change time MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 45 of 1708

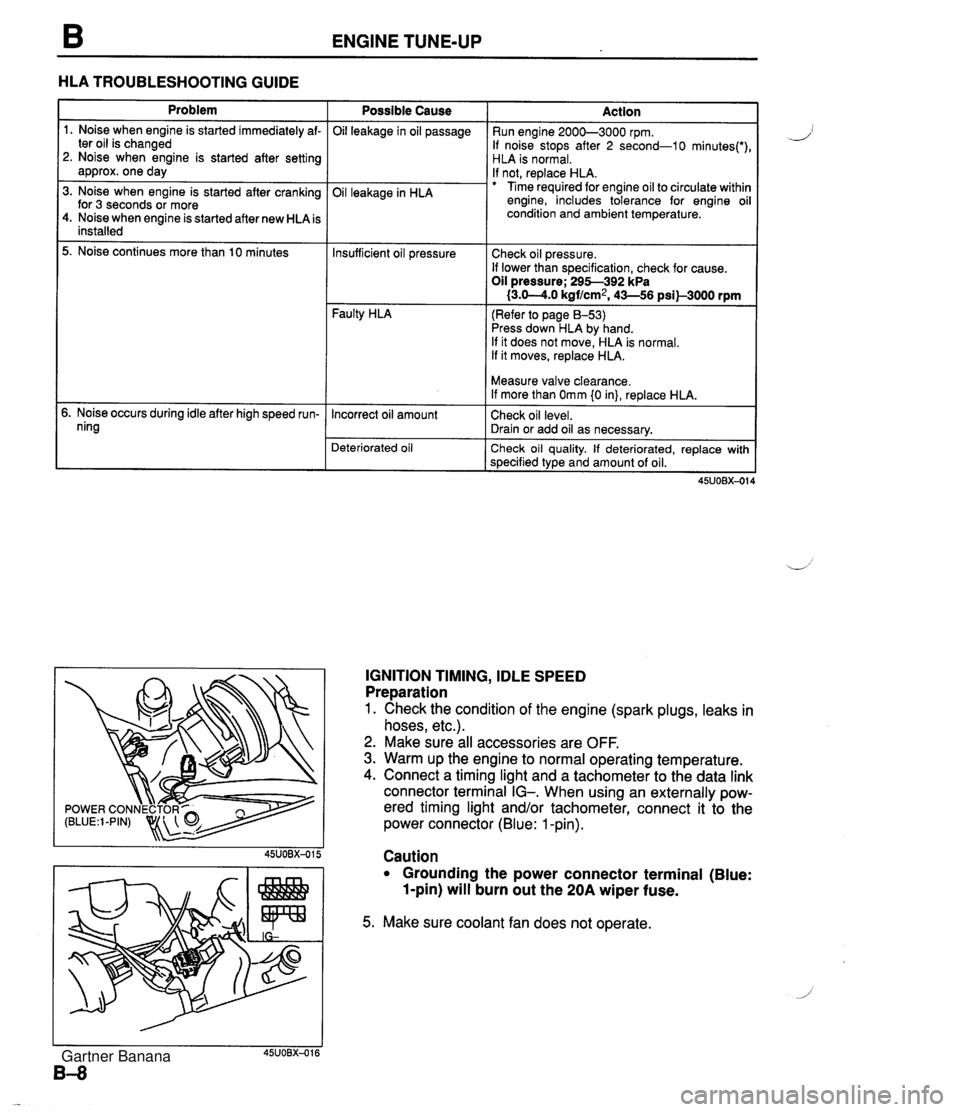

ENGINE TUNE-UP HLA TROUBLESHOOTING GUIDE Problem 1. Noise when engine is started immediately af- ter oil is changed 2. Noise when engine is started after setting approx. one day 3. Noise when engine is started after cranking for 3 seconds or more 4. Noise when engine is started after new HLA is installed 5. Noise continues more than 10 minutes 5. Noise occurs during idle after high speed run- ning Possible Cause Oil leakage in oil passage Oil leakage in HLA Faulty HLA Action Run engine 2000-3000 rpm. If noise stops after 2 second-10 minutes(') HLA is normal. If not, replace HLA. Time required for engine oil to circulate withir engine, includes tolerance for engine oi condition and ambient temperature. Insufficient oil pressure (Refer to page 8-53) Press down HLA by hand. If it does not move, HLA is normal. If it moves, replace HLA. Check oil pressure. If lower than specification, check for cause. Oil pressure; 295-392 kPa I3.0-4.0 kgf/cm2, 43-56 psil-3000 rpm Deteriorated oil Check oil quality. If deteriorated, replace with specified type and amount of oil. Incorrect oil amount IGNITION TIMING, IDLE SPEED Preparation 1. Check the condition of the engine (spark plugs, leaks in hoses, etc.). 2. Make sure all accessories are OFF. 3. Warm up the engine to normal operating temperature. 4. Connect a timing light and a tachometer to the data link connector terminal IG-. When using an externally pow- ered timing light and/or tachometer, connect it to the power connector (Blue: 1 -pin). Measure valve clearance. If more than Omm {0 in}, replace HLA. Check oil level. Drain or add oil as necessary. Caution Grounding the power connector terminal (Blue: 1-pin) will burn out the 20A wiper fuse. 5. Make sure coolant fan does not operate. Gartner Banana

