display MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 370 of 909

F2–218

TROUBLESHOOTING

6 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to appropriate DTC test.

7 Access ECT PID.

Inspect ECT PID while warming up engine.

Is PID value correct?Yes Go to next step.

No Inspect ECT sensor and related wiring harnesses.

8 Access IAT PID.

Inspect IAT PID while running engine.

Is PID value correct?Yes Go to next step.

No Inspect IAT sensor and related wiring harnesses.

9 Visually inspect CKP sensor and teeth of pulse

wheel.

Are CKP sensor and teeth of pulse wheel okay?Yes Go to next step.

No Replace malfunctioning parts.

10 Measure gap between CKP sensor and teeth of

pulse wheel.

Specification

1.5—2.5 mm {0.059—0.098 in}

Is gap within specification?Yes Go to next step.

No Adjust CKP sensor position.

11 Visually inspect CMP sensor and teeth of pulse

wheel.

Are CMP sensor and teeth of pulse wheel okay?Yes Inspect following PIDs:

(See F2–65 PCM INSPECTION)

•ECT

•IAT

•MAF

•MAP

•RPM

If PID value is not as specified, repair or replace

malfunctioning parts.

If PID value is okay, go to next step.

No Replace malfunctioning parts.

12 Perform EGR system inspection.

Is EGR system okay?Yes Go to next step.

No Repair or replace malfunctioning part according to

EGR system operation results.

13 Remove parts necessary to inspect

turbocharger.

Note

•Do not remove turbocharger.

Inspect if turbocharger compressor wheel is

bent, damaged, or interfering with housing on

vehicle.

Is there any problem?Yes Replace turbocharger.

No Go to next step. STEP INSPECTION RESULTS ACTION

Page 373 of 909

TROUBLESHOOTING

F2–221

F2

End Of Sie

3 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

4 Inspect adjustment of accelerator position

sensor and idle switch.

(See F2–72 ACCELERATOR POSITION

SENSOR INSPECTION)

(See F2–70 IDLE SWITCH INSPECTION)

Are accelerator position sensor and idle switch

adjusted correctly?Yes Go to next step.

No Adjust accelerator position sensor and idle switch

correctly.

(See F2–73 ACCELERATOR POSITION SENSOR

ADJUSTMENT)

(See F2–71 IDLE SWITCH ADJUSTMENT)

5 Inspect adjustment of neutral switch.

(See F2–69 NEUTRAL SWITCH INSPECTION)

Is neutral switch adjusted correctly?Yes Go to next step.

No Adjust neutral switch correctly.

6 Visually inspect CMP sensor and teeth of pulse

wheel.

Are CMP sensor and teeth of pulse wheel okay?Yes Inspect following PIDs:

(See F2–65 PCM INSPECTION)

•ECT

•IAT

•MAF

•RPM

If PID value is not as specified, repair or replace

malfunctioning parts.

If PID value is okay, go to next step.

No Replace malfunctioning parts.

7 Inspect fuel injector.

(See F2–56 FUEL INJECTOR INSPECTION)

Is fuel injector okay?Yes Inspect following systems:

•Wheels

•Transaxle and mounts

•Driveline

•Suspension

Service as necessary.

No Repair or replace as necessary.

8 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 374 of 909

F2–222

TROUBLESHOOTING

NO.23 A/C DOES NOT WORK SUFFICIENTLYA6E408018881225

Diagnostic Procedure

End Of Sie

23 A/C DOES NOT WORK SUFFICIENTLY

DESCRIPTION•A/C compressor magnetic clutch does not engage when A/C switch is turned on.

POSSIBLE

CAUSE•Improper refrigerant charge amount

•Open A/C switch magnetic clutch

•Open circuit between A/C relay and A/C magnetic clutch

•Poor GND of A/C magnetic clutch

•Improper A/C magnetic clutch clearance

•Refrigerant pressure switch is stuck open

•A/C relay is stuck open

•Improper A/C cut-off control

•Open circuit between A/C switch and PCM through both refrigerant pressure switch and A/C amplifier

STEP INSPECTION RESULTS ACTION

1 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

YesNo DTC is displayed:

Go to appropriate DTC test.

2 Disconnect A/C compressor connector.

Start engine and turn A/C switch to ON.

Is there correct voltage at terminal of A/C

compressor magnetic clutch connector?

Specification

More than 10.5 VYes Inspect for GND condition of magnetic clutch on A/C

compressor.

If GND condition is okay, inspect magnetic clutch coil

for open circuit.

No Go to next step.

3 Disconnect refrigerant pressure switch

connector.

Connect jumper wire between terminals of

refrigerant pressure switch connector.

Turn engine switch to ON.

Turn A/C switch on and set blower fan at any

speed.

Measure PCM terminal 84 voltage.

Is voltage below 1.0 V?Yes Inspect refrigerant pressure switch operation.

If switch is okay, go to next step.

No Inspect for following:

•A/C switch is stuck open

•Open circuit between refrigerant pressure switch

and PCM terminal 84

•Open circuit of blower motor fan switch and

resistor (if blower motor does not operate)

•Evaporator temperature sensor and A/C amplifier

4 Inspect A/C cut-off operation.

Does A/C cut-off work properly?Yes Go to next step.

No Repair or replace malfunctioning part according to A/C

cut-off system inspection results.

5 Remove jumper wire from switch connector.

Reconnect connector to refrigerant pressure

switch.

Start engine and turn A/C switch on.

Does fan operate?Yes Inspect for stuck open A/C relay.

Replace if necessary.

No Inspect following and repair or replace as necessary:

•Refrigerant charging amount

•Seized A/C compressor

6 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 375 of 909

TROUBLESHOOTING

F2–223

F2

NO.24 A/C ALWAYS ON OR A/C COMPRESSOR RUNS CONTINUOUSLYA6E408018881226

Diagnostic Procedure

End Of Sie

24 A/C ALWAYS ON OR A/C COMPRESSOR RUNS CONTINUOUSLY

DESCRIPTION•A/C compressor magnetic clutch does not disengage.

POSSIBLE

CAUSE•A/C compressor magnetic clutch stuck engagement

•A/C relay is stuck closed

•Improper A/C compressor magnetic clutch clearance

•Short to GND circuit between A/C switch and PCM

•Short to GND circuit between A/C relay and PCM

•A/C relay to magnetic clutch circuit shorts to battery power

STEP INSPECTION RESULTS ACTION

1 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to appropriate DTC test.

2 Start engine and run it at idle.

Turn A/C switch on.

Remove A/C relay.

Does A/C magnetic clutch disengage?Yes Inspect for following:

•A/C relay is stuck closed

•Short to GND circuit between A/C relay and PCM

terminal 73

If both items are okay, go to next step.

No Inspect if circuit between A/C relay and magnetic

clutch shorts to battery power circuit.

If circuit is okay, inspect magnetic clutch stuck

engagement or clearance.

3 Start engine and turn A/C switch on.

Measure PCM terminal 84 voltage while

disconnecting refrigerant pressure switch

connector.

Note

•PCM terminal 84 voltage should read B+

when disconnecting connector. If PCM

terminal 84 voltage reading remains

below 1.0 V, short to GND circuit may be

present.

Is voltage B+?Yes Inspect for short to GND circuit between refrigerant

pressure switch and PCM terminal 84.

No Go to next step.

4 Reconnect refrigerant pressure switch

connector.Measure PCM terminal 84 voltage

while turning off A/C switch.

Note

•PCM terminal 84 voltage should read B+

when turning A/C switch off. If PCM

terminal 84 voltage reading remains

below 1.0 V, short to GND circuit maybe

present.

Does voltage remain B+?Yes Inspect for following:

•Short to GND circuit between A/C switch and A/C

amplifier.

•Short to GND circuit between A/C amplifier and

refrigerant pressure switch.

No Inspect for stuck closed A/C switch.

5 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 376 of 909

F2–224

TROUBLESHOOTING

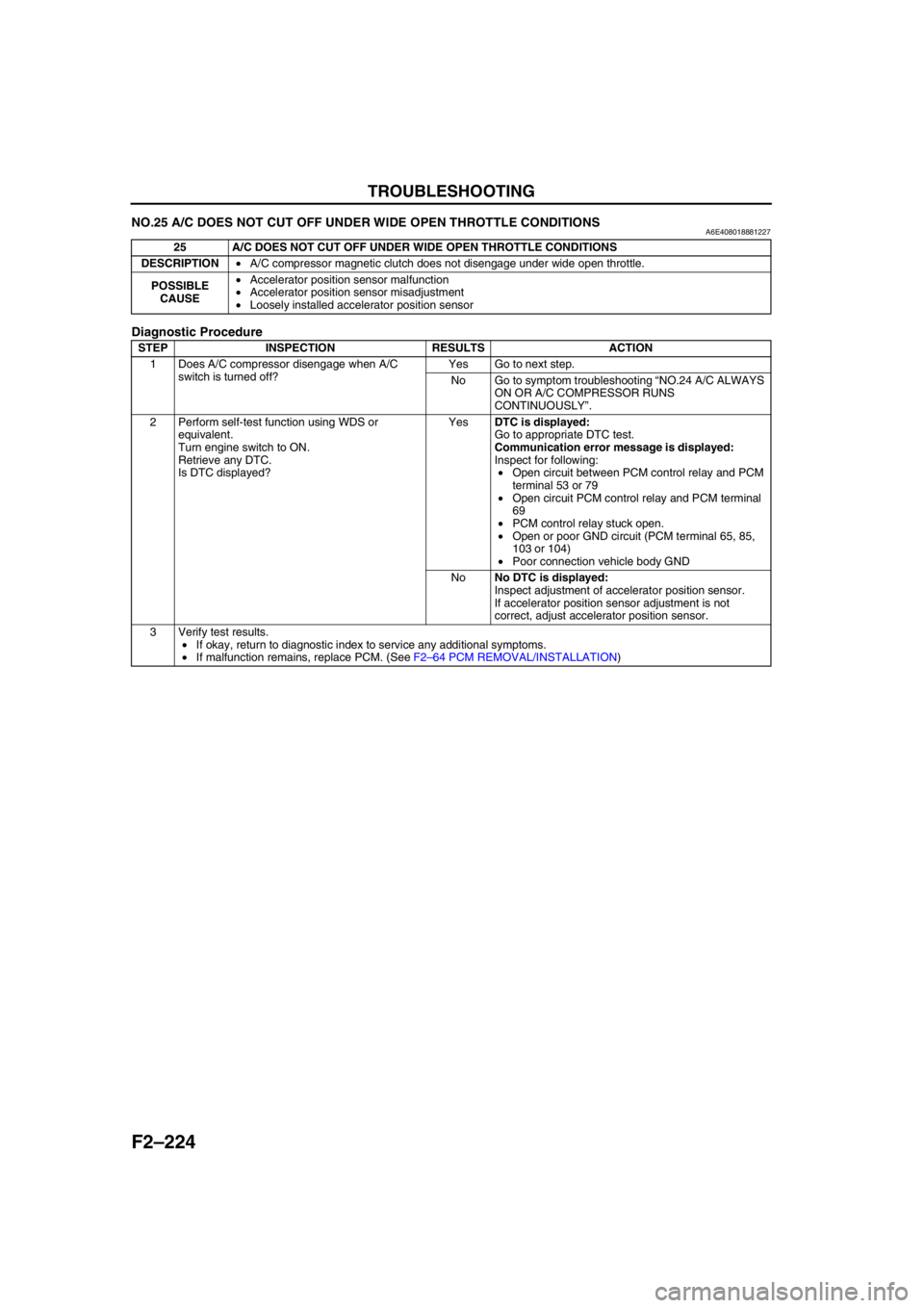

NO.25 A/C DOES NOT CUT OFF UNDER WIDE OPEN THROTTLE CONDITIONSA6E408018881227

Diagnostic Procedure

End Of Sie

25 A/C DOES NOT CUT OFF UNDER WIDE OPEN THROTTLE CONDITIONS

DESCRIPTION•A/C compressor magnetic clutch does not disengage under wide open throttle.

POSSIBLE

CAUSE•Accelerator position sensor malfunction

•Accelerator position sensor misadjustment

•Loosely installed accelerator position sensor

STEP INSPECTION RESULTS ACTION

1 Does A/C compressor disengage when A/C

switch is turned off?Yes Go to next step.

No Go to symptom troubleshooting “NO.24 A/C ALWAYS

ON OR A/C COMPRESSOR RUNS

CONTINUOUSLY”.

2 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open.

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Inspect adjustment of accelerator position sensor.

If accelerator position sensor adjustment is not

correct, adjust accelerator position sensor.

3 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 467 of 909

K2–52

AUTOMATIC TRANSAXLE

Operation

Range determination

•Each range is determined by operating the selector lever, and switching ON/OFF the switch in the TR switch

internal circuit. The present range is detected according to the ON/OFF signal of the switch.

•The following switches are built into the TR switch, and determine each range when the switch is on.

P position switch

R position switch

N position switch

D range switch

End Of Sie

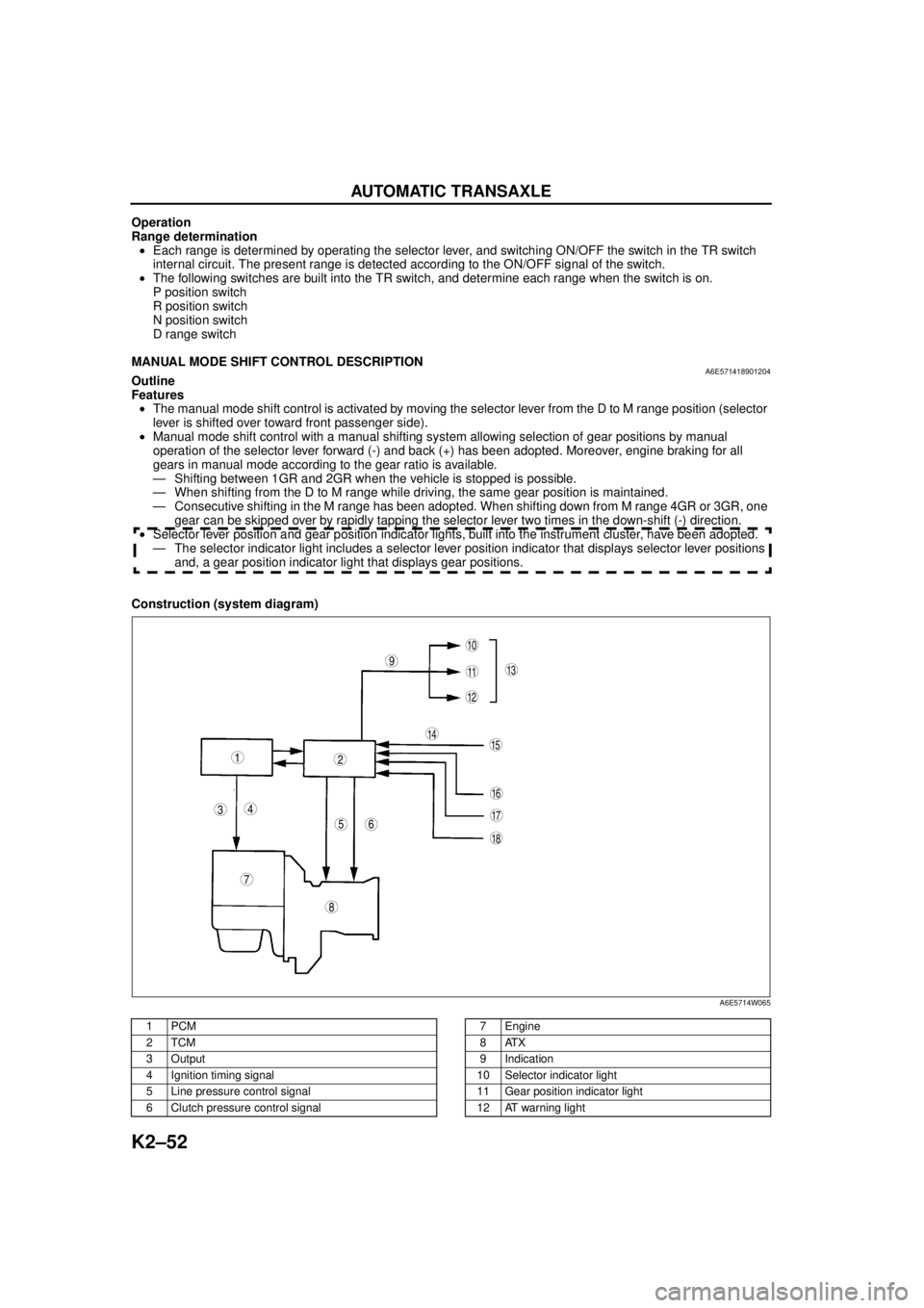

MANUAL MODE SHIFT CONTROL DESCRIPTIONA6E571418901204Outline

Features

•The manual mode shift control is activated by moving the selector lever from the D to M range position (selector

lever is shifted over toward front passenger side).

•Manual mode shift control with a manual shifting system allowing selection of gear positions by manual

operation of the selector lever forward (-) and back (+) has been adopted. Moreover, engine braking for all

gears in manual mode according to the gear ratio is available.

— Shifting between 1GR and 2GR when the vehicle is stopped is possible.

— When shifting from the D to M range while driving, the same gear position is maintained.

— Consecutive shifting in the M range has been adopted. When shifting down from M range 4GR or 3GR, one

gear can be skipped over by rapidly tapping the selector lever two times in the down-shift (-) direction.

•Selector lever position and gear position indicator lights, built into the instrument cluster, have been adopted.

— The selector indicator light includes a selector lever position indicator that displays selector lever positions

and, a gear position indicator light that displays gear positions.

Construction (system diagram)

.

9

8

7

5

43

12

10

18

17

15

16

14

1311

12

6

A6E5714W065

1PCM

2TCM

3Output

4 Ignition timing signal

5 Line pressure control signal

6 Clutch pressure control signal7Engine

8ATX

9 Indication

10 Selector indicator light

11 Gear position indicator light

12 AT warning light

Page 483 of 909

K2–68

AUTOMATIC TRANSAXLE

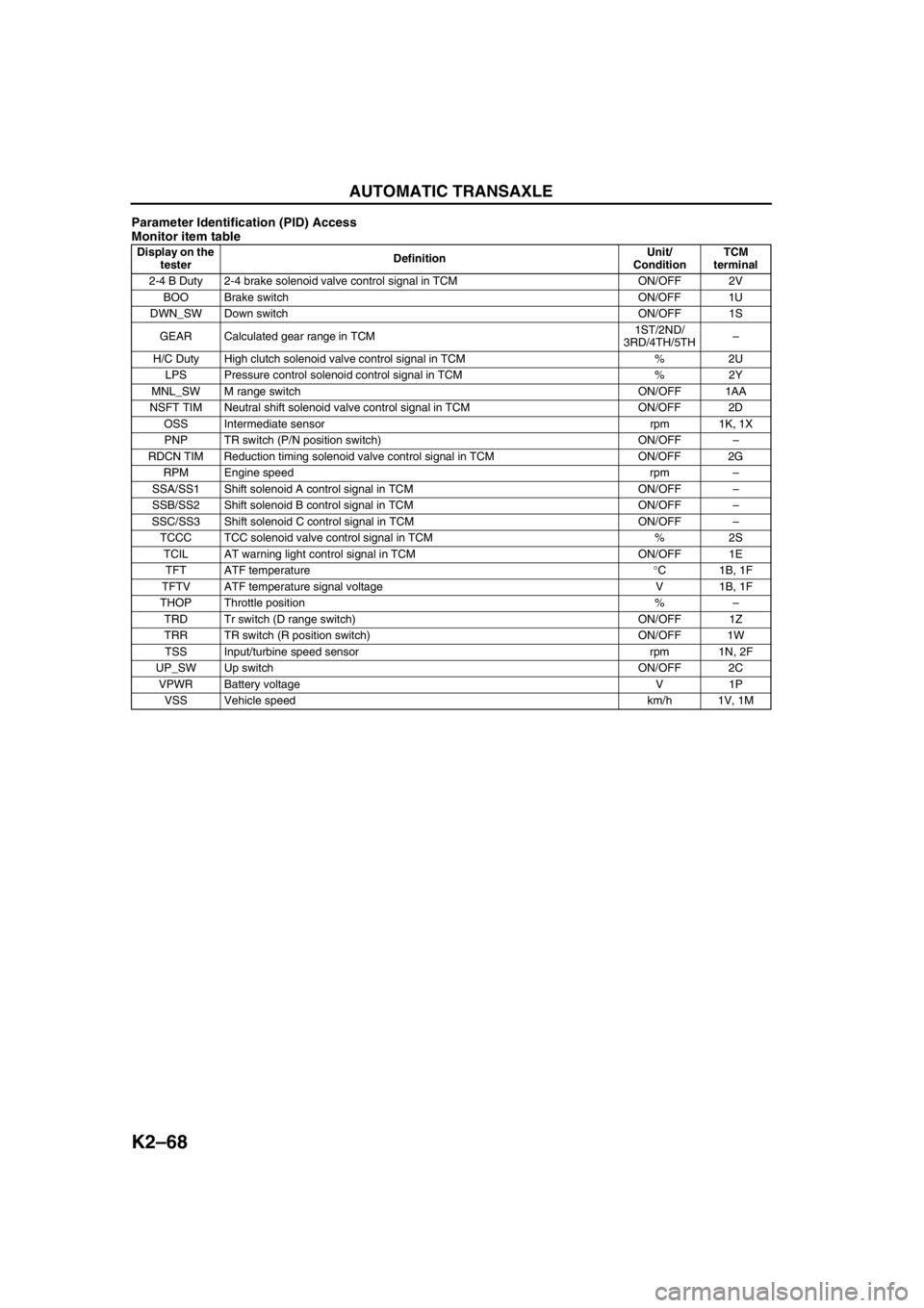

Parameter Identification (PID) Access

Monitor item table

End Of Sie

Display on the

testerDefinitionUnit/

ConditionTCM

terminal

2-4 B Duty 2-4 brake solenoid valve control signal in TCM ON/OFF 2V

BOO Brake switch ON/OFF 1U

DWN_SW Down switch ON/OFF 1S

GEAR Calculated gear range in TCM1ST/2ND/

3RD/4TH/5TH–

H/C Duty High clutch solenoid valve control signal in TCM % 2U

LPS Pressure control solenoid control signal in TCM % 2Y

MNL_SW M range switch ON/OFF 1AA

NSFT TIM Neutral shift solenoid valve control signal in TCM ON/OFF 2D

OSS Intermediate sensor rpm 1K, 1X

PNP TR switch (P/N position switch) ON/OFF–

RDCN TIM Reduction timing solenoid valve control signal in TCM ON/OFF 2G

RPM Engine speed rpm–

SSA/SS1 Shift solenoid A control signal in TCM ON/OFF–

SSB/SS2 Shift solenoid B control signal in TCM ON/OFF–

SSC/SS3 Shift solenoid C control signal in TCM ON/OFF–

TCCC TCC solenoid valve control signal in TCM % 2S

TCIL AT warning light control signal in TCM ON/OFF 1E

TFT ATF temperature°C1B, 1F

TFTV ATF temperature signal voltage V 1B, 1F

THOP Throttle position %–

TRD Tr switch (D range switch) ON/OFF 1Z

TRR TR switch (R position switch) ON/OFF 1W

TSS Input/turbine speed sensor rpm 1N, 2F

UP_SW Up switch ON/OFF 2C

VPWR Battery voltage V 1P

VSS Vehicle speed km/h 1V, 1M

Page 646 of 909

M–16

ELECTRONIC 4WD CONTROL SYSTEM

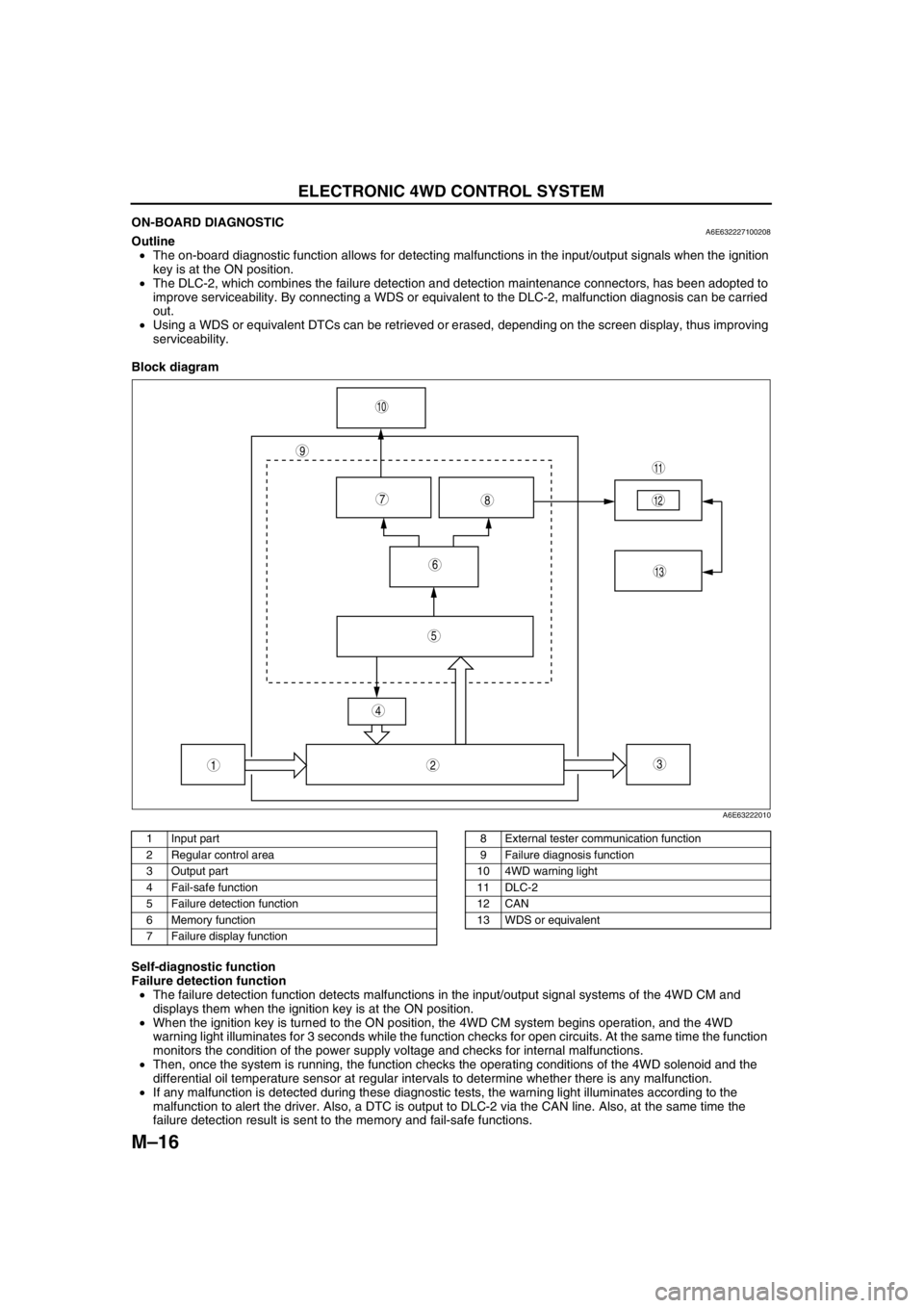

ON-BOARD DIAGNOSTICA6E632227100208Outline

•The on-board diagnostic function allows for detecting malfunctions in the input/output signals when the ignition

key is at the ON position.

•The DLC-2, which combines the failure detection and detection maintenance connectors, has been adopted to

improve serviceability. By connecting a WDS or equivalent to the DLC-2, malfunction diagnosis can be carried

out.

•Using a WDS or equivalent DTCs can be retrieved or erased, depending on the screen display, thus improving

serviceability.

Block diagram

.

Self-diagnostic function

Failure detection function

•The failure detection function detects malfunctions in the input/output signal systems of the 4WD CM and

displays them when the ignition key is at the ON position.

•When the ignition key is turned to the ON position, the 4WD CM system begins operation, and the 4WD

warning light illuminates for 3 seconds while the function checks for open circuits. At the same time the function

monitors the condition of the power supply voltage and checks for internal malfunctions.

•Then, once the system is running, the function checks the operating conditions of the 4WD solenoid and the

differential oil temperature sensor at regular intervals to determine whether there is any malfunction.

•If any malfunction is detected during these diagnostic tests, the warning light illuminates according to the

malfunction to alert the driver. Also, a DTC is output to DLC-2 via the CAN line. Also, at the same time the

failure detection result is sent to the memory and fail-safe functions.

9

87

5

4

3

10

13

11

12

6

12

A6E63222010

1 Input part

2 Regular control area

3 Output part

4 Fail-safe function

5 Failure detection function

6 Memory function

7 Failure display function8 External tester communication function

9 Failure diagnosis function

10 4WD warning light

11 DLC-2

12 CAN

13 WDS or equivalent

Page 647 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–17

M

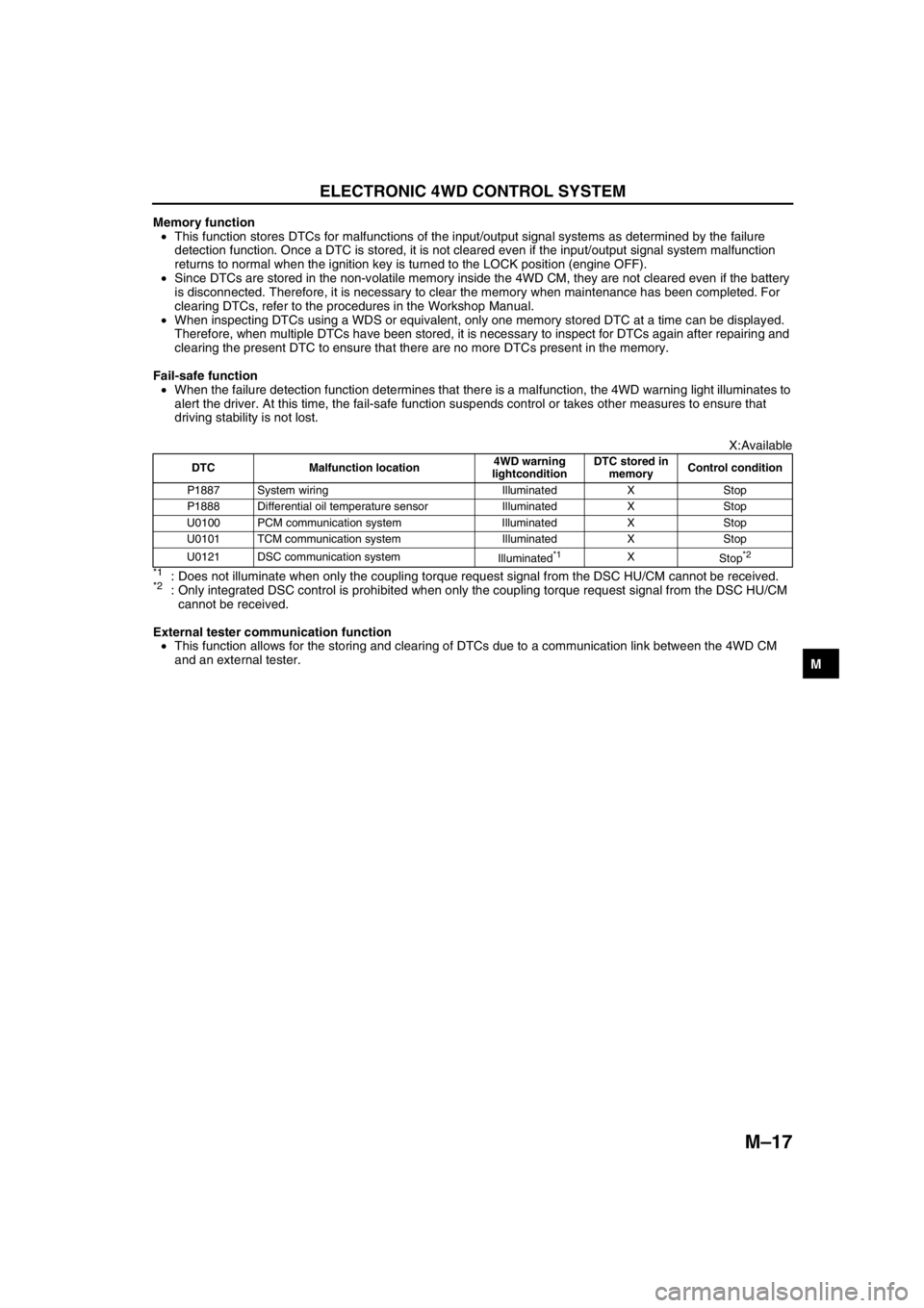

Memory function

•This function stores DTCs for malfunctions of the input/output signal systems as determined by the failure

detection function. Once a DTC is stored, it is not cleared even if the input/output signal system malfunction

returns to normal when the ignition key is turned to the LOCK position (engine OFF).

•Since DTCs are stored in the non-volatile memory inside the 4WD CM, they are not cleared even if the battery

is disconnected. Therefore, it is necessary to clear the memory when maintenance has been completed. For

clearing DTCs, refer to the procedures in the Workshop Manual.

•When inspecting DTCs using a WDS or equivalent, only one memory stored DTC at a time can be displayed.

Therefore, when multiple DTCs have been stored, it is necessary to inspect for DTCs again after repairing and

clearing the present DTC to ensure that there are no more DTCs present in the memory.

Fail-safe function

•When the failure detection function determines that there is a malfunction, the 4WD warning light illuminates to

alert the driver. At this time, the fail-safe function suspends control or takes other measures to ensure that

driving stability is not lost.

X:Available

*1: Does not illuminate when only the coupling torque request signal from the DSC HU/CM cannot be received.*2: Only integrated DSC control is prohibited when only the coupling torque request signal from the DSC HU/CM

cannot be received.

External tester communication function

•This function allows for the storing and clearing of DTCs due to a communication link between the 4WD CM

and an external tester.

End Of Sie

DTC Malfunction location4WD warning

lightconditionDTC stored in

memoryControl condition

P1887 System wiring Illuminated X Stop

P1888 Differential oil temperature sensor Illuminated X Stop

U0100 PCM communication system Illuminated X Stop

U0101 TCM communication system Illuminated X Stop

U0121 DSC communication system

Illuminated

*1X

Stop*2

Page 706 of 909

M–76

ON-BOARD DIAGNOSTIC

ELECTRONIC 4WD CONTROL SYSTEM ON-BOARD DIAGNOSISA6E637027100202Reading DTCs Procedure

1. Connect WDS or equivalent to the vehicle DLC-2

16-pin connector.

2. Retrieve DTC by WDS or equivalent.

•If a DTC is displayed, proceed with inspection

steps for that DTC.

3. After repair, clear DTCs stored in the 4WD CM by

referring to the Clearing DTCs Procedure.

Clearing DTCs Procedures

1. Connect WDS or equivalent to the vehicle DLC-2

16-pin connector.

2. Clear DTCs by WDS or equivalent.

3. Turn the ignition key to OFF.

4. Perform the DTC inspection again, and verify that

no DTC appears.

5. Disconnect the WDS or equivalent.

DTC Table

End Of Sie

DLC-2

DLC-2

L.H.D.

R.H.D.

A6E63702005

DLC-2

DLC-2

L.H.D.

R.H.D.

A6E63702005

DTC

Diagnosis system component Page

WDS or equivalent

P1887 System wiring (See M–77 DTC P1887)

P1888 Differential oil temperature sensor (See M–79 DTC P1888)

U0100 PCM communication (See M–80 DTC U0100)

U0101 TCM communication (See M–80 DTC U0101)

U0121 ABS/DSC communication (See M–80 DTC U0121)