Air Force MAZDA MIATA 1991 Factory Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1991, Model line: MIATA, Model: MAZDA MIATA 1991Pages: 392, PDF Size: 29.45 MB

Page 127 of 392

A double-lock mechanism is used on clockspring connectors. DO NOT use excessive force when

disconnecting connectors, as damage to connector may occur.

DISABLING & ACTIVATING AIR BAG SYSTEM

AIR BAG SYSTEM

DISABLING SYSTEM

On Miata, obtain radio code number from customer, and deactivate audio anti-theft function. On all models,

turn ignition switch off. Disconnect and shield negative battery cable. Remove knee protector. Disconnect

Orange and Blue clockspring connectors at base of steering column. See Fig. 1

.

ACTIVATING SYSTEM

Reconnect battery and clockspring connectors. Turn ignition switch to RUN position. Check AIR BAG

indicator li

ght to ensure system is operating properly. See SYSTEM OPERATION CHECK. WARNING:Wait about 10 MINUTES after disabling air bag system before servicing.

Air bag system voltage is maintained for about 10 MINUTES after system

is disabled. Failure to wait 10 MINUTES before servicing system may

cause accidental air bag deployment and possible personal injury.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 2 © 2005 Mitchell Repair Information Company, LLC.

Page 129 of 392

ADJUSTMENTS

CLOCKSPRING CENTERING

Set front wheels in straight-ahead position. Turn clockspring connector clockwise until it stops (do not force).

Return connector 2 3/4 turns counterclockwise. Rotate clockspring connector further, if necessary, to align

marks on connector and outer housing.

DISPOSAL PROCEDURES

DEPLOYED AIR BAG

Dispose deployed air bag module as you would any other part. Wear gloves and safety glasses when handling

air bag module.

SCRAPPED VEHICLE

1. Ensure vehicle is outside, and away from other vehicles and people. Open convertible top and doors.

Disconnect negative battery cable.

2. Ensure air bag module is firmly mounted to steering wheel. Remove knee protector and disconnect

Orange and Blue clockspring connectors at base of steering column. See Fig. 1

. Cut clockspring

connector Blue wires.

3. Connect 2 jumper wires (20 feet long) to cut clockspring wires. Connect other ends of wires to a 12-volt

battery to deploy air bag. Because of heat, wait 10 MINUTES before touching deployed air bag.

REMOVAL & INSTALLATION

CRASH SENSORS NOTE: Perform the following procedures when scrapping a vehicle with undeployed air

bag.

WARNING:Follow air bag service precautions to prevent accidentalair bag

deployment and personal injury. See SERVICE PRECAUTIONS.

NOTE: After component replacement, check system to ensure proper operation. See

SYSTEM OPERATION CHECK.

NOTE: Crash sensor orientation and mounting is important for proper operation. All

sensors must be positioned so that arrow points forward. If there is sheet metal

damage near sensor mounting point, inspect body structure at sensor

mounting point for deformation. If damaged, restore to original shape. Ensure

sensor mounting bolts or nuts are tightened to specification. See TORQUE

SPECIFICATIONS table.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 131 of 392

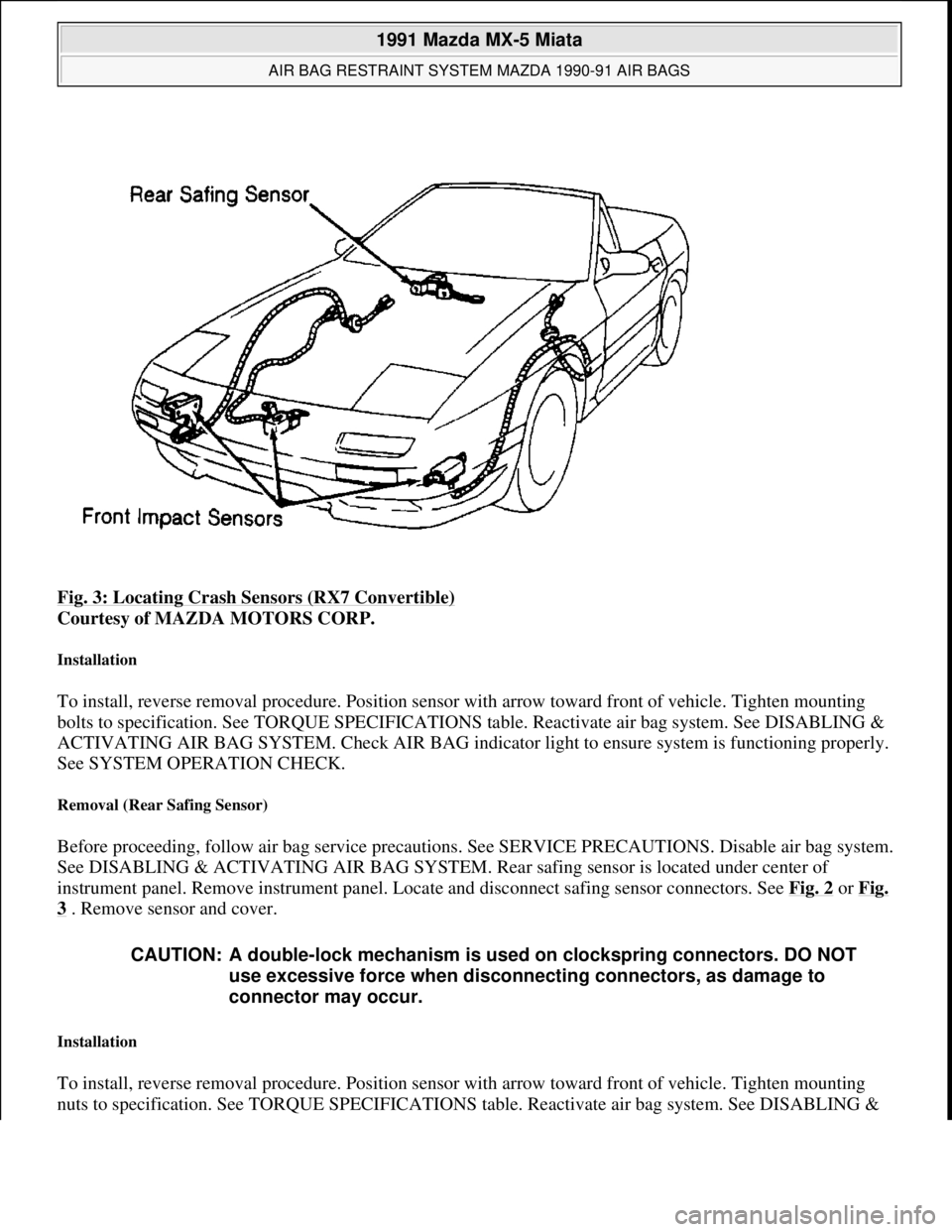

Fig. 3: Locating Crash Sensors (RX7 Convertible)

Courtesy of MAZDA MOTORS CORP.

Installation

To install, reverse removal procedure. Position sensor with arrow toward front of vehicle. Tighten mounting

bolts to specification. See TORQUE SPECIFICATIONS table. Reactivate air bag system. See DISABLING &

ACTIVATING AIR BAG SYSTEM. Check AIR BAG indicator light to ensure system is functioning properly.

See SYSTEM OPERATION CHECK.

Removal (Rear Safing Sensor)

Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS. Disable air bag system.

See DISABLING & ACTIVATING AIR BAG SYSTEM. Rear safing sensor is located under center of

instrument panel. Remove instrument panel. Locate and disconnect safing sensor connectors. See Fig. 2

or Fig.

3 . Remove sensor and cover.

Installation

To install, reverse removal procedure. Position sensor with arrow toward front of vehicle. Tighten mounting

nuts to specification. See TORQUE SPECIFICATIONS table. Reactivate air ba

g system. See DISABLING &

CAUTION: A double-lock mechanism is used on clockspring connectors. DO NOT

use excessive force when disconnecting connectors, as damage to

connector may occur.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 209 of 392

engagement while rotating adjusting screw to prevent burring screw slots. Ensure adjusting screw rotates

freely.

PARKING BRAKE

B2200 & B2600i

1. Depress brake pedal several times while vehicle is moving in Reverse. Ensure brakes are properly

adjusted. Pull parking brake lever with a force of 44 lbs. (20 kg). If stroke is 7-12 notches, parking brake

is properly adjusted.

2. If stroke is not 7-12 notches, raise and support rear of vehicle. Release parking brake lever. Loosen cable

lock nut at lever end of cable. Rotate adjusting nut until correct stroke is obtained. Operate parking brake

several times and ensure rear wheels rotate freely. Ensure parking brake warning light illuminates when

brake lever is pulled one notch.

Navajo

1. Adjust service brakes before adjusting parking brake cable. Ensure brake drums are cold. Apply parking

brake to fully depressed position. Grip threaded rod to prevent it from spinning.

2. Thread equalizer nut 6 full turns past its original position on threaded rod. See Fig. 4

. Check cable

tension at rear of equalizer assembly using Cable Tension Gauge (021-00018). If tension is not 400-600

lbs. (182-272 k

g), repeat step 2).

1991 Mazda MX-5 Miata

BRAKE SYSTEM 1991 BRAKES Mazda Brake System

Microsoft

Sunday, July 05, 2009 2:18:08 PMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 210 of 392

Fig. 4: Adjusting Parking Brake (Navajo)

Courtesy of FORD MOTOR CO.

3. Release pedal, and check rear wheel drag. If drag is noted, remove drums, and check for clearance

between parking brake lever and cam plate. Cables should be tight enough to allow full application of rear

brakes and loose enough to allow full release of rear brakes.

929

1. Depress brake pedal several times. Pull parking brake lever with a force of 44 lbs. (20 kg). If stroke is 6-8

notches, parking brake is properly adjusted. If stroke is not 6-8 notches, adjust parking brake shoes. See

PARKING BRAKE SHOES under ADJUSTMENTS

.

NOTE: Tension limiter will reset parking brake tension any time system is

disconnected if distance between bracket and cinch strap hook is reduced

during adjustment. When adjustment has been performed so cinch strap

contacts bracket, system tension will increase greatly. This may cause an over-

tension condition. When available adjustment travel has been used, replace

tension limiter.

NOTE: If rear brake shoes are removed for any reason, parking brake cable

1991 Mazda MX-5 Miata

BRAKE SYSTEM 1991 BRAKES Mazda Brake System

Microsoft

Sunday, July 05, 2009 2:18:08 PMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 211 of 392

2. Release parking brake lever. Using a screwdriver, reach through parking brake handle hole in console and

rotate adjusting screw until stroke is 6-8 notches. Ensure rear wheels rotate freely. Ensure parking brake

warning light illuminates when brake lever is pulled one notch.

Miata, MX-6, MPV, Protege, RX7, 323, 626

1. On models with rear disc brakes, depress brake pedal several times. On models with rear drum brakes,

start engine and depress brake pedal several times while vehicle is moving in Reverse. Stop engine.

2. On all models, pull parking brake lever with a force of 22 lbs. (10 kg). If stroke is 5-7 notches, parking

brake is properly adjusted. If stroke is not 5-7 notches, raise and support rear of vehicle. Release parking

brake lever.

3. Rotate cable adjusting nut at lever end of cable (under console cover) until stroke is within specification.

On models equipped with rear disc brakes, ensure clearance between stopper and lever (at each caliper) is

not less than .08" (2 mm) on RX7, or zero on all other models. On all models, ensure parking brake

warning light illuminates when brake lever is pulled one notch.