Page 164 of 1708

TROUBLESHOOTING GUIDE DIAGNOSTIC INDEX Cranks normally but will not start (No com- Engine cranks at normal speed but shows no sign of bustion) I #firingN I F-17 I No. 1 TROUBLESHOOTING ITEM Will not crank or cranks slowly -- -- Cranks normally but will not start (Partial combustion) -When engine is cold Cranks normally but will not start (Partial combustion) - After warm-up Cranks normally but hard to start - Always Cranks normally but hard to start - When engine is cold - Engine cranks at normal speed but shows partial com- bustion and will not continue to run Engine cranks at normal speed but shows partial com- bustion and will not continue to run after running and hot soaked Engine cranks at normal speed but requires excessive cranking time (more than 5 sec.) before starting Same condition as No.5 when engine is cold Restarts OK after warm-up 8 DESCRIPTION Refer to Engine Electrical System Low idle speed1Rough idle - Before warm- UP Low idle speed/Rough idle -After warm-up PAGE SECTION G Cranks normally but hard to start - After warm-up Rough idle - Always Engine speed low or engine vibrates excessively at idle during warm-up Engine runs normally at idle during warm-up but vi- brates excessively after warm-up High idle speed - After warm-up Low idle speed - When NC, PIS, or EIL ON l5 1 Engine stalls at idle - Always Engine starts normally but vibrates excessively and stalls at idle in every condition I F40 1 13 14 Same condition as No.5 after running and hot soaked Starts normally when cold Engine vibrates excessively at idle in every condition Engine idle excessive for operation mode Engine speed decreases at idle when NC, PIS, or EIL is ON 18 1 Engine stalls during start-up 1 Engine unexpectedly stops running while starting I F-45 F-26 F-27 F-34 F-36 Rough idle just after starting Idle moves up and down 16 17 l9 1 Engine stalls on deceleration I Engine unexpectedly stops running while decelerating or after deceleration Engine starts normally but vibrates excessively only just after starting Engine speed up and down periodically at idle Engine stalls at idle - Before warm-up Engine stalls at idle - After warm-up Engine stalls at idle -When AIC, PIS, or EIL running at idle when 1 20 1 ON I F-50 1 F-37 F-38 I I . . I 21 1 Engine stalls suddenly (Intermittent) I Engine intermittently stops running I F-52 Engine starts normally but vibrates excessively and stalls at idle before warm-up Engine runs normally at idle during warm-up but be- comes rouclh and stalls after warm-up F-43 F-44 24 1 Lack of power Performance is poor under load Maximum speed re- 1 duced I F-57 I Hesitates/Stumbles on acceleration Surges while cruising I I I 25 / Poor acceleration I Performance is poor while accelerating 1 F-61 I Flat spot occurs just after accelerator is depressed or mild jerking occurs during acceleration Unexpected, usually repetitive change in engine speed Knocking F-53 F-55 Runs rough on deceleration1Afterburn Abnormal combustion accompanied by audible "ping- ing" noise I F-67 I Engine runs rough while decelerating and abnormal combustion in exhaust system 1 30 1 High oil consumption I Oil consumption excessive I F-70 1 F-65 28 1 Fuel odor 29 / Exhaust sulfur smell 1 31 1 Poor fuel economy I Fuel economy unsatisfactory I F-71 I Gasoline odor in cabin Exhaust gas smells abnormal (rotten egg smell) F-69 F-70 Gartner Banana

Page 174 of 1708

TROUBLESHOOTING GUIDE CRANKS NORMALLY BUT HARD TO START - WHEN ENGINE IS COLD c Engine cranks at normal speed but requires excessive cranking time before starting IESCRIPTION Battery in normal condition Restarts OK after warm-up TROUBLESHOOTING HINTS] D AirIFuel mixture too rich Air cleaner element clogged Idle speed control malfunction Q AirJFuel mixture too lean Fuel injection control malfunction (Correction for coolant temperature) O Poor atomization of fuel Low RVP (summer) fuel used in cold weather INSPECTION Check if "00" is displayed on Self-Diagnosis Check- er with ignition switch ON page F-79 ACTION - Yes - No - Yes GO to next sGP Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) E+T page F-81 "88" flashes Check PCME terminal 1 E voltage page F-145 Specification : Battery positive voltage (Ignition switch ON) c:, If OK, replace PCME page F-143 o If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Check if PCME terminal voltages are OK (1 C, 2D, 20 and 2Q) page F-145 Go to next step Check for cause (Refer to "Check Point for Each Termi- nal") I@ page F-148 Check if engine starts easily when depressing ac- celerator while cranking Yes Check if idle air control valve is OK @F page F-106 o If OK, check air valve page F-105 6 If not OK, replace IAC valve page F-106 No - Yes - No Go to next step Check for correct intake manifold vacuum at idle Go to next step Vacuum: More than 450 mmHg (17.7 inHg} VACUUM GAUGE / Check for air leakage of intake air system components US= page F-1 00 Check if air cleaner element is clean @&Y page F-76 Yes - No Go to next step Replace air cleaner element page F-99 Try known good PCME and check if condition @&Y page F-144 Yes - No - Replace PCME Change fuel to another brand Gartner Banana

Page 175 of 1708

![MAZDA MX-5 1994 Workshop Manual F TROUBLESHOOTING GUIDE [TROUBLESHOOTING HINTS] D AirIFuel mixture too rich 7 Q Vaoor lock CRANKS NORMALLY BUT HARD TO START - AFTER WARM-UP Fuel pressure not held in fuel line after engine stops 0 Hi MAZDA MX-5 1994 Workshop Manual F TROUBLESHOOTING GUIDE [TROUBLESHOOTING HINTS] D AirIFuel mixture too rich 7 Q Vaoor lock CRANKS NORMALLY BUT HARD TO START - