engine MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 302 of 909

F2–150

ON-BOARD DIAGNOSTIC

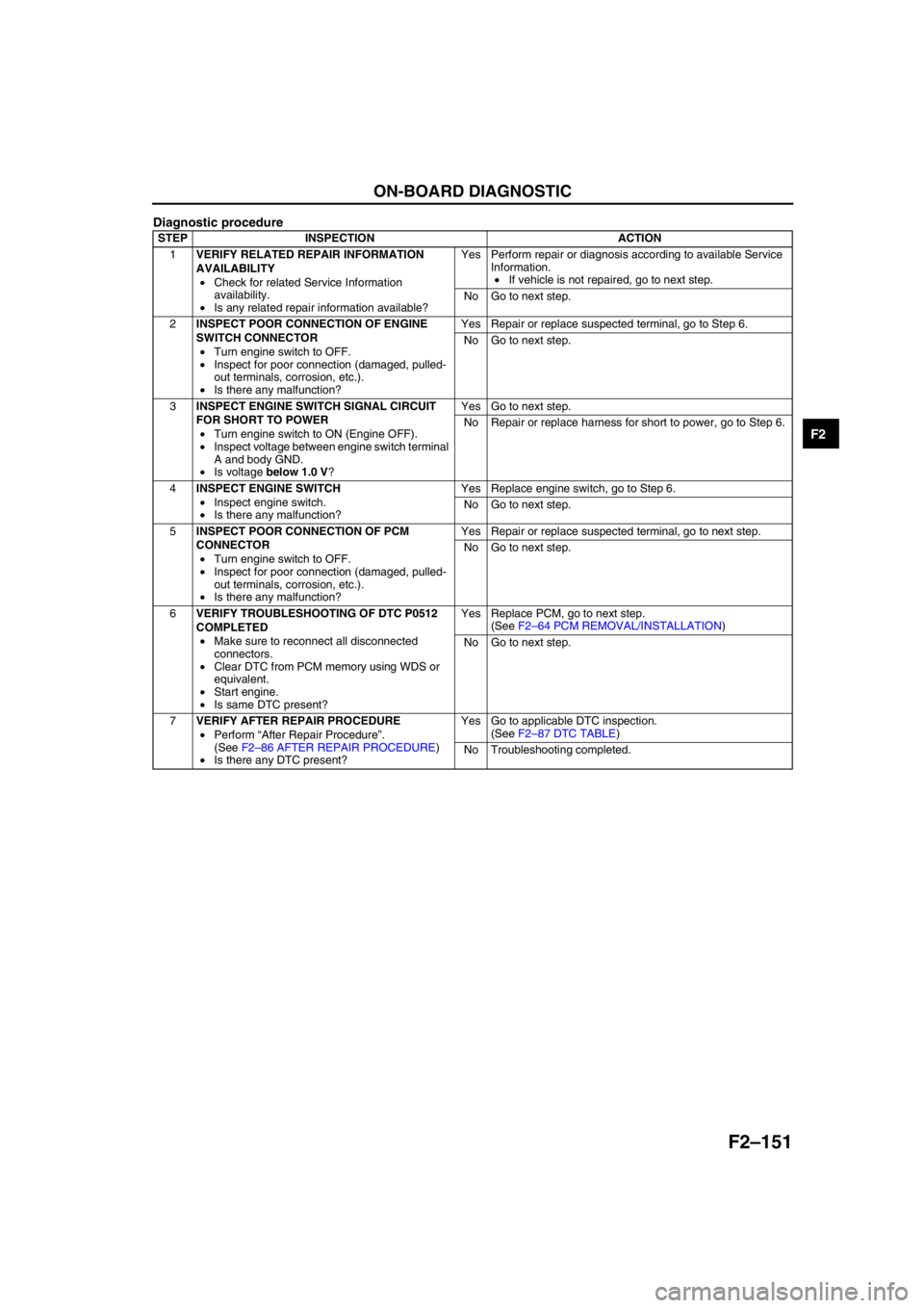

DTC P0512A6E407001082236

DTC P0512 Engine switch circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from engine switch while engine is running. If input voltage from engine switch

is B+ when engine speed is 1,200 rpm or above, PCM determines engine switch circuit malfunction.

