service MAZDA MIATA 1991 Factory Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1991, Model line: MIATA, Model: MAZDA MIATA 1991Pages: 392, PDF Size: 29.45 MB

Page 126 of 392

AIR BAG RESTRAINT SYSTEM

MAZDA 1990-91 AIR BAGS

DESCRIPTION & OPERATION

The air bag restraint system, when used in conjunction with seat belt, provides increased protection for the

driver in a collision. The air bag restraint system consists of the following: AIR BAG warning light, air bag

module, clockspring connector, diagnostic module, crash sensors, back-up battery, and wiring harnesses.

The air bag is designed to deploy when rear safing sensor and at least one front impact sensor close in a

collision, and ignition switch is in the ON position. The back-up battery supplies current for the ignitor if the

vehicle battery or fuses fail during a collision. The diagnostic module monitors the air bag system for failures. I

f

any failures are detected by the module, the driver is warned of such failure(s) through the activation or flashing

of the AIR BAG warning light.

SERVICE PRECAUTIONS

Disable air bag system before servicing any air bag system or steering column component. See

DISABLING & ACTIVATING AIR BAG

SYSTEM

Wait about 10 MINUTES after disabling air bag system before servicing. Air bag system voltage is

maintained for about 10 MINUTES after system is disabled. Failure to wait 10 MINUTES before

servicing system may cause accidental air bag deployment and possible personal injury.

On Miata, obtain radio code number from customer and deactivate radio anti-theft function before

disconnecting battery.

Because of the critical system operating requirements, DO NOT service any air bag system component.

Corrections are made by replacement only.

DO NOT use an ohmmeter to check resistance of air bag module, as it may cause air bag deployment.

When carrying a live (undeployed) module, ensure trim cover is pointed away from your body. This

minimizes chance of injure in the event ofaccidental air bag deployment.

When placing a live air bag module on any surface, always face trim cover upward to reduce motion of

module if it is accidentally deployed.

If an open circuit is present, replace entire wiring harness. DO NOT attempt wire repair.

Impact sensors must always be installed with arrow marks facing front of vehicle. Also, check sensors for

cracks, defects or rust before installation. Replace impact sensor(s) if required.

Air bag system clockspring MUST be aligned in the neutral position, since its rotation ability is limited.

DO NOT turn steerin

g wheel or column after removal of steering gear. WARNING:To avoid injury from accidental air bag deployment, read and carefully

follow all WARNINGS and SERVICE PRECAUTIONS.

NOTE: The following precautions should be observed when working with air bag

systems.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, July 05, 2009 2:11:26 PMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 129 of 392

ADJUSTMENTS

CLOCKSPRING CENTERING

Set front wheels in straight-ahead position. Turn clockspring connector clockwise until it stops (do not force).

Return connector 2 3/4 turns counterclockwise. Rotate clockspring connector further, if necessary, to align

marks on connector and outer housing.

DISPOSAL PROCEDURES

DEPLOYED AIR BAG

Dispose deployed air bag module as you would any other part. Wear gloves and safety glasses when handling

air bag module.

SCRAPPED VEHICLE

1. Ensure vehicle is outside, and away from other vehicles and people. Open convertible top and doors.

Disconnect negative battery cable.

2. Ensure air bag module is firmly mounted to steering wheel. Remove knee protector and disconnect

Orange and Blue clockspring connectors at base of steering column. See Fig. 1

. Cut clockspring

connector Blue wires.

3. Connect 2 jumper wires (20 feet long) to cut clockspring wires. Connect other ends of wires to a 12-volt

battery to deploy air bag. Because of heat, wait 10 MINUTES before touching deployed air bag.

REMOVAL & INSTALLATION

CRASH SENSORS NOTE: Perform the following procedures when scrapping a vehicle with undeployed air

bag.

WARNING:Follow air bag service precautions to prevent accidentalair bag

deployment and personal injury. See SERVICE PRECAUTIONS.

NOTE: After component replacement, check system to ensure proper operation. See

SYSTEM OPERATION CHECK.

NOTE: Crash sensor orientation and mounting is important for proper operation. All

sensors must be positioned so that arrow points forward. If there is sheet metal

damage near sensor mounting point, inspect body structure at sensor

mounting point for deformation. If damaged, restore to original shape. Ensure

sensor mounting bolts or nuts are tightened to specification. See TORQUE

SPECIFICATIONS table.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 130 of 392

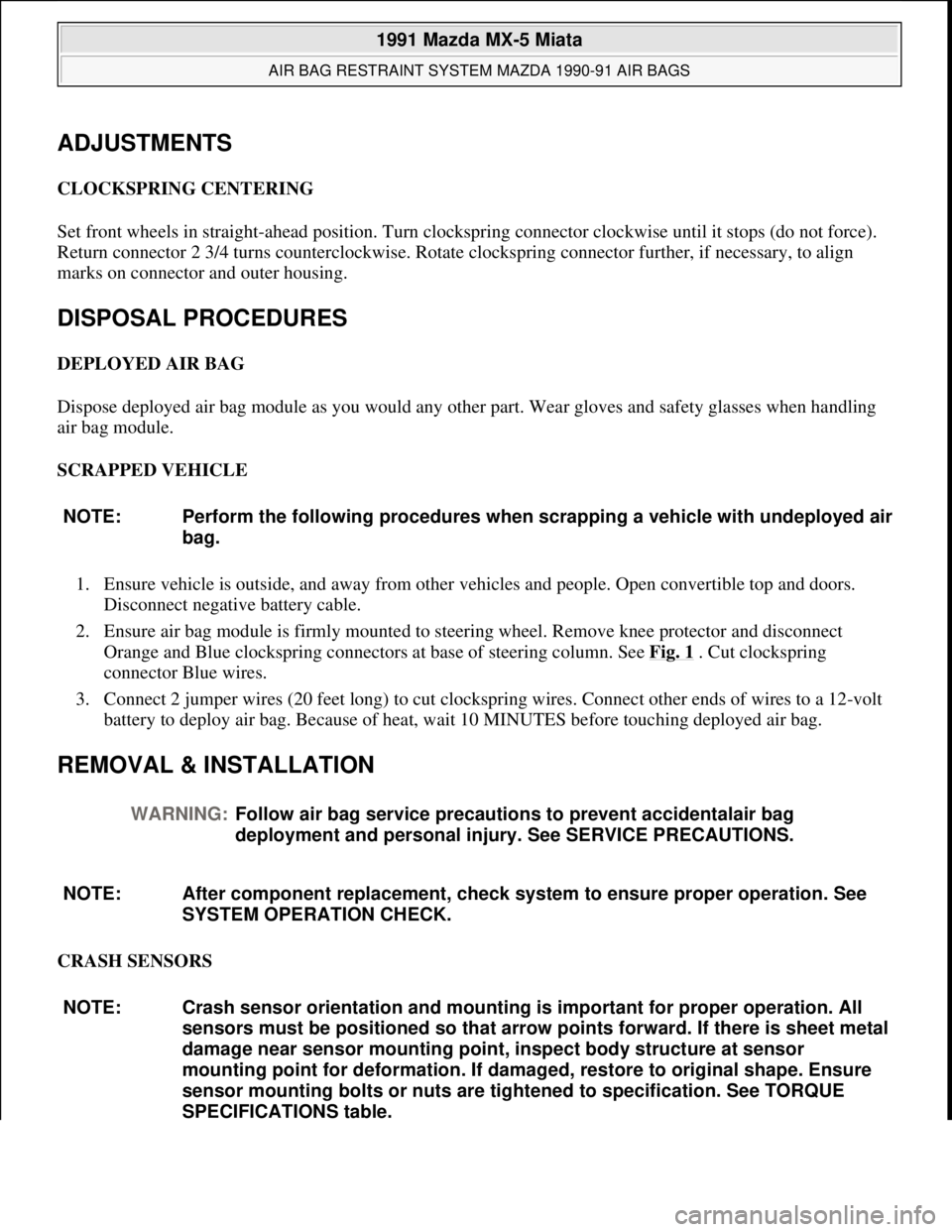

Removal (Front Impact Sensors)

1. Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS. Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM.

