run flat MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 754 of 1865

5 STARTER (GASOLINE ENGINE, 1.4 KW TYPE)

86U05X-034

Snap ring

Internal gear

Drive pinion I Gear shaft

r i

rt

n I I Washer

OC

Stopper

7BU05X-037

Overrunning Clutch Stopper

1. Remove the overrunning clutch stopper using a

pipe.

2. Disassemble the drive pinion, internal gear and

washer from the gear shaft.

Brush and Brush Holder

Remove the brush from the brush holder using a flat-

tip screwdriver.

7BU05X-038

5-48

Page 760 of 1865

5 STARTER (GASOLINE ENGINE, 1.4 KW TYPE)

7BU05X-048

86U05X-038

7BU05X-050

Installation of Brush Holder

Install the brush holder assembly and rear cover and

align the through bolts.

CHECKING OPERATION

Magnetic Switch

Make the following tests:

Pull-out test

1. Check that the pinion is pulled out when 12V is con-

nected to the S terminal and the body is grounded.

2. Measure the pinion gap while the pinion is pulled

out.

Specification: 0.5—2.0 mm (0.02—0.08 in)

3. Adjust the pinion gap with an adjust washer (drive

housing front cover—magnetic switch) if it is not

within specification.

Return test

1. Disconnect the motor wire from the M terminal, and

then connect the battery power to the M terminal

and ground the body.

2. Pull out the overrunning clutch with a flat-tip screw-

driver. Check that the overrunning clutch returns

to its original position when released.

86U05X-039

5-54

Page 937 of 1865

ON-VEHICLE MAINTENANCE 7B

ON-VEHICLE MAINTENANCE

AUTOMATIC TRANSAXLE FLUID (ATF)

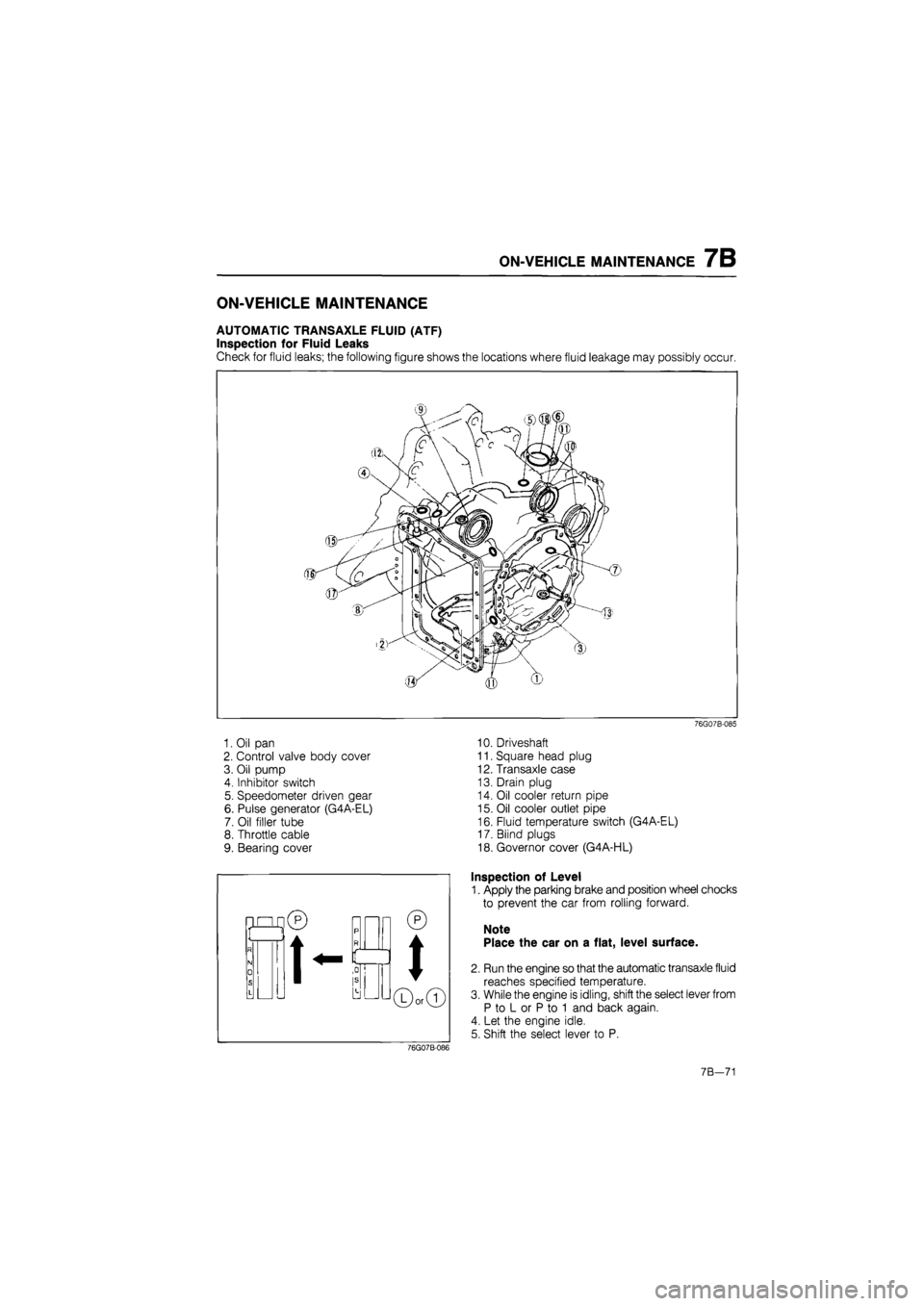

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Oil pan

2. Control valve body cover

3. Oil pump

4. Inhibitor switch

5. Speedometer driven gear

6. Pulse generator (G4A-EL)

7. Oil filler tube

8. Throttle cable

9. Bearing cover

76G07B-085

10. Driveshaft

11. Square head plug

12. Transaxle case

13. Drain plug

14. Oil cooler return pipe

15. Oil cooler outlet pipe

16. Fluid temperature switch (G4A-EL)

17. Blind plugs

18. Governor cover (G4A-HL)

Inspection of Level

1. Apply the parking brake and position wheel chocks

to prevent the car from rolling forward.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches specified temperature.