POSSIBLE

CAUSE•Engine switch malfunction

•Connector or terminal malfunction

•Short to power circuit in wiring between engine switch terminal A and PCM terminal 57

•PCM malfunction

ENGINE SWITCH

F

AMAIN FUSE

E

FC

DA

B

57 57PCM

4

2

235

ENGINE SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 303 of 909

ON-BOARD DIAGNOSTIC

F2–151

F2

Diagnostic procedure

End Of Sie

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2INSPECT POOR CONNECTION OF ENGINE

SWITCH CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 6.

No Go to next step.

3INSPECT ENGINE SWITCH SIGNAL CIRCUIT

FOR SHORT TO POWER

•Turn engine switch to ON (Engine OFF).

•Inspect voltage between engine switch terminal

A and body GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 6.

4INSPECT ENGINE SWITCH

•Inspect engine switch.

•Is there any malfunction?Yes Replace engine switch, go to Step 6.

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0512

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 304 of 909

F2–152

ON-BOARD DIAGNOSTIC

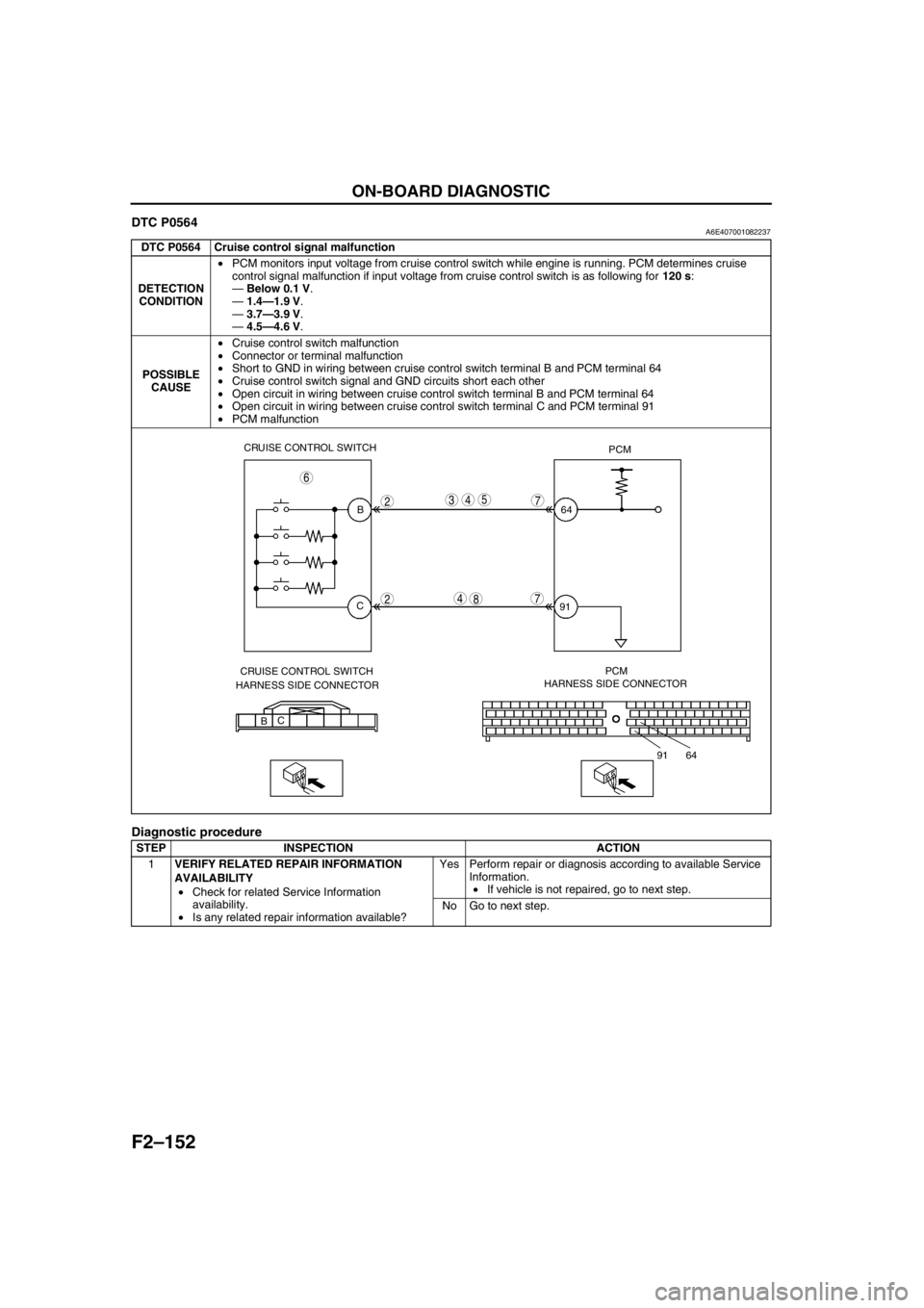

DTC P0564A6E407001082237

Diagnostic procedure

DTC P0564 Cruise control signal malfunction

DETECTION

CONDITION•PCM monitors input voltage from cruise control switch while engine is running. PCM determines cruise

control signal malfunction if input voltage from cruise control switch is as following for 120 s:

—Below 0.1 V.

—1.4—1.9 V.

—3.7—3.9 V.

—4.5—4.6 V.

POSSIBLE

CAUSE•Cruise control switch malfunction

•Connector or terminal malfunction

•Short to GND in wiring between cruise control switch terminal B and PCM terminal 64

•Cruise control switch signal and GND circuits short each other

•Open circuit in wiring between cruise control switch terminal B and PCM terminal 64

•Open circuit in wiring between cruise control switch terminal C and PCM terminal 91

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

CRUISE CONTROL SWITCH

PCM

B

C64

91

CRUISE CONTROL SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

BC

64 91

2

2

543

4

7

6

78

Page 305 of 909

ON-BOARD DIAGNOSTIC

F2–153

F2

End Of Sie

2INSPECT POOR CONNECTION OF CRUISE

CONTROL SWITCH CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 9.

No Go to next step.

3INSPECT CRUISE CONTROL SWITCH SIGNAL

CIRCUIT FOR SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between cruise control

switch terminal B and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 9.

No Go to next step.

4INSPECT CRUISE CONTROL SWITCH CIRCUIT

FOR SHORT WITH EACH OTHER

•Turn engine switch to OFF.

•Inspect continuity between cruise control

switch terminals B and C.

•Is there continuity?Yes Repair or replace harness for short with each other, go to

Step 9.

No Go to next step.

5INSPECT CRUISE CONTROL SWITCH SIGNAL

CIRCUIT FOR OPEN

•Turn engine switch to ON. (Engine OFF)

•Inspect voltage at cruise control switch terminal

B (harness side).

•Is voltage below 1.0 V?Yes Repair or replace harness for open, go to Step 9.

No Go to next step.

6INSPECT CRUISE CONTROL SWITCH

•Inspect cruise control switch.

•Is there any malfunction?Yes Replace cruise control switch, go to Step 9.

No Go to next step.

7INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 9.

No Go to next step.

8INSPECT CRUISE CONTROL SWITCH GND

CIRCUIT FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between cruise control

switch terminal C and PCM terminal 91.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

9VERIFY TROUBLESHOOTING OF DTC P0564

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

10VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 308 of 909

F2–156

ON-BOARD DIAGNOSTIC

DTC P0661A6E407001082241

Diagnostic procedure

DTC P0661 VSC solenoid valve circuit low input

DETECTION

CONDITION•PCM monitors input voltage from VSC solenoid valve while engine is running. If input voltage from VSC

solenoid valve is below 0.1 V, PCM determines suction control valve circuit low input.

POSSIBLE

CAUSE•VSC solenoid valve malfunction

•Connector or terminal malfunction

•Short to GND in wiring between VSC solenoid valve terminal A and PCM control relay terminal C

•Short to GND in wiring between VSC solenoid valve terminal B and PCM terminal 101

•Open circuit in wiring between VSC solenoid valve terminal PCM control relay terminal C

•Open circuit in wiring between VSC solenoid valve terminal B and PCM terminal 101

•PCM malfunction

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

A

B VSC SOLENOID VALVEPCM

101 A B3

632

6

5101

4

2

PCM CONTROL RELAY

TERMINAL C

VSC SOLENOID VALVE

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 309 of 909

ON-BOARD DIAGNOSTIC

F2–157

F2

End Of Sie

2INSPECT POOR CONNECTION OF VSC

SOLENOID VALVE CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

3INSPECT VSC SOLENOID VALVE CIRCUIT FOR

SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—VSC solenoid valve terminal A and PCM

control relay terminal C.

—VSC solenoid valve terminal B and PCM

terminal 101.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 7.

No Go to next step.

4INSPECT VSC SOLENOID VALVE

•Inspect VSC solenoid valve.

(See F2–42 VARIABLE SWIRL CONTROL

(VSC) SOLENOID VALVE INSPECTION)

• Is there any malfunction?Yes Replace VSC solenoid valve, go to Step 7.

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 7.

No Go to next step.

6INSPECT VSC SOLENOID VALVE CIRCUIT FOR

OPEN

•Turn engine switch to OFF.

•Inspect continuity between following

harnesses:

—VSC solenoid valve terminal A and PCM

control relay terminal C.

—VSC solenoid valve terminal B and PCM

terminal 101.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

7VERIFY TROUBLESHOOTING OF DTC P0661

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION

Page 310 of 909

F2–158

ON-BOARD DIAGNOSTIC

DTC P0662A6E407001082242

DTC P0662 VSC solenoid valve circuit high input

DETECTION

CONDITION•PCM monitors input voltage from VSC solenoid valve while engine is running. If input voltage from VSC

solenoid valve is above B+, PCM determines suction control valve circuit high input.

POSSIBLE

CAUSE•VSC solenoid valve malfunction

•Connector or terminal malfunction

•Short to power circuit in wiring between VSC solenoid valve terminal B and PCM terminal 101

•PCM malfunction

A

B VSC SOLENOID VALVE

A

B

101101PCM

4

2

235

VSC SOLENOID VALVE

HARNESS SIDE CONNECTORPCM CONTROL RELAY

TERMINAL C

PCM

HARNESS SIDE CONNECTOR

Page 311 of 909

ON-BOARD DIAGNOSTIC

F2–159

F2

Diagnostic procedure

End Of Sie

STEP INSPECTION ACTION

1PERFORM DTC CONFIRMATION PROCEDURE

•Perform “DTC Confirmation Procedure”.

(See F2–85 DTC CONFIRMATION

PROCEDURE)

•Is same DTC present during KOEO or KOER

self-test?Yes Go to next step.

No Intermittent concern exists. Go to “Intermittent Concern

Troubleshooting”.

(See F2–227 INTERMITTENT CONCERN

TROUBLESHOOTING)

2INSPECT POOR CONNECTION OF VSC

SOLENOID VALVE CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 6.

No Go to next step.

3INSPECT VSC SOLENOID VALVE CIRCUIT FOR

SHORT TO POWER

•Turn engine switch to ON (Engine switch OFF).

•Inspect voltage between VSC solenoid valve

terminal B and body GND.

•Is voltage below 1.0 V?Yes Go to next step.

No Repair or replace harness for short to power, go to Step 6.

4INSPECT VSC SOLENOID VALVE

•Inspect VSC solenoid valve.

