MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1 of 1865

Mazda

expert22 fl/ia http://rutracker.org

787

Page 2 of 1865

Mazda

626

Workshop

Manual

FOREWORD

This workshop manual is intended for use

by service technicians of authorized Mazda

dealers to help them service Mazda vehicles.

This manual can be also useful in diagnosing

certain problems and performing some repair

and maintenance on Mazda vehicles.

For proper repair and maintenance, it is im-

portant to be thoroughly familiarized with this

manual. It is recommended that this manual al-

ways be kept in a handy place for quick and

easy reference.

All the contents of this manual, including pho-

tographs, drawings, and specifications, are the

latest available at the time of printing. As modifi-

cations affecting repair or maintenance occur,

relevant information supplementary to this

volume will be made available at Mazda deal-

ers. This manual should be kept up-to-date.

Mazda Motor Corporation reserves the right

to alter the specifications and contents of this

manual without obligation or advance notice.

All rights reserved. No part of this book may

be reproduced or utilized in any form or by any

means, electronic or mechanical, including

photocopying, recording, or by any informa-

tion storage and retrieval system, without per-

mission in writing.

Mazda Motor Corporation

HIROSHIMA JAPAN

Refer to the following wiring diagrams if

necessary.

Refer to From No.

5095-10-87 G L.H.D.

5096-10-87 G R.H.D.

5096-20-871 Germany

5095-30-871 French

CONTENTS

Title Section

General Information G

Pre-Delivery Inspection and Scheduled

Maintenance 0

Gasoline F6, F8, FE 1A

Engine

Gasoline

FE (DOHC) 1B

Diesel RF-CX, RF-N 1C

Lubrication System

Gasoline 2A

Lubrication System

Diesel 2B I

Cooling System

Gasoline 3A 1

Cooling System

Diesel 3B

Carburetor F6, F8, FE 4A

Fuel and Emission Fuel FE 4B I

Control Systems Injection FE (DOHC) 4C

Diesel RF-CX, RF-N 4D j

Engine Electrical System 5

Clutch 6

Manual 7A

Transaxle

Automatic

EC-AT

and

4-Speed

7B

3-Speed 7C

Front and Rear Axles 9

Steering System 10

Braking System 11

Wheels and Tires 12

Suspension 13

Body 14 |

Body Electrical System 15

Air Conditioning System 16

Technical Data 30

Special Tools 40

© 1987 Mazda Motor Corporation

PRINTED IN JAPAN, JULY'87 ©

1163-10-87G

expert22 flna http://rutracker.org

Page 3 of 1865

GENERAL INFORMATION

IMPORTANT INFORMATION G— 2

FUNDAMENTAL PROCEDURES G— 2

JACK AND SAFETY STAND (RIGID RACK)

POSITIONS G— 6

VEHICLE LIFT (2-SUPPORT TYPE)

POSITIONS G- 7

TOWING G— 8

CHASSIS NUMBER LOCATION G— 9

ENGINE MODEL AND NUMBER

LOCATION G— 9

UNITS G— 9

ABBREVIATIONS G— 9

CAUTION G—10 76G0GX-001

Page 4 of 1865

G IMPORTANT INFORMATION/FUNDAMENTAL PROCEDURES

IMPORTANT INFORMATION

BASIC ASSUMPTIONS

This workshop manual assumes that you have arid know how to properly use certain special tools

which are necessary for the safe and efficient performance of service operations on Mazda vehicles.

The manual also assumes that you are familiar generally with automobile systems and basic service

and repair procedures. You should not attempt to use this manual unless these assumptions are cor-

rect and you understand the consequences described below.

SAFETY RISK

This manual contains certain notes, warnings, etc., which you should carefully read and follow in or-

der to eliminate the risk of personal injury to yourself or others and the risk of improper service which

may damage the vehicle or render it unsafe. The fact that there are no such notes, etc., with respect

to any specific service method does not mean that there is no possibility that personal safety or vehicle

safety will be jeopardized by the use of incorrect methods or tools.

POSSIBLE LOSS OF WARRANTY

The manufacturer's warranty on Mazda vehicles and engines can be voided if improper service or

repairs are performed by persons other than an authorized Mazda dealer.