PARKING BRAKE SHOES

929

Raise and support vehicle. Remove rear wheels. Remove service plug from rotor. Using a screwdriver, rotate

star wheel adjuster toward axle until rotor locks. Rotate adjuster in opposite direction 3-5 notches. Ensure rotors

turn freely and parking brake functions properly. Install service plug and rear wheels.

PEDAL FREE PLAY

Depress pedal a few times to eliminate vacuum. Pedal free play should be .16-.28" (4-7 mm). Adjust play by

loosening push rod lock nut. Turn push rod until correct free play is obtained. Tighten push rod lock nut.

PEDAL HEIGHT & STOPLIGHT SWITCH

1. Released pedal height is measured from carpet surface on vertical portion of firewall to pedal pad center.

Disconnect stoplight switch electrical connector. Loosen lock nut on stoplight switch. Move switch away

from pedal. Loosen push rod lock nut. Turn rod until correct pedal height is obtained. See BRAKE

PEDAL HEIGHT SPECIFICATIONS .

2. Adjust pedal free play. See PEDAL FREE PLAY

under ADJUSTMENTS. Tighten push rod lock nut.

Rotate stoplight switch until it contacts pedal and then rotate an additional 1/2 turn. Tighten stoplight

switch lock nut. Reconnect stoplight switch electrical connector.

3. Applied pedal height is measured from angled portion of firewall (without carpet) to pedal pad center.

Start engine. On B2200, B2600i and MPV, depress brake pedal with 33 lbs. (15 kg) pressure. On all other

models, depress brake pedal with 132 lbs. (60 k

g) pressure. tension should be checked and adjusted.

NOTE: Pedal height and stoplight switch information is not available for Navajo.

1991 Mazda MX-5 Miata

BRAKE SYSTEM 1991 BRAKES Mazda Brake System

Microsoft

Sunday, July 05, 2009 2:18:08 PMPage 8 © 2005 Mitchell Repair Information Company, LLC.

Page 261 of 392

3. Using Bearing Nut Wrench (49 0603 635A ) and Shaft Holder (49 S120 645A ), remove bearing lock nut

from axle shaft. Remove bearing and bearing retainer from axle using Puller (49 S120 520A ). Remove

outer race from hub.

END PLAY SPECIFICATIONS

(1)

Installation

1. Press new oil seal and bearing outer race into bearing retainer. Coat bearing race and outer seal with

grease. Tap inner oil seal flush with end of axle housing. Coat inner seal lip with grease.

2. Position brake backing plate onto axle shaft. Install spacer against backing plate with chamfer facing

backing plate. Using Press Attachment (49 S120 748 ) and a press, install wheel bearing onto axle shaft.

Standard press force is 4.6-6.7 tons (4200-6100 kg). If press fit force is too high or too low, replace the

bearing collar or shaft.

3. Using Bearing Nut Wrench (49 0603 635A ), install bearing lock nut to axle shaft and tighten to 145-217

ft. lbs. (196-245 N.m). Bend tab up into groove. Install one axle shaft into axle housing. Tighten backing

plate nuts to specification. Install dial indicator on backing plate and check drive axle end play.

4. To adjust end play, remove axle and insert appropriate size adjustment shim between axle hub and

housing. End play for second drive axle installed should be set to normal end play clearance of .002-

.010" (.05-.25 mm), with both axles installed.

5. Install parking brake cable, attaching pin and brake line. Install brake shoes and actuating hardware.

Bleed brake system. Install wheel and tire.

BEARING RETAINER SHIMS (B2200 & B2600i)

MPV 4WD

NOTE: On B2200 and B2600i, left axle bearing lock nut has left-hand threads.

ApplicationIn. (mm)

B2200 & B2600i

One Axle Installed.026-.037 (.65-.95)

Both Axles Installed.002-.010 (.05-.25)

(1)Check at axle flange with dial indicator.

NOTE: Ensure end play for first drive axle is within specification before inserting

second drive axle. Use shims to adjust end play if necessary.

Part NumberThickness In. (mm)

083 26 165.004 (.10)

083 26 166.006 (.15)

083 26 167.020 (.50)

083 26 168.030 (.75)

1991 Mazda MX-5 Miata

1990-91 DRIVE AXLES Differentials & Drive Axles - 929, B2200, B2600i, MX-5 Miata, MPV, Protege & RX-7

Microsoft

Sunday, July 05, 2009 2:17:01 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 275 of 392

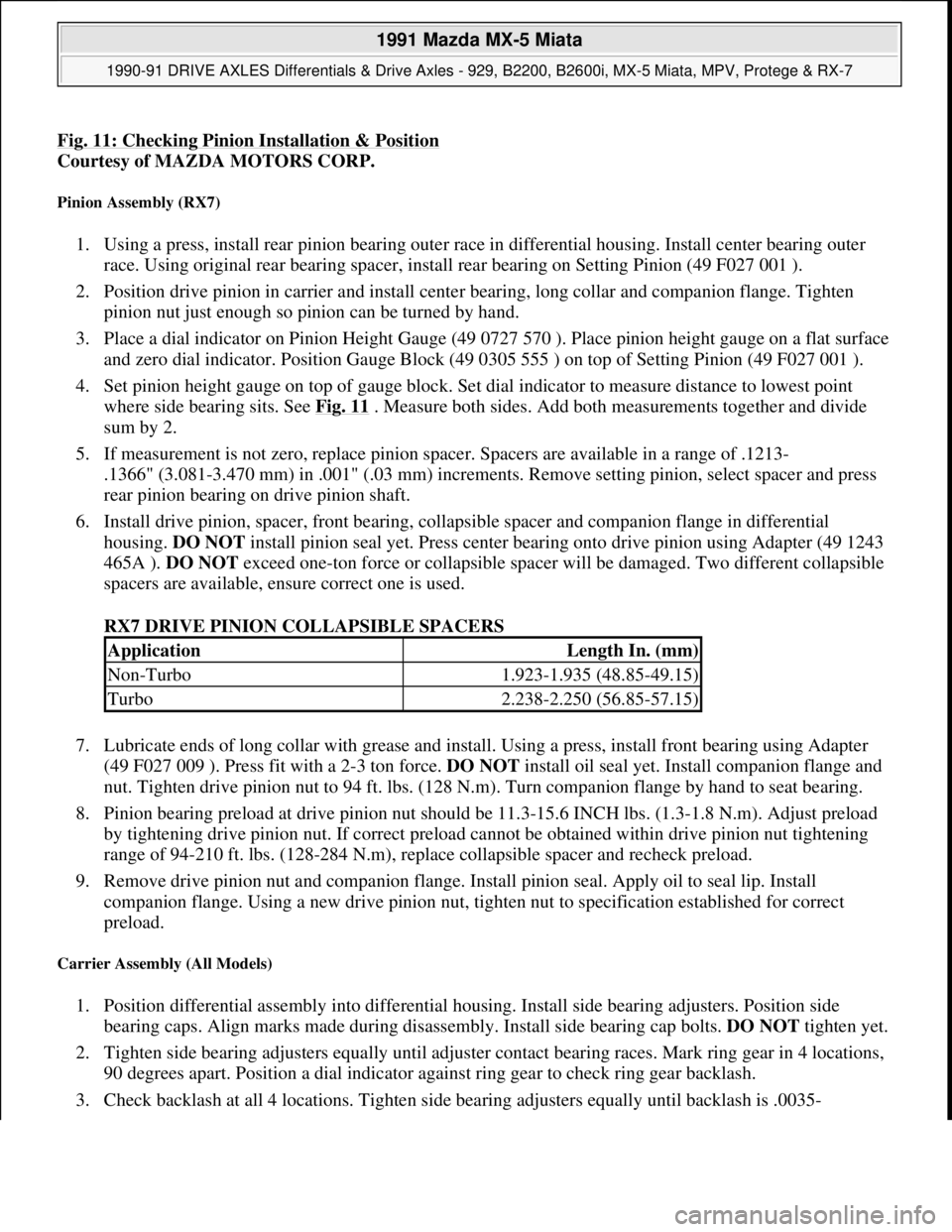

4. Set pinion height gauge on top of gauge block. Set dial indicator to measure distance to a point where

side bearing sits. Measure lowest point. See Fig. 11

. Measure both sides. Add both measurements

together and divide sum by 2.

5. If measurement is not zero, replace pinion spacer. Spacers are available in a range of .1213-

.1366" (3.081-3.470 mm), in .001" (.03 mm) increments. Remove dummy pinion shaft. Press rear pinion

bearing on pinion shaft.

6. Install pinion shaft, spacer, front bearing, collapsible spacer and companion flange in differential housing.

DO NOT install pinion seal at this time. DO NOT exceed one ton force or collapsible spacer will be

damaged.

7. Temporarily tighten drive pinion nut. Turn companion flange by hand to seat bearing. Tighten drive

pinion nut to 94-130 ft. lbs. (128-177 N.m). Check pinion bearing preload, at drive pinion nut. See

PINION PRELOAD SPECIFICATIONS

. If pinion bearing preload is not as specified, replace

collapsible spacer and recheck preload.

8. Remove drive pinion nut and companion flange. Install pinion seal. Apply oil to seal lip. Install

companion flange. Using a new drive pinion nut, tighten nut to 94-130 ft. lbs. (128-177 N.m). Recheck

pinion bearing preload.

PINION PRELOAD SPECIFICATIONS

4WD &

929

Miata49 N027 001

ApplicationINCH lbs. (N.m)

B2200 & 92911.3-15.6 (1.3-1.8)

B2600i 4WD

Front11.3-15.6 (1.3-1.8)

Rear7.8-12.2 (0.9-1.4)

Miata & Protege 4WD (Rear)2.6-6.1 (0.3-0.7)

MPV 4WD

Front7.8-12.2 (0.9-1.4)

Rear11.3-15.6 (1.3-1.8)

RX7

Non-Turbo7.8-12.1 (0.9-1.4)

Turbo11.3-15.6 (1.3-1.8)

1991 Mazda MX-5 Miata

1990-91 DRIVE AXLES Differentials & Drive Axles - 929, B2200, B2600i, MX-5 Miata, MPV, Protege & RX-7

Microsoft

Sunday, July 05, 2009 2:17:01 PMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 277 of 392

Fig. 11: Checking Pinion Installation & Position

Courtesy of MAZDA MOTORS CORP.

Pinion Assembly (RX7)

1. Using a press, install rear pinion bearing outer race in differential housing. Install center bearing outer

race. Using original rear bearing spacer, install rear bearing on Setting Pinion (49 F027 001 ).

2. Position drive pinion in carrier and install center bearing, long collar and companion flange. Tighten

pinion nut just enough so pinion can be turned by hand.

3. Place a dial indicator on Pinion Height Gauge (49 0727 570 ). Place pinion height gauge on a flat surface

and zero dial indicator. Position Gauge Block (49 0305 555 ) on top of Setting Pinion (49 F027 001 ).

4. Set pinion height gauge on top of gauge block. Set dial indicator to measure distance to lowest point

where side bearing sits. See Fig. 11

. Measure both sides. Add both measurements together and divide

sum by 2.

5. If measurement is not zero, replace pinion spacer. Spacers are available in a range of .1213-

.1366" (3.081-3.470 mm) in .001" (.03 mm) increments. Remove setting pinion, select spacer and press

rear pinion bearing on drive pinion shaft.

