Exhaust MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 62 of 1865

1 A ON-VEHICLE MAINTENANCE (VALVE SEAL)

Installation note

Valve seal

1. Apply engine oil to the inside of the new valve seal.

2. Push it on gently with the SST.

86U01X-049

Valve spring

Cylinder head side

Valve spring

1. (12-valve)

Install the valve spring with the narrower pitch to-

ward the cylinder head side.

(8-valve)

Install the outer valve spring with the narrower pitch

toward the cylinder head side.

2. Install the valve keepers, and tap the end of the

valve stem lightly two or three times with a plastic

hammer to confirm that the keepers are all fully

seated.

76G01A-038

12-valve Rocker arm, rocker arm shaft

1. Remove the rocker arm shafts and camshaft caps.

2. (12-valve)

Assemble the rocker arms and springs to the shaft.

Note

a) The intake side shaft has twice as many oil

holes as the exhaust side shaft.

b) The stepped ends are the rear sides of both

intake and exhaust shafts.

76G01A-039

(8-valve)

Assemble the camshaft caps, rocker arms, and

springs, to the shafts.

Caution

Be sure both rocker arm shaft oil holes (in the

center camshaft cap) face each other.

76G01A-040

1A—30

Page 67 of 1865

REMOVAL 1A

1. Battery and battery carrier 13. Three-way solenoid 22. P/S oil pump