FUNDAMENTAL PROCEDURES

As you read through the procedure, you will come

across NOTES, CAUTIONS, and WARNINGS. Each

one is there for a specific purpose. NOTES give you

added information that will help you to complete a

particular procedure. CAUTIONS are given to pre-

vent you from making an error that could damage

the vehicle. WARNINGS remind you to be espe-

cially careful in those areas where carelessness can

cause personal injury. The following list contains

some general WARNINGS that you should follow

when you work on a vehicle.

PROTECTION OF THE VEHICLE

Always be sure to cover fenders, seats, and floor

areas before starting work.

A WORD ABOUT SAFETY

The following precautions must be followed when

jacking up the vehicle.

1. Block wheels.

2. Use only specified jacking positions.

3. Support vehicle with safety stands (rigid racks).

Start the engine only after making certain the engine

compartment is clear of tools and people.

G—2 expert22 fl/i* http://rutracker.org

Page 5 of 1865

FUNDAMENTAL PROCEDURES G

PREPARATION OF TOOLS AND MEASURING

EQUIPMENT

Be sure that all necessary tools and measuring equip-

ment are available before starting any work activity.

47U0GX-004

SPECIAL TOOLS

Use special tools when they are required.

47U0GX-005

REMOVAL OF PARTS

While correcting a problem, try also to determine its

cause. Begin work only after first learning which parts

and subassemblies must be removed and disassem-

bled for replacement or repair.

47U0GX-006

DISASSEMBLY

If the disassembly procedure is complex, requiring

many parts to be disassembled, all parts should be

disassembled in a way that will not affect their per-

formance or external appearance, and be identified

so that reassembly can be performed easily and effi-

ciently.

47U0GX-007

G—3

l

Page 6 of 1865

G FUNDAMENTAL PROCEDURES

DISASSEMBLY

1. Inspection of parts

Each part when removed should be carefully inspect-

ed for malfunctioning, deformation, damage, and

other problems.

2. Arrangement of parts

All disassembled parts should be carefully arranged

for reassembly.

Be sure to separate or otherwise identify the parts to

be replaced from those that will be reused.

3. Cleaning parts for reuse

All parts to be reused should be carefully and

thoroughly cleaned in the appropriate method.

REASSEMBLY

Standard values, such as torques and certain adjust-

ments, must be strictly observed in the reassembly

of all parts.

If removed, these parts should be replaced with new

ones:

1. Oil seals

2. Gasket

3. O-rings

4. Lock washers

5. Cotter pins (split pins)

6. Nylon nuts

G—4

Page 7 of 1865

FUNDAMENTAL PROCEDURES G

Depending on where they are;

1. Sealant should be applied to gaskets

2. Oil should be applied to the moving components

of parts

3. Specified oil or grease should be applied at the

prescribed locations (oil seals, etc.) before as-

sembly.

47U0GX-012

ADJUSTMENTS

Use suitable gauges and/or testers when making var-

ious adjustments.

67U0GX-002

ELECTRICAL SYSTEM

Be sure to disconnect the battery cable from the nega-

tive (-) terminal of the battery.

Never pull on the wiring when disconnecting con-

nectors.

When locking connectors, make sure to listen for a

click that will let you know they are securely locked.

Handle sensors and relays carefully. Be careful not

to drop them or strike them against other parts.

47U0GX-014

RUBBER PARTS AND TUBING

Always prevent gasoline or oil from getting on rub-

ber parts or tubing.

47U0GX-015

G—5

Page 8 of 1865

G

JACK AND

SAFETY STAND

(RIGID RACK)

POSITIONS

JACK AND SAFETY STAND

(RIGID RACK)

POSITIONS

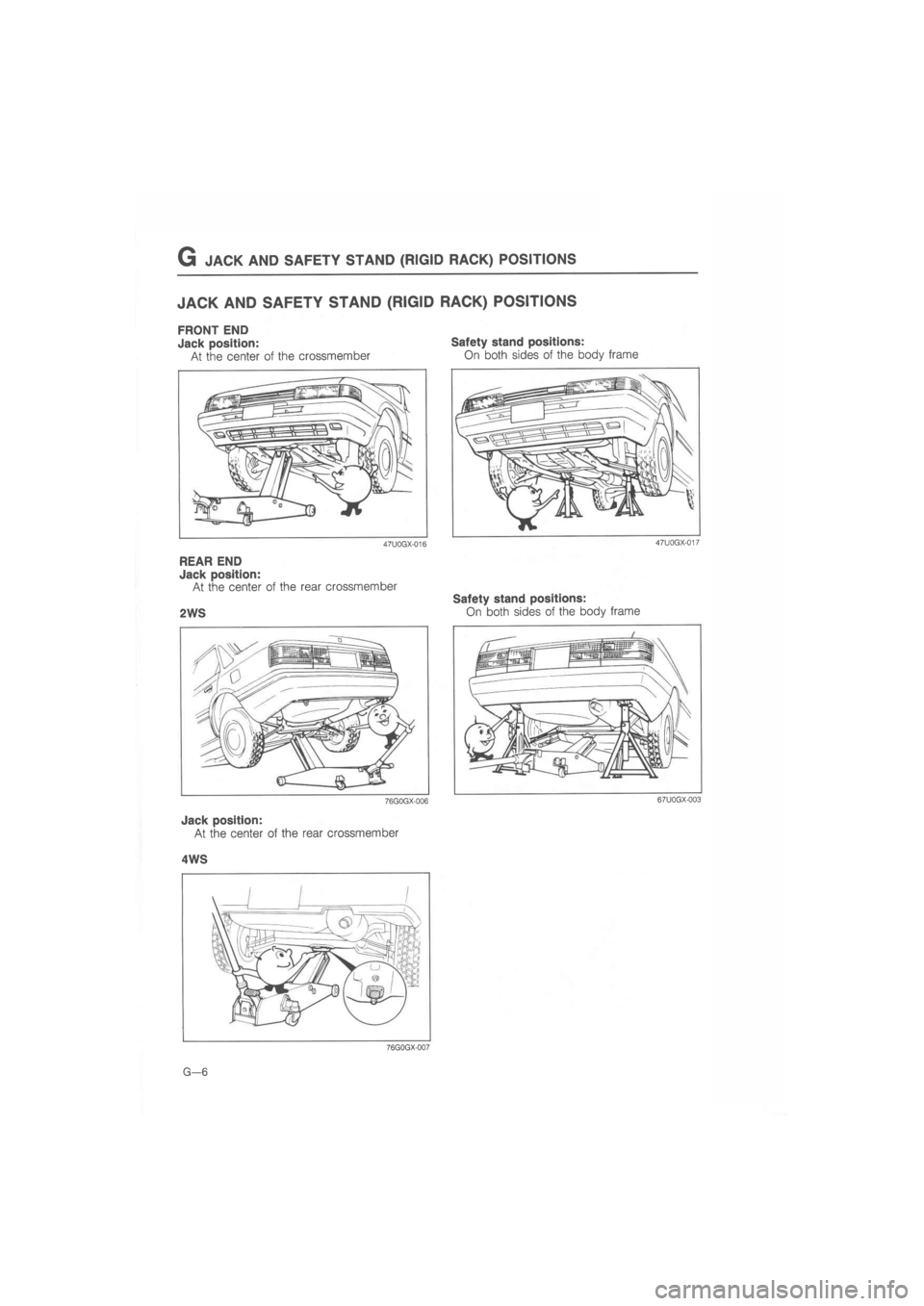

FRONT END

Jack position:

At the center of the crossmember

Safety stand positions:

On both sides of the body frame

47U0GX-017 47U0GX-016

REAR END

Jack position:

At the center of the rear crossmember

2WS

76G0GX-006

Jack position:

At the center of the rear crossmember

Safety stand positions:

On both sides of the body frame

4WS

76G0GX-007

G—6

Page 9 of 1865

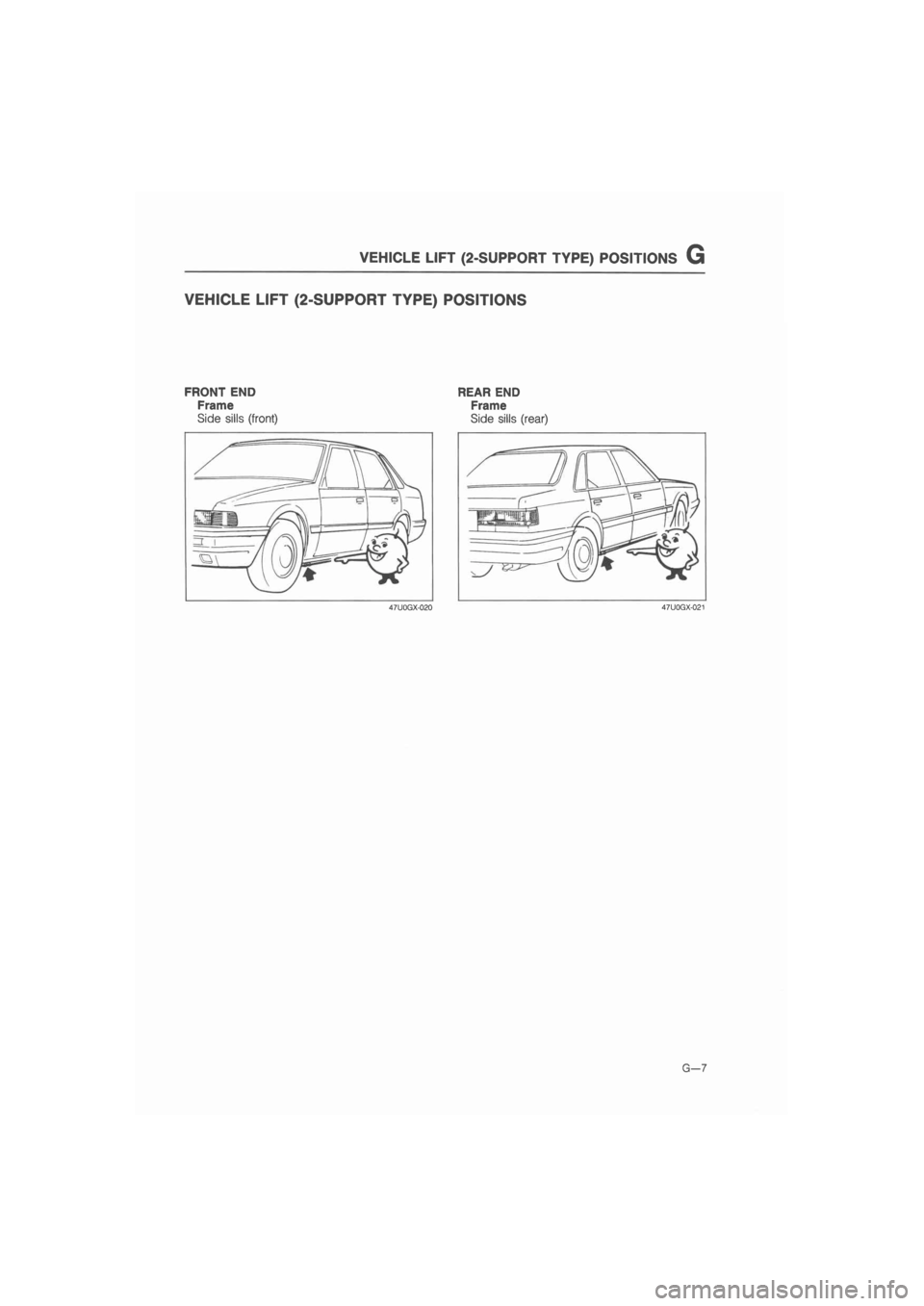

VEHICLE LIFT (2-SUPPORT TYPE)

POSITIONS G

VEHICLE

LIFT

(2-SUPPORT

TYPE)

POSITIONS

FRONT END

Frame

Side sills (front)

REAR END

Frame

Side sills (rear)

47U0GX-020 47U0GX-021

G—7

Page 10 of 1865

G TOWING

76GOGX-OQ2

i-^C.