3. While the engine is idling, shift the select lever from

P to L or P to 1 and back again.

4. Let the engine idle.

5. Shift the select lever to P.

76G07B-086

7B—71

Page 1139 of 1865

ON-VEHICLE MAINTENANCE 7C

ON-VEHICLE MAINTENANCE

AUTOMATIC TRANSAXLE FLUID (ATF)

Inspection for Fluid Leaks

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Kick-down solenoid

2. Vacuum diaphragm

3. Manual shaft

4. Speedometer driven gear

5. Oil level tube

6. Governor cover

7. Governor

8. Oil pan

9. Oil pump

10. Inhibitor switch

11. Transaxle case

12. Oil pump

13. Square head plugs

14. Bearing cover

15. Drive shaft

76G07C-041

©

i

©

[JdQ©

I

Inspection of Level

1. Apply the parking brake and block the wheels to

prevent the vehicle from rolling.

Note

Place the car on a flat, level surface.

2. Run the engine so that the automatic transaxle fluid

reaches operating temperature.

3. While the engine is idling, shift the select lever from

P to 1 and back again.

4. Let the engine idle.

5.Shift the select lever to P.

76G07C-042

7C-25

Page 1547 of 1865

1 3 FRONT WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT

86U13X-108

69G10X-031

Pre-inspection

1. Check the tire inflation and bring to the recom-

mended pressure.

2. Inspect the front wheel bearing play and correct,

it if necessary.

3. Inspect the wheel and tire runout.

4. Inspect the ball joints and steering linkage for any

excessive looseness.

5. The vehicle must be on level ground and have no

luggage or passenger load.

6. The difference in height between the left and right

sides from the center of the wheel to the fender

brim must be within 10 mm (0.39 in).

Caution

a) Front and rear wheel alignment should be

checked simultaneously. If adjustment is

made to either the front or rear wheels,

recheck the alignment, particularly toe-in,

on all other wheels.

b) Check and adjust the steering angle trans-

fer shaft after adjusting the front wheel

alignment. (Refer to Section 10)

TOE-IN

Inspection

1. Raise the front of the vehicle until the wheels clear

the ground.

2. Turn the wheels by hand, mark a line in the center

of each tire tread using a scribing block.

3. Place the front wheels in the straight-ahead posi-

tion and lower the vehicle.

4. Measure the distance between the lines at the front

and rear of the wheels.

Both measurements must be taken at equal

distances from the ground.

Toe-in (distance greater at rear than front):

3 ± 3 mm (0.12 ± 0.12 in)

Adjustment

To adjust the toe-in, loosen the left and right tie-rod

lock nuts, then turn the tie-rods by the same amount.

Caution

a) The left and right tie-rods are both right

threaded, so, to increase the toe-in, turn the

right tie-rod toward the front of the vehicle,

and turn the left tie-rod by the same amount

toward the rear.

b) One turn of the tie-rod (both sides) changes

the toe-in by about 7.2 mm (0.28 in).

c) Tighten the tie-rod locknuts to the specified

torque.

Tightening torque: 69—98 N-m

(7—10 m-kg, 51—72 ft-lb) 86U13X-110

13-50

Page 1549 of 1865

13 REAR WHEEL ALIGNMENT

76G13X-033

86U13X-116

86U13X-117

86U13X-116

13-52

REAR WHEEL ALIGNMENT

PRE-INSPECTION

1. Check the tire inflation and bring to the recom-

mended pressure.

2. Inspect the wheel and tire runout.

3. The vehicle must be on level ground and have no

luggage or passenger load.

4. Check that the suspension is correctly adjusted.

5. The difference in height between the left and right

sides from the center of the wheel to the fender

rim should be within 10 mm (0.39 in).

Caution

a) Front and rear wheel alignments should be

checked simultaneously. If adjustment is

made to either the front or rear wheels,

recheck the alignment, particularly toe-in,

on all other wheels.

b) Check and adjust the steering angle trans-

fer shaft after adjusting the rear wheel align-

ment. (Refer to Section 10.)

TOE-IN

Inspection

1. Raise the rear of the vehicle until the wheels clear

the ground.

2. Turn the wheels by hand, mark a line in the center

of each tire tread using a scribing block.

3. Lower the vehicle.

4. Measure the distance between the marked lines

at the front and rear of the wheels.

Toe-in

0 ± 3 mm (0 ±0.12 in) 2WS

3 ± 3 mm (0.12 ±0.12 in) 4WS

Adjustment (2WS)

1. Loosen the adjusting rod lock nuts, then adjust the

toe-in.

2. To increase the toe-in, turn the adjusting rods as

follows:

Right rod — Turn counterclockwise

Left rod — Turn clockwise

To decrease the toe-in, turn the adjusting rods as

follows:

Right rod — Turn clockwise

Left rod — Turn counterclockwise

Caution

a) Both the left and right rods must be adjust-

ed by the same amount.

b) One turn of the adjusting rod (both sides)

changes the toe-in by about 11.6 mm (0.46

in).

3. Tighten the adjusting rod lock nuts to the speci-

fied torque.

Tightening torque:

55—80 N-m (5.6—8.2 m-kg, 41—59 ft-lb)