(See F2–42 VARIABLE SWIRL CONTROL

(VSC) SOLENOID VALVE INSPECTION)

• Is there any malfunction?Yes Replace VSC solenoid valve, go to Step 6.

No Go to next step.

5INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to next step.

No Go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0662

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed.

Page 312 of 909

F2–160

ON-BOARD DIAGNOSTIC

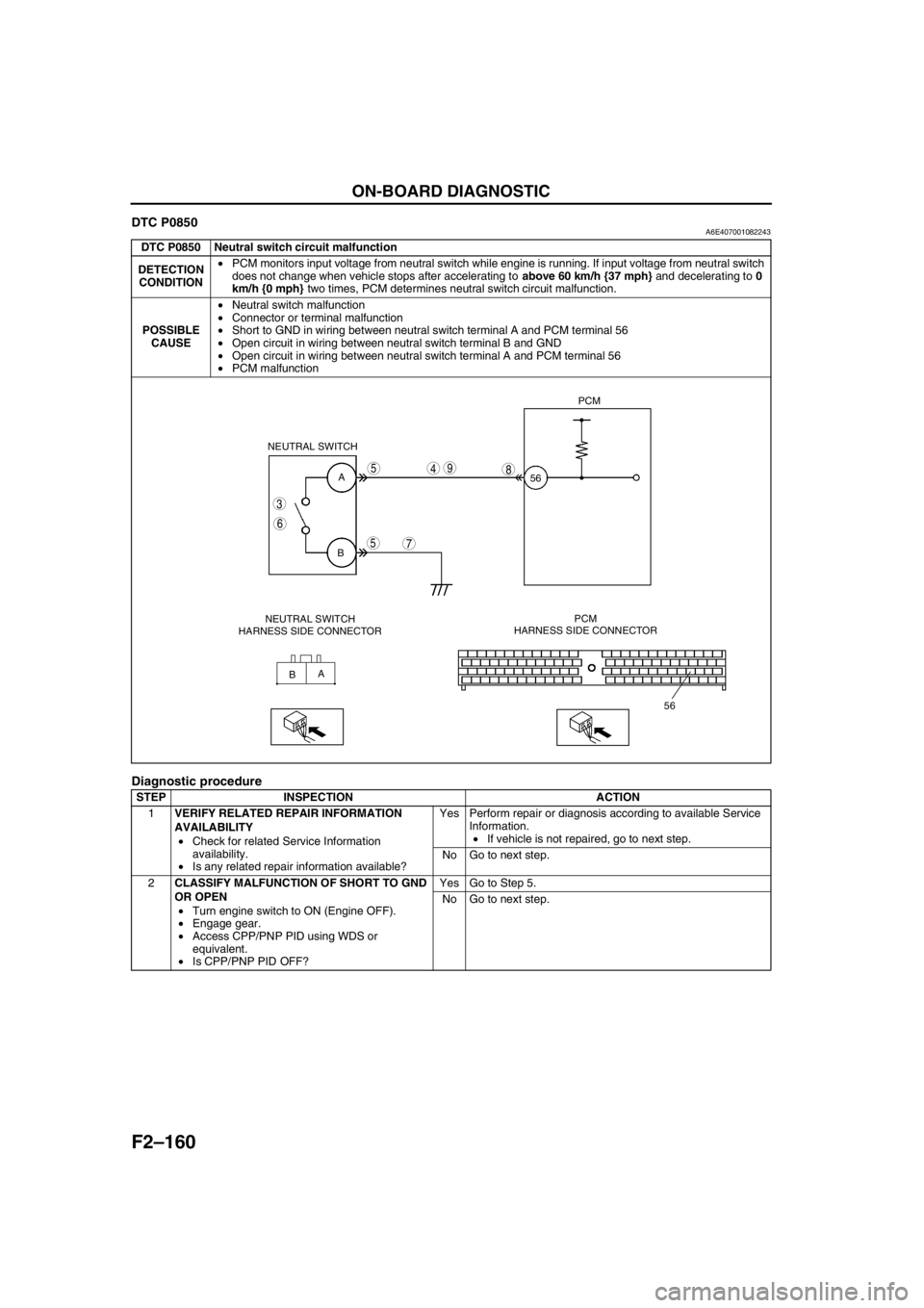

DTC P0850A6E407001082243

Diagnostic procedure

DTC P0850 Neutral switch circuit malfunction

DETECTION

CONDITION•PCM monitors input voltage from neutral switch while engine is running. If input voltage from neutral switch

does not change when vehicle stops after accelerating to above 60 km/h {37 mph} and decelerating to 0

km/h {0 mph} two times, PCM determines neutral switch circuit malfunction.

POSSIBLE

CAUSE•Neutral switch malfunction

•Connector or terminal malfunction

•Short to GND in wiring between neutral switch terminal A and PCM terminal 56

•Open circuit in wiring between neutral switch terminal B and GND

•Open circuit in wiring between neutral switch terminal A and PCM terminal 56

•PCM malfunction

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Information

availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available Service

Information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2CLASSIFY MALFUNCTION OF SHORT TO GND

OR OPEN

•Turn engine switch to ON (Engine OFF).

•Engage gear.

•Access CPP/PNP PID using WDS or

equivalent.

•Is CPP/PNP PID OFF?Yes Go to Step 5.

No Go to next step.

A

B

A

B NEUTRAL SWITCH

56PCM

56

3

6

5

5

7

498

NEUTRAL SWITCH

HARNESS SIDE CONNECTORPCM

HARNESS SIDE CONNECTOR

Page 313 of 909

ON-BOARD DIAGNOSTIC

F2–161

F2

End Of Sie

3INSPECT NEUTRAL SWITCH FOR CLOSE

STUCK

•Turn engine switch to ON (Engine OFF).

•Disconnect neutral switch connector.

•Access CPP/PNP PID using WDS or

equivalent.

•Is CPP/PNP PID OFF?Yes Replace neutral switch, go to Step 10.

No Go to next step.

4INSPECT NEUTRAL SWITCH SIGNAL CIRCUIT

FOR SHORT TO GND

•Turn engine switch to OFF.

•Inspect continuity between neutral switch

terminal A and body GND.

•Is there continuity?Yes Repair or replace harness for short to GND, go to Step 10.

No Go to next step.

5INSPECT POOR CONNECTION OF NEUTRAL

SWITCH CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 10.

No Go to next step.

6INSPECT NEUTRAL SWITCH FOR OPEN

STUCK

•Turn engine switch to ON (Engine OFF).

•Disconnect neutral switch connector.

•Connect jumper wire between neutral switch

connector terminals.

•Access CPP/PNP PID using WDS or

equivalent.

•Is CPP/PNP PID ON?Yes Replace neutral switch, go to Step 10.

No Go to next step.

7INSPECT NEUTRAL SWITCH GND CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between neutral switch

terminal B and body GND.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to Step 10.

8INSPECT POOR CONNECTION OF PCM

CONNECTOR

•Turn engine switch to OFF.

•Inspect for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Is there any malfunction?Yes Repair or replace suspected terminal, go to Step 10.

No Go to next step.

9INSPECT NEUTRAL SWITCH SIGNAL CIRCUIT

FOR OPEN

•Turn engine switch to OFF.

•Inspect continuity between neutral switch

terminal A and PCM terminal 56.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open, go to next step.

10VERIFY TROUBLESHOOTING OF DTC P0850

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from PCM memory using WDS or

equivalent.

•Start engine.

•Is same DTC present?Yes Replace PCM, go to next step.

(See F2–64 PCM REMOVAL/INSTALLATION)

No Go to next step.

11VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See F2–86 AFTER REPAIR PROCEDURE)

•Is there any DTC present?Yes Go to applicable DTC inspection.

(See F2–87 DTC TABLE)

No Troubleshooting completed. STEP INSPECTION ACTION