2. Air cleaner assembly assembly 23. Engine side cover

3. High-tension lead 14. Canister hose (Fl, Middle 24. Front wheel

4. Accelerator cable East) 25. Tie-rod end

5. Throttle cable (ATX) 15. Heater hose 26. Stabilizer control rod

6. Fuel hose 16. Transaxle harness 27. Lower arm bushing

7. Radiator hose 17. Speedometer cable 28. Driveshaft

8. ATF hose (ATX) 18. Clutch release cylinder 29. Change rod (MTX)

9. Radiator harness (MTX) 30. Extension bar (MTX)

10. Radiator and cooling fan 19. Control cable (ATX) 31. Exhaust pipe

11. Engine harness 20. Drive belt 32. Engine mount

12. Brake vacuum hose 21. A/C compressor and 33. Engine and transaxle

bracket 34. Transaxle

76G01A-046

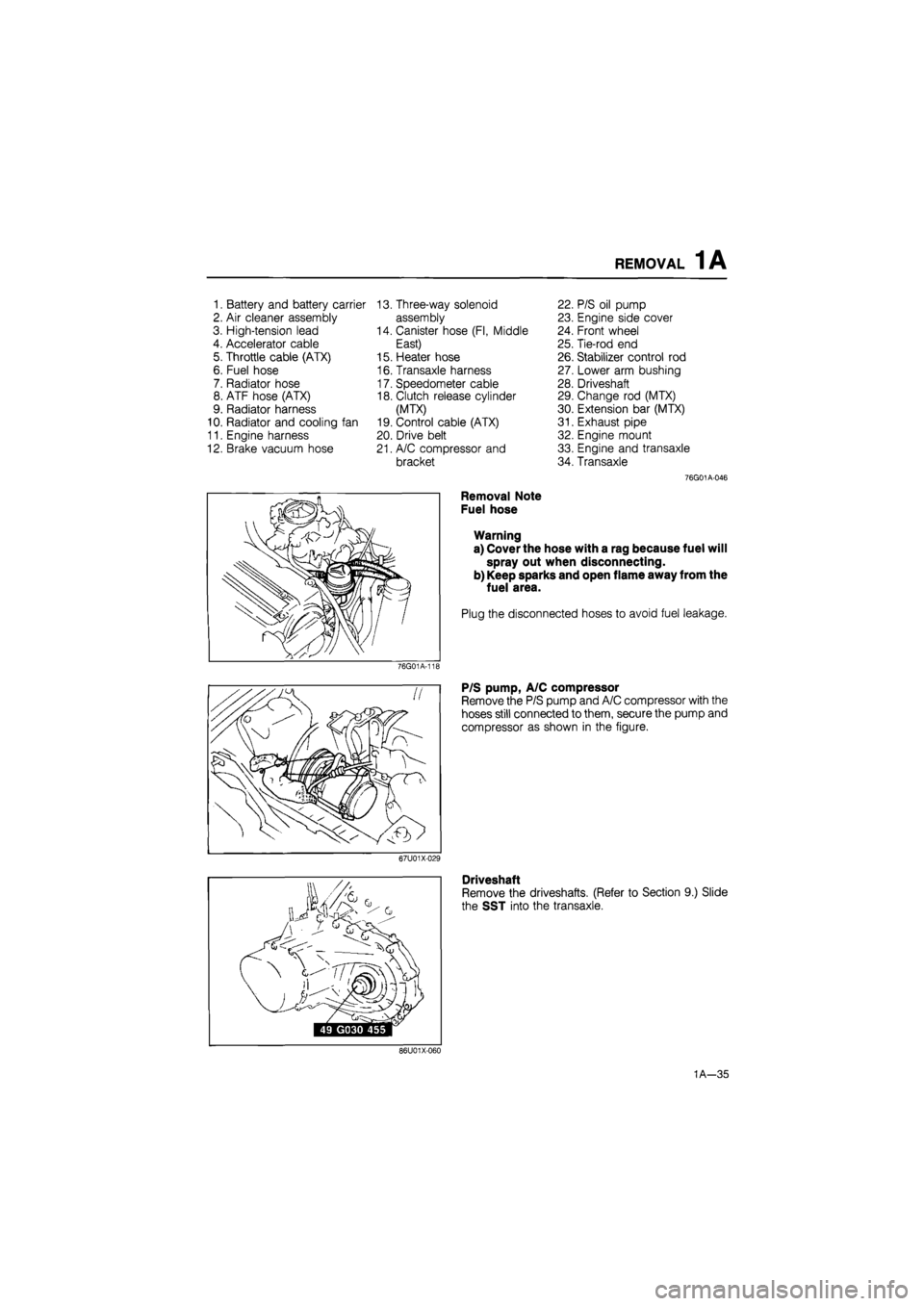

Removal Note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep sparks and open flame away from the

fuel area.

Plug the disconnected hoses to avoid fuel leakage.

76G01A-11E

P/S pump, A/C compressor

Remove the P/S pump and A/C compressor with the

hoses still connected to them, secure the pump and

compressor as shown in the figure.

67U01X-029

Driveshaft

Remove the driveshafts. (Refer to Section 9.) Slide

the SST into the transaxle.

86U01X-060

1A—35

Page 69 of 1865

DISASSEMBLY (AUXILIARY PARTS) 1 A

1. Oil level gauge

2. P/S oil pump bracket

3. Secondary air pipe assembly (except

General)

