applicable

—: Not applicable

*

1: For MTX model

*2: With Immobilizer system

CONTROL SYSTEM

Item SignalMazda6 (GG, GY)

Remark for new model

4WD ATX Unleaded

(RON 90 or

above)Current

model

MAF/IAT sensor MAF and IAT×Same as current model

TP sensor TP×Same as current model

MAP sensor MAP×Same as current model

ECT sensor ECT×Same as current model

CMP sensorCylinder

identification×Same as current model

CKP sensor Engine revolution×Same as current model

Knock sensor Knocking×Same as current model

HO2S (Front, Rear)Oxygen

concentration×Same as current model

BARO sensor BARO×—×Same as current model

Neutral switch*

1Load/no load

distinction×Same as current model

Clutch switch*

1Load/no load

distinction×Same as current model

Brake switchBrake pedal

condition×Same as current model

PSP switchP/S oil pump load

condition×Same as current model

VSS Vehicle speed—×—

A/C switch, refrigerant

pressure switch (high,

low pressure)A/C operational×Same as current model

Refrigerant pressure

switch (middle

pressure)A/C compressor load×—×Same as current model

Battery Battery voltage×Same as current model

Generation voltage

(Generator terminal P)Generation voltage×Same as current model

Immobilizer unit*

2Immobilizer system

communication×—×Same as current model

Page 106 of 909

F1–18

CONTROL SYSTEM

*1: For MTX model

*2: For 2WD ATX model

*3: For L3 engine

End Of Sie

1 MAF/IAT sensor

2 TP sensor

3 MAP sensor

4 CMP sensor

5 CKP sensor

6 ECT sensor

7 Knock sensor

8 HO2S (front, rear)

9 PSP switch

10 Vehicle speedometer sensor

11

Clutch switch*

1

12

Neutral switch*1

13

TR switch*2

14 Brake switch

15 A/C switch

16 Refrigerant pressure switch

17 Generator (terminal P: generation voltage)

18 Battery

19

VAD control solenoid valve*

3

20 IAC valve

21

VIC solenoid valve*

3

22 Variable tumble control solenoid valve

23

OCV*

3

24 Fuel injector

