boot MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 675 of 909

REAR DRIVE SHAFT

M–45

M

REAR DRIVE SHAFT DISASSEMBLY/ASSEMBLYA6E6317255002031. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

.

SST

R

R

R

R

R

R

R

GREASEGREASE

GREASEGREASE

7

4

3

1

1

10

6

9

9

8

52

2

11

A6J63172003

1 Boot band (wheel side)

(See M–35 Boot Band (Wheel Side) Disassembly

Note)

(See M–38 Boot Band (Wheel Side) Assembly

Note)

2 Boot band (differential side)

(See M–35 Boot Band (Transaxle Side)

Disassembly Note)

(See M–38 Boot Band (Transaxle Side) Assembly

Note)

3Clip

See M–46 Clip Disassembly Note

See M–47 Outer Ring, Clip Assembly Note

4 Outer ring

(See M–47 Outer Ring, Clip Assembly Note)

5 Snap ring

(See M–46 Snap Ring Disassembly Note)

(See M–47 Cage, Inner Ring, Balls, Snap Ring

Assembly Note)6 Balls

(See M–46 Balls, Inner Ring, Cage Disassembly

Note)

(See M–47 Cage, Inner Ring, Balls, Snap Ring

Assembly Note)

7 Inner Ring

(See M–46 Balls, Inner Ring, Cage Disassembly

Note)

(See M–47 Cage, Inner Ring, Balls, Snap Ring

Assembly Note)

8Cage

(See M–46 Balls, Inner Ring, Cage Disassembly

Note)

(See M–47 Cage, Inner Ring, Balls, Snap Ring

Assembly Note)

9Boot

(See M–47 Boot Assembly Note)

10 ABS sensor rotor

(See M–36 ABS Sensor Rotor (With ABS)

Disassembly Note)

(See M–46 ABS Sensor Rotor Assembly Note)

11 Drive shaft, joint component

Page 677 of 909

REAR DRIVE SHAFT

M–47

M

Boot Assembly Note

Note

•The wheel side and differential side boots are different.

1. Fill the wheel side boot with the specified grease.

Caution

•Do not touch grease with your hand. Apply it from the tube to prevent foreign matter from entering

the boot.

Grease amount

75—95 g {2.65—3.35 oz}

2. With the splines of the shaft wrapped in tape, install the boot.

3. Remove the tape.

Cage, Inner Ring, Balls, Snap Ring Assembly Note

1. Align the marks and install the balls and cage to

the inner ring in the direction shown in the figure.

Caution

•Install the cage so that the major

diameter is at the same side as the snap

ring groove. If incorrectly installed, the

drive shaft may become disengaged.

2. Align the marks and install the inner ring to the

shaft.

3. Install a new snap ring.

Outer Ring, Clip Assembly Note

1. Fill the outer ring and boot (differential side) with the specified grease.

Caution

•Do not touch grease with your hand. Apply it from the tube to prevent foreign matter from entering

the boot.

Grease amount

65—85 g {2.30—2.99 oz}

2. Align the marks, and install the outer ring on to

the shaft.

3. Install a new clip to the outer ring clip groove.

4. Install the boot.

CAGEBALLS

SNAP RING

GROOVEINNER

RING

MARK

A6E6316W011

MARK

A6E6316W010

Page 678 of 909

M–48

REAR DRIVE SHAFT, REAR DIFFERENTIAL

5. Release any trapped air from the boots by

carefully lifting up the small end of each boot with

a cloth wrapped screwdriver.

Caution

•Do not let grease leak.

•Do not damage the boot.

6. Set the drive shaft to the standard length.

Standard length

mm {in}

7. Verify that the drive shaft length is within the standard.

•If not, repeat from Step 5.

End Of Sie

DIFFERENTIAL OIL INSPECTIONA6E6319271002031. Place the vehicle on level ground.

2. Remove the filler plug and washer.

3. Verify that the oil is at the brim of the filler plug

hole.

4. If it is low, add the specified oil.

5. Install a new washer and the filler plug, and

tighten.

Tightening torque

39.2—53.9 N·m {4.0—5.4 kgf·m, 29.0—39.7

ft·lbf}

End Of SieDIFFERENTIAL OIL REPLACEMENTA6E6319271002041. Place the vehicle on level ground.

2. Remove the filler plug.

3. Remove the drain plug and drain the differential

oil into a container.

4. Install a new washer and the drain plug, and

tighten.

Tightening torque

39—53 N·m {4.0—5.4 kgf·m, 29—39 ft·lbf}

5. Add the specified differential oil from the filler plug

until the level reaches the brim of the plug hole.

Specified oil

Type (API service GL-5)

Above -18°C {0°F}: SAE 90

Below -18°C {0°F}: SAE 80

Capacity (Approximate quantity):

1.00 L {1.06 US qt, 0.88 Imp qt}

6. After filling with differential oil, perform oil level inspection.

7. Install a new washer and the drain plug, and tighten.

Tightening torque

39.2—53.9 N·m {4.0—5.4 kgf·m, 29.0—39.7 ft·lbf}

Left side Right side

805.4—815.4

{31.71—32.10}852.4—862.4

{33.56—33.95}A6E6316W007

REAR DIFFERENTIAL

FILLER PLUG

A6E63192101

FILLER PLUG

DRAIN PLUG

A6E63192102

Page 770 of 909

R–8

WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT (WGN)A6E741201015201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.*3: Distance between wheel center and fender brim is 405 mm {15.94 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.

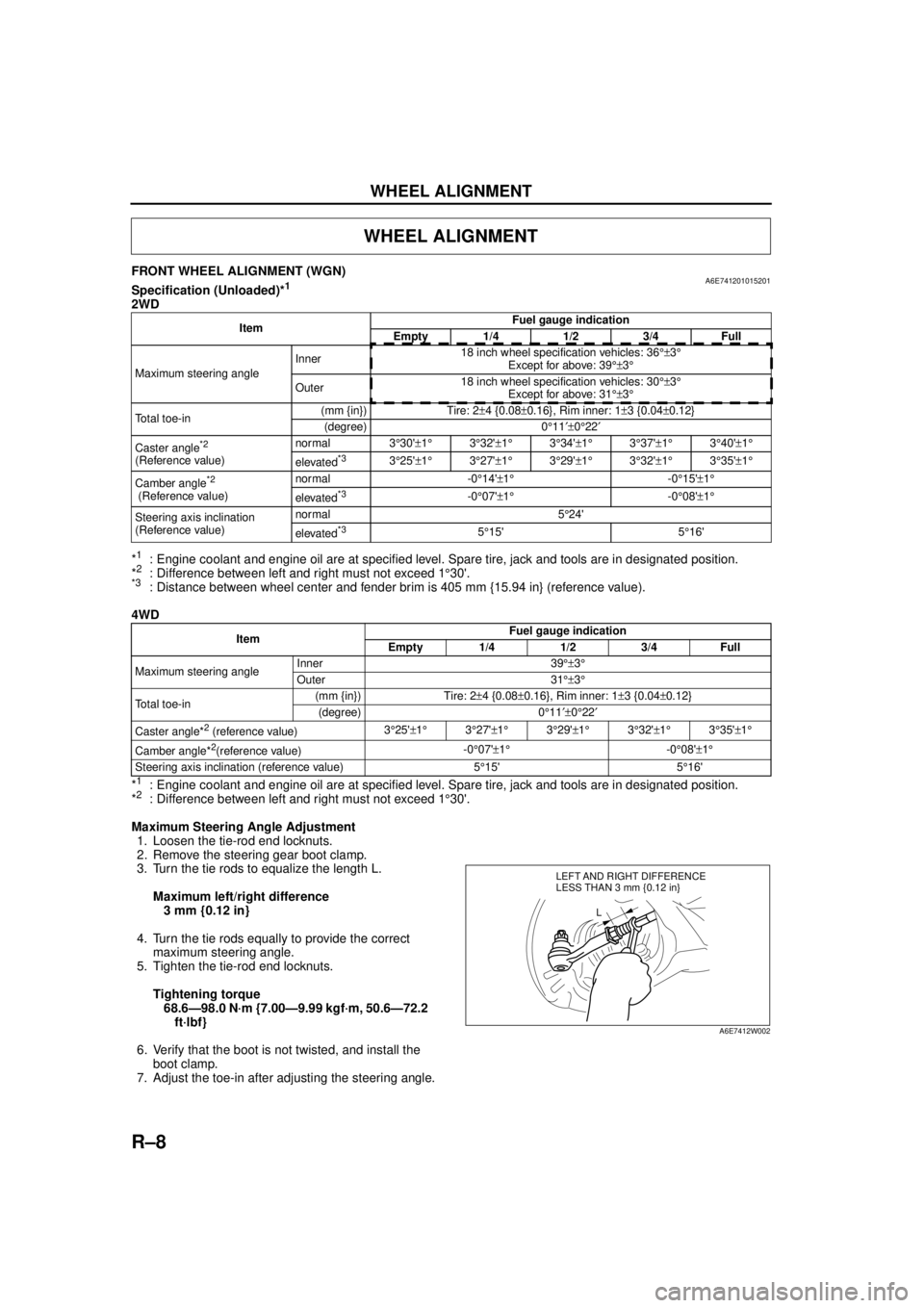

Maximum Steering Angle Adjustment 1. Loosen the tie-rod end locknuts.

2. Remove the steering gear boot clamp.

3. Turn the tie rods to equalize the length L.

Maximum left/right difference3 mm {0.12 in}

4. Turn the tie rods equally to provide the correct maximum steering angle.

5. Tighten the tie-rod end locknuts.

Tightening torque68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

6. Verify that the boot is not twisted, and install the boot clamp.

7. Adjust the toe-in after adjusting the steering angle.

WHEEL ALIGNMENT

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

Outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle

*2

(Reference value) normal 3

°30' ±1 ° 3°32' ±1 ° 3°34' ±1° 3°37' ±1° 3°40' ±1 °

elevated*33 °25' ±1 ° 3°27' ±1 ° 3°29' ±1° 3°32' ±1° 3°35' ±1 °

Camber angle

*2

(Reference value) normal -0

°14' ±1 ° -0°15' ±1°

elevated*3-0 °07' ±1 ° -0°08' ±1°

Steering axis inclination

(Reference value) normal 5

°24'

elevated

*35 °15' 5 °16'

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner 39

°±3°

Outer 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle*

2 (reference value) 3

°25' ±1 ° 3°27' ±1 ° 3°29' ±1 ° 3°32' ±1 ° 3°35' ±1 °

Camber angle*

2(reference value) -0

°07' ±1 ° -0°08' ±1°

Steering axis inclination (reference value) 5 °15' 5 °16'

LEFT AND RIGHT DIFFERENCE

L

LESS THAN 3 mm {0.12 in}

A6E7412W002

Page 771 of 909

WHEEL ALIGNMENT

R–9

R

Total Toe-in Adjustment

1. Center the steering wheel and confirm that the vehicle wheels/tires are pointing straight.

2. Loosen the left and right tie-rod end locknuts and turn the tie-rods equally. Both tie rods are right threaded, so

turning the right tie-rod toward the front of the vehicle and the left toward the rear increases toe-in.

Note

•Turning both tie-rods one complete turn changes toe-in by about 6 mm {0.24 in} (0°36').

3. Tighten the tie-rod end locknuts to the specified torque.

Tightening torque

68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

4. Verify that the boot is not twisted, and install the boot clamp.

End Of Sie

REAR WHEEL ALIGNMENT (WGN)A6E741201016201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.*3: Distance between wheel center and fender brim is 407 mm {16.02 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.

Note

•Adjust the toe-in after adjusting the camber.

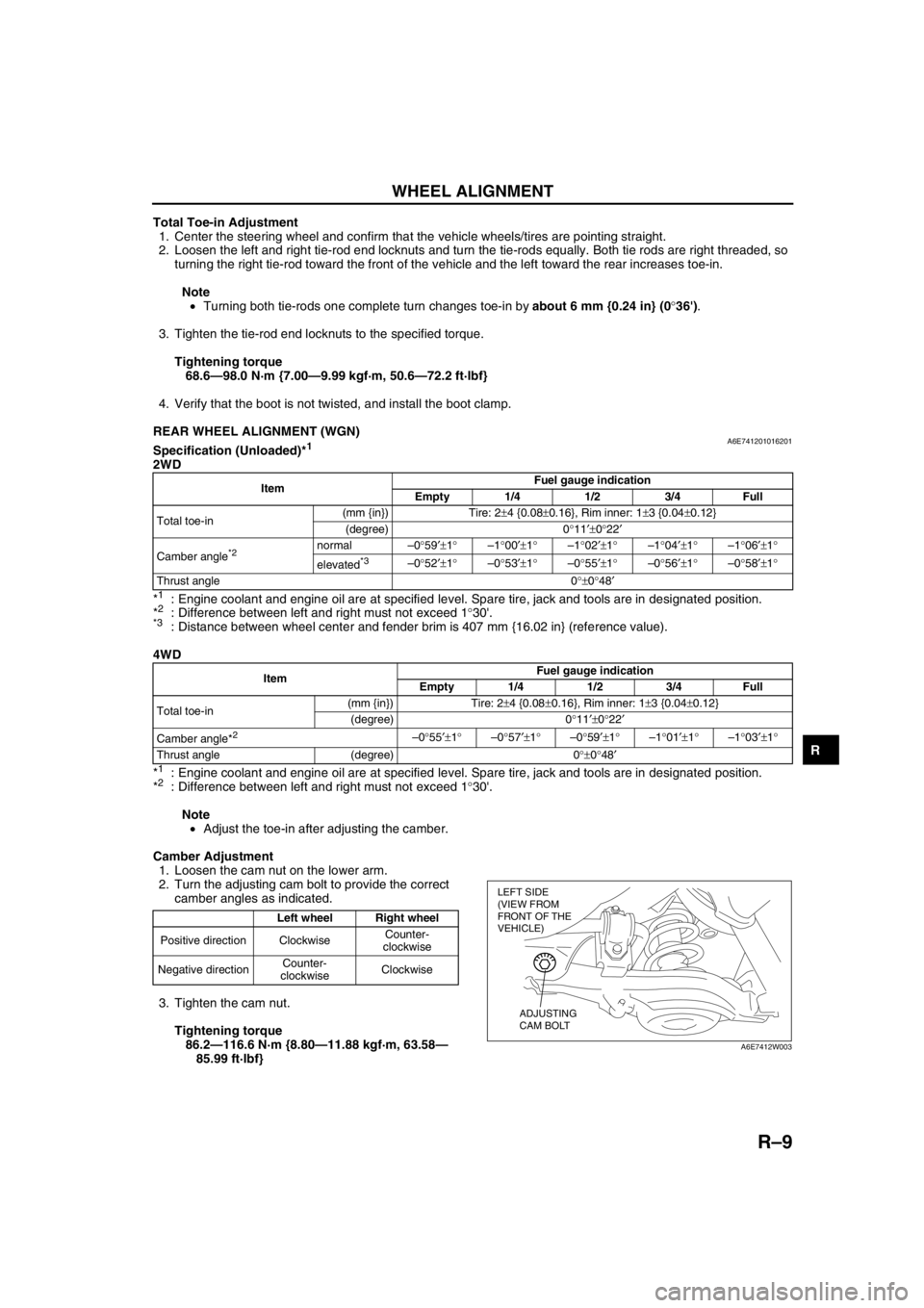

Camber Adjustment

1. Loosen the cam nut on the lower arm.

2. Turn the adjusting cam bolt to provide the correct

camber angles as indicated.

3. Tighten the cam nut.

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—

85.99 ft·lbf}

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle

*2 normal–0°59′±1°–1°00′±1°–1°02′±1°–1°04′±1°–1°06′±1°

elevated

*3–0°52′±1°–0°53′±1°–0°55′±1°–0°56′±1°–0°58′±1°

Thrust angle 0°±0°48′

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle*

2 –0°55′±1°–0°57′±1°–0°59′±1°–1°01′±1°–1°03′±1°

Thrust angle (degree) 0°±0°48′

Left wheel Right wheel

Positive direction ClockwiseCounter-

clockwise

Negative directionCounter-

clockwiseClockwise

LEFT SIDE

(VIEW FROM

FRONT OF THE

VEHICLE)

ADJUSTING

CAM BOLT

A6E7412W003

Page 773 of 909

REAR SUSPENSION

R–11

R

SUSPENSION CONTROL SYSTEM ON-VEHICLE INSPECTION (WGN)A6E7416010132021. Pull up the dust boot and visually inspect the piston rod for oil leakage.

2. Remove all cargo and drive the vehicle, with only the driver aboard, for 1 km {0.62 miles} or more. After

driving, verify that the rear vehicle height (distance measured from the fender brim to the center of the wheel) is

360 mm {14.2 in} or more

*. If not as specified, replace the rear shock absorbers.

3. Place a load equivalent to five people riding in

order to make the rear vehicle height to be 330

mm {13.0 in} or less.

4. Immediately after driving the vehicle for 5 km {3.0

miles} or more, under the same load conditions,

verify that the rear vehicle height is 335 mm {13.2

in} or more. If not as specified replace the rear

shock absorbers.

*: Indicates rear vehicle height with fuel tank full.

Height will vary 6—8 mm {0.24—0.31 in} between a

full and empty fuel tank.

End Of SieREAR SHOCK ABSORBER REMOVAL/INSTALLATION (WGN)A6E741628700201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

REAR SUSPENSION

SECTION

A—AMEASURING POINT

A

A

A6E7412W001

1 Rear shock absorber and bracket

2Bracket

(See R–12 Bracket Installation Note)

3 Rear shock absorber

1

3

37.2—51.9

{3.80—5.29,

27.5—38.2}

286.2—116.6

{8.80—11.88,

63.58—85.99}

86.2—116.6

{8.80—11.88,

63.58—85.99}

N·m {kgf·m, ft·lbf}

A6E74162006

Page 898 of 909

TD–6

TECHNICAL DATA

FRONT AND REAR AXLEA6E931001018201

End Of Sie

STEERING SYSTEMA6E931001034201

End Of Sie

Item Specification

FRONT DRIVE SHAFT

Shaft length

(Air in boot at atmospheric

pressure)(mm {in})Left sideMZR-CD (RF Turbo): 666.1—676.1 {26.23—26.61}

4WD: 667—677 {26.26—26.65}

Right sideMZR-CD (RF Turbo): 615.9—625.9 {24.25—24.64}

4WD: 631—641 {24.85—25.23}

REAR DRIVE SHAFT (4WD)

Shaft length

(Air in boot at atmospheric

pressure)(mm {in})Left side 805.4—815.4 {31.71—32.10}

Right side 852.4—862.4 {33.56—33.95}

REAR DIFFERENTIAL (4WD)

Pinion height (mm {in})–0.025—0.025 {–0.001—0.001}

Backlash of side gear and differential pinion (mm {in}) 0.1 {0.004} or less

Drive pinion preload (N·m kgf·cm, in·lbf) 1.3—1.8 {13.3—18.3, 11.5—15.9}

Backlash of drive pinion and

ring gear(mm {in})Standard 0.09—0.11 {0.0036—0.0043}

Minimum 0.05 {0.002}

Differential oilGrade API service GL-5

ViscosityAbove –18°C {0°F}: SAE 90

Below –18°C {0°F}: SAE 80

Capacity

(Approximate quantity)(L {US qt, lmp qt}) 1.00 {1.06, 0.88}

ELECTRONIC 4WD CONTROL SYSTEM

Differential oil temperature

sensor(kilohm)0°C {32°F} 91—100

10°C {50°F} 56—61

20°C {68°F} 35—39

30°C {86°F} 23—25

40°C {104°F} 14—17

50°C {122°F} 10—11

60°C {140°F} 7.1—7.9

70°C {158°F} 5.0—5.6

80°C {176°F} 3.6—4.0

4WD solenoid

(Rear differential oil temperature

at 20°C {68°F})(ohm) 1.5—2.0

Item Specification

ENGINE SPEED SENSING POWER STEERING

Power

steering oil

pumpOil pump fluid pressure 2WD (Except MZR-CD (RF Turbo)):

10.80—11.29 {110.2—115.1, 1,567—1,637}

MZR-CD (RF Turbo):

11.31—11.80 {115.4—120.3, 1,641—1,711}

4WD: 10.30—10.79 {105.1—110.0, 1,490—1,564} (MPa {kgf·cm

2, psi})

Gear housing fluid pressure 2WD (Except MZR-CD (RF Turbo)):

10.80—11.29 {110.2—115.1, 1,567—1,637}

MZR-CD (RF Turbo):

11.31—11.80 {115.4—120.3, 1,641—1,711}

4WD: 10.30—10.79 {105.1—110.0, 1,490—1,564} (MPa {kgf·cm

2, psi})

Power

steering

systemFluid type

ATF M-

III or equivalent (e.g. Dexron®II)

Capacity (Approximate quantity) MTX (Except MZR-CD (RF Turbo)): 0.80 {0.85, 0.70}

ATX (Except 4WD): 0.87 {0.92, 0.77}

MZR-CD (RF Turbo): 0.86 {0.91, 0.76}

4WD: 0.89 {0.94, 0.78} (L {US qt, Imp qt})

Page 906 of 909

SPECIAL TOOLS

ST–5

ST

49 F026 103

Wheel hub

puller49 G030 797

Handle49 F027 005

Attachment

φ 62

49 G033 107A

Dust cover

installer49 H026 104

Guide block49 F027 004

Attachment

φ 80

49 B014 001

Oil seal installer49 W034 301

Support block49 G030 370

Removing plate

49 H027 002

Bearing

remover49 F027 003

Handle49 B025 004

Dust seal

installer

49 S231 626

Support block49 W027 003

Bearing installer49 B025 006A

Sensor rotor

installer

49 T025 001

Boot clamp

crimper49 B025 009A

Installer

attachment49 G030 796

Body

49 S120 710

Coupling flange

holder49 0839 425C

Bearing puller

set49 W011 102

Oil seal installer

49 L027 0A2

Diff hanger set49 L027 005

Diff hanger

(Part of 49 L027

0A2)49 L027 011

Bolt set

(Part of 49 L027

0A2)