4. EGR pipe (Fl, Unleaded carb.)

5. Exhaust manifold insulator

6. Exhaust manifold assembly

7. Coolant inlet pipe and bypass pipe

8. Engine hanger

9. Alternator

10. Alternator strap and bracket

11. Engine mount bracket

12. Distributor and high-tension lead

13. Spark plug

14. Thermostat and thermostat cover

15. Intake manifold bracket (Fl)

16. Intake manifold assembly

17. Oil filter

18. Oil cooler (8-valve...only ECE, 12-valve)

19. Oil pressure switch

76G01A-047

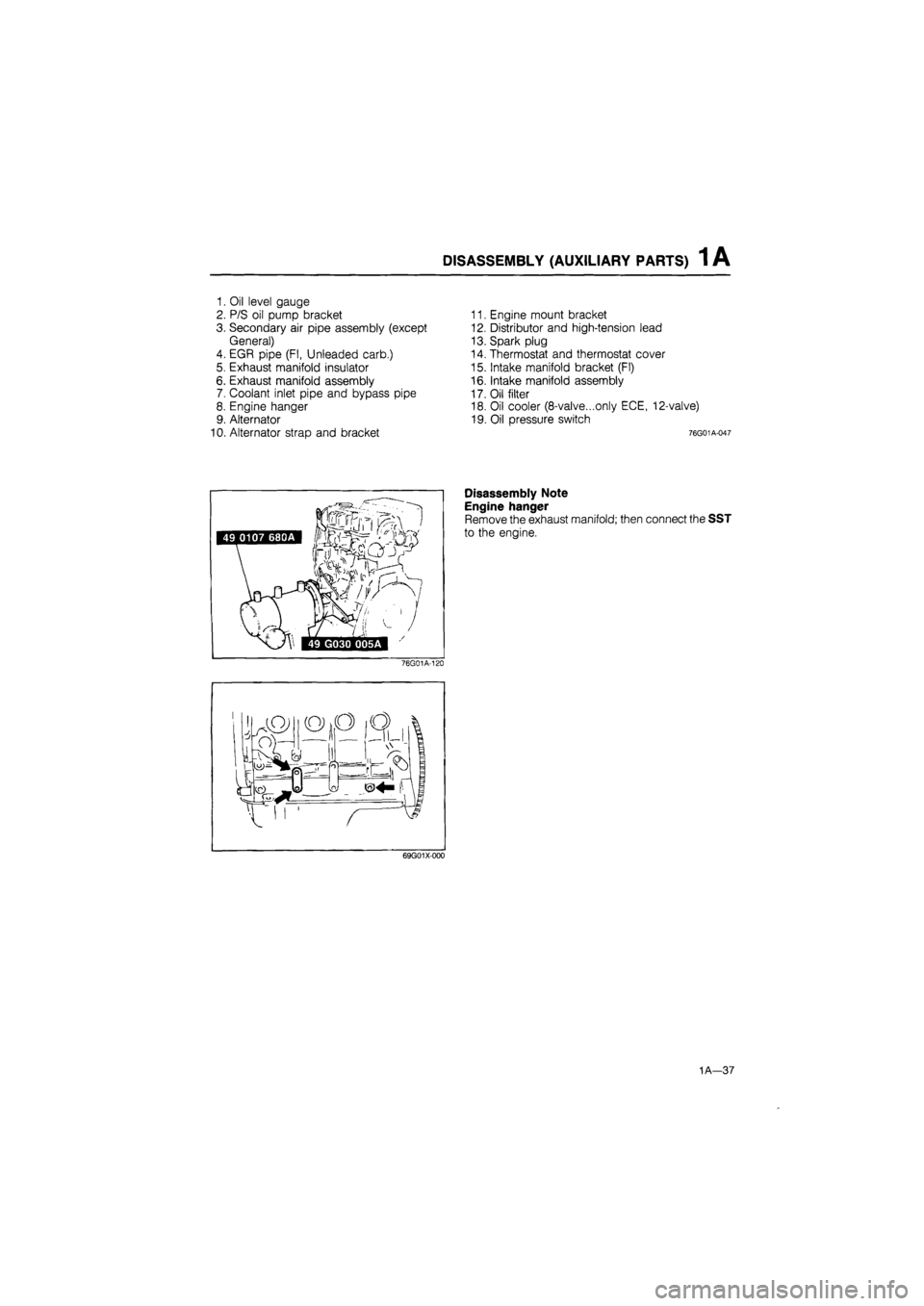

Disassembly Note

Engine hanger

Remove the exhaust manifold; then connect the SST

to the engine.

76G01A-120

69G01X-000

1A—37

Page 82 of 1865

INSPECTION AND REPAIR 1 A

86U01X-082

Valve guide

Cylinder head

76G01A-057

(2) Method No. 2

Measure the valve stem play at a point close

to the valve guide with the valve lifted slightly

off the valve seat.

Clearance

IN : 0.025—0.060 mm (0.0010—0.0024 in)

EX: 0.030—0.065 mm (0.0012—0.0026 in)

Maximum: 0.20 mm (0.0079 in)

7. If the clearance exceeds the maximum, replace the

valve and/or valve guide.

8. Check that the valve guide projection height

(dimension A in the figure). Replace if necessary.

Height:

19.8—20.3 mm (0.780—0.799 in)... 12-valve

19.1—19.6 mm (0.752—0.772 in)...8-valve

Replacement of valve guide

Note

Although the shapes of the intake and exhaust

valve guides are different, use the exhaust

valve guide on both sides as a replacement.

86U01X-214

Removal

1. Gradually heat the cylinder head in water to ap-

prox. 90°C (194°F).

76G01A-131

1A—50

Page 107 of 1865

ASSEMBLY (CYLINDER HEAD) 1 A

86U01X-148

86U01X-149

86U01X-150

Camshaft

1. Apply a liberal amount of engine oil to the journals

and bearings.

2. Place the camshaft in position with the dowel pin

facing straight up.

Hydraulic Lash Adjuster (HLA)

1. Pour engine oil into the oil reservoir in the rocker

arm.

2. Apply engine oil to the new HLA.

3. Carefully install the HLA into the rocker arm.

Caution

Be careful not to damage the O-ring when in-

stalling the HLA.

Camshaft Cap, Rocker Arm and Shaft Assembly

1. Assemble the rocker arm and shaft assembly as

shown in the figure.

Note

a) The intake side shaft has twice as many oil

holes as the exhaust side shaft.

b)The stepped ends are the rear of the shafts.

2. Apply silicon sealant to the shaded areas shown

in the figure.

76G01A-140

1 A—75

Page 122 of 1865

1 A ASSEMBLY (AUXILIARY PARTS)

76G01A-093

76G01A-094

76G01A-095

Exhaust Manifold Assembly

1. Place the new gaskets in position with the ridge

facing the cylinder head.

2. Install the exhaust manifold assembly.

3. Tighten the nuts in two or three steps.

Tightening torque:

34—49

N

m (3.5—5.0 m-kg, 25—36 ft-lb)

Exhaust Manifold Insulator

Install the exhaust manifold insulator.

Tightening torque:

19—30

N

m (1.9—3.1 m-kg, 14—22 ft-lb)

EGR Pipe

Install the EGR pipe.

Tightening torque:

34—44 Nm (3.5—4.5 m-kg, 25—33 ft-lb)

Secondary Air Pipe Assembly

Install the secondary air pipe assembly.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

P/S Oil Pump Bracket

Install the P/S oil pump bracket.

Tightening torque:

37—63 Nm (3.8—6.4 m-kg, 27—46 ft-lb)

86U01X-178

1A—90

Page 125 of 1865

INSTALLATION 1A

Engine Mount

Install the engine mount.

76G01A-096

86U01X-181

Exhaust Pipe

1. Install the exhaust pipe.

Tightening torque

31—46

N

m

(3.2—4.7 m-kg, 23—34 ft-lb)

(§): 64—89

N

m

(6.5—9.1 m-kg, 47—66 ft-lb)

2. Tighten the bracket bolt.

Tightening torque:

19—25 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

Extension Bar (MTX)

Install the extension bar to the transaxle.

Tightening torque:

31—46

N

m (3.2—4.7 m-kg, 23—34 ft-lb)

Change Rod (MTX)

Install the change rod to the transaxle.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

1A—93

Page 135 of 1865

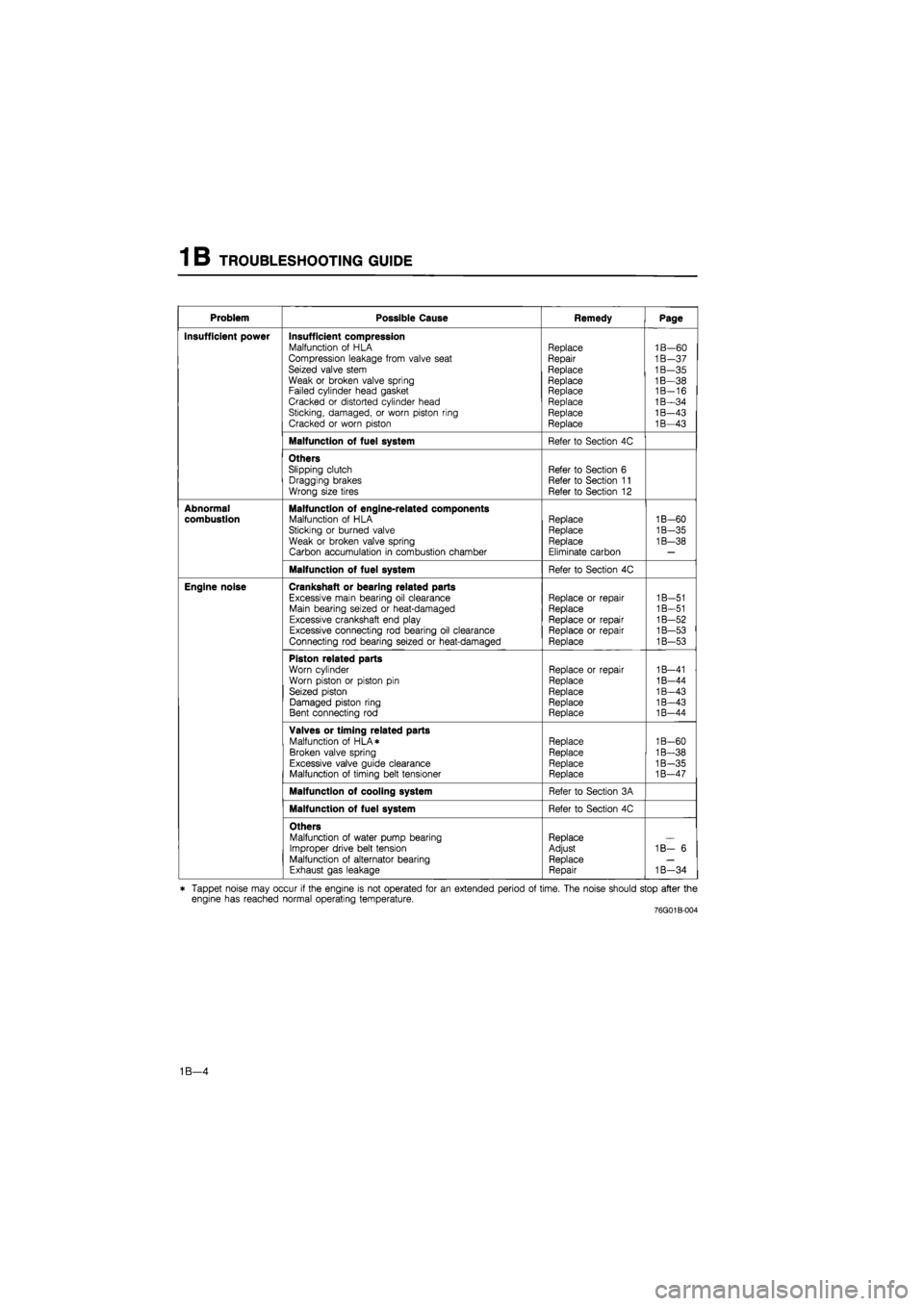

TROUBLESHOOTING GUIDE 1 B

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Malfunction of HLA Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Replace Repair

Replace

Replace Replace Replace Replace Replace

1B—60 1B—37 1B—35 1B—38 1B-16 1B—34 1B—43 1B—43

Malfunction of fuel system Refer to Section 4C

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal combustion Malfunction of engine-related components Malfunction of HLA Sticking or burned valve

Weak or broken valve spring Carbon accumulation in combustion chamber

Replace Replace Replace

Eliminate carbon

1B-60

1B-35

1B—38

Malfunction of fuel system Refer to Section 4C

Engine noise Crankshaft or bearing related parts

Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1B-51 1B—51 1B—52 1B—53 1B—53

Piston related parts

Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair

Replace

Replace Replace Replace

1B—41 1B-44 1B—43 1B—43 1B-44

Valves or timing related parts Malfunction of HLA* Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Replace Replace Replace Replace

1B-60 1B—38 1B—35 1B—47

Malfunction of cooling system Refer to Section 3A

Malfunction of fuel system Refer to Section 4C

Others Malfunction of water pump bearing Improper drive belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1B— 6

1B—34

* Tappet noise may occur if the engine is not operated for an extended period of time. The noise should stop after the engine has reached normal operating temperature. 76G01B-004

1B—4

Page 140 of 1865

TUNE-UP PROCEDURE 1 B

76G01B-015

6. If necessary, adjust the ignition timing by turning

the distributor.

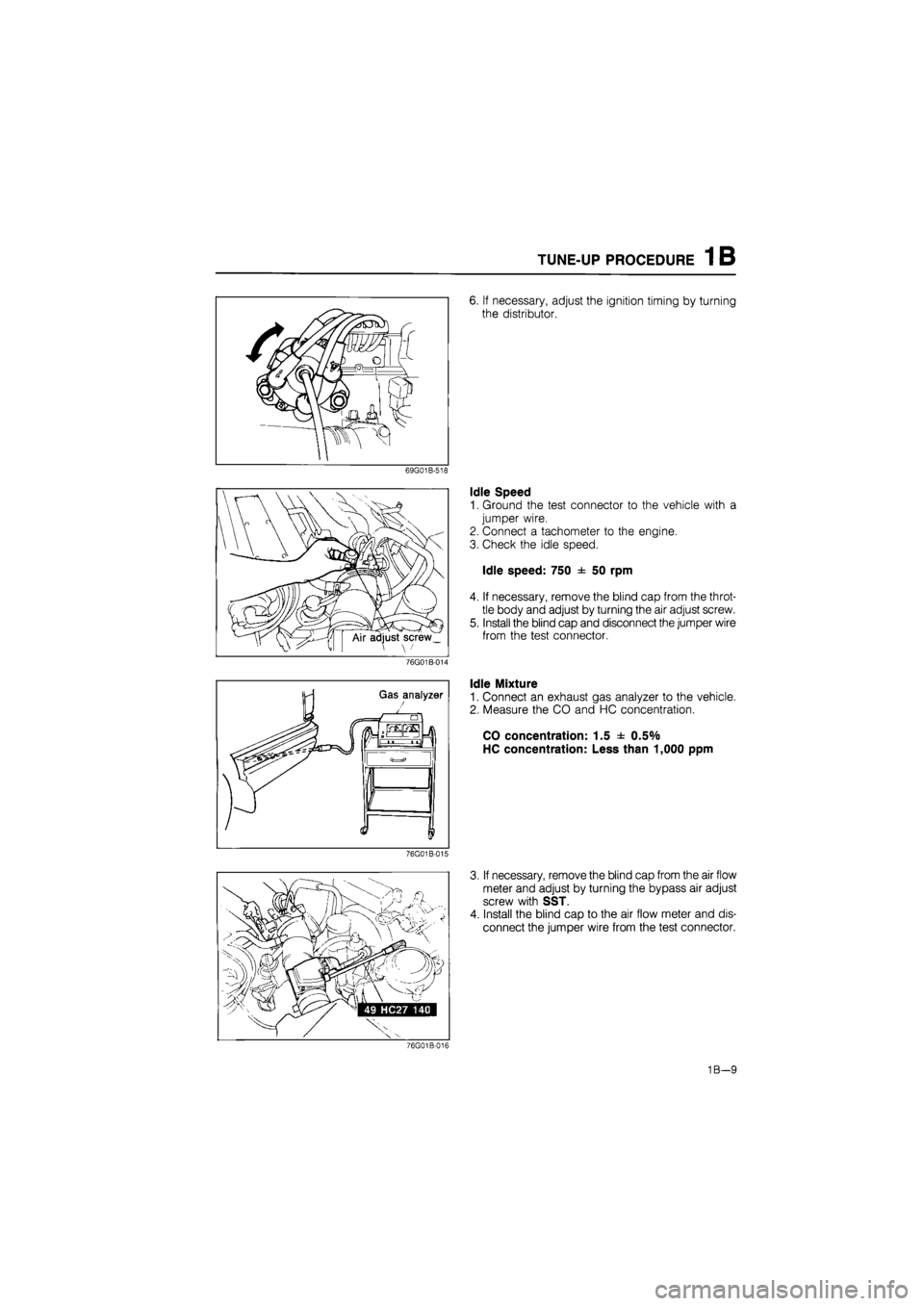

Idle Speed

1. Ground the test connector to the vehicle with a

jumper wire.

2. Connect a tachometer to the engine.

3. Check the idle speed.

Idle speed: 750 ± 50 rpm

4. If necessary, remove the blind cap from the throt-

tle body and adjust by turning the air adjust screw.

5. Install the blind cap and disconnect the jumper wire

from the test connector.

Idle Mixture

1. Connect an exhaust gas analyzer to the vehicle.

2. Measure the CO and HC concentration.

CO concentration: 1.5 ± 0.5%

HC concentration: Less than 1,000 ppm

3. If necessary, remove the blind cap from the air flow

meter and adjust by turning the bypass air adjust

screw with SST.

4. Install the blind cap to the air flow meter and dis-

connect the jumper wire from the test connector.