25 Fuel pump relay

26 Ignition coil

27 Purge solenoid valve

28 EGR valve

29 Oxygen sensor heater (front, rear)

30 A/C relay

31 Cooling fan relay

32 Generator (terminal D: field coil)

33

VAD control*

3

34 IAC

35

VIC*

3

36 VTCS

37

Variable valve timing control*

3

38 Fuel injection control

39 Fuel pump control

40 Electronic spark advance (ESA) control

41 Purge control

42 EGR control

43 Oxygen sensor heater control

44 A/C cut-off control

45 Electrical fan control

46 Generator control

Page 107 of 909

CONTROL SYSTEM

F1–19

F1

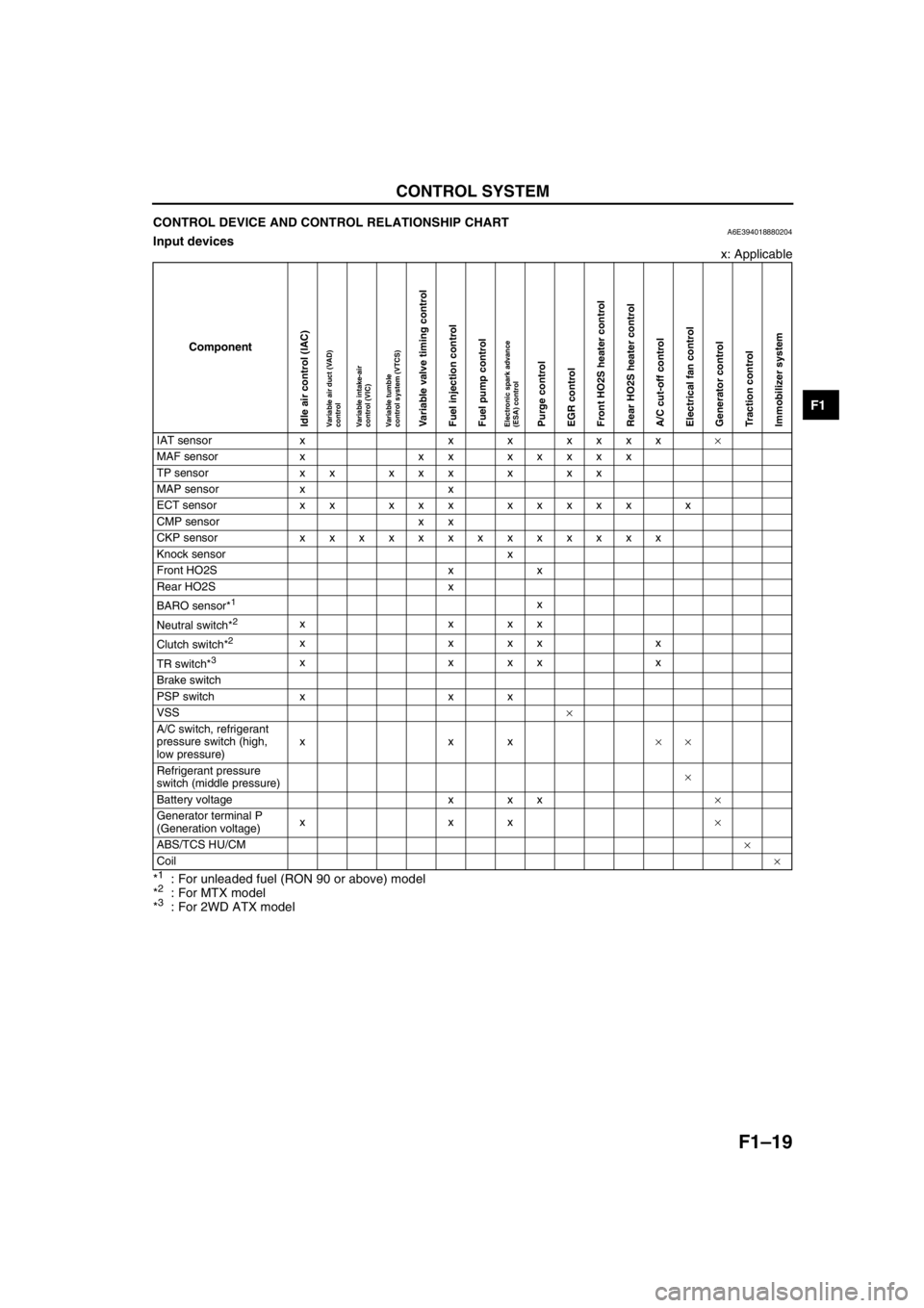

CONTROL DEVICE AND CONTROL RELATIONSHIP CHARTA6E394018880204Input devices

x: Applicable

*

1: For unleaded fuel (RON 90 or above) model

*2: For MTX model

*3: For 2WD ATX model

Component

IAT sensor x x x xxxx×

MAF sensor x xx xxxxx

TP sensor x x x x x x x x

MAP sensor x x

ECT sensor xx xxx xxxxx x

CMP sensor x x

CKP sensor xxxxxxxxxxxxx

Knock sensor x

Front HO2S x x

Rear HO2S x

BARO sensor*

1x

Neutral switch*

2xxxx

Clutch switch*

2xxxxx

TR switch*

3xxxxx

Brake switch

PSP switch x x x

VSS×

A/C switch, refrigerant

pressure switch (high,

low pressure)xxx××

Refrigerant pressure

switch (middle pressure)×

Battery voltage x x x×

Generator terminal P

(Generation voltage)xxx×

ABS/TCS HU/CM×

Coil×

Idle air control (IAC)Variable air duct (VAD)

controlVariable intake-air

control (VIC)Variable tumble

control system (VTCS)Variable valve timing controlFuel injection controlFuel pump controlElectronic spark advance

(ESA) controlPurge controlEGR controlFront HO2S heater controlRear HO2S heater controlA/C cut-off controlElectrical fan controlGenerator controlTraction controlImmobilizer system

Page 110 of 909

F1–22

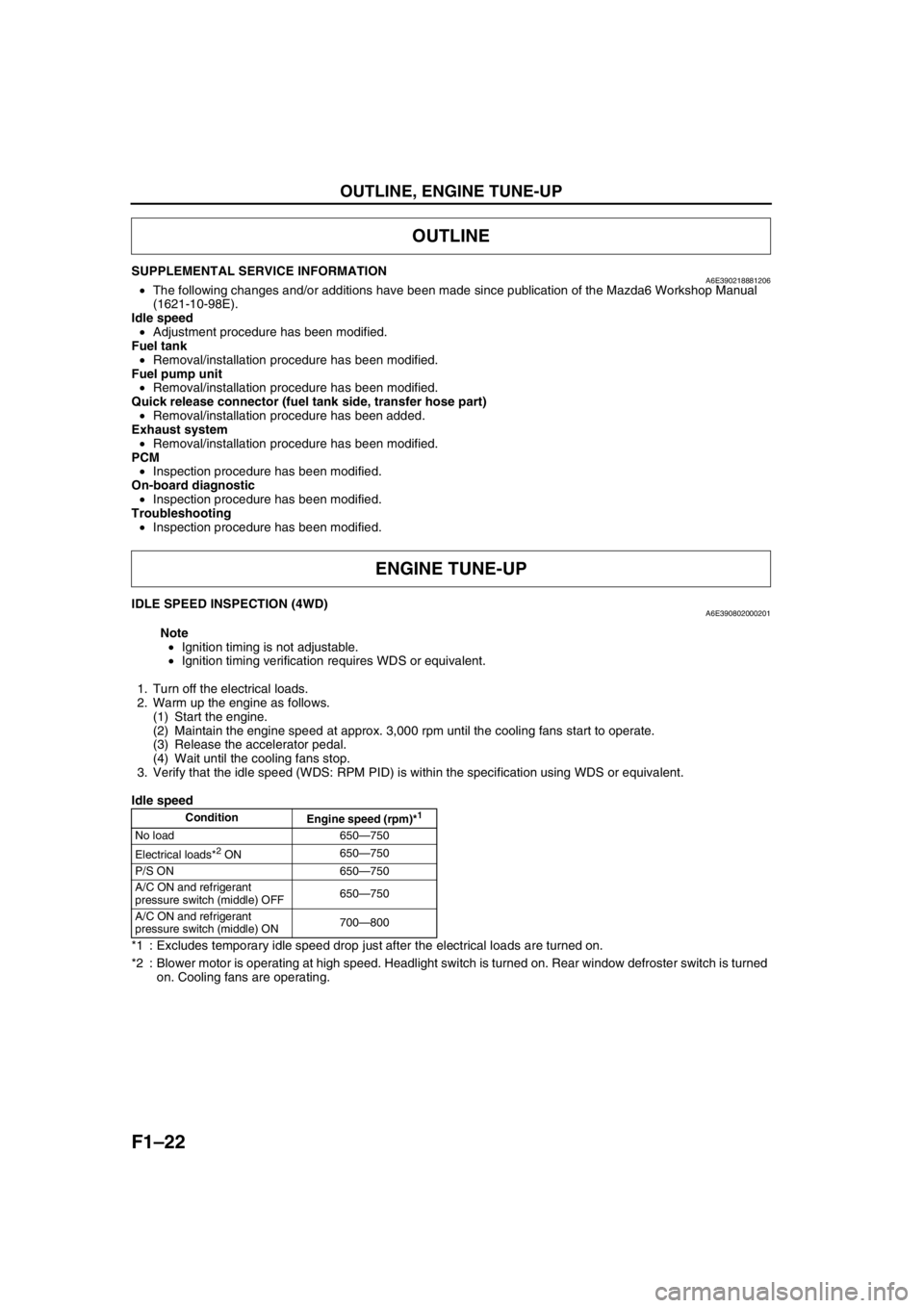

OUTLINE, ENGINE TUNE-UP

SUPPLEMENTAL SERVICE INFORMATIONA6E390218881206•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1621-10-98E).

Idle speed

•Adjustment procedure has been modified.

Fuel tank

•Removal/installation procedure has been modified.

Fuel pump unit

•Removal/installation procedure has been modified.

Quick release connector (fuel tank side, transfer hose part)

•Removal/installation procedure has been added.

Exhaust system

•Removal/installation procedure has been modified.

PCM

•Inspection procedure has been modified.

On-board diagnostic

•Inspection procedure has been modified.

Troubleshooting

•Inspection procedure has been modified.

End Of Sie

IDLE SPEED INSPECTION (4WD)A6E390802000201

Note

•Ignition timing is not adjustable.

•Ignition timing verification requires WDS or equivalent.

1. Turn off the electrical loads.

2. Warm up the engine as follows.

(1) Start the engine.

(2) Maintain the engine speed at approx. 3,000 rpm until the cooling fans start to operate.

(3) Release the accelerator pedal.

(4) Wait until the cooling fans stop.

3. Verify that the idle speed (WDS: RPM PID) is within the specification using WDS or equivalent.

Idle speed

*1 : Excludes temporary idle speed drop just after the electrical loads are turned on.

*2 : Blower motor is operating at high speed. Headlight switch is turned on. Rear window defroster switch is turned

on. Cooling fans are operating.

End Of Sie

OUTLINE

ENGINE TUNE-UP

Condition

Engine speed (rpm)*1

No load 650—750

Electrical loads*

2 ON650—750

P/S ON 650—750

A/C ON and refrigerant

pressure switch (middle) OFF650—750

A/C ON and refrigerant

pressure switch (middle) ON700—800

Page 122 of 909

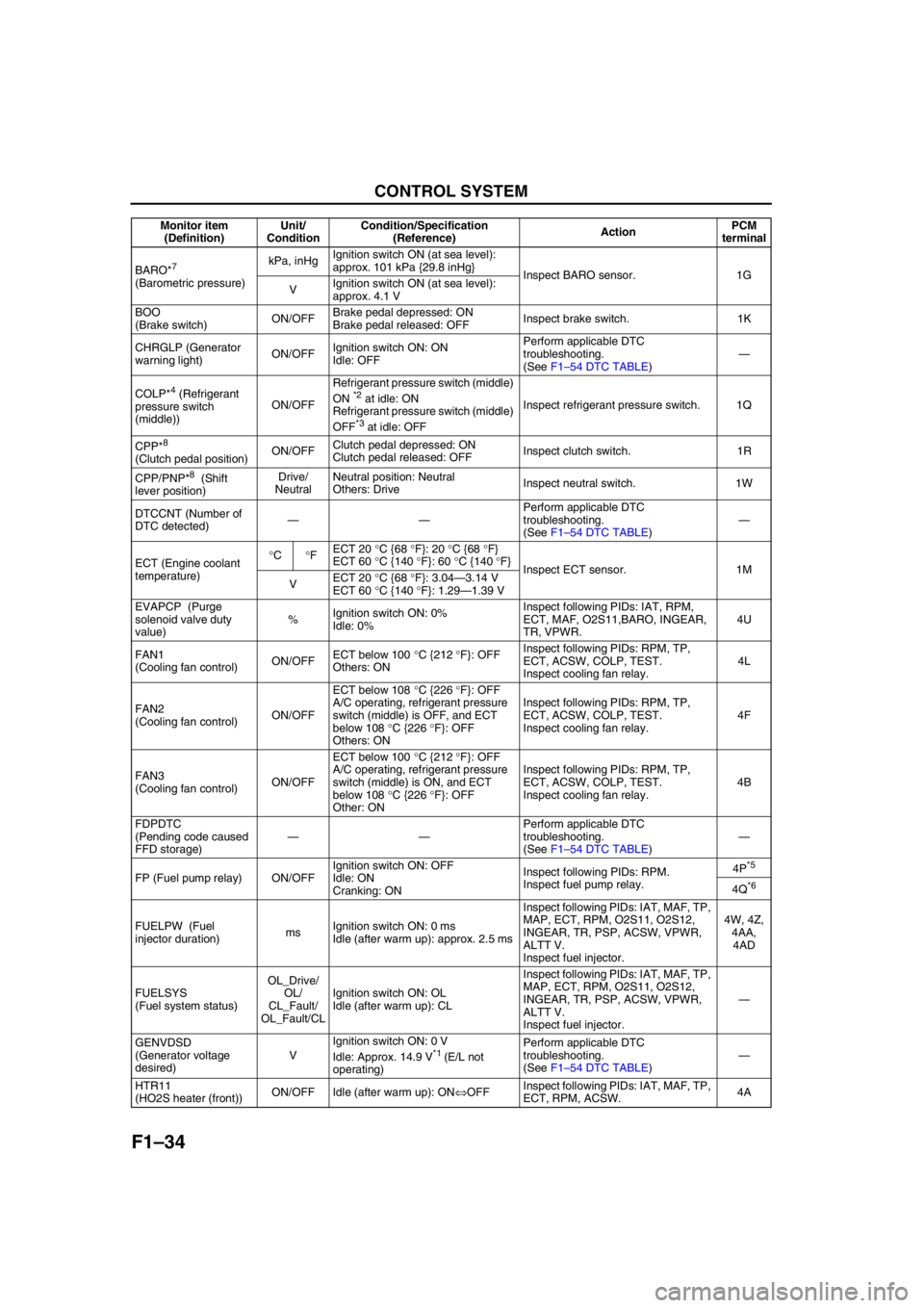

F1–34

CONTROL SYSTEM

BARO*7

(Barometric pressure)kPa, inHgIgnition switch ON (at sea level):

approx. 101 kPa {29.8 inHg}

Inspect BARO sensor. 1G

VIgnition switch ON (at sea level):

approx. 4.1 V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Brake pedal released: OFFInspect brake switch. 1K

CHRGLP (Generator

warning light)ON/OFFIgnition switch ON: ON

Idle: OFFPerform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

COLP*

4 (Refrigerant

pressure switch

(middle))ON/OFFRefrigerant pressure switch (middle)

ON *2 at idle: ON

Refrigerant pressure switch (middle)

OFF

*3 at idle: OFFInspect refrigerant pressure switch. 1Q

CPP*

8

(Clutch pedal position)ON/OFFClutch pedal depressed: ON

Clutch pedal released: OFFInspect clutch switch. 1R

CPP/PNP*

8 (Shift

lever position)Drive/

NeutralNeutral position: Neutral

Others: DriveInspect neutral switch. 1W

DTCCNT (Number of

DTC detected)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

ECT (Engine coolant

temperature)°C°FECT 20 °C {68 °F}: 20 °C {68 °F}

ECT 60 °C {140 °F}: 60 °C {140 °F}

Inspect ECT sensor. 1M

VECT 20 °C {68 °F}: 3.04—3.14 V

ECT 60 °C {140 °F}: 1.29—1.39 V

EVAPCP (Purge

solenoid valve duty

value)%Ignition switch ON: 0%

Idle: 0%Inspect following PIDs: IAT, RPM,

ECT, MAF, O2S11,BARO, INGEAR,

TR, VPWR.4U

FAN1

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4L

FAN2

(Cooling fan control)ON/OFFECT below 108 °C {226 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is OFF, and ECT

below 108 °C {226 °F}: OFF

Others: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4F

FAN3

(Cooling fan control)ON/OFFECT below 100 °C {212 °F}: OFF

A/C operating, refrigerant pressure

switch (middle) is ON, and ECT

below 108 °C {226 °F}: OFF

Other: ONInspect following PIDs: RPM, TP,

ECT, ACSW, COLP, TEST.

Inspect cooling fan relay.4B

FDPDTC

(Pending code caused

FFD storage)——Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

FP (Fuel pump relay) ON/OFFIgnition switch ON: OFF

Idle: ON

Cranking: ONInspect following PIDs: RPM.

Inspect fuel pump relay.4P

*5

4Q*6

FUELPW (Fuel

injector duration)msIgnition switch ON: 0 ms

Idle (after warm up): approx. 2.5 msInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.4W, 4Z,

4AA,

4AD

FUELSYS

(Fuel system status)OL_Drive/

OL/

CL_Fault/

OL_Fault/CLIgnition switch ON: OL

Idle (after warm up): CLInspect following PIDs: IAT, MAF, TP,

MAP, ECT, RPM, O2S11, O2S12,

INGEAR, TR, PSP, ACSW, VPWR,

ALTT V.

Inspect fuel injector.—

GENVDSD

(Generator voltage

desired)VIgnition switch ON: 0 V

Idle: Approx. 14.9 V

*1 (E/L not

operating)Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

HTR11

(HO2S heater (front))ON/OFF Idle (after warm up): ON⇔OFFInspect following PIDs: IAT, MAF, TP,