6. Install drive pinion, spacer, front bearing, collapsible spacer and companion flange in differential

housing. DO NOT install pinion seal yet. Press center bearing onto drive pinion using Adapter (49 1243

465A ). DO NOT exceed one-ton force or collapsible spacer will be damaged. Two different collapsible

spacers are available, ensure correct one is used.

RX7 DRIVE PINION COLLAPSIBLE SPACERS

7. Lubricate ends of long collar with grease and install. Using a press, install front bearing using Adapter

(49 F027 009 ). Press fit with a 2-3 ton force. DO NOT install oil seal yet. Install companion flange and

nut. Tighten drive pinion nut to 94 ft. lbs. (128 N.m). Turn companion flange by hand to seat bearing.

8. Pinion bearing preload at drive pinion nut should be 11.3-15.6 INCH lbs. (1.3-1.8 N.m). Adjust preload

by tightening drive pinion nut. If correct preload cannot be obtained within drive pinion nut tightening

range of 94-210 ft. lbs. (128-284 N.m), replace collapsible spacer and recheck preload.

9. Remove drive pinion nut and companion flange. Install pinion seal. Apply oil to seal lip. Install

companion flange. Using a new drive pinion nut, tighten nut to specification established for correct

preload.

Carrier Assembly (All Models)

1. Position differential assembly into differential housing. Install side bearing adjusters. Position side

bearing caps. Align marks made during disassembly. Install side bearing cap bolts. DO NOT tighten yet.

2. Tighten side bearing adjusters equally until adjuster contact bearing races. Mark ring gear in 4 locations,

90 degrees apart. Position a dial indicator against ring gear to check ring gear backlash.

3. Check backlash at all 4 locations. Ti

ghten side bearing adjusters equally until backlash is .0035-

ApplicationLength In. (mm)

Non-Turbo1.923-1.935 (48.85-49.15)

Turbo2.238-2.250 (56.85-57.15)

1991 Mazda MX-5 Miata

1990-91 DRIVE AXLES Differentials & Drive Axles - 929, B2200, B2600i, MX-5 Miata, MPV, Protege & RX-7

Microsoft

Sunday, July 05, 2009 2:17:01 PMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 320 of 392

Any modification to the exhaust system on turbo models, which reduces exhaust backpressure, will lead to lean

fuel mixtures and excessive spark advance. This could cause serious engine damage.

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

ENGINE OIL

FUEL SYSTEM SERVICE

HALOGEN BULBS

Halogen bulbs contain pressurized gas which may explode if overheated. DO NOT touch glass portion of bulb

with bare hands. Eye protection should be worn when handling or working around halogen bulbs.

HEADLIGHT RETRACTOR

RADIATOR CAP

RADIATOR FAN WARNING:Many solid state electrical components can be damaged by static

electricity (ESD). Some will display a warning label, but many will not.

Discharge personal static electricity by touching a metal ground point on

the vehicle prior to servicing any ESD sensitive component.

CAUTION: Never use non-detergent or straight mineral oil.

WARNING:Relieve fuel system pressure prior to servicing any fuel system

component (fuel injection models).

CAUTION: If headlight retractor freezes during cold weather operation, DO NOT

attempt to force mechanism. Headlights should be kept raised at all times

in cold weather. To raise them, use only headlight retractor switch. DO

NOT use headlight switch.

CAUTION: Always disconnect the fan motor when working near the radiator fan. The

fan is temperature controlled and could start at any time even when the

ignition key is in the OFF position. DO NOT loosen or remove radiator cap

when cooling system is hot.

WARNING:Keep hands away from radiator fan. Fan is controlled by a thermostatic

switch which may come on or run for up to 15 minutes even after engine

is turned off.

1991 Mazda MX-5 Miata

FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1990-95 Mazda

Microsoft

Sunday, July 05, 2009 2:15:54 PMPage 7 © 2005 Mitchell Repair Information Company, LLC.