transmission MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 641 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–11

M

4WD solenoid control current is ON

•When the 4WD solenoid control current is ON, current flows from the 4WD CM to the 4WD solenoid, and the

coupling operates in the following manner.

1. Magnetic flux forms at the electromagnetic coil of the 4WD solenoid.

2. Due to the magnetic flux in the armature, the pilot clutch is suctioned towards the magnetic coil side and

made to engage. This causes frictional torque to generate in the pilot clutch.

3. The torque is transmitted to the pilot cam, which is engaged with the pilot clutch.

4. A rotational difference is created between the pilot cam and the main cam. Due to this relative torsion, the

cam mechanism operates, transmitting torque from the pilot cam to the ball and then to the main cam. In

this way, the push force exerted on the main clutch is amplified.

5. As the main clutch engages, the drive torque from the front wheels is transmitted to the rear wheels.

•The amount of push force exerted on the main clutch by the main cam (that is, the strength of the drive torque

transmitted to the rear wheels) changes in accordance with the proportion of the force acting upon the pilot

cam, engaged with the pilot clutch. Therefore, by changing the periodicity of the electric current from the 4WD

CM to the 4WD solenoid (ON/OFF rate of the 4WD solenoid = force acting on the pilot cam), the module

controls the transmission of drive torque to the rear wheels.

.

End Of Sie

98

75

4

3

10

11

6

12

56

7

12

A6E63222005

1 Main clutch

2Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)

5Main cam

6Pilot cam7Ball

8Armature

9 Drive torque

10 Magnetic flux

11 Input

12 Output

Page 643 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–13

M

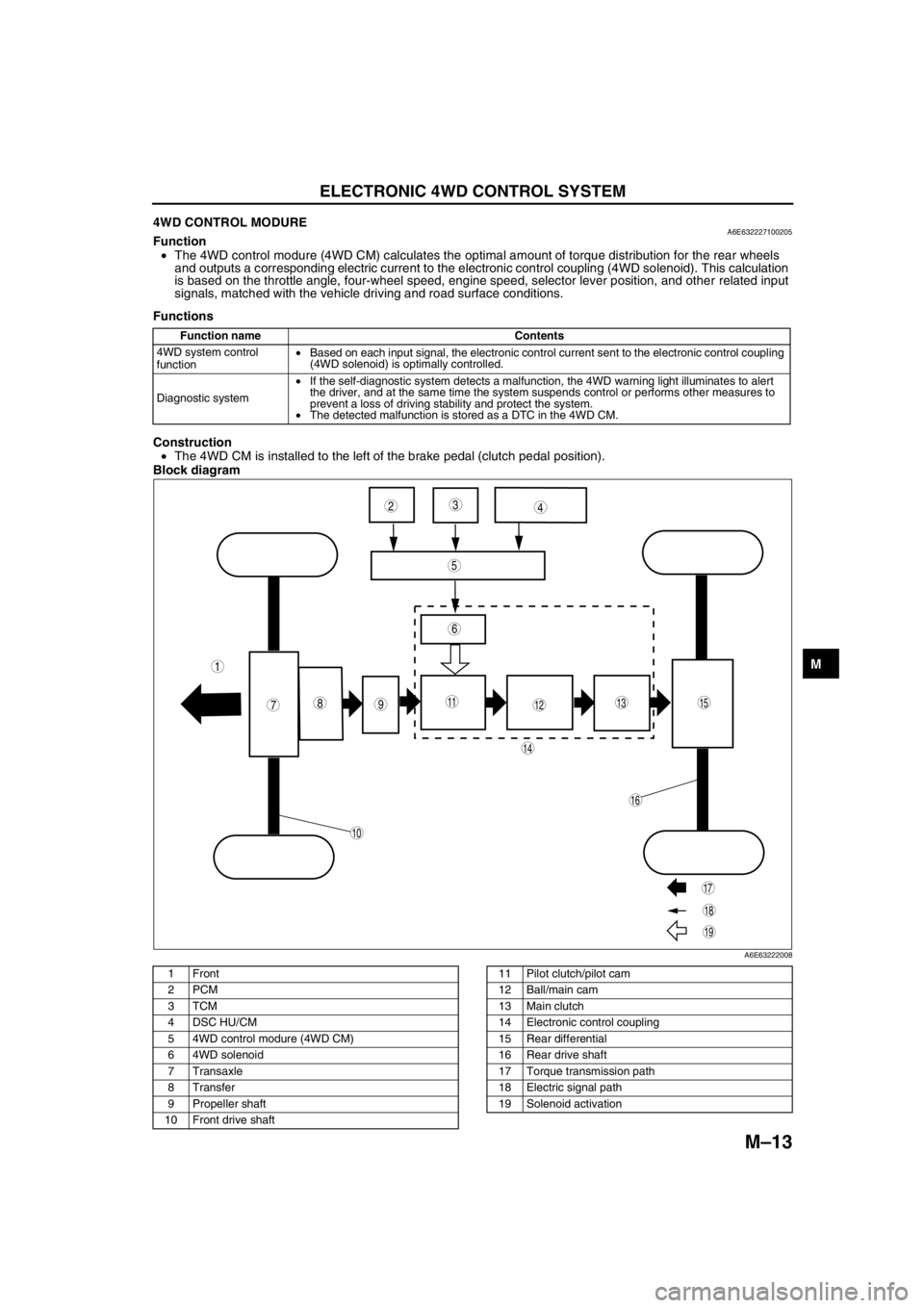

4WD CONTROL MODUREA6E632227100205Function

•The 4WD control modure (4WD CM) calculates the optimal amount of torque distribution for the rear wheels

and outputs a corresponding electric current to the electronic control coupling (4WD solenoid). This calculation

is based on the throttle angle, four-wheel speed, engine speed, selector lever position, and other related input

signals, matched with the vehicle driving and road surface conditions.

Functions

Construction

•The 4WD CM is installed to the left of the brake pedal (clutch pedal position).

Block diagram

.

Function name Contents

4WD system control

function•Based on each input signal, the electronic control current sent to the electronic control coupling

(4WD solenoid) is optimally controlled.

Diagnostic system•If the self-diagnostic system detects a malfunction, the 4WD warning light illuminates to alert

the driver, and at the same time the system suspends control or performs other measures to

prevent a loss of driving stability and protect the system.

•The detected malfunction is stored as a DTC in the 4WD CM.

987

5

43

10

19

18

17

15

16

14

131112

6

1

2

A6E63222008

1Front

2PCM

3TCM

4 DSC HU/CM

5 4WD control modure (4WD CM)