y -

- r^jfftj&H

r —I

76UQGX-003

86U0GX-004

G—8

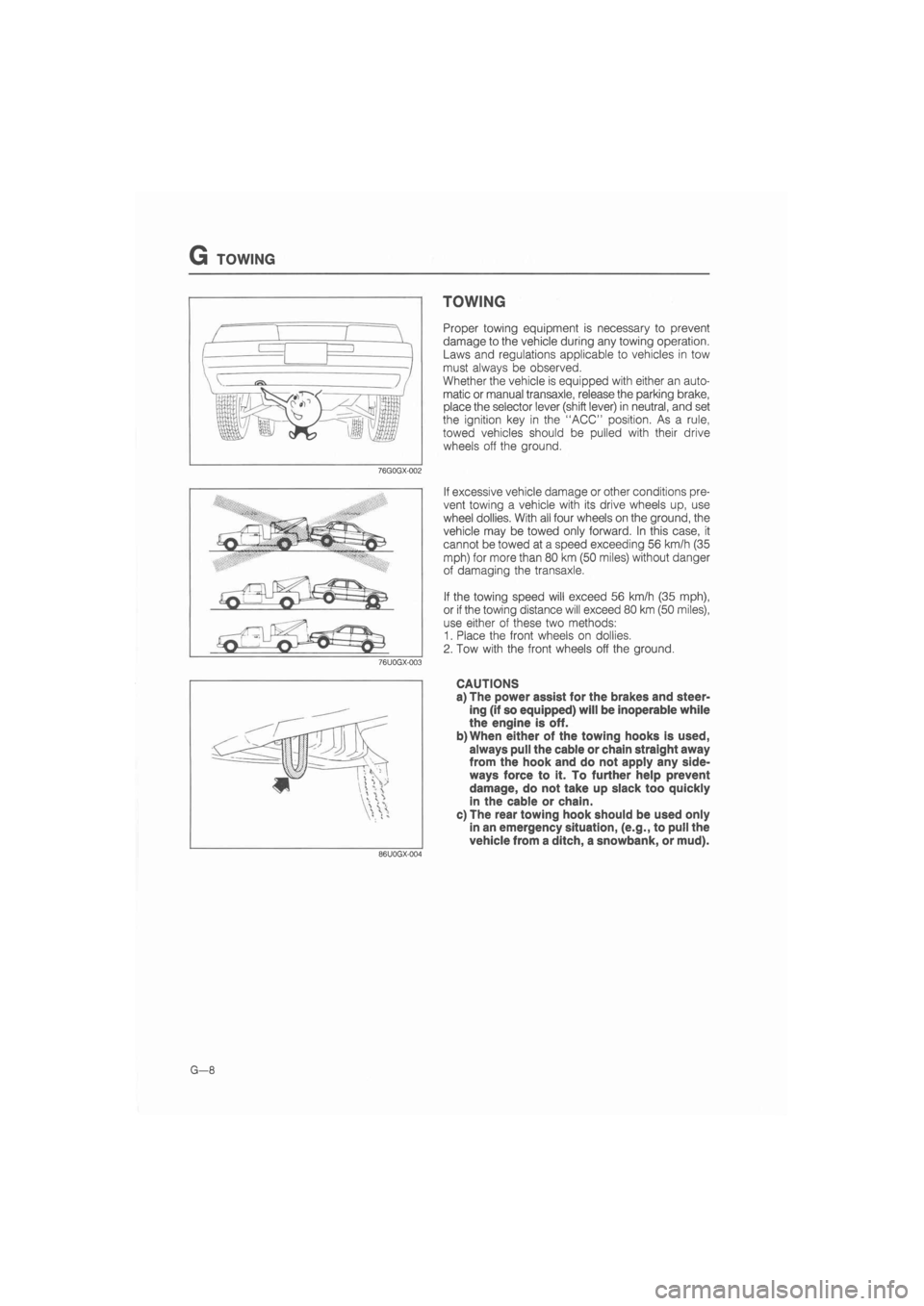

TOWING

Proper towing equipment is necessary to prevent

damage to the vehicle during any towing operation.

Laws and regulations applicable to vehicles in tow

must always be observed.

Whether the vehicle is equipped with either an auto-

matic or manual transaxle, release the parking brake,

place the selector lever (shift lever) in neutral, and set

the ignition key in the "ACC" position. As a rule,

towed vehicles should be pulled with their drive

wheels off the ground.

If excessive vehicle damage or other conditions pre-

vent towing a vehicle with its drive wheels up, use

wheel dollies. With all four wheels on the ground, the

vehicle may be towed only forward. In this case, it

cannot be towed at a speed exceeding 56 km/h (35

mph) for more than 80 km (50 miles) without danger

of damaging the transaxle.

If the towing speed will exceed 56 km/h (35 mph),

or if the towing distance will exceed 80 km (50 miles),

use either of these two methods:

1. Place the front wheels on dollies.

2. Tow with the front wheels off the ground.

CAUTIONS

a) The power assist for the brakes and steer-

ing (if so equipped) will be inoperable while

the engine is off.

b)When either of the towing hooks is used,

always pull the cable or chain straight away

from the hook and do not apply any side-

ways force to it. To further help prevent

damage, do not take up slack too quickly

in the cable or chain.

c) The rear towing hook should be used only

in an emergency situation, (e.g., to pull the

vehicle from a ditch, a snowbank, or mud).