ECT, RPM, ACSW.4A Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

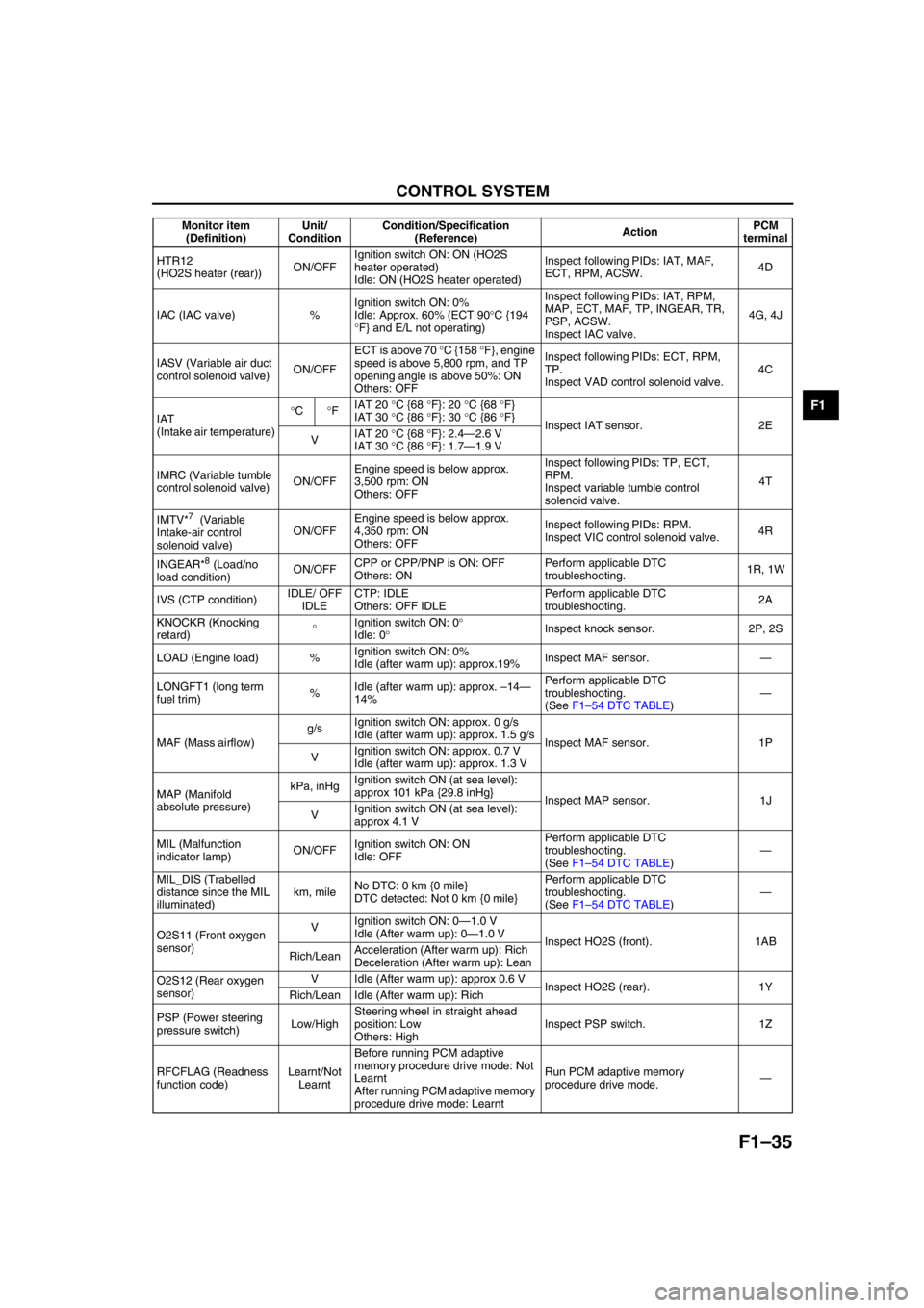

Page 123 of 909

CONTROL SYSTEM

F1–35

F1

HTR12

(HO2S heater (rear))ON/OFFIgnition switch ON: ON (HO2S

heater operated)

Idle: ON (HO2S heater operated)Inspect following PIDs: IAT, MAF,

ECT, RPM, ACSW.4D

IAC (IAC valve) %Ignition switch ON: 0%

Idle: Approx. 60% (ECT 90°C {194

°F} and E/L not operating) Inspect following PIDs: IAT, RPM,

MAP, ECT, MAF, TP, INGEAR, TR,

PSP, ACSW.

Inspect IAC valve.4G, 4J

IASV (Variable air duct

control solenoid valve)ON/OFFECT is above 70 °C {158 °F}, engine

speed is above 5,800 rpm, and TP

opening angle is above 50%: ON

Others: OFFInspect following PIDs: ECT, RPM,

TP.

Inspect VAD control solenoid valve.4C

IAT

(Intake air temperature)°C°FIAT 20 °C {68 °F}: 20 °C {68 °F}

IAT 30 °C {86 °F}: 30 °C {86 °F}

Inspect IAT sensor. 2E

VIAT 20 °C {68 °F}: 2.4—2.6 V

IAT 30 °C {86 °F}: 1.7—1.9 V

IMRC (Variable tumble

control solenoid valve)ON/OFFEngine speed is below approx.

3,500 rpm: ON

Others: OFFInspect following PIDs: TP, ECT,

RPM.

Inspect variable tumble control

solenoid valve.4T

IMTV*

7 (Variable

Intake-air control

solenoid valve)ON/OFFEngine speed is below approx.

4,350 rpm: ON

Others: OFFInspect following PIDs: RPM.

Inspect VIC control solenoid valve.4R

INGEAR*

8 (Load/no

load condition)ON/OFFCPP or CPP/PNP is ON: OFF

Others: ONPerform applicable DTC

troubleshooting.1R, 1W

IVS (CTP condition)IDLE/ OFF

IDLECTP: IDLE

Others: OFF IDLEPerform applicable DTC

troubleshooting.2A

KNOCKR (Knocking

retard)°Ignition switch ON: 0°

Idle: 0°Inspect knock sensor. 2P, 2S

LOAD (Engine load) %Ignition switch ON: 0%

Idle (after warm up): approx.19%Inspect MAF sensor.—

LONGFT1 (long term

fuel trim)%Idle (after warm up): approx. –14—

14%Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

MAF (Mass airflow)g/sIgnition switch ON: approx. 0 g/s

Idle (after warm up): approx. 1.5 g/s

Inspect MAF sensor. 1P

VIgnition switch ON: approx. 0.7 V

Idle (after warm up): approx. 1.3 V

MAP (Manifold

absolute pressure)kPa, inHgIgnition switch ON (at sea level):

approx 101 kPa {29.8 inHg}

Inspect MAP sensor. 1J

VIgnition switch ON (at sea level):

approx 4.1 V

MIL (Malfunction

indicator lamp)ON/OFFIgnition switch ON: ON

Idle: OFFPerform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

MIL_DIS (Trabelled

distance since the MIL

illuminated)km, mileNo DTC: 0 km {0 mile}

DTC detected: Not 0 km {0 mile}Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

O2S11 (Front oxygen

sensor)VIgnition switch ON: 0—1.0 V

Idle (After warm up): 0—1.0 V

Inspect HO2S (front). 1AB

Rich/LeanAcceleration (After warm up): Rich

Deceleration (After warm up): Lean

O2S12 (Rear oxygen

sensor)V Idle (After warm up): approx 0.6 V

Inspect HO2S (rear). 1Y

Rich/Lean Idle (After warm up): Rich

PSP (Power steering

pressure switch)Low/HighSteering wheel in straight ahead

position: Low

Others: HighInspect PSP switch. 1Z

RFCFLAG (Readness

function code)Learnt/Not

LearntBefore running PCM adaptive

memory procedure drive mode: Not

Learnt

After running PCM adaptive memory

procedure drive mode: LearntRun PCM adaptive memory

procedure drive mode.— Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 124 of 909

F1–36

CONTROL SYSTEM

*1: Calculated value; differs from terminal voltage

*2: Refrigerant pressure switch (middle) turns on when the refrigerant pressure is 1.69—1.84 MPa {17.3—18.7

kgf/cm2, 247—265 psi}

*3: Refrigerant pressure switch (middle) turns off when the refrigerant pressure is 1.26—1.49 MPa {12.9—15.1

kgf/cm2, 184—214 psi}

*4: L3 and L8, LF (Intensely hot area) engine models

*5: Immobilizer system equipped model

*6: Immobilizer system not equipped

*7: L3 engine model only

*8: MTX model only

•Following PIDs are for the ATX models. If inspects for following PIDs, see K2–180 PID/DATA MONITOR

INSPECTION.

PIDs for the ATX models

—GEAR, LINEDES, LPS, OP_SW_B, SSA/SS1, SSB/SS2, SSC/SS3, TCS, TFT, TFTV, THOP, TR,

TR_SENS, TSS

RO2FT1 (Rear oxygen

sensor fuel trim)—Idle (after warm up): approx. –

0.03—0.03Perform applicable DTC

troubleshooting.—

RPM (Engine speed) rpm

LF Unleaded fuel (RON 90 or

above) model

No load: 600—700 rpm

E/L operating: 650—750 rpm

P/S operating: 650—750 rpm

A/C ON: 700—800 rpm

L3 4WD ATX model

No load: 650—750 rpm

E/L operating: 650—750 rpm

P/S operating: 650—750 rpm

A/C ON: 650—750 rpm*

2, 700—

800 rpm*3

Inspect CKP sensor. 2D, 2G

SEGRP (EGR valve

(stepping motor)

position)StepIgnition switch ON: 0 step

Idle: 0 step

Cranking: 0—60 stepsInspect following PIDs: MAF, TP,

ECT, RPM, VSS.

Inspect EGR valve.4E, 4H,

4K, 4N

SHRTFT1 (Short term

fuel trim)%Idle (after warm up): approx.–30—

25%Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

SPARKADV (Ignition

timing)°Ignition switch ON: BTDC 0°

Idle: BTDC approx. 10°Inspect following PIDs: MAF, TP,

ECT, RPM, INGEAR, TR, PSP,

ACSW, VPWR.

Inspect ignition timing.2J, 2M

TEST (Test mode) ON/OFF———

TP (TP)%CTP: 13—23%

WOT: 86—96%

Inspect TP sensor. 2A

VCTP: 0.65—1.15 V

WOT: 4.3—4.8 V

TPCT

(TP sensor voltage at

CTP )V0.65—1.15 V Inspect TP sensor. 2A

VPWR (Battery positive

voltage)V Ignition switch ON: B+Inspect main relay.

Inspect battery.2Y, 2Z

VSS (Vehicle speed) kph, mphVehicle speed 20 kph {12 mph}:

20 kph {12 mph}

Vehicle speed 40 kph {25 mph}:

20 kph {12 mph}Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

VT DUTY1*

7% Idle: 0%Inspect following PIDs: TP, ECT,

RPM.

Inspect OCV.2I, 2L Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

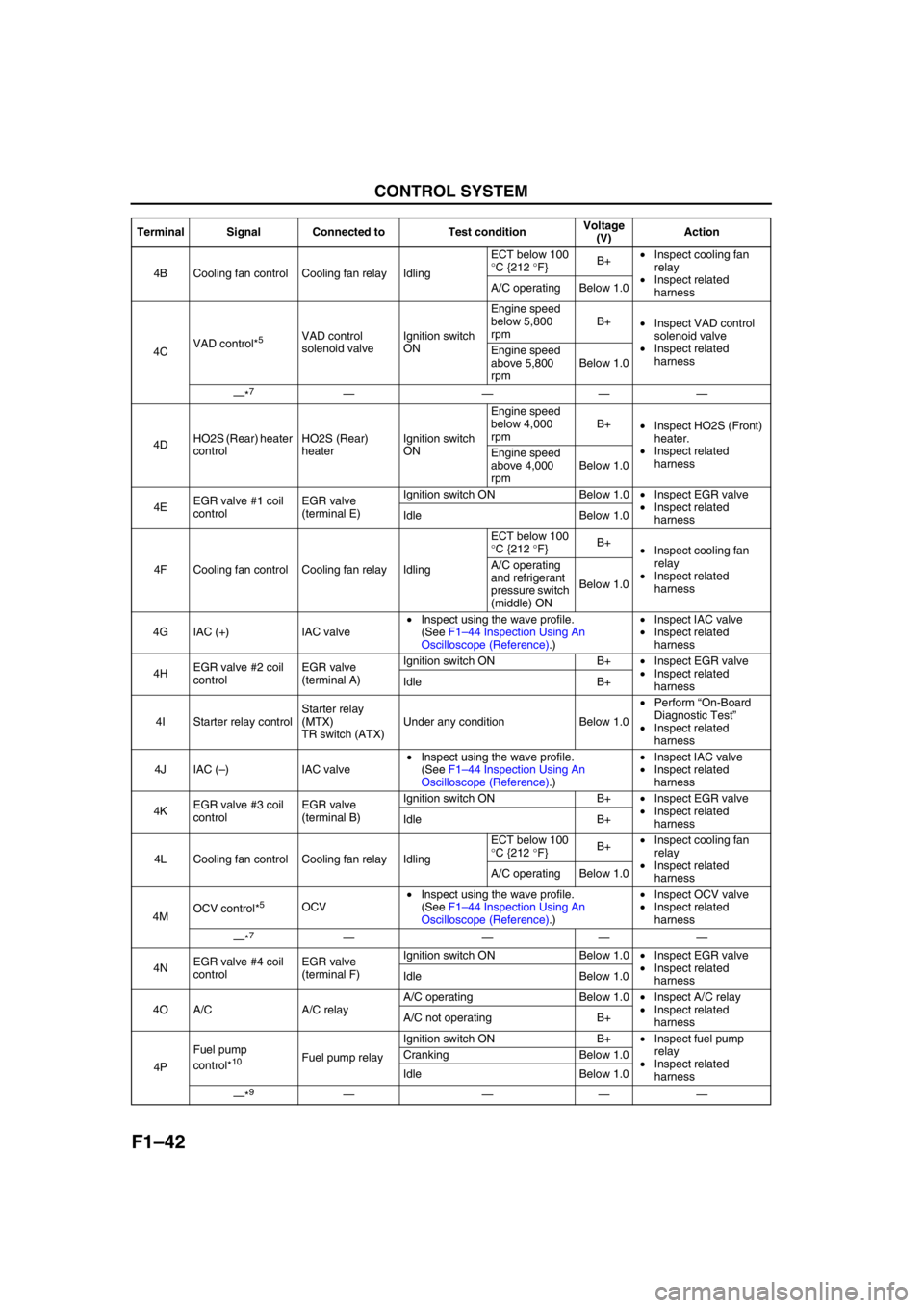

Page 130 of 909

F1–42

CONTROL SYSTEM

4B Cooling fan control Cooling fan relay IdlingECT below 100

°C {212 °F}B+•Inspect cooling fan

relay

•Inspect related

harness A/C operating Below 1.0

4CVAD control*

5VAD control

solenoid valveIgnition switch

ONEngine speed

below 5,800

rpmB+

•Inspect VAD control

solenoid valve

•Inspect related

harness Engine speed

above 5,800

rpmBelow 1.0

—*

7————

4DHO2S (Rear) heater

controlHO2S (Rear)

heaterIgnition switch

ONEngine speed

below 4,000

rpmB+

•Inspect HO2S (Front)

heater.

•Inspect related

harness Engine speed

above 4,000

rpmBelow 1.0

4EEGR valve #1 coil

controlEGR valve

(terminal E)Ignition switch ON Below 1.0•Inspect EGR valve

•Inspect related

harness Idle Below 1.0

4F Cooling fan control Cooling fan relay IdlingECT below 100

°C {212 °F}B+

•Inspect cooling fan

relay

•Inspect related

harness A/C operating

and refrigerant

pressure switch

(middle) ONBelow 1.0

4G IAC (+) IAC valve•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect IAC valve

•Inspect related

harness

4HEGR valve #2 coil

controlEGR valve

(terminal A)Ignition switch ON B+•Inspect EGR valve

•Inspect related

harness Idle B+

4I Starter relay controlStarter relay

(MTX)

TR switch (ATX)Under any condition Below 1.0•Perform “On-Board

Diagnostic Test”

•Inspect related

harness

4J IAC (–)IAC valve•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect IAC valve

•Inspect related

harness

4KEGR valve #3 coil

controlEGR valve

(terminal B)Ignition switch ON B+•Inspect EGR valve

•Inspect related

harness Idle B+

4L Cooling fan control Cooling fan relay IdlingECT below 100

°C {212 °F}B+•Inspect cooling fan

relay

•Inspect related

harness A/C operating Below 1.0

4MOCV control*

5OCV•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect OCV valve

•Inspect related

harness

—*

7————

4NEGR valve #4 coil

controlEGR valve

(terminal F)Ignition switch ON Below 1.0•Inspect EGR valve

•Inspect related

harness Idle Below 1.0

4O A/C A/C relayA/C operating Below 1.0•Inspect A/C relay

•Inspect related

harness A/C not operating B+

4PFuel pump

control*

10Fuel pump relayIgnition switch ON B+•Inspect fuel pump

relay

•Inspect related

harness Cranking Below 1.0

Idle Below 1.0

—*

9———— Terminal Signal Connected to Test conditionVoltage

(V)Action

Page 147 of 909

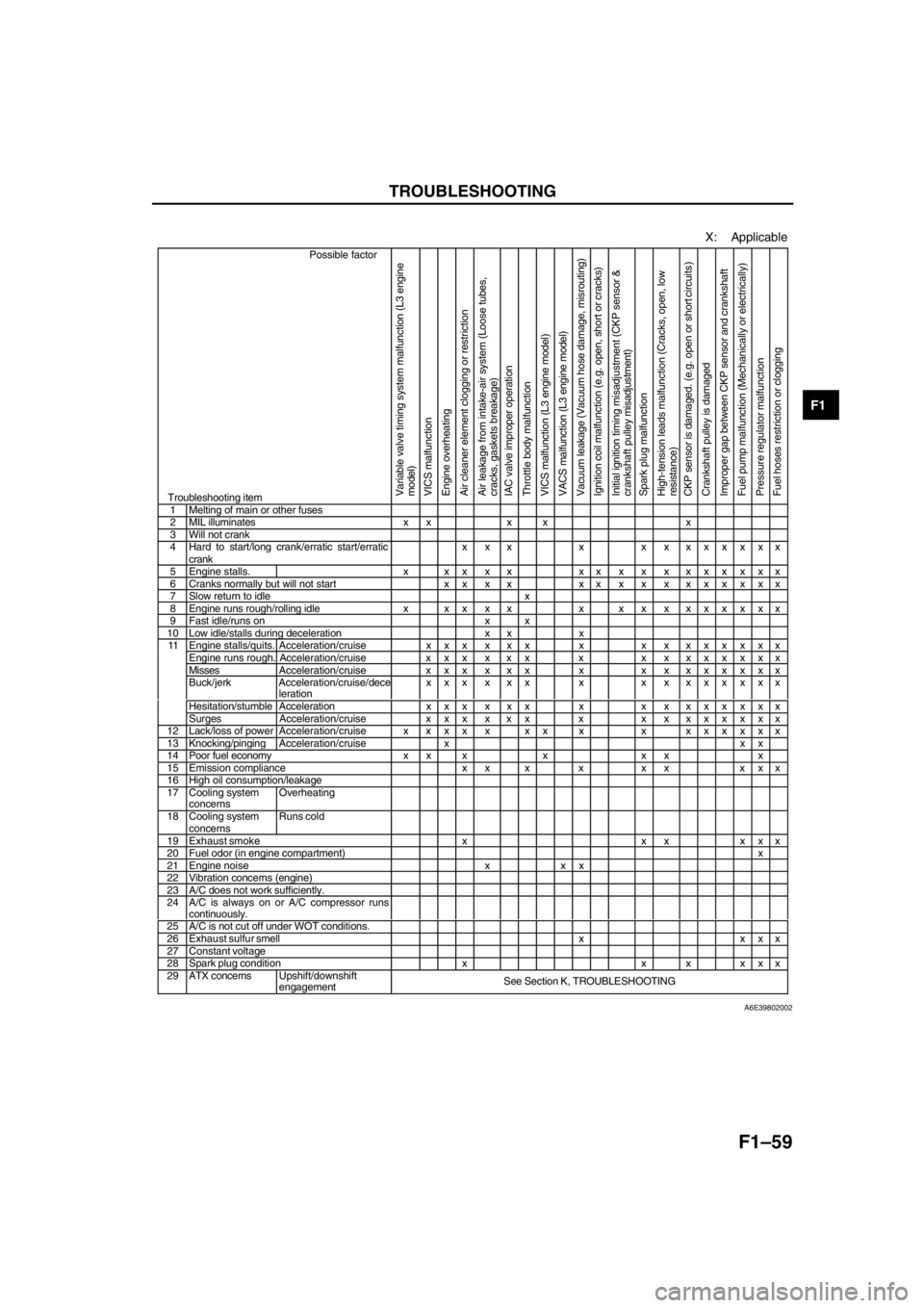

TROUBLESHOOTING

F1–59

F1

X: Applicable

Possible factor

Troubleshooting itemVariable valve timing system malfunction (L3 engine

model)

VICS malfunction

Engine overheating

Air cleaner element clogging or restriction

Air leakage from intake-air system (Loose tubes,

cracks, gaskets breakage)

IAC valve improper operation

Throttle body malfunction

VICS malfunction (L3 engine model)

VACS malfunction (L3 engine model)

Vacuum leakage (Vacuum hose damage, misrouting)

Ignition coil malfunction (e.g. open, short or cracks)

Initial ignition timing misadjustment (CKP sensor &

crankshaft pulley misadjustment)

Spark plug malfunction

High-tension leads malfunction (Cracks, open, low

resistance)

CKP sensor is damaged. (e.g. open or short circuits )

Crankshaft pulley is damaged

Improper gap between CKP sensor and crankshaft

Fuel pump malfunction (Mechanically or electrically)

Pressure regulator malfunction

Fuel hoses restriction or clogging

1 Melting of main or other fuses2 MIL illuminates x x x x x3 Will not crank4 Hard to start/long crank/erratic start/erratic

crankx x x x x x xxxxxx

5 Engine stalls. x x x x x xxxxxxxxxxx6 Cranks normally but will not start x x x x xxxxxxxxxxx7 Slow return to idle x8 Engine runs rough/rolling idle x x x x x x x x xxxxxxx9 Fast idle/runs on x x10 Low idle/stalls during deceleration x x xEngine stalls/quits. Acceleration/cruise x x x x x x x x xxxxxxxEngine runs rough. Acceleration/cruise x x x x x x x x xxxxxxxMissesAcceleration/cruise x x x x x x x x xxxxxxxBuck/jerk Acceleration/cruise/dece

lerationxxx x xx x x x xxxxxx

Hesitation/stumble Acceleration x x x x x x x x xxxxxxx

11

Surges Acceleration/cruise x x x x x x x x xxxxxxx

12 Lack/loss of powerAcceleration/cruise x x x x x x x x xxxxxxx13 Knocking/pingingAcceleration/cruise x x x14 Poor fuel economy x x x x x x x15 Emission compliance x x x x x x x x x16 High oil consumption/leakage17 Cooling system

concernsOverheating

18 Cooling system

concernsRuns cold

19 Exhaust smoke x x x x x x20 Fuel odor (in engine compartment)x21 Engine noise x x x22 Vibration concerns (engine)23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smell x x x x27 Constant voltage28 Spark plug condition x x x x x x29 ATX concernsUpshift/downshift

engagementSee Section K, TROUBLESHOOTING

A6E39802002