6 4WD solenoid

7Transaxle

8Transfer

9 Propeller shaft

10 Front drive shaft11 Pilot clutch/pilot cam

12 Ball/main cam

13 Main clutch

14 Electronic control coupling

15 Rear differential

16 Rear drive shaft

17 Torque transmission path

18 Electric signal path

19 Solenoid activation

Page 698 of 909

M–68

ELECTRONIC 4WD CONTROL SYSTEM

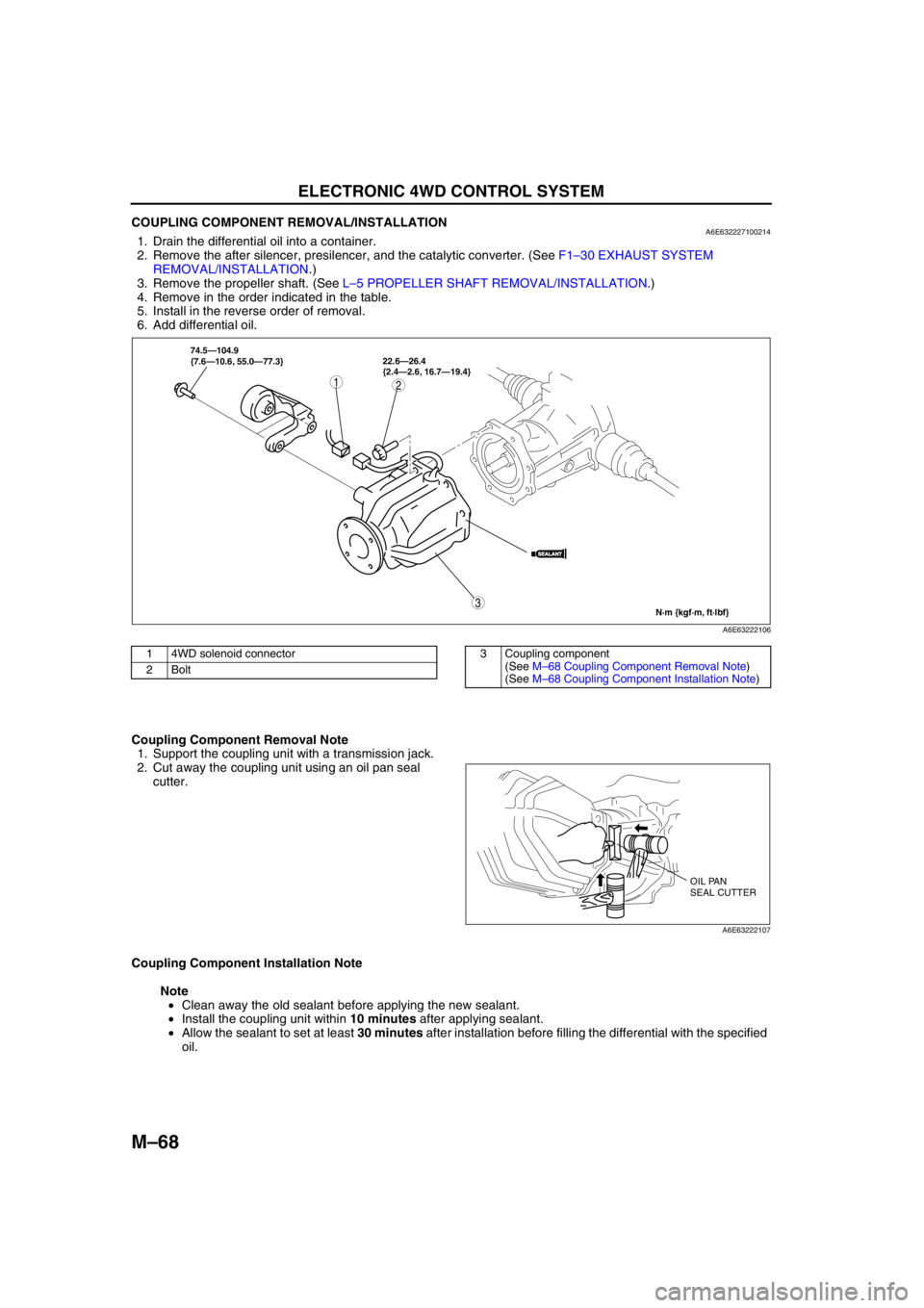

COUPLING COMPONENT REMOVAL/INSTALLATIONA6E6322271002141. Drain the differential oil into a container.

2. Remove the after silencer, presilencer, and the catalytic converter. (See F1–30 EXHAUST SYSTEM

REMOVAL/INSTALLATION.)

3. Remove the propeller shaft. (See L–5 PROPELLER SHAFT REMOVAL/INSTALLATION.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Add differential oil.

.

Coupling Component Removal Note

1. Support the coupling unit with a transmission jack.

2. Cut away the coupling unit using an oil pan seal

cutter.

Coupling Component Installation Note

Note

•Clean away the old sealant before applying the new sealant.

•Install the coupling unit within 10 minutes after applying sealant.

•Allow the sealant to set at least 30 minutes after installation before filling the differential with the specified

oil.

3

12

SEALANTSEALANT

74.5—104.9

{7.6—10.6, 55.0—77.3}22.6—26.4

{2.4—2.6, 16.7—19.4}

N·m {kgf·m, ft·lbf}

A6E63222106

1 4WD solenoid connector

2Bolt3 Coupling component

(See M–68 Coupling Component Removal Note)

(See M–68 Coupling Component Installation Note)

OIL PAN

SEAL CUTTER

A6E63222107

Page 816 of 909

MULTIPLEX COMMUNICATION SYSTEM

T–5

T

End Of Sie

Cruise main indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Cruise set indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Desired gear/

selector lever

positionFN4A-EL OUT–IN–IN

JA5AX-EL IN OUT IN IN IN

ECT OUT IN–IN

Engine control condition OUT–IN––

Engine displacement OUT–IN––

Engine loss torque (except

MZR-CD (RF Turbo))OUT IN–––

Engine speed OUT IN IN IN IN

Engine torque (except

MZR-CD (RF Turbo))OUT IN–––

Fuel injection information OUT–IN––

Fuel type and delivery OUT–IN––

Gear position IN OUT IN IN IN

Generator warning light

conditions (except MZR-

CD (RF Turbo))OUT–––IN

Glow indicator light

condition (MZR-CD (RF

Turbo))OUT–––IN

HOLD indicator light

conditions (FN4A-EL)OUT–––IN

Idle speed up request IN OUT–––

MIL condition (except

MZR-CD (RF Turbo))OUT–––IN

MIL indicate request IN OUT–––

Number of cylinders OUT–IN––

Racing select

determinationIN OUT–––

TCC condition IN OUT–––

Tire circumference (front/

rear)OUT–IN––

Torque reduction inhibit OUT IN IN––

TP OUTINININ–

Transmission/axle type OUT–IN––

Travelled distanceIN–OUT––

IN OUT––IN

OUT–––IN

Torque

reduction

requestJA5AX-EL IN OUT–––

except

JA5AX-ELIN–OUT––

Turbine speed IN OUT–––

Upper torque limit IN OUT–––

Vehicle speedOUT–––IN

IN OUT–––

Wheel speed (front left/

front right/rear left/rear

right)IN IN OUT IN–

OUT–––IN

4WD system operating

condition (warning light

information)–––OUT IN SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster