wiring MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 2 of 909

VEHICLE IDENTIFICATION NUMBERS (VIN)

U.K. specs.

JMZ GG12R20# 100001—

JMZ GG12T20# 100001—

JMZ GG14R20# 100001—

JMZ GG14T20# 100001—

JMZ GY19320# 100001—

JMZ GY19820# 100001—

JMZ GY19F20# 100001—

JMZ GY19F50# 100001—

JMZ GY19R20# 100001—

JMZ GY19T20# 100001—

JMZ GY89370# 100001—

European (L.H.D.) specs.

JMZ GG12R2✻# 100001—

JMZ GG12T2✻# 100001—

JMZ GG14R2✻# 100001—

JMZ GG14T2✻# 100001—JMZ GY1932✻# 100001—

JMZ GY1982✻# 100001—

JMZ GY19F2✻# 100001—

JMZ GY19F5✻# 100001—

JMZ GY19R2✻# 100001—

JMZ GY19T2✻# 100001—

JMZ GY8937✻# 100001—

GCC specs.

JM7 GG32F✻✻# 100001—

JM7 GG42F✻✻# 100001—

JM7 GG34F✻✻# 100001—

JM7 GG44F✻✻# 100001—

JM7 GY49F✻✻# 100001—

JM7 GY39F✻✻# 100001—

JM7 GY49F✻0# 100001—

JM7 GY39F✻0# 100001—

RELATED MATERIALS

Mazda6 Training Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3359–1*–02C

Mazda6 Workshop Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 1730–1*–02C

Engine Workshop Manual L8, LF, L3 . . . . . . . . . . . . . . 1731–1*–02C

Engine Workshop Manual MZR–CD (RF Turbo) . . . . . 1744–1E–02D

Manual Transaxle Workshop Manual G35M–R . . . . . . 1732–1*–02C

Manual Transaxle Workshop Manual A65M–R . . . . . . 1739–1E–02D

Automatic Transaxle Workshop Manual FN4A–EL . . . 1623–10–98E

Automatic Transaxle Workshop Manual

Supplement FN4A–EL . . . . . . . . . . . . . . . . . . . . . . . . . 1746–1*–02C

Automatic Transaxle Workshop Manual JA5A–EL . . . 1738–1E–02D

Automatic Transaxle Workshop Manual

Supplement JA5AX–EL . . . . . . . . . . . . . . . . . . . . . . . . 1765–1*–02H

Mazda6 Wiring Diagram

(European (L.H.D.), GCC specs.) . . . . . . . . . . . . . . . . 5558–1*–02G

Mazda6 Wiring Diagram

(U.K. specs.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5559–1*–02G

Mazda6 Bodyshop Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3360–1*–02C

Mazda6 Bodyshop Manual Supplement

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3368–1*–02I

EOBD Training Manual

(European (L.H.D. U.K.), Australian specs.) . . . . . . . 3345–1*–00B

* : Indicates the printing location

E: Europe

0: Japan

Page 26 of 909

B1–4

OUTLINE, ENGINE

SUPPLEMENTAL SERVICE INFORMATIONA6E220202000205•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Engine

•Removal/Installation procedure for 4WD has been adopted.

End Of Sie

ENGINE REMOVAL/INSTALLATION (4WD)A6E222401001201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”.

1. Remove the battery.

2. Remove the battery tray.

3. Remove the radiator.

4. Drain the transaxle oil.

5. Remove the P/S oil pump with the oil hose still connected. Position the P/S oil pump so that it is out of the way.

Use wire or rope to secure.

6. Remove the A/C compressor with the pipes still connected. Position the A/C compressor so that it is out of the

way. Use wire or rope to secure.

7. Remove the propeller shaft from the transfer.

8. Remove the joint shaft. (See M–31 JOINT SHAFT (4WD) DISASSEMBLY/ASSEMBLY.)

9. Remove the front drive shaft (LH) from the transaxle. (See M–39 FRONT DRIVE SHAFT (4WD)

DISASSEMBLY/ASSEMBLY.)

10. Remove the air cleaner, intake air duct, accelerator cable and bracket, and vacuum hose.

11. Remove the ATF hose and selector cable.

12. Remove the vacuum hose and heater hose.

13. Disconnect the fuel hose. (See F1–27 Plastic Fuel Hose Removal Note.) (See F1–28 Plastic Fuel Hose

Installation Note.)

14. Disconnect the wiring harness from the engine side.

15. Remove the three way catalyst (TWC). (See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Start the engine and:

•Inspect for the engine oil, engine coolant, transaxle oil and fuel leakage.

•Verify the ignition timing, idle speed and idle mixture. (See F1–22 IDLE SPEED INSPECTION (4WD).)

19. Perform a road test.

OUTLINE

ENGINE

Page 89 of 909

![MAZDA 6 2002 Workshop Manual Suplement F1–1

F1

F1FUEL AND EMISSION CONTROL SYSTEM

[L8, LF, L3]

OUTLINE.............................................................. F1-2

OUTLINE OF CONSTRUCTION ....................... F1-2

FEATURES ..... MAZDA 6 2002 Workshop Manual Suplement F1–1

F1

F1FUEL AND EMISSION CONTROL SYSTEM

[L8, LF, L3]

OUTLINE.............................................................. F1-2

OUTLINE OF CONSTRUCTION ....................... F1-2

FEATURES .....](/img/28/57057/w960_57057-88.png)

F1–1

F1

F1FUEL AND EMISSION CONTROL SYSTEM

[L8, LF, L3]

OUTLINE.............................................................. F1-2

OUTLINE OF CONSTRUCTION ....................... F1-2

FEATURES ........................................................ F1-2

SPECIFICATIONS ............................................. F1-2

CONTROL SYSTEM DIAGRAM (4WD)............. F1-3

CONTROL SYSTEM WIRING DIAGRAM

(4WD).............................................................. F1-4

FUEL SYSTEM..................................................... F1-9

OUTLINE ........................................................... F1-9

STRUCTURAL VIEW......................................... F1-9

SYSTEM DIAGRAM ........................................ F1-10

FUEL PUMP (TRANSFER).............................. F1-10

QUICK RELEASE CONNECTOR (FUEL TANK

SIDE, TRANSFER HOSE PART) ................. F1-12

EXHAUST SYSTEM........................................... F1-13

OUTLINE ......................................................... F1-13

STRUCTURAL VIEW....................................... F1-13

CONTROL SYSTEM........................................... F1-14

OUTLINE ......................................................... F1-14

STRUCTURAL VIEW (4WD) ........................... F1-16

BLOCK DIAGRAM ........................................... F1-17

CONTROL DEVICE AND CONTROL

RELATIONSHIP CHART .............................. F1-19

CONTROLLER AREA NETWORK (CAN) ....... F1-21

OUTLINE............................................................ F1-22

SUPPLEMENTAL SERVICE

INFORMATION ............................................. F1-22

ENGINE TUNE-UP............................................. F1-22

IDLE SPEED INSPECTION (4WD) ................. F1-22

FUEL SYSTEM................................................... F1-23

FUEL TANK REMOVAL/INSTALLATION ........ F1-23

FUEL PUMP UNIT

REMOVAL/INSTALLATION .......................... F1-26

FUEL HOSE (FUEL TANK SIDE,

TRANSFER HOSE PART)

REMOVAL/INSTALLATION .......................... F1-29

EXHAUST SYSTEM........................................... F1-30

EXHAUST SYSTEM

REMOVAL/INSTALLATION .......................... F1-30

CONTROL SYSTEM........................................... F1-33

PCM INSPECTION (4WD)............................... F1-33

ON-BOARD DIAGNOSTIC................................. F1-50

OUTLINE ......................................................... F1-50

CONTROL DEVICE AND MONITORING

SYSTEM RELATIONSHIP CHART .............. F1-50

DIAGNOSTIC TEST MODE (4WD) ................. F1-50

DTC (4WD) ...................................................... F1-52

OBD DRIVE MODE ......................................... F1-52

DTC TABLE ..................................................... F1-54

TROUBLESHOOTING........................................ F1-57ENGINE SYMPTOM

TROUBLESHOOTING .................................. F1-57

QUICK DIAGNOSTIC CHART ......................... F1-58

NO.14 POOR FUEL ECONOMY ..................... F1-62

NO.22 VIBRATION CONCERNS

(ENGINE) ...................................................... F1-64 FEATURES

SERVICE

Page 92 of 909

F1–4

OUTLINE

CONTROL SYSTEM WIRING DIAGRAM (4WD)A6E390218881205With Immobilizer System

.

2Y

2Z

2AC

1AB

1Y

2K

2A

1J

1G

1M

2E

1P

2H

2U

2R

2P

2S

2D

2G

2J

2M4Z

4W

4AD

4AA

4G

4J

4A

4D

2X

4O

4B

4L

4F

4Q

2T

2Q

2W

4I

9

87

5

4

3

10

19

18

17

15

16

14

13

11

12

20

29

28

27

25

26

24

23

21

22

30

6

1

2

3132

A6E39022001

1 HO2S (front)

2 HO2S (rear)

3 TP sensor

4 MAP sensor

5 BARO sensor6ECT sensor

7 MAF/IAT sensor

8 IAT sensor

9 MAF sensor

10 Controller area network (CAN)

Page 125 of 909

CONTROL SYSTEM

F1–37

F1

Without Using the SST

Caution

•The PCM terminal voltages vary with change in measuring conditions and vehicle conditions.

Always carry out a total inspection of the input systems, output systems, and PCM to determine

the cause of trouble. Otherwise, a wrong diagnosis will be made.

1. Measure the voltage at each terminal.

•If any incorrect voltage is detected, inspect the related system(s), wiring harnesses and connector(s)

referring to the Action column in the terminal voltage table.

Terminal voltage table (Reference)

Terminal Signal Connected to Test conditionVoltage

(V)Action

1A IGT1Ignition coil (No. 1,

4 cylinders)•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect ignition coil

•Inspect related

harness

1B IGT2Ignition coil (No. 2,

3 cylinders)•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect ignition coil

•Inspect related

harness

1C GND GND Under any condition Below 1.0•Inspect related

harness

1D GND GND Under any condition Below 1.0•Inspect related

harness

1E—— — ——

1F—— — ——

1G BARO BARO sensor Ignition switch ON (at sea level)Approx.

4.1 V•Inspect BARO sensor

•Inspect related

harness

1H—— — ——

1I—— — ——

1JManifold absolute

pressureMAP sensorIgnition switch ON (Engine OFF)Approx.

4.1•Inspect MAP sensor

•Inspect related

harness

IdleApprox.

1.5

1K Brake Brake switchBrake pedal depressed B+•Inspect brake switch

•Inspect related

harness Brake pedal released Below 1.0

1L—— — ——

1M ECT ECT sensorIgnition switch

ONECT 20 °C

{68 °F}3.04—

3.14•Inspect ECT sensor

•Inspect related

harness ECT 60 °C

{140 °F}1.29—

1.39

1N—— — ——

1O—— — ——

1P MAF MAF sensorIgnition switch ONApprox.

0.7•Inspect MAF sensor

•Inspect related

harness

Idle (after warm up)Approx.

1.3

1B 1A

1E 1D

1C 1H 1G 1J

1F 1I 1M

1L 1N 1K 1T 1Q1P 1S

1O 1R 1W1V

1Z 1Y

1X1AC1AB

1AA 1AD1U 2B 2A

2E 2D

2C 2H 2G 2J

2F 2I 2M

2L 2N 2K 2T 2Q2P 2S

2O 2R 2W2V

2Z 2Y

2X2AC2AB

2AA 2AD2U 3B 3A

3E 3D

3C 3H 3G 3J

3F 3I 3M

3L 3N 3K 3T 3Q3P 3S

3O 3R 3W3V

3Z 3Y

3X3AA3U 4B 4A

4E 4D

4C 4H 4G 4J

4F 4I 4M

4L 4N 4K 4T 4Q4P 4S

4O 4R 4W4V

4Z 4Y

4X4AC4AB

4AA 4AD4U

A6A3940W002

Page 153 of 909

![MAZDA 6 2002 Workshop Manual Suplement F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR MAZDA 6 2002 Workshop Manual Suplement F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR](/img/28/57057/w960_57057-152.png)

F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATURES ........................................................ F2-3

SPECIFICATIONS ............................................. F2-3

CONTROL SYSTEM DIAGRAM ........................ F2-4

CONTROL SYSTEM WIRING DIAGRAM.......... F2-5

INTAKE-AIR SYSTEM.......................................... F2-8

OUTLINE ........................................................... F2-8

STRUCTURAL VIEW......................................... F2-9

FUEL SYSTEM................................................... F2-10

OUTLINE ......................................................... F2-10

STRUCTURAL VIEW....................................... F2-11

EXHAUST SYSTEM........................................... F2-13

OUTLINE ......................................................... F2-13

STRUCTURAL VIEW....................................... F2-13

EMISSION SYSTEM........................................... F2-14

OUTLINE ......................................................... F2-14

STRUCTURAL VIEW....................................... F2-15

WARM UP OXIDATION CATALYTIC

CONVERTER DESCRIPTION ...................... F2-16

CONTROL SYSTEM........................................... F2-16

OUTLINE ......................................................... F2-16

STRUCTURAL VIEW....................................... F2-18

BLOCK DIAGRAM ........................................... F2-20

CONTROL DEVICE AND CONTROL

RELATIONSHIP CHART .............................. F2-22

CRUISE CONTROL SYSTEM ......................... F2-23

CONTROLLER AREA NETWORK (CAN) ....... F2-24

ON-BOARD DIAGNOSTIC................................. F2-24

OUTLINE ......................................................... F2-24

DTC.................................................................. F2-24

KOEO/KOER SELF-TEST ............................... F2-26

PID/DATA MONITOR AND RECORD ............. F2-27

SIMULATION TEST ......................................... F2-27

LOCATION INDEX............................................. F2-28

INTAKE-AIR SYSTEM ..................................... F2-28

FUEL SYSTEM ................................................ F2-29

EMISSION SYSTEM........................................ F2-31

CONTROL SYSTEM........................................ F2-32

ENGINE TUNE-UP............................................. F2-34

ENGINE TUNE-UP PREPARATION ............... F2-34

IDLE SPEED INSPECTION ............................. F2-34

CORRECTION PROCEDURE ......................... F2-34

INTAKE-AIR SYSTEM........................................ F2-35

VACUUM TUBE ROUTING DIAGRAM............ F2-35

INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION .......................... F2-36

AIR CLEANER ELEMENT INSPECTION ........ F2-37

TURBOCHARGER INSPECTION ................... F2-38

GUIDE BLADE ACTUATOR INSPECTION ..... F2-39

VARIABLE BOOST CONTROL (VBC)

SOLENOID VALVE INSPECTION ................ F2-40VARIABLE BOOST CONTROL (VBC)

CHECK VALVE INSPECTION ...................... F2-41

VARIABLE SWIRL CONTROL (VSC)

VALVE ACTUATOR INSPECTION ............... F2-41

VARIABLE SWIRL CONTROL (VSC)

SOLENOID VALVE INSPECTION ................ F2-42

GLOW PLUG REMOVAL/INSTALLATION ...... F2-42

GLOW PLUG INSPECTION ............................ F2-43

GLOW PLUG LEAD INSPECTION .................. F2-43

ACCELERATOR PEDAL COMPONENT

REMOVAL/INSTALLATION .......................... F2-44

ACCELERATOR PEDAL COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-44

FUEL SYSTEM................................................... F2-45

BEFORE REPAIR PROCEDURE .................... F2-45

AFTER REPAIR PROCEDURE ....................... F2-45

FUEL TANK REMOVAL/INSTALLATION ........ F2-45

FUEL TANK INSPECTION .............................. F2-49

NONRETURN VALVE INSPECTION............... F2-50

FUEL FILTER COMPONENT

REMOVAL/INSTALLATION .......................... F2-50

FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-51

FUEL WARMER INSPECTION........................ F2-51

SEDIMENTOR WATER DRAINING................. F2-52

SEDIMENTOR SWITCH INSPECTION ........... F2-52

SUPPLY PUMP REMOVAL/INSTALLATION .. F2-53

SUPPLY PUMP INSPECTION......................... F2-54

SUCTION CONTROL VALVE INSPECTION ... F2-54

COMMON RAIL INSPECTION ........................ F2-54

FUEL INJECTOR REMOVAL/INSTALLATION F2-55

FUEL INJECTOR INSPECTION ...................... F2-56

EXHAUST SYSTEM........................................... F2-57

EXHAUST SYSTEM INSPECTION ................. F2-57

EXHAUST SYSTEM

REMOVAL/INSTALLATION .......................... F2-57

EMISSION SYSTEM........................................... F2-59

EGR VALVE REMOVAL/INSTALLATION........ F2-59

EGR VALVE INSPECTION .............................. F2-59

EGR SOLENOID VALVE (VACUUM)

INSPECTION ................................................ F2-60

EGR SOLENOID VALVE (VENT)

INSPECTION ................................................ F2-60

EGR CONTROL SOLENOID VALVE

INSPECTION ................................................ F2-61

INTAKE SHUTTER VALVE ACTUATOR

INSPECTION ................................................ F2-62

INTAKE SHUTTER SOLENOID VALVE

INSPECTION ................................................ F2-63

CONTROL SYSTEM........................................... F2-64

PCM REMOVAL/INSTALLATION .................... F2-64

PCM INSPECTION .......................................... F2-65

PCM CONFIGURATION .................................. F2-68

CLUTCH SWITCH INSPECTION .................... F2-68

NEUTRAL SWITCH INSPECTION .................. F2-69

IDLE SWITCH INSPECTION ........................... F2-70

IDLE SWITCH ADJUSTMENT ......................... F2-71

ACCELERATOR POSITION SENSOR

INSPECTION ................................................ F2-72

ACCELERATOR POSITION SENSOR

ADJUSTMENT .............................................. F2-73 FEATURES

SERVICE

Page 157 of 909

OUTLINE

F2–5

F2

CONTROL SYSTEM WIRING DIAGRAMA6E400218881205

BA

ABA

ABA

ABA

A1A

1B 1C 1D 1E 1F1G

1H2A

2B 2C2D

2E

2F2G 2H

a

b

c

d

e

f

g

30 42

44 4543 1A

1B 1C 1D 1E 1F

13 39

80

28 78

A 57

E5633 1

427 73464

1041038565 9169

E53

79 9

1460

CBD AE C

A

Dh

i

j

k

l

m

n

o C

D

LOCKACCONSTB

ACCIG2IG1ST

AA

M

BA

A

AAB

9

8

7

5

4

3

10

19

18

17

1516

14

131112

20

6

1

2

23

21

22

A6E40022002

Page 192 of 909

F2–40

INTAKE-AIR SYSTEM

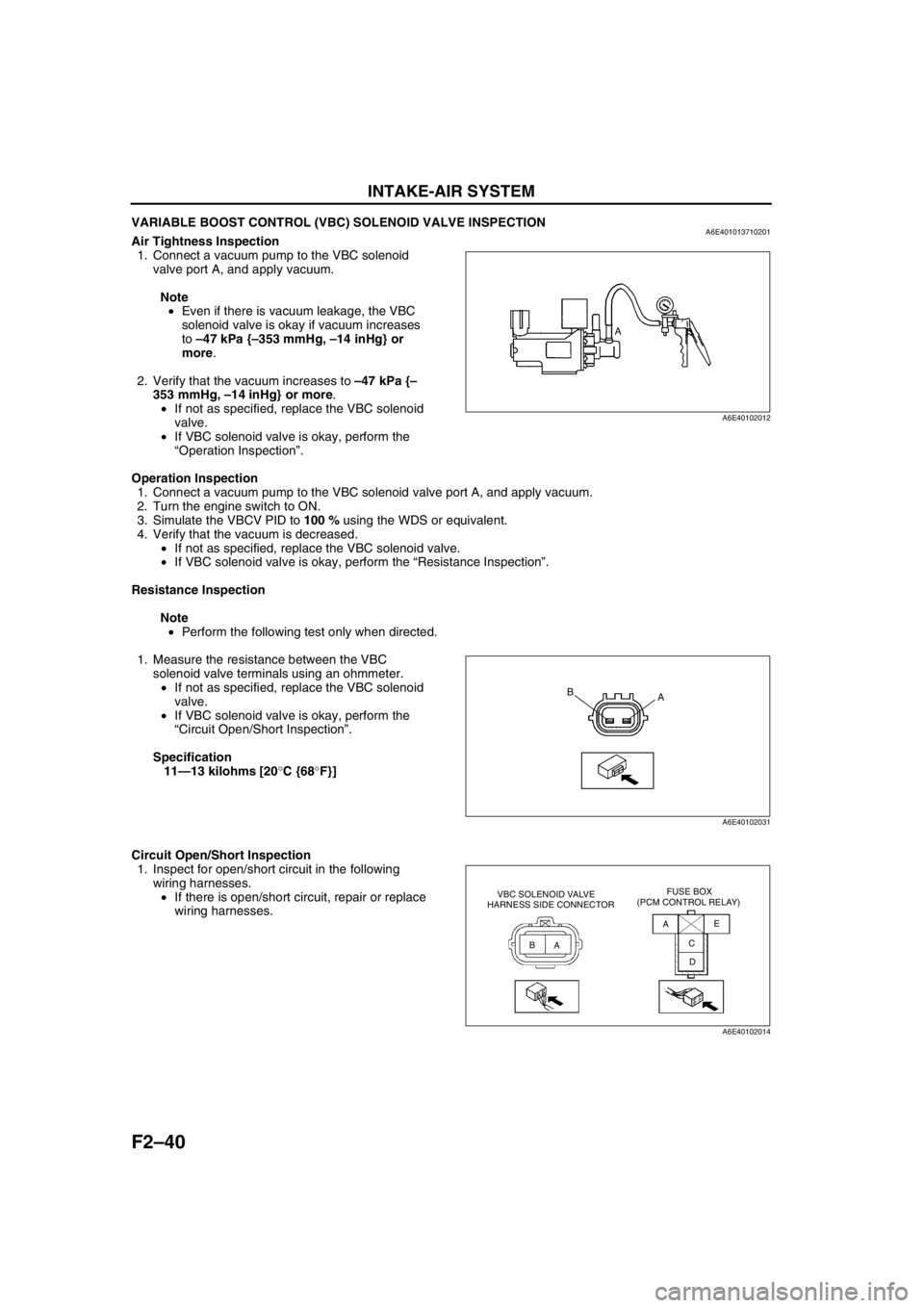

VARIABLE BOOST CONTROL (VBC) SOLENOID VALVE INSPECTIONA6E401013710201Air Tightness Inspection

1. Connect a vacuum pump to the VBC solenoid

valve port A, and apply vacuum.

Note

•Even if there is vacuum leakage, the VBC

solenoid valve is okay if vacuum increases

to –47 kPa {–353 mmHg, –14 inHg} or

more.

2. Verify that the vacuum increases to –47 kPa {–

353 mmHg, –14 inHg} or more.

•If not as specified, replace the VBC solenoid

valve.

•If VBC solenoid valve is okay, perform the

“Operation Inspection”.

Operation Inspection

1. Connect a vacuum pump to the VBC solenoid valve port A, and apply vacuum.

2. Turn the engine switch to ON.

3. Simulate the VBCV PID to 100 % using the WDS or equivalent.

4. Verify that the vacuum is decreased.

•If not as specified, replace the VBC solenoid valve.

•If VBC solenoid valve is okay, perform the “Resistance Inspection”.

Resistance Inspection

Note

•Perform the following test only when directed.

1. Measure the resistance between the VBC

solenoid valve terminals using an ohmmeter.

•If not as specified, replace the VBC solenoid

valve.

•If VBC solenoid valve is okay, perform the

“Circuit Open/Short Inspection”.

Specification

11—13 kilohms [20°C {68°F}]

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

A

A6E40102012

A B

A6E40102031

AA

BC

DE VBC SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

A6E40102014

Page 194 of 909

F2–42

INTAKE-AIR SYSTEM

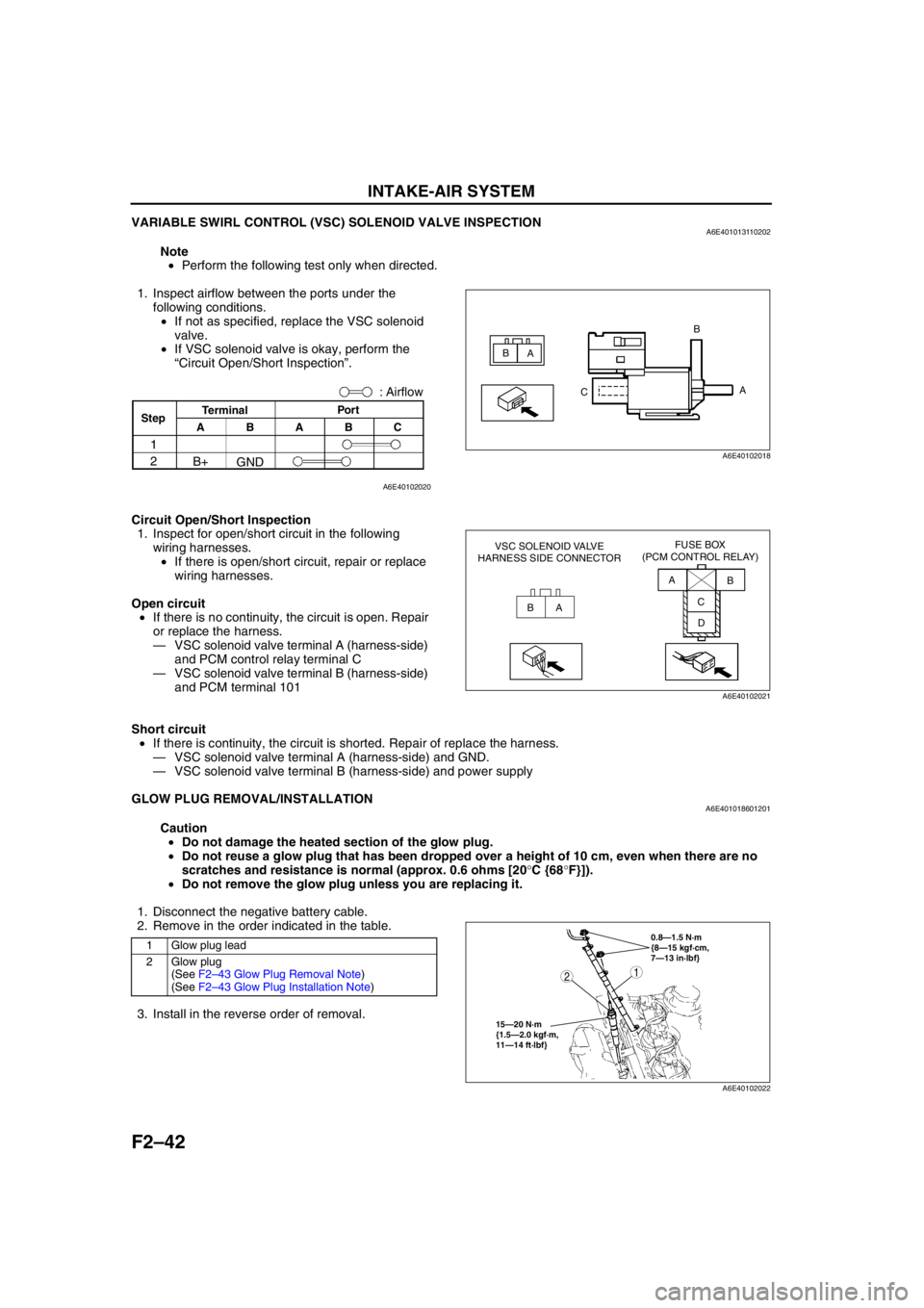

VARIABLE SWIRL CONTROL (VSC) SOLENOID VALVE INSPECTIONA6E401013110202

Note

•Perform the following test only when directed.

1. Inspect airflow between the ports under the

following conditions.

•If not as specified, replace the VSC solenoid

valve.

•If VSC solenoid valve is okay, perform the

“Circuit Open/Short Inspection”.

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—VSC solenoid valve terminal A (harness-side)

and PCM control relay terminal C

—VSC solenoid valve terminal B (harness-side)

and PCM terminal 101

Short circuit

•If there is continuity, the circuit is shorted. Repair of replace the harness.

—VSC solenoid valve terminal A (harness-side) and GND.

—VSC solenoid valve terminal B (harness-side) and power supply

End Of Sie

GLOW PLUG REMOVAL/INSTALLATIONA6E401018601201

Caution

•Do not damage the heated section of the glow plug.

•Do not reuse a glow plug that has been dropped over a height of 10 cm, even when there are no

scratches and resistance is normal (approx. 0.6 ohms [20°C {68°F}]).

•Do not remove the glow plug unless you are replacing it.

1. Disconnect the negative battery cable.

2. Remove in the order indicated in the table.

3. Install in the reverse order of removal.

A

A B

B

C

A6E40102018

: Airflow

Por t

C B

A

GND B+

ABTerminal

Step

1

2

A6E40102020

BAA

B

C

D VSC SOLENOID VALVE

HARNESS SIDE CONNECTORFUSE BOX

(PCM CONTROL RELAY)

A6E40102021

1 Glow plug lead

2Glow plug

(See F2–43 Glow Plug Removal Note)

(See F2–43 Glow Plug Installation Note)0.8—1.5 N·m

{8—15 kgf·cm,

7—13 in·lbf}

15—20 N·m

{1.5—2.0 kgf·m,

11—14 ft·lbf}

12

A6E40102022

Page 203 of 909

FUEL SYSTEM

F2–51

F2

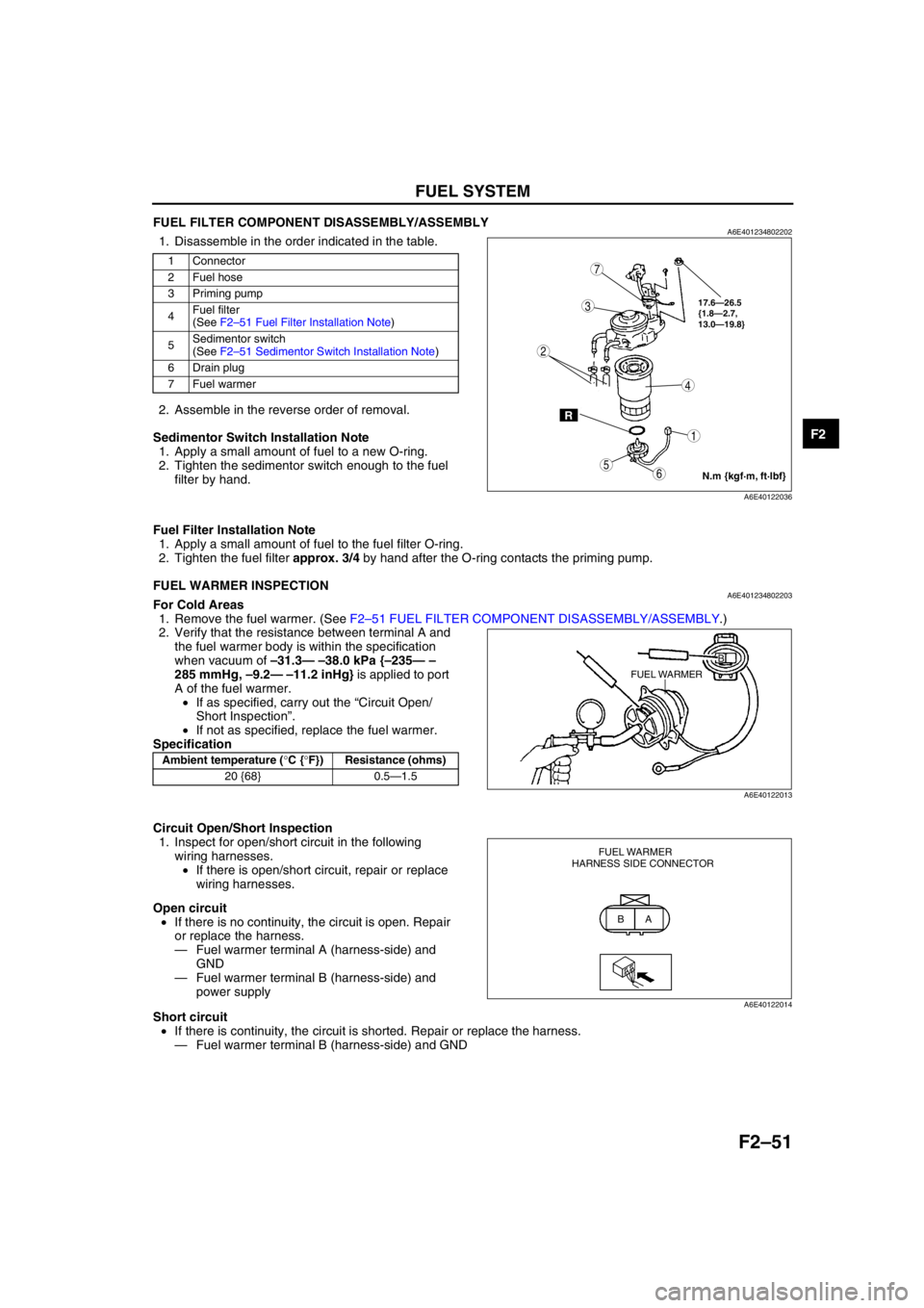

FUEL FILTER COMPONENT DISASSEMBLY/ASSEMBLYA6E4012348022021. Disassemble in the order indicated in the table..

2. Assemble in the reverse order of removal.

Sedimentor Switch Installation Note

1. Apply a small amount of fuel to a new O-ring.

2. Tighten the sedimentor switch enough to the fuel

filter by hand.

Fuel Filter Installation Note

1. Apply a small amount of fuel to the fuel filter O-ring.

2. Tighten the fuel filter approx. 3/4 by hand after the O-ring contacts the priming pump.

End Of Sie

FUEL WARMER INSPECTIONA6E401234802203For Cold Areas

1. Remove the fuel warmer. (See F2–51 FUEL FILTER COMPONENT DISASSEMBLY/ASSEMBLY.)

2. Verify that the resistance between terminal A and

the fuel warmer body is within the specification

when vacuum of –31.3— –38.0 kPa {–235— –

285 mmHg, –9.2— –11.2 inHg} is applied to port

A of the fuel warmer.

•If as specified, carry out the “Circuit Open/

Short Inspection”.

•If not as specified, replace the fuel warmer.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—Fuel warmer terminal A (harness-side) and

GND

—Fuel warmer terminal B (harness-side) and

power supply

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Fuel warmer terminal B (harness-side) and GND

End Of Sie

1 Connector

2 Fuel hose

3 Priming pump

4Fuel filter

(See F2–51 Fuel Filter Installation Note)

5Sedimentor switch

(See F2–51 Sedimentor Switch Installation Note)

6 Drain plug

7 Fuel warmer

R

17.6—26.5

{1.8—2.7,

13.0—19.8}

7

5

4

3

6

1

2

N.m {kgf·m, ft·lbf}

A6E40122036

Ambient temperature (°C {°F}) Resistance (ohms)

20 {68} 0.5—1.5

FUEL WARMER

B

A6E40122013

A B FUEL WARMER

HARNESS SIDE CONNECTOR

A6E40122014