76G01B-016

1B—9

Page 141 of 1865

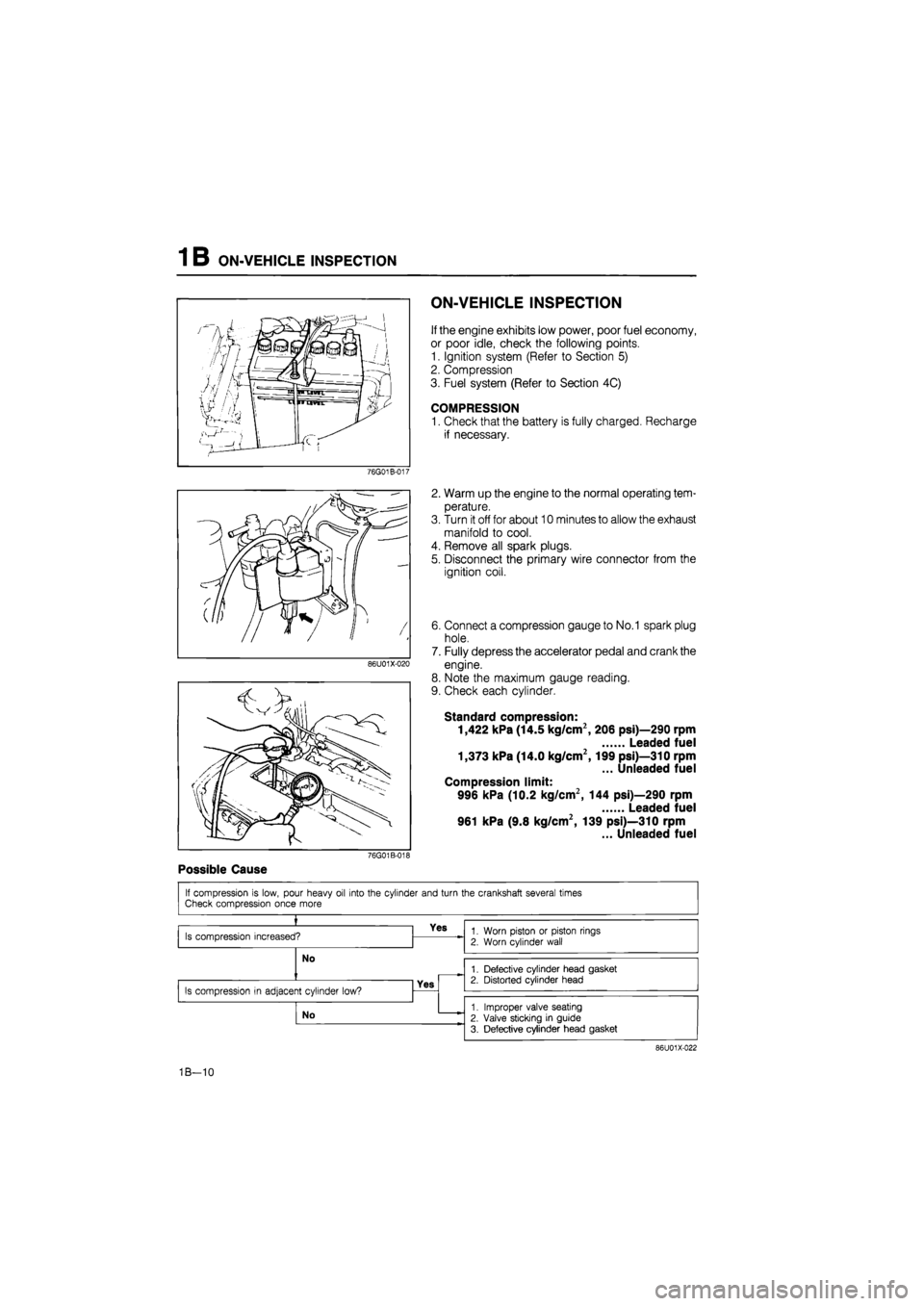

1 B ON-VEHICLE INSPECTION

76G01B-017

86U01X-020

76G01B-018

Possible Cause

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following points.

1. Ignition system (Refer to Section 5)

2. Compression

3. Fuel system (Refer to Section 4C)

COMPRESSION

1. Check that the battery is fully charged. Recharge

if necessary.

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all spark plugs.

5. Disconnect the primary wire connector from the

ignition coil.

6. Connect a compression gauge to No.1 spark plug

hole.

7. Fully depress the accelerator pedal and crank the

engine.

8. Note the maximum gauge reading.

9. Check each cylinder.

Standard compression:

1,422 kPa (14.5 kg/cm2, 206 psi)—290 rpm

Leaded fuel

1,373 kPa (14.0 kg/cm2,199 psi)—310 rpm

... Unleaded fuel

Compression limit:

996 kPa (10.2 kg/cm2, 144 psi)—290 rpm

Leaded fuel

961 kPa (9.8 kg/cm2, 139 psi)—310 rpm

... Unleaded fuel

If compression is low, pour heavy oil into the cylinder and turn the crankshaft several times Check compression once more

»

Is compression increased? Yes 1. Worn piston or piston rings

2. Worn cylinder wall

No

1. Worn piston or piston rings

2. Worn cylinder wall

No 1. Defective cylinder head gasket 2. Distorted cylinder head

Is compression in adjacent cylinder low? Yes

1. Defective cylinder head gasket 2. Distorted cylinder head

Is compression in adjacent cylinder low?

No 1. Improper valve seating

2. Valve sticking in guide

3. Defective cylinder head gasket

86U01X-022

1B—10