brake fluid MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 541 of 909

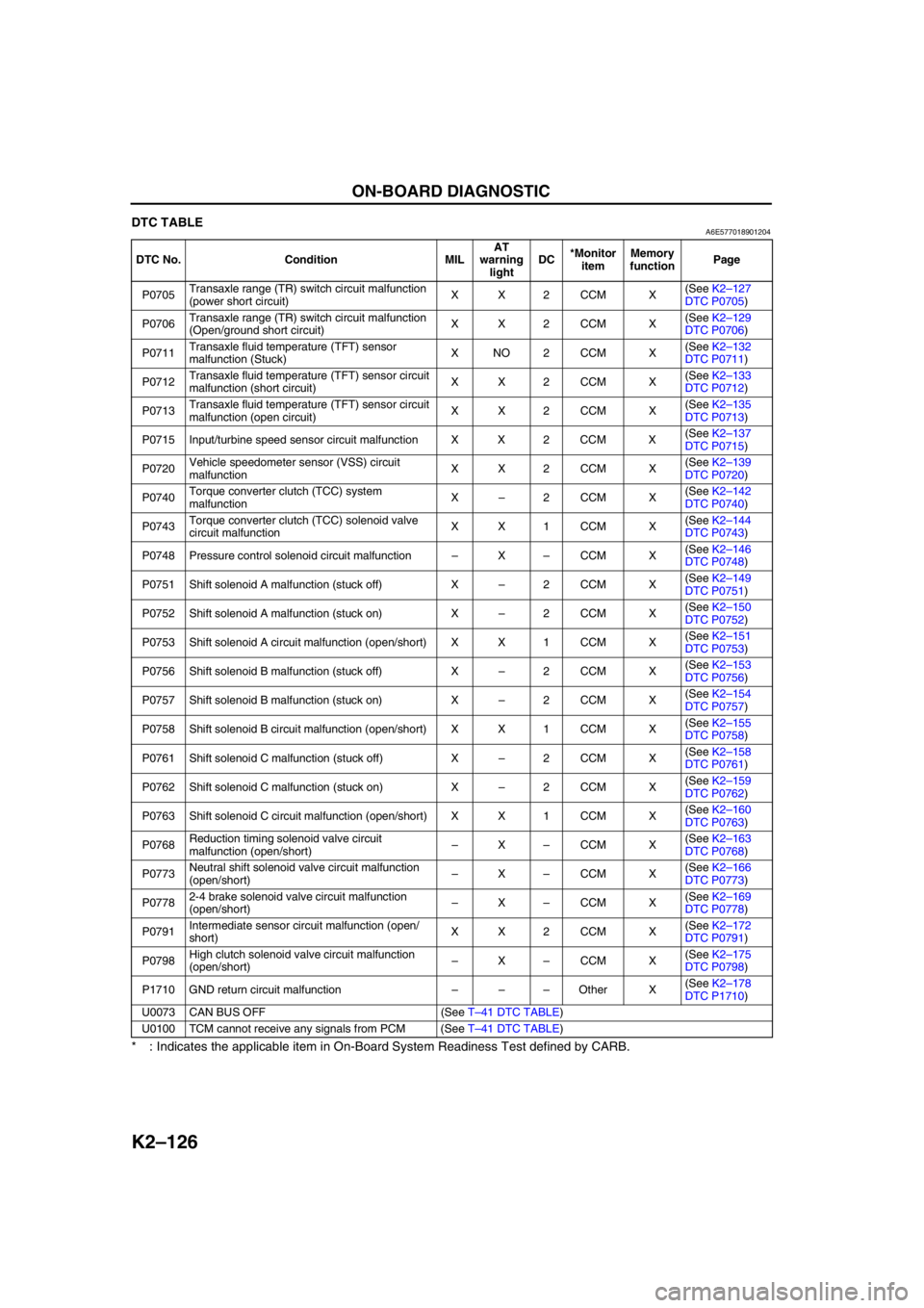

K2–126

ON-BOARD DIAGNOSTIC

DTC TABLEA6E577018901204

* : Indicates the applicable item in On-Board System Readiness Test defined by CARB.

End Of Sie

DTC No. Condition MILAT

warning

lightDC*Monitor

itemMemory

functionPage

P0705Transaxle range (TR) switch circuit malfunction

(power short circuit)XX2CCM X(See K2–127

DTC P0705)

P0706Transaxle range (TR) switch circuit malfunction

(Open/ground short circuit)XX2CCM X(See K2–129

DTC P0706)

P0711Transaxle fluid temperature (TFT) sensor

malfunction (Stuck)XNO2CCM X(See K2–132

DTC P0711)

P0712Transaxle fluid temperature (TFT) sensor circuit

malfunction (short circuit)XX2CCM X(See K2–133

DTC P0712)

P0713Transaxle fluid temperature (TFT) sensor circuit

malfunction (open circuit)XX2CCM X(See K2–135

DTC P0713)

P0715 Input/turbine speed sensor circuit malfunction X X 2 CCM X(See K2–137

DTC P0715)

P0720Vehicle speedometer sensor (VSS) circuit

malfunctionXX2CCM X(See K2–139

DTC P0720)

P0740Torque converter clutch (TCC) system

malfunctionX–2CCM X(See K2–142

DTC P0740)

P0743Torque converter clutch (TCC) solenoid valve

circuit malfunctionXX1CCM X(See K2–144

DTC P0743)

P0748 Pressure control solenoid circuit malfunction–X–CCM X(See K2–146

DTC P0748)

P0751 Shift solenoid A malfunction (stuck off) X–2CCM X(See K2–149

DTC P0751)

P0752 Shift solenoid A malfunction (stuck on) X–2CCM X(See K2–150

DTC P0752)

P0753 Shift solenoid A circuit malfunction (open/short) X X 1 CCM X(See K2–151

DTC P0753)

P0756 Shift solenoid B malfunction (stuck off) X–2CCM X(See K2–153

DTC P0756)

P0757 Shift solenoid B malfunction (stuck on) X–2CCM X(See K2–154

DTC P0757)

P0758 Shift solenoid B circuit malfunction (open/short) X X 1 CCM X(See K2–155

DTC P0758)

P0761 Shift solenoid C malfunction (stuck off) X–2CCM X(See K2–158

DTC P0761)

P0762 Shift solenoid C malfunction (stuck on) X–2CCM X(See K2–159

DTC P0762)

P0763 Shift solenoid C circuit malfunction (open/short) X X 1 CCM X(See K2–160

DTC P0763)

P0768Reduction timing solenoid valve circuit

malfunction (open/short)–X–CCM X(See K2–163

DTC P0768)

P0773Neutral shift solenoid valve circuit malfunction

(open/short)–X–CCM X(See K2–166

DTC P0773)

P07782-4 brake solenoid valve circuit malfunction

(open/short)–X–CCM X(See K2–169

DTC P0778)

P0791Intermediate sensor circuit malfunction (open/

short)XX2CCM X(See K2–172

DTC P0791)

P0798High clutch solenoid valve circuit malfunction

(open/short)–X–CCM X(See K2–175

DTC P0798)

P1710 GND return circuit malfunction–––Other X(See K2–178

DTC P1710)

U0073 CAN BUS OFF (See T–41 DTC TABLE)

U0100 TCM cannot receive any signals from PCM (See T–41 DTC TABLE)

Page 651 of 909

GENERAL PROCEDURES

M–21

M

PRECAUTION (FRONT AND REAR AXLE)A6E631001018201Wheel and Tire Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}

Brake Line Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid gets on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

2. If any brake line has been disconnected any time during the procedure, add brake fluid, bleed the brakes, and

inspect for leakage after the procedure has been completed.

Suspension Arm Removal/Installation

1. Tighten any part of the suspension that uses rubber bushings only after vehicle has been lowered and

unloaded.

Note

•Unloaded: Fuel tank is full. Engine coolant and engine oil are at specified level. Spare tire, jack, and tools

are in designated position.

Connector Disconnection

1. Disconnect the negative (-) battery cable before disconnecting connectors.

Electronic Control 4WD System Parts

1. After servicing the electronic control 4WD system parts, verify that no DTC has been stored. Clear any DTCs

remaining in the memory.

End Of Sie

GENERAL PROCEDURES

Page 735 of 909

P–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E690201020201•The construction and operation of the braking system is the same as that of the current Mazda6 (GG) L8, LF,

L3 engine 2WD model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E690201020202Modifications to match vehicle characteristics

•Due to the addition of the MZR-CD (RF Turbo) engine, the vacuum pump and vacuum switch have been

added.

•Due to the addition of the 4WD model, DSC HU/CM uses the forward-G signal from combine sensor to control

DSC.

End Of Sie

SPECIFICATIONSA6E690201020203

Bold frames: New specifications

End Of Sie

OUTLINE

ItemSpecification

New Mazda6 (GG, GW) Current Mazda6 (GG)

Brake pedalType Suspended

Pedal lever ratio 2.7

Max. stroke (mm {in}) 128.5 {5.06}

Master

cylinderType Tandem (with level sensor)

Cylinder diameter (mm {in}) 20.64 {0.813}

Front disc

brakeType Ventilated disc

Cylinder bore (mm {in}) 57.15 {2.250}

Pad dimensions (area × thickness) L8, LF (GCC specs.):

4,220 {6.75} × 10.0 {0.39}

LF (European (L.H.D. U.K.)

specs.), L3, MZR-CD (RF Turbo):

4,010 {6.42} × 12.0 {0.47}L8, LF (GCC specs.):

4,220 {6.75} × 10.0 {0.39}

LF (European (L.H.D. U.K.) specs.),

L3: 4,010 {6.42} × 12.0 {0.47} (mm

2 {in2} × mm {in})

Disc plate dimensions

(outer diameter × thickness)L8, LF (GCC specs.):

274 {10.8} × 24.0 {0.945}

LF (European (L.H.D. U.K.)

specs.), L3, MZR-CD (RF Turbo):

283 {11.1} × 25.0 {0.984}L8, LF (GCC specs.):

274 {10.8} × 24.0 {0.945}

LF (European (L.H.D. U.K.) specs.),

L3: 283 {11.1} × 25.0 {0.984} (mm {in} × mm {in})

Rear brake

(disc)Type Solid disc

Cylinder bore (mm {in}) 34.93 {1.375}

Pad dimensions (area × thickness)

2,810 {4.51} × 8.0 {0.31}

(mm

2 {in2} × mm {in})

Disc plate dimensions

(outer diameter × thickness)

280 {11.0} × 10.0 {0.39}

(mm {in})

Power brake

unitType Vacuum multiplier, single diaphragm

Diameter (mm {in}) 279 {10.9}

Braking force

control deviceTypeWith ABS: EBD (Electronic Brakeforce Distribution)

Without ABS: Dual proportioning valve

Parking brakeType Mechanical two-rear-wheel control

Operation system Center lever type

Brake fluid TypeEuropean (L.H.D. U.K.) specs.: SAE J1703, FMVSS116 DOT3 OR DOT4

GCC specs.: SAE J1703, FMVSS116 DOT3

Page 743 of 909

P–10

OUTLINE , GENERAL PROCEDURES

SUPPLEMENTAL SERVICE INFORMATIONA6E690201020205•The following changes have been made since publication of the Mazda6 Workshop Manual (1730-1*-02C).

Power brake unit

•Removal/installation procedure has been modified.

Vacuum switch (MZR-CD (RF Turbo))

•Inspection procedure has been added.

•Removal/installation procedure has been added.

Vacuum pump (MZR-CD (RF Turbo))

•Inspection procedure has been added.

•Removal/installation procedure has been added.

Front brake (disc)

•Inspection procedure has been modified.

•Removal/installation procedure has been modified.

Disc pad (front)

•Replacement procedure has been modified.

Parking brake (lever type)

•Adjustment procedure has been modified.

DSC HU/CM

•Inspection procedure has been modified.

Combine sensor (Forward-G sensor)

•Inspection procedure has been modified.

On-board diagnostic (ABS/TCS)

•4WD and MZR-CD (RF Turbo) have been added.

End Of Sie

PRECAUTION (BRAKES)A6E691001020201Wheels and Tires Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}.

Brake Lines Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid does get on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

•If any brake line has been disconnected anytime during the procedure, add brake fluid, bleed the brakes,

and inspect for leakage after the procedure has been completed.

Connectors Disconnection

1. Disconnect the negative battery cable before doing any work that requires handling of connectors. Reconnect

the negative battery cable only after the work is completed.

ABS, ABS/TCS, or DSC Components Operations

1. Make sure that there are no DTCs in the ABS, ABS/TCS, or DSC memory after working on ABS, ABS/TCS or

DSC components.

•If there are any DTCs in the memory, clear them.

End Of Sie

OUTLINE

GENERAL PROCEDURES

Page 754 of 909

ON-BOARD DIAGNOSTIC

P–21

P

DSC ON-BOARD DIAGNOSISA6E697067650201DTC Table

Note

•There is no change except for the code marked with an asterisk *

ON-BOARD DIAGNOSTIC

DTC

Diagnosis system component

WDS or

equivalent

B1318 DSC power supply

B1342 DSC HU/CM

B1483 Stop switch signal (with DSC only)

B1484 Stop switch signal (with DSC only)

B1486 Stop switch signal (with DSC only)

B1627 Reverse signal (with DSC only)

B2477 Module configuration (with DSC only)

C1095 Motor relay, pump motor

C1096 Motor relay, pump motor

C1119* Engine control system

C1125 Brake fluid level sensor (with DSC only)

C1140 DSC HU (pump) (with DSC only)

C1145 Right front wheel-speed sensor

C1148 Right front wheel-speed sensor/sensor rotor

C1155 Left front wheel-speed sensor

C1158 Left front wheel-speed sensor/sensor rotor

C1165 Right rear wheel-speed sensor

C1168 Right rear wheel-speed sensor/sensor rotor

C1175 Left rear wheel-speed sensor

C1178 Left rear wheel-speed sensor/sensor rotor

C1186 Fail-safe relay

C1194 Left front pressure reduction solenoid valve

C1198 Left front pressure retention solenoid valve

C1210 Right front pressure reduction solenoid valve

C1214 Right front pressure retention solenoid valve

C1233 Left front wheel-speed sensor/sensor rotor

C1234 Right front wheel-speed sensor/sensor rotor

C1235 Right rear wheel-speed sensor/sensor rotor

C1236 Left rear wheel-speed sensor/sensor rotor

C1242 Left rear pressure reduction solenoid valve

C1246 Right rear pressure reduction solenoid valve

C1250 Left rear pressure retention solenoid valve

C1254 Right rear ABS pressure retention solenoid valve

C1266 Fail-safe relay

C1280 Combine sensor (with DSC only)

C1400 Right front traction switch solenoid valve (with DSC only)

C1410 Left front traction switch solenoid valve (with DSC only)

C1414 DSC HU/CM (with DSC only)

C1507 DSC control (with DSC only)

C1508 TCS control

C1510 Right front solenoid valve, motor or wheel-speed sensor/sensor rotor

C1511 Left front solenoid valve, motor or wheel-speed sensor/sensor rotor

C1512 Right rear solenoid valve, motor or wheel-speed sensor/sensor rotor

C1513 Left rear solenoid valve, motor or wheel-speed sensor/sensor rotor

Page 755 of 909

P–22

ON-BOARD DIAGNOSTIC

PID/DATA Monitor Table

Note

•There is no change except for the PID marked with an asterisk *

C1730 Combine sensor (with DSC only)

C1949* Combine sensor (with DSC only)

C1950* Combine sensor (with DSC only)

C1951 Combine sensor (with DSC only)

C1952 Combine sensor (with DSC only)

C1953 Brake fluid pressure sensor (with DSC only)

C1954 Brake fluid pressure sensor (with DSC only)

C1955 Steering angle sensor (with DSC only)

C1956 Steering angle sensor (with DSC only)

C1957 Right front DSC switch solenoid valve (with DSC only)

C1958 Left front DSC switch solenoid valve (with DSC only)

C1959 Combine sensor (with DSC only)

U1900 CAN communication

U2021 Invalid/fault data received

U2511* CAN communication

U2516 CAN communicationDTC

Diagnosis system component

WDS or

equivalent

PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

RPM

(Engine speed signal input)RPM•Engine is stopped: 0 RPM

•Engine is running: Indicates

engine speedInspect PCM.—

TRANSGR

*

(with DSC only)

(Transaxle gear position)FN4A-EL:

R/N/D/S/L

JA5AX-EL:

R/N/D•Selector lever position is

displayed

—R: R

—N: N

—D: D

—S: SInspect PCM, TR

switch, or DSC HU/

CM.

—

TRAC_SW

(TCS OFF switch input)ON/OFF•TCS (DSC) OFF switch is

depressed: ON

•TCS (DSC) OFF switch is

released: OFFInspect TCS (DSC)

OFF switch.

AA

TC LVAL (with DSC only)

(Traction switch solenoid valve

(LF-RR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

TC RVAL (with DSC only)

(Traction switch solenoid valve

(RF-LR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

L_DSC O (with DSC only)

(Stability control solenoid

valve (LF-RR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

R_DSC O (with DSC only)

(Stability control solenoid

valve (RF-LR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

CCNTABS

(Number of continuous codes)—DTC is detected: 1—255

DTC is not detected: 0Perform inspection

using appropriate

DTC.—

Page 756 of 909

ON-BOARD DIAGNOSTIC

P–23

P

PMPSTAT

(Pump motor output state)ON/OFF•Pump motor is activated:

ON

•Pump motor is deactivated:

OFFInspect DSC HU/CM

—

BRK_FLUID (with DSC only)

(Brake fluid level sensor input)OK/LOW•Brake fluid is above LOW:

OK

•Brake fluid is below LOW:

LOWInspect brake fluid

level.

Inspect brake fluid

level sensor.—

BOO_ABS

(Brake pedal switch input)ON/OFF•Brake pedal is depressed:

ON

•Brake pedal is released:

OFFInspect brake switch.

ABS (ABS/

TCS): Y

DSC: L

ABS_LAMP

(ABS warning light driver

output state)ON/OFF•ABS warning light is

illuminated: ON

•ABS warning light is not

illuminated: OFFInspect ABS warning

light.

—

BRAKE_LMP

(BRAKE system warning light

output state)ON/OFF•BRAKE system warning

light is illuminated: ON

•BRAKE system warning

light is not illuminated: OFFInspect BRAKE

system warning light.

—

ABSRR_O

(Right rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLR_O

(Left rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS or EBD control:

ON/OFF

(solenoid valve is activated/

deactivated)

•Not ABS and EBD control:

OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSRF_O

(Right front ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLF_O

(Left front ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSRR_I

(Right rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLR_I

(Left rear ABS pressure

retention solenoid valve output

state)ON/OFF•During ABS or EBD control:

ON/OFF

(solenoid valve is activated/

deactivated)

•Not ABS and EBD control:

OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.— PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

Page 757 of 909

P–24

ON-BOARD DIAGNOSTIC

ABSRF_I

(Right front ABS pressure

retention solenoid valve output

state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLF_I

(Left front ABS pressure

retention solenoid valve output

state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSVLVRLY

(Fail-safe relay output state)ON/OFF•Fail-safe relay is

activated: ON

•Fail-safe relay is

deactivated: OFFInspect ABS (ABS/

TCS) or DSC HU/CM.

—

ABSPMPRLY

(Motor relay output state)ON/OFF•Motor relay is activated: ON

•Motor relay is deactivated:

OFFInspect ABS (ABS/

TCS) or DSC HU/CM.—

SWA POS (with DSC only)

(Steering angle sensor input)ANGLE•Steering wheel is in neutral

position: 0 DEG

•Steering wheel is turned to

left: Changes between

0 DEG and -1,638.40 DEG

•Steering wheel is turned to

right: Changes between

0 DEG and 1,638.35 DEGInspect steering angle

sensor.

R, U, W, X

LF_WSPD

(Left front wheel-speed sensor

input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): E, I

DSC: F, J

RF_WSPD

(Right front wheel-speed

sensor input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): D, G

DSC: I, M

LR_WSPD

(Left rear wheel-speed sensor

input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): C, F

DSC: N, Q

RR_WSPD

(Right rear wheel-speed

sensor input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): A, B

DSC: H, K

LAT ACC (with DSC only)

(Lateral-G sensor input)ACCELERATION•Vehicle is stopped or driving

straight: 0 G

•Cornering to left: Changes

between 0 G and 1.27 G

•Cornering to right: Changes

between 0 G and -1.28 GInspect ABS wheel-

speed sensor/sensor

rotor.

O

YAW_RATE (with DSC only)

(Yaw rate sensor input)ACCELERATION•Vehicle is stopped or driving

straight: 0 DG/S

•Cornering to left: Changes

between 0 DG/S and 127

DG/S

•Cornering to right: Changes

between 0 DG/S and -128

DG/SInspect combine

sensor.

T

MCYLI P (with DSC only)

(Brake fluid pressure sensor

input)PRESSURE•Brake pedal is released:

0 MPa

•Brake pedal is depressed:

Changes between 0 MPa

and 25.5 MPaInspect DSC HU/CM.

— PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

Page 815 of 909

T–4

MULTIPLEX COMMUNICATION SYSTEM

SYSTEM WIRING DIAGRAMA6E811155430203

.

End Of SieCAN SIGNAL-CHARTA6E811155430204

OUT: Output (sends signal)

IN: Input (receives signal)

1

2

67

3

8

4

5

ROAF AG

HG

2M2J2W

2X

9

10

CAN_L

CAN_H

A6E81111102

1PCM

2 DSC HU/CM (with DSC)

3 ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS))

4 Data link connector-2

5 Instrument cluster

6 TCM (JA5AX-EL)7 4WD control module (4WD)

8Twist pair

9 2R (except MZR-CD (RF Turbo))

39 (MZR-CD (RF Turbo))

10 2U (except MZR-CD (RF Turbo))

13 (MZR-CD (RF Turbo))

SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Accelerator pedal position

(MZR-CD (RF Turbo))OUT IN IN–IN

Air induction type OUT–IN––

ATF temperature IN OUT–––

AT warning light conditions

(JA5AX-EL)IN OUT––IN

Battery reconnection

(except MZR-CD (RF

Turbo))OUT IN–––

Brake system configuration

(EBD/ABS/TCS/DSC)IN–OUT–IN

Brake system

statusABS IN–OUT––

EBD/ABS/

TCS/DSC––OUT IN IN

Brake system warning light

conditions (brake fluid level

sensor)––IN–OUT

Country OUT–IN––

Coupling torque (with

DSC)––IN OUT–

Coupling torque request

(with DSC)––OUT IN–

Page 897 of 909

TECHNICAL DATA

TD–5

TD

End Of SieAUTOMATIC TRANSAXLEA6E931001024203

End Of Sie

PROPELLER SHAFTA6E931001024204

End Of Sie

Item Specification

Transaxle typeJA5AX-EL

Line pressure

(kPa {kgf/cm

2, psi})D range, M range (2GR)Idle 290—490 {3.0—5.0, 42—71}

Stall 1,550—1,750 {15.8—17.8, 225—254}

M range (1GR), R positionIdle 550—750 {5.6—7.6, 80—109}

Stall 1,550—1,750 {15.8—17.8, 225—254}

Engine stall speed

D, M (1GR, 2GR), R 2,200—2,600

(rpm)

Time lag (second)N-D Approx. 0.5—1.0

N-R Approx. 0.6—1.0

Transaxle fluid

temperature (TFT)

sensor-20 °C {−4 °F} 15.87—17.54

0 °C {32 °F} 5.73—6.33

20 °C {68 °F} 2.38—2.63

40 °C {104 °F} 1.10—1.22

60 °C {140 °F} 0.56—0.62

80 °C {176 °F} 0.31—0.34

(kilohm) 100 °C {212 °F} 0.18—0.20

120 °C {248 °F} 0.11—0.12

130 °C {266 °F} 0.09—0.10

Input/turbine

speed sensor(ohm) ATF temperature: 20 °C {68 °F} 513—627

Intermediate

sensor(ohm) ATF temperature: 20 °C {68 °F} 513—627

Vehicle

speedometer

sensor(ohm) ATF temperature: 20 °C {68 °F} 513—627

Solenoid valves (ohm)Shift solenoid A 14—18

Shift solenoid B 14—18

Shift solenoid C 14—18

Neutral shift solenoid valve 14—18

Reduction timing solenoid valve 14—18

TCC solenoid valve 12.0—13.2

2-4 brake solenoid valve 2.6—3.2

High clutch solenoid valve 2.6—3.2

Pressure control solenoid 2.6—3.2

Automatic transaxle fluid

(ATF)Type

M-

III or equivalent (e.g. Dexron ® III )

Capacity (Approximate quantity) (L {US qt, Imp qt}) 8.3 {8.8, 7.3}

Transfer oilGrade API service GL-5

Viscosity SAE 80W-90

Capacity (Approximate quantity) (L {US qt, Imp qt}) 0.62 {0.65, 0.54}

Item Specification

Runout limit mm {in} 0.3 {0.01}

Starting torqueN·m

{kgf·cm}0.29—0.78 {3.0—7.9}