check oil MAZDA MIATA 1997 Factory Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1997, Model line: MIATA, Model: MAZDA MIATA 1997Pages: 514, PDF Size: 17.89 MB

Page 140 of 514

RECTIFIER/DIODE ASSEMBLY

1. Using an ohmmeter, check continuity of each diode in both directions (polarity). See Fig. 2

thru Fig. 4. If

diode shows high resistance in one direction and low resistance in other direction, diode is okay.

2. If diode shows low resistance in both directions, diode is shorted. If diode shows high resistance in both

directions, diode is open. If any diode is defective, replace rectifier assembly.

ROTOR & SLIP RINGS

Measure resistance between rotor slip ring contacts. See Fig. 5

thru Fig. 9 . If resistance is not within

specification, replace rotor. See ROTOR RESISTANCE SPECIFICATIONS

table. Check continuity

between individual slip rings and rotor core/shaft. If continuity exists, replace rotor.

ROTOR RESISTANCE SPECIFICATIONS

STATOR

Check continuity between stator coil leads and stator core. See Fig. 5

thru Fig. 9 . If continuity exists, replace

stator. Check continuity between leads of stator coil. If continuity does not exist, replace stator.

BRUSHES

Replace brushes if worn to limit line. See Fig. 5

thru Fig. 9 . Replace brush springs if corroded. For brush

replacement procedure, see OVERHAUL

.

Application(1) Ohms

Miata3.5-4.5

(1)If continuity does not exist, replace rotor.

1997 Mazda MX-5 Miata

GENERATOR & REGULATOR 1997 STARTING & CHARGING SYSTEMS Mazda - Generators & Regulators

Microsoft

Sunday, July 05, 2009 1:53:16 PMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 160 of 514

Submerge other end of hose in container of brake fluid.

2. Fill reservoir with DOT 3 brake fluid. Have an assistant press and release clutch pedal several times, then

hold pedal down. With pedal pressed, loosen bleeder screw to let air and fluid escape.

3. Repeat step 2) until no more air bubbles emerge from hose. Tighten bleeder screw. Fill reservoir. Operate

clutch while inspecting for leaks. Check clutch and brake operation.

REMOVAL & INSTALLATION

CLUTCH ASSEMBLY

Removal (B2300, B2500, B3000 & B4000)

1. Disconnect negative battery cable. Shift transmission into Neutral. Remove gearshift lever. Raise and

support vehicle. Mark drive shaft flanges for installation reference. Remove drive shaft. Using Clutch

Disconnect Tool (T88T-70522-A), disconnect hydraulic line at transmission. See Fig. 2

. Plug hydraulic

line to prevent contamination. Disconnect wiring at transmission.

2. Remove starter. Remove exhaust components as necessary for clearance. On 4WD models, remove skid

plate and transfer case. On all models, secure transmission jack under transmission. Remove transmission

mount-to-crossmember nuts and bolts.

3. Remove nuts securing crossmember to frame side rails, and remove crossmember. Lower transmission

enough to gain access to transmission-to-engine block bolts. Remove transmission-to-engine block bolts.

Remove transmission.

4. If clutch parts are going to be reused, mark clutch cover and flywheel for reassembly reference. Loosen

pressure plate bolts evenly in crisscross pattern until springs are not under tension. Remove clutch cover

and clutch disc.

Inspection (B2300, B2500, B3000 & B4000)

1. Inspect disc for loose rivets, worn or defective springs, excessive wear, or oil contamination. Inspect

flywheel and clutch cover for burns, scoring, or grooves.

2. Measure flywheel and clutch cover runout. Resurface or replace flywheel and clutch cover if beyond

specification. See CLUTCH RUNOUT (MAXIMUM)

table.

3. Measure clutch disc runout. Replace disc if it is not to specification. See CLUTCH RUNOUT

(MAXIMUM) table. Inspect disc hub and input shaft splines for excessive wear. Hub must slide

smoothly on input shaft splines.

4. Inspect pilot bearing for wear. Apply inward pressure while rotating pilot bearing. If bearing sticks or has

excessive resistance, replace bearing. Check for tight fit in crankshaft. Replace as necessary. Inspect

release bearing for smooth operation, wear, damage, or looseness. Replace bearing as necessary.

CLUTCH RUNOUT (MAXIMUM)

ApplicationIn. (mm)

Disc0.028 (0.7)

Flywheel0.008 (0.20)

1997 Mazda MX-5 Miata

CLUTCH 1997-98 CLUTCHES Mazda - RWD

Microsoft

Sunday, July 05, 2009 1:36:47 PMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 165 of 514

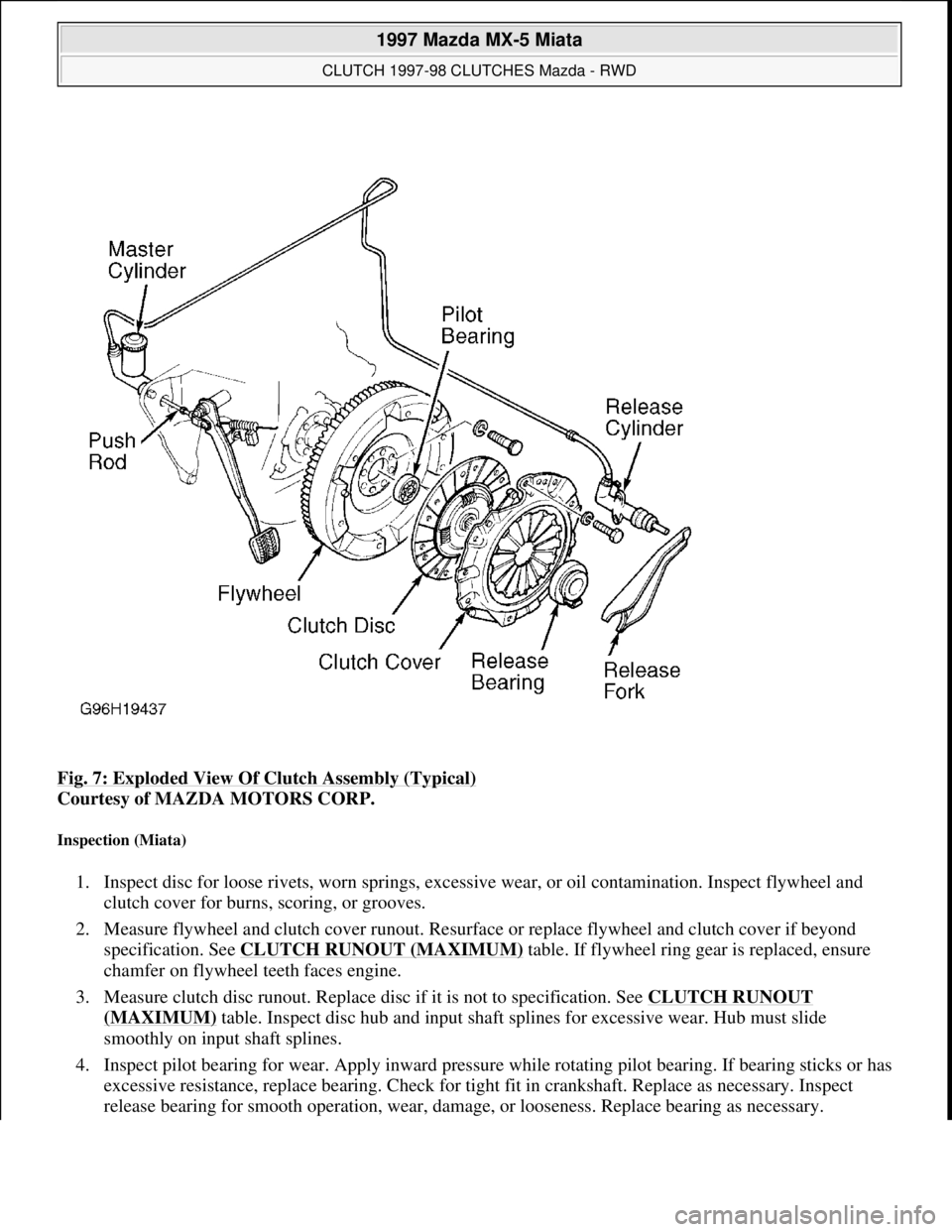

Fig. 7: Exploded View Of Clutch Assembly (Typical)

Courtesy of MAZDA MOTORS CORP.

Inspection (Miata)

1. Inspect disc for loose rivets, worn springs, excessive wear, or oil contamination. Inspect flywheel and

clutch cover for burns, scoring, or grooves.

2. Measure flywheel and clutch cover runout. Resurface or replace flywheel and clutch cover if beyond

specification. See CLUTCH RUNOUT (MAXIMUM)

table. If flywheel ring gear is replaced, ensure

chamfer on flywheel teeth faces engine.

3. Measure clutch disc runout. Replace disc if it is not to specification. See CLUTCH RUNOUT

(MAXIMUM) table. Inspect disc hub and input shaft splines for excessive wear. Hub must slide

smoothly on input shaft splines.

4. Inspect pilot bearing for wear. Apply inward pressure while rotating pilot bearing. If bearing sticks or has

excessive resistance, replace bearing. Check for tight fit in crankshaft. Replace as necessary. Inspect

release bearing for smooth operation, wear, damage, or looseness. Replace bearing as necessary.

1997 Mazda MX-5 Miata

CLUTCH 1997-98 CLUTCHES Mazda - RWD

Microsoft

Sunday, July 05, 2009 1:36:47 PMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 181 of 514

axle shaft housing. Remove axle oil seal. See Fig. 5. With axle shaft removed, remove retaining ring.

Remove ABS sensor rotor.

4. To remove bearing collar, grind collar until a section about .02" (.50 mm) remains. Using chisel, cut

remaining bearing collar from axle shaft. Using Puller (49-S121-520A), remove axle bearing from axle

shaft. Remove dust shield and backing plate.

5. Using dial indicator and "V" blocks, check axle shaft for straightness. Maximum axle shaft runout

is .059" (1.50 mm). Also check axle shaft splines for wear and damage. Use a press to replace wheel studs

as necessary. DO NOT reuse wheel studs if removed.

Installation

To install, reverse removal procedure. Lubricate oil seal lip before replacement. Use Attachment (49-1011-748)

and a press to install axle bearing onto axle shaft. DO NOT lubricate bearing collar before replacement. Use

Attachment (49-1011-748) and a press to install NEW bearing collar. If press fit of collar requires less than 2.7

tons (2699 k

g) to install, replace axle shaft. Tighten nuts to specification. See TORQUE SPECIFICATIONS.

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

Microsoft

Sunday, July 05, 2009 1:52:42 PMPage 7 © 2005 Mitchell Repair Information Company, LLC.

Page 194 of 514

Fig. 12: Checking Drive Pinion Installation & Position

Courtesy of MAZDA MOTORS CORP.

6. Install dial indicator on Pinion Height Gauge (49-0727-570). Place pinion height gauge on a flat surface

and zero dial indicator. Position gauge block on top of dummy drive pinion assembly. See GAUGE

BLOCK SELECTION table.

GAUGE BLOCK SELECTION

7. Place pinion height gauge on top of gauge block. Position dial indicator to measure distance to a point

where side bearing sits. Measure lowest point. See Fig. 12

. Measure both sides. Add both measurements

together and divide by 2.

8. If result is not zero, replace pinion spacer. Spacers are available in a range of .1213-.1366" (3.080-3.470

mm) in .001" (.03 mm) increments. Remove dummy drive pinion. Press rear bearing onto drive pinion.

9. Install drive pinion, spacer, front bearing, collapsible spacer and companion flange in differential carrier.

DO NOT install pinion oil seal yet. DO NOT exceed one-ton force; collapsible spacer will be damaged.

10. Install washer and drive pinion lock nut. Temporarily tighten drive pinion lock nut. Turn companion

flange by hand to seat bearing. Using torque wrench, tighten drive pinion lock nut to specification. See

TORQUE SPECIFICATIONS

. Check pinion bearing preload at drive pinion lock nut. See PINION

PRELOAD SPECIFICATIONS table. If pinion bearing preload is not as specified, replace collapsible

spacer and recheck preload.

PINION PRELOAD SPECIFICATIONS

11. Remove drive pinion lock nut, washer and companion flange. Install pinion oil seal. Lubricate oil seal lip

with differential oil. Install companion flange and washer. Install NEW drive pinion lock nut and tighten

to specification. See TORQUE SPECIFICATIONS

. Recheck pinion bearing preload. Lubricate end of

companion flange with grease.

12. Position differential assembly into differential carrier. Install side bearing adjusters. Position side bearing

caps. Align marks made during disassembly. Install side bearing cap bolts and hand-tighten bolts.

13. Ti

ghten side bearing adjusters equally until adjusters contact bearing races. Mark ring gear in 4 locations,

ApplicationGauge Block No.

Front Differential

MPV

4WD49-0305-555

Rear Differential

Miata49-0305-555

MPV49-0660-555

ApplicationINCH Lbs. (N.m)

Miata7.8-12.1 (0.9-1.3)

MPV 2WD11.3-15.6 (1.3-1.8)

MPV 4WD

Front7.8-12.2 (0.9-1.4)

Rear11.3-15.6 (1.3-1.8)

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

Microsoft

Sunday, July 05, 2009 1:52:42 PMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 207 of 514

1997-98 ENGINES

1.8L 4-Cylinder

ENGINE IDENTIFICATION

Engines can be identified by engine model and number. See ENGINE IDENTIFICATION CODE. On Miata,

engine model and number are stamped on flange at upper right rear of cylinder block deck, as viewed from

flywheel. On Protege, engine model and number are stamped on flange at upper left rear of cylinder block deck,

as viewed from flywheel.

ENGINE IDENTIFICATION CODE

ADJUSTMENTS

VALVE CLEARANCE ADJUSTMENT

REMOVAL & INSTALLATION

FUEL PRESSURE RELEASE & PRIMING

Releasing Pressure (Miata)

Locate and remove fuel pump relay from under left side of dash, near steering column. Start engine and allow to

stall. After engine stalls, attempt to restart engine to ensure no residual pressure exists. Turn ignition off and

reinstall fuel pump relay. When disconnecting fuel hoses, cover connection with shop rag to catch fuel leakage.

To avoid excessive cranking after servicing, prime fuel system before starting engine.

Releasing Pressure (Protege)

NOTE: For repair procedures not covered in this article, see ENGINE OVERHAUL

PROCEDURES article in GENERAL INFORMATION.

ApplicationCode

Miata & Protege (1.8L DOHC)BP

NOTE: Valve clearance is not adjustable. Some Hydraulic Lash Adjuster (HLA) noise

may occur during engine start-up. Noise should disappear after engine reaches

normal operating temperature. If noise persists and oil level is okay, change

engine oil. If oil change does not reduce noise, check with manufacturer for

modified HLA.

NOTE: For reassembly reference, label all electrical connectors, vacuum hoses and

fuel lines before removal. Also place mating marks on engine hood and other

major assemblies before removal.

1997 Mazda MX-5 Miata

1997-98 ENGINES 1.8L 4-Cylinder

1997 Mazda MX-5 Miata

1997-98 ENGINES 1.8L 4-Cylinder

Microsoft

Sunday, July 05, 2009 1:55:15 PMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, July 05, 2009 1:55:19 PMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 219 of 514

Inspection (All Models)

Check timing belt for cracks, peeling, abrasion or other damage. Check tensioner bearing for looseness or

roughness of rotation. Inspect tensioner spring for stretching. Replace parts as necessary.

Installation (All Models)

1. Position notch on crankshaft sprocket to 12 o'clock position (aligned with mark on oil pump). Align

timing marks on camshaft sprockets. See Fig. 8

. Ensure crankshaft timing mark is at TDC. Install belt

around crankshaft sprocket, then working in a counterclockwise direction, route belt around camshaft

sprockets.

2. Loosen timing belt tensioner lock bolt and allow spring to apply tension on belt. Snug tensioner lock bolt.

Rotate crankshaft 2 complete turns in direction of normal engine rotation. Ensure timing marks align. If

timing marks are not aligned, remove belt, realign all timing marks, and repeat installation procedure.

3. Check timing belt deflection with 22 lbs. (10 kg) of pressure applied to belt. See Fig. 9

. Ensure timing

belt deflection is within specification. See TIMING BELT DEFLECTION

.

TIMING BELT DEFLECTION

Application(1) Deflection In. (mm)

Miata & Protege.35-.45 (9.0-11.5)

(1)Deflection measurement is with 22 lbs. (10 kg) of pressure applied to timing belt. See Fig. 9 .

1997 Mazda MX-5 Miata

1997-98 ENGINES 1.8L 4-Cylinder

Microsoft

Sunday, July 05, 2009 1:55:15 PMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 229 of 514

Courtesy of MAZDA MOTORS CORP.

Removal & Installation (Protege)

1. Disconnect negative battery cable. Remove engine undercovers. Drain engine oil. Remove exhaust header

downpipe and brackets from front exhaust system. Remove oil pan retaining bolts.

2. DO NOT damage sealant contact surfaces. Remove oil pan by prying between oil pan and mounting

surface. On Protege, remove stiffener by prying between stiffener and cylinder block. On all models,

clean all sealant from oil pan, bolts, engine block and both sides of stiffener (Protege).

3. On Protege, apply oil resistant sealant to engine block and stiffener. Install stiffener. On all models, apply

sealant and install oil pan within 5 minutes of applying sealant. To complete installation, reverse removal

procedure. Tighten all bolts to specification. See TORQUE SPECIFICATIONS

. Fill engine with oil to

specification. See ENGINE LUBRICATION SYSTEM

under ENGINE OILING.

OVERHAUL

CYLINDER HEAD

Cylinder Head

Clean carbon and gasket material from all mating surfaces. Using a tap, clean cylinder head threads. Check

cylinder head warpage. If warpage exceeds specification, resurface head, but DO NOT exceed grinding limit.

See CYLINDER HEAD

under ENGINE SPECIFICATIONS. After resurfacing cylinder head, check cylinder

head height. Replace cylinder head if height is less than minimum specification.

Valve Springs

Ensure valve spring free length, out-of-square and compressed length are within specification. See VALVES &

VALVE SPRINGS under ENGINE SPECIFICATIONS. Replace valve spring if necessary.

Valve Stem Oil Seals

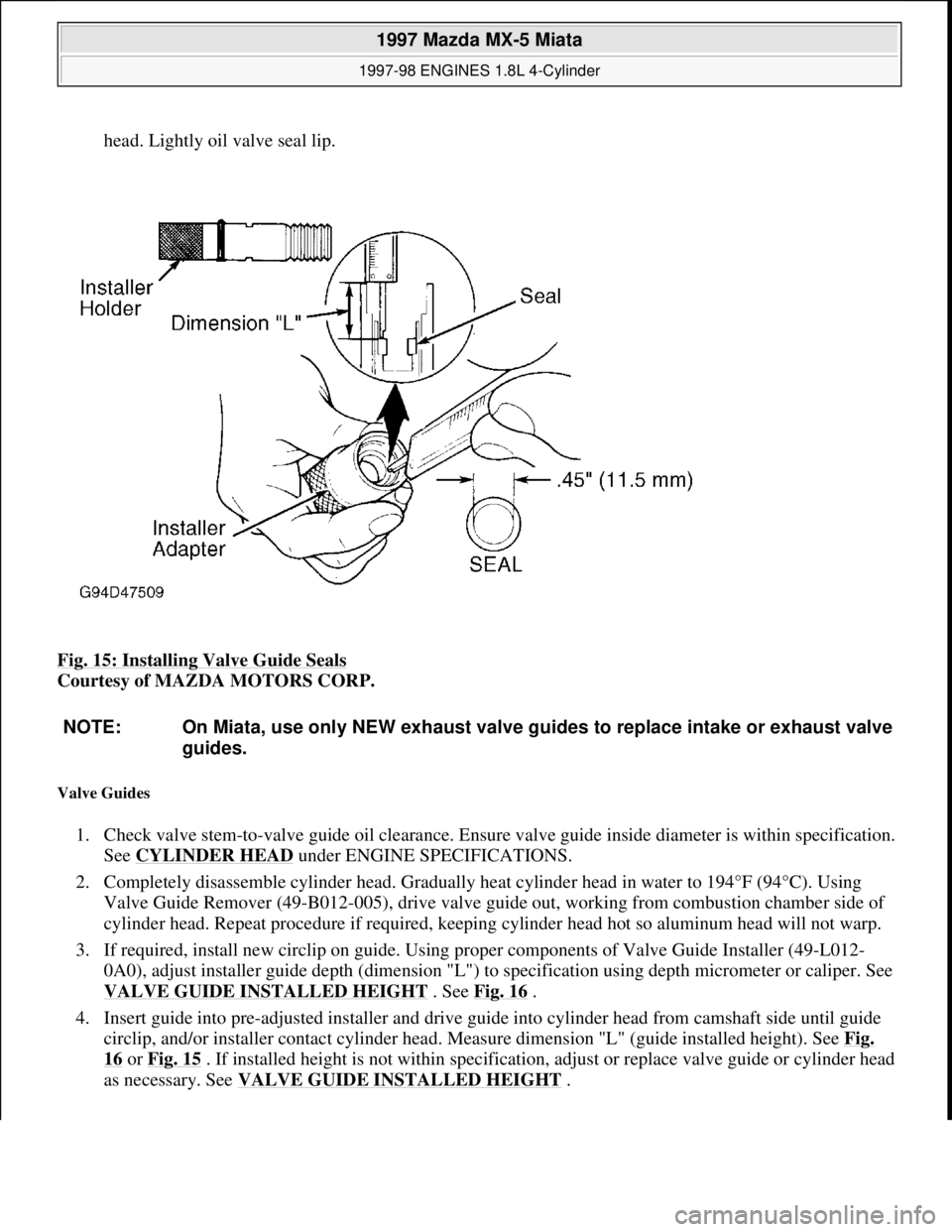

1. On Miata, use Installer Set (49-L012-0A0) to install valve seals. See Fig. 15 . Adjust installer dimension

"L" to seal depth of .720-.744" (18.3-18.9 mm). Using hand pressure ONLY, install seal until it contacts

cylinder head. Lightly oil valve seal lip.

2. On Protege, use Installer Set (49-L012-0A0) to install valve seals. See Fig. 15

. Adjust installer

dimension "L" to seal depth of .783" (19.9 mm). Using hand pressure, install seal until it contacts cylinder CAUTION: If reusing old oil pan bolts, remove old sealant from bolt threads.

Failure to remove old sealant may result in cracked block at bolt

holes.

NOTE: Intake and exhaust valve stem seals are different. Exhaust seals can be

identified by ridges molded into top of seal. Intake seals do not have identifying

ridges. Incorrect installation of valve stem seals will cause premature failure.

1997 Mazda MX-5 Miata

1997-98 ENGINES 1.8L 4-Cylinder

Microsoft

Sunday, July 05, 2009 1:55:15 PMPage 23 © 2005 Mitchell Repair Information Company, LLC.

Page 230 of 514

head. Lightly oil valve seal lip.

Fig. 15: Installing Valve Guide Seals

Courtesy of MAZDA MOTORS CORP.

Valve Guides

1. Check valve stem-to-valve guide oil clearance. Ensure valve guide inside diameter is within specification.

See CYLINDER HEAD

under ENGINE SPECIFICATIONS.

2. Completely disassemble cylinder head. Gradually heat cylinder head in water to 194°F (94°C). Using

Valve Guide Remover (49-B012-005), drive valve guide out, working from combustion chamber side of

cylinder head. Repeat procedure if required, keeping cylinder head hot so aluminum head will not warp.

3. If required, install new circlip on guide. Using proper components of Valve Guide Installer (49-L012-

0A0), adjust installer guide depth (dimension "L") to specification using depth micrometer or caliper. See

VALVE GUIDE INSTALLED HEIGHT

. See Fig. 16 .

4. Insert guide into pre-adjusted installer and drive guide into cylinder head from camshaft side until guide

circlip, and/or installer contact cylinder head. Measure dimension "L" (guide installed height). See Fig.

16 or Fig. 15 . If installed height is not within specification, adjust or replace valve guide or cylinder head

as necessary. See VALVE GUIDE INSTALLED HEIGHT

.

NOTE: On Miata, use only NEW exhaust valve guides to replace intake or exhaust valve

guides.

1997 Mazda MX-5 Miata

1997-98 ENGINES 1.8L 4-Cylinder

Microsoft

Sunday, July 05, 2009 1:55:15 PMPage 24 © 2005 Mitchell Repair Information Company, LLC.

Page 233 of 514

Valves

Check valve face angle, head diameter, margin thickness and stem diameter. Service or replace valves if

measurements are not within specifications. See VALVES & VALVE SPRINGS

under ENGINE

SPECIFICATIONS.

Valve Seat Correction Angles

Measure seat contact width on valve. See VALVE SEAT. If seat width is not within specification or if valve

face does not contact center of valve seat, correct seat using a 70-degree grinding stone. After correcting seat,

lightly finish seat with 45-degree grinding stone.

VALVE TRAIN

Hydraulic Lash Adjusters

1. Remove camshaft cover. Check movement of each Hydraulic Lash Adjuster (HLA) by pushing

downward using hand pressure only. If HLA compresses, replace HLA. To remove HLA, remove

camshafts. See CAMSHAFT

under REMOVAL & INSTALLATION. Mark location of HLA before

removing from bore. Lift HLA from cylinder head.

2. Inspect HLA friction surfaces for wear and damage. Replace HLA if required. Coat HLA with engine oil

and install in original location. Ensure HLA moves smoothly in bore by using small magnet attached to

HLA.

CYLINDER BLOCK ASSEMBLY

Piston & Connecting Rod Assembly

1. Before removing rod cap from crankshaft, measure and record rod side play. See CONNECTING RODS

under ENGINE SPECIFICATIONS. Before removing connecting rods, measure and record connecting

rod bearing oil clearance. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS

under

ENGINE SPECIFICATIONS.

2. Before separating piston from connecting rod, mark piston in relation to connecting rod. Check

oscillation movement of piston and rod assembly (hold piston horizontally, lift rod and allow rod to drop

by its own weight). If pin binds in pin bore (rod does not drop), replace piston and/or pin as necessary.

3. To separate components, press piston pin out of piston and rod assembl

y, noting pressure required to

Normal1.772-1.791 (45.00-45.50)

Serviceable1.733-1.772 (45.60-46.50)

NOTE: If hydraulic lash adjusters are persistently noisy, check with manufacturer

for availability of modified adjusters.

NOTE: During disassembly, match mark components for reassembly reference.

1997 Mazda MX-5 Miata

1997-98 ENGINES 1.8L 4-Cylinder

Microsoft

Sunday, July 05, 2009 1:55:15 PMPage 27 © 2005 Mitchell Repair Information Company, LLC.