2. Front impact sensors are located in left front and right front of vehicle. See Fig. 2

or Fig. 3 . To remove

left or right sensor, remove wheelwell undercover, and disconnect connector(s). Remove retaining clips

and bolts. Remove sensor(s).

Fig. 2: Locating Crash Sensors (Miata)

Courtesy of MAZDA MOTORS CORP.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 131 of 392

Fig. 3: Locating Crash Sensors (RX7 Convertible)

Courtesy of MAZDA MOTORS CORP.

Installation

To install, reverse removal procedure. Position sensor with arrow toward front of vehicle. Tighten mounting

bolts to specification. See TORQUE SPECIFICATIONS table. Reactivate air bag system. See DISABLING &

ACTIVATING AIR BAG SYSTEM. Check AIR BAG indicator light to ensure system is functioning properly.

See SYSTEM OPERATION CHECK.

Removal (Rear Safing Sensor)

Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS. Disable air bag system.

See DISABLING & ACTIVATING AIR BAG SYSTEM. Rear safing sensor is located under center of

instrument panel. Remove instrument panel. Locate and disconnect safing sensor connectors. See Fig. 2

or Fig.

3 . Remove sensor and cover.

Installation

To install, reverse removal procedure. Position sensor with arrow toward front of vehicle. Tighten mounting

nuts to specification. See TORQUE SPECIFICATIONS table. Reactivate air ba

g system. See DISABLING &

CAUTION: A double-lock mechanism is used on clockspring connectors. DO NOT

use excessive force when disconnecting connectors, as damage to

connector may occur.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 6 © 2005 Mitchell Repair Information Company, LLC.

Page 132 of 392

ACTIVATING AIR BAG SYSTEM. Check AIR BAG indicator light to ensure system is functioning properly.

See SYSTEM OPERATION CHECK.

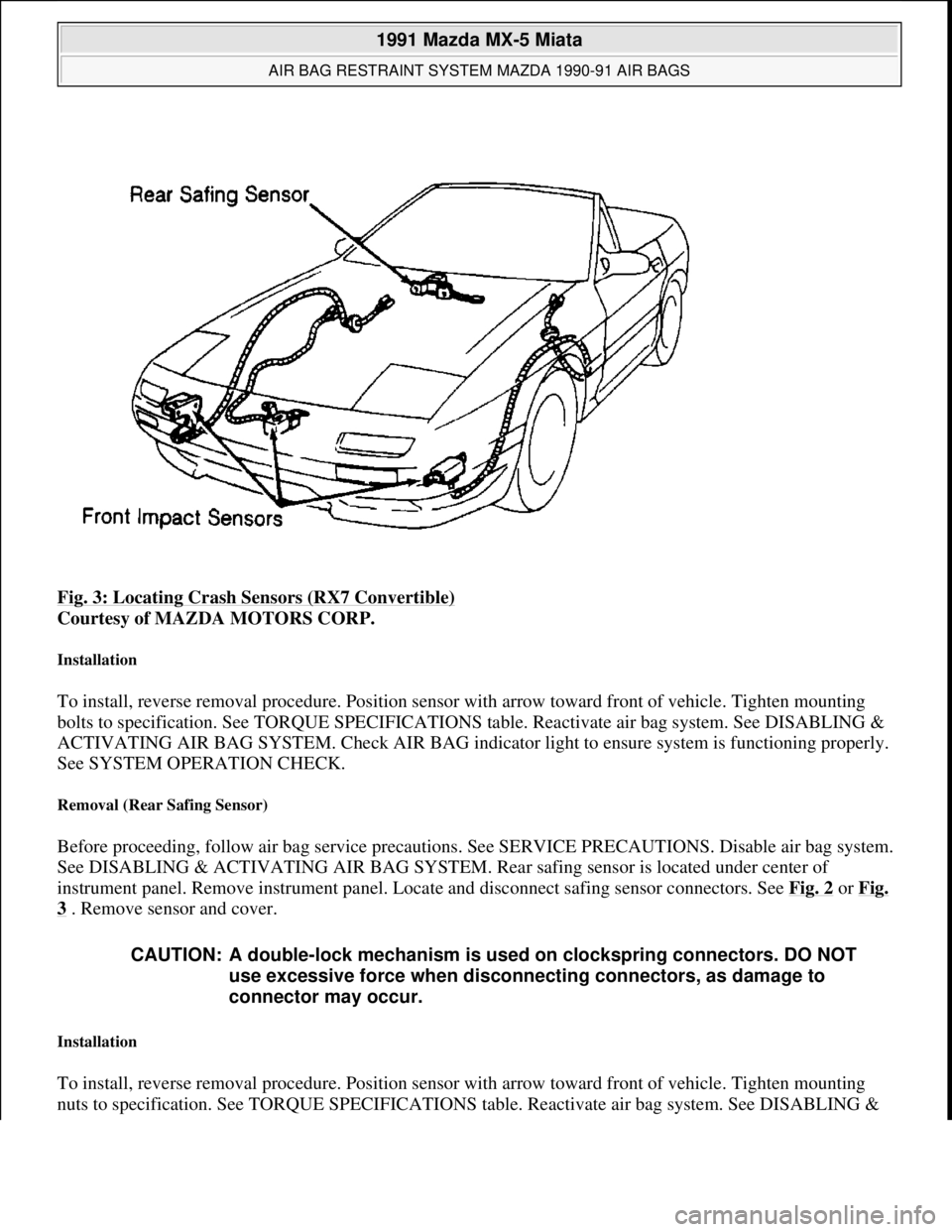

AIR BAG MODULE

Removal & Installation

1. Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS. Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM.

2. Air bag module is located on center of steering wheel. See Fig. 4

or Fig. 5 . Remove air bag module nuts

and remove module from steering wheel. To install, reverse removal procedure. Tighten air bag module

mounting nuts to specification. See TORQUE SPECIFICATIONS table. Reactivate air bag system. See

DISABLING & ACTIVATING AIR BAG SYSTEM. Check AIR BAG indicator light to ensure system is

functioning properly. See SYSTEM OPERATION CHECK.

Fig. 4: Identifying Air Bag System Components (Miata)

Courtesy of MAZDA MOTORS CORP.

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 134 of 392

Removal

1. Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS. Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM.

2. Clockspring connector assembly is located under steering wheel, in steering column. See Fig. 4

or Fig. 5.

Remove air bag module. See AIR BAG MODULE. Remove steering wheel nut and remove steering

wheel with steering wheel puller. Remove column covers. Remove screws. Remove clockspring

connector and combination switch as an assembly.

DIAGNOSTIC MODULE & BACK-UP BATTERY

Removal & Installation

1. Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS. Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM.

2. Diagnostic module and back-up battery is located under left side of instrument panel. See Fig. 4

or Fig.

5 . Disconnect diagnostic module and back-up battery connectors. Remove nuts. Remove diagnostic

module and back-up battery as an assembly. To install, reverse removal procedure. After diagnostic

module and back-up battery are installed, reactivate air bag system. See DISABLING & ACTIVATING

AIR BAG SYSTEM. Check AIR BAG indicator light to ensure system is functioning properly. See

SYSTEM OPERATION CHECK.

SYSTEM OPERATION CHECK

Turn ignition switch to the ON or START position. AIR BAG warning light in instrument cluster should

illuminate for approximately 6 seconds then go out. This indicates that the air bag system is functioning

properly. If any of the following conditions exists, air bag system is malfunctioning and needs repair.

AIR BAG warning light does not illuminate as described.

AIR BAG warning light stays on for more than 6 seconds.

AIR BAG warning light illuminates while driving.

If air bag system components are replaced for any reason, air bag system must be checked for proper function

after repair. Turn ignition on. AIR BAG warning light should illuminate for approximately 6 seconds then go

out. If AIR BAG warning light does not illuminate as described, air bag system is malfunctioning and needs

repair. If warning light functions as described, check horn operation. If horn does not sound, remove air bag

module and check air bag module and horn switch connections. Always follow service precautions and

deactivate air bag system before performing repairs. See DISABLING & ACTIVATING AIR BAG

SYSTEM .

WIRE REPAIR

DO NOT repair air bag system wiring. If air bag harness connectors are faulty, replace faulty wiring harness.

TORQUE SPECIFICATIONS

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 135 of 392

TORQUE SPECIFICATIONS

DIAGNOSIS & TESTING

SELF-DIAGNOSTIC SYSTEM

Trouble Shooting

AIR BAG warning light flashes are used to diagnose air bag system. The number of warning light flashes

depends on the type of fault being detected. Codes are prioritized so that if 2 or more faults are present, the

highest test-priority fault indication will remain until corrected.

Warning Light Does Not Illuminate

Check for blown fuses, burned-out bulb, disconnected diagnostic module, or open circuit between warning light

and diagnostic module.

Warning Light Flashes Or Remains On

Check code output of AIR BAG warning light. See AIR BAG FLASH CODES table.

AIR BAG FLASH CODES

ApplicationFt. Lbs. (N.m)

Air Bag Module Nuts12-15 (16-20)

Steering Wheel Nut29-36 (39-49)

INCH Lbs. (N.m)

Front Impact Sensor Bolts78-113 (9-13)

Rear Safing Sensor Nuts

Miata78-113 (9-13)

RX761-87 (7-10)

WARNING:Follow air bag service precautions to prevent accidentalair bag

deployment and personal injury. See SERVICE PRECAUTIONS.

NOTE: After component replacement, check system to ensure proper operation. See

SYSTEM OPERATION CHECK.

PriorityFlash CodeCause/Diagnosis

1Remains OnFaulty Diagnostic Module

Poor Connection Of Diagnostic

Module Connector (See

DIAGNOSTIC TEST NO. 1)

2Flashes 3 TimesOpen Circuit

Poor Connection Of Power Source

1991 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM MAZDA 1990-91 AIR BAGS

Microsoft

Sunday, July 05, 2009 2:11:16 PMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 155 of 392

OPERATION

Under normal driving conditions, the anti-lock brake system functions as a standard brake system. When

vehicle speed reaches 3.8 MPH, the ABS system will diagnose pump motor by briefly operating motor. Pump

motor operation may be heard inside vehicle.

The Electronic Control Unit (ECU) controls ABS by detecting speed sensor signals and activating solenoid

valve in hydraulic unit. Control unit also controls pump motor and self-diagnostic function. If a problem in the

ABS system is detected, ABS system functions as a conventional brake system. The ANTI-LOCK brake

warning light will also come on.

With detection of wheel lock-up, short pedal pulsations, occurring in rapid succession, will be felt in brake

pedal and steering wheel. Vehicle body may also vibrate slightly. These conditions are normal. Pedal pulsation

will continue until there is no longer a need for anti-lock function or until vehicle is stopped.

ANTI-LOCK BRAKE SAFETY PRECAUTIONS

NEVER open a bleeder valve or loosen a hydraulic line while ABS is pressurized.

NEVER disconnect or reconnect any electrical connectors while ignition is on. Damage to ABS control

unit may result.

DO NOT attempt to bleed hydraulic system without first referring to the appropriate article.

Only use specially designed brake hoses/lines on ABS-equipped vehicles.

DO NOT tap on speed sensor components (sensor, sensor rings). Speed rings must be pressed, NOT

hammered into hubs. Striking these components can cause demagnetization or a loss of polarization,

affecting the accuracy of the speed signal returning to the ABS control unit.

DO NOT mix tire sizes. Increasing the width, as long as tires remain close to the original diameter, is

acceptable. Rolling diameter must be identical for all 4 tires. Some manufacturers recommend tires of the

same brand, style and type. Failure to follow this precaution may cause inaccurate wheel speed readings.

DO NOT contaminate speed sensor components with grease. Only use recommended anti-corrosion

coating.

When speed sensor components have been removed, ALWAYS check sensor-to-ring air gaps when

applicable. These specifications can be found in each appropriate article.

ONLY use recommended brake fluids. DO NOT use silicone brake fluids in an ABS-equipped vehicle.

When installing transmitting devices (CB's, telephones, etc.) on ABS-equipped vehicles, DO NOT locate

the antenna near the ABS control unit (or any control unit).

Disconnect all on-board computers, when using electric welding equipment. CAUTION: See ANTI-LOCK BRAKE SAFETY PRECAUTIONS below.

WARNING:Refer to appropriate Anti-Lock Brakes (ABS) article for description,

operation, depressurizing, testing, system bleeding, trouble shooting and

system service. Failure to depressurize ABS could lead to physical injury.

1991 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1988-91 BRAKES Mazda Anti-Lock Brake System

Microsoft

Sunday, July 05, 2009 2:17:31 PMPage 3 © 2005 Mitchell Repair Information Company, LLC.

Page 164 of 392

1. Disconnect hydraulic unit 12-pin connector. Using a DVOM, measure resistance between Green/Black

and Yellow/Red wires, Green/White and Yellow/Red wires and Yellow and Yellow/Red wires.

Resistance should be 1-1.2 ohms in each measurement.

2. If resistance if not as specified, replace hydraulic unit. If resistance is as specified, check wiring harness

between ABS control unit and hydraulic unit.

HYDRAULIC UNIT

Only serviceable parts of hydraulic unit are motor relay and valve relay. If other parts of unit malfunction,

replace hydraulic unit assembly.

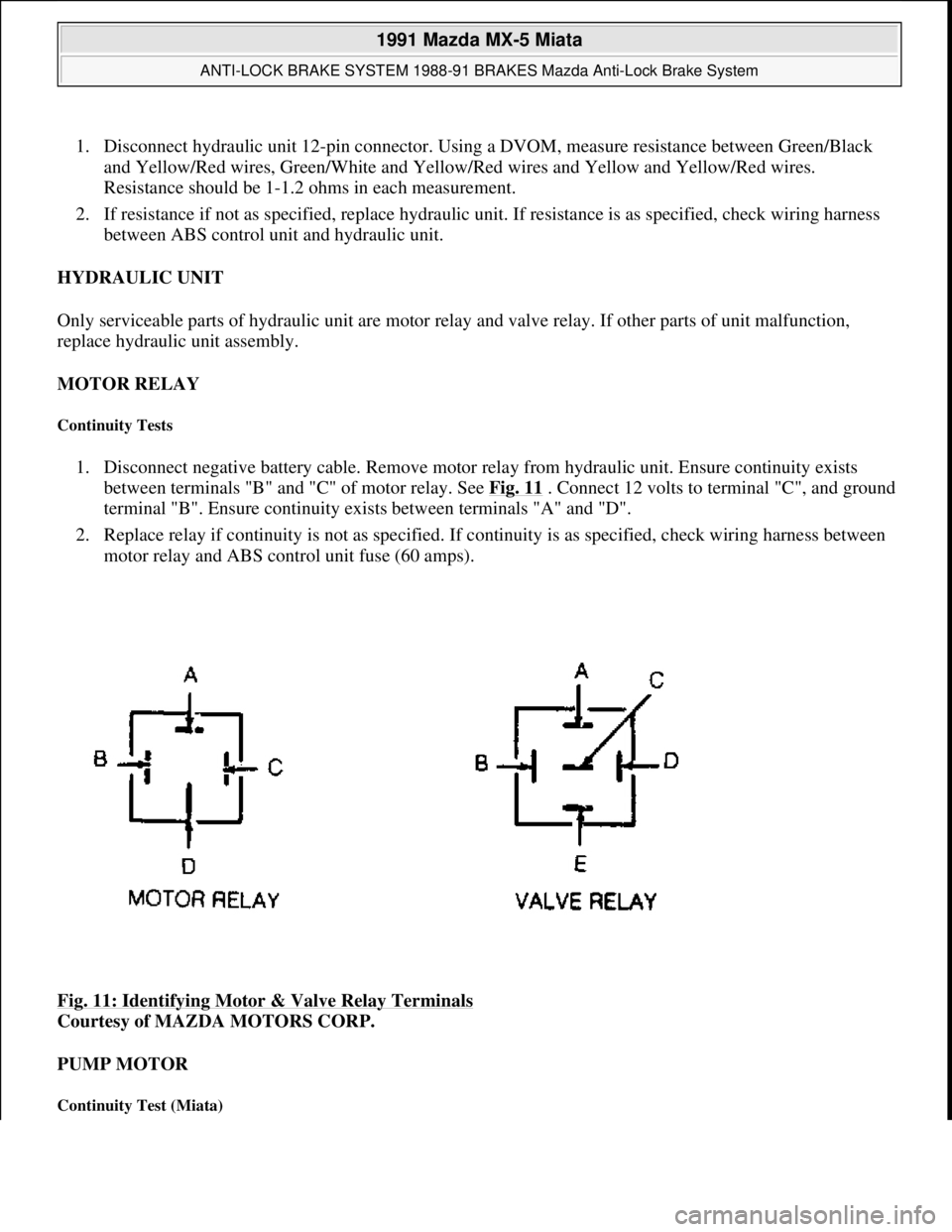

MOTOR RELAY

Continuity Tests

1. Disconnect negative battery cable. Remove motor relay from hydraulic unit. Ensure continuity exists

between terminals "B" and "C" of motor relay. See Fig. 11

. Connect 12 volts to terminal "C", and ground

terminal "B". Ensure continuity exists between terminals "A" and "D".

2. Replace relay if continuity is not as specified. If continuity is as specified, check wiring harness between

motor relay and ABS control unit fuse (60 amps).

Fig. 11: Identifying Motor & Valve Relay Terminals

Courtesy of MAZDA MOTORS CORP.

PUMP MOTOR

Continuity Test (Miata)

1991 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1988-91 BRAKES Mazda Anti-Lock Brake System

Microsoft

Sunday, July 05, 2009 2:17:32 PMPage 12 © 2005 Mitchell Repair Information Company, LLC.

Page 205 of 392

Fig. 1: Adjusting Brake Booster Push Rod (Navajo)

Courtesy of FORD MOTOR CO.

2. Place gauge against master cylinder mounting surface of booster. Adjust push rod screw by turning it

until end of screw just touches inner edge of gauge slot.

REAR BRAKE SHOES

B2200 & B2600i 2WD

NOTE: Self-adjusting rear brakes only require manual adjustment when brake shoe is

replaced or operating lever is moved during service operations.

1991 Mazda MX-5 Miata

BRAKE SYSTEM 1991 BRAKES Mazda Brake System

Microsoft

Sunday, July 05, 2009 2:18:08 PMPage 2 © 2005 Mitchell Repair Information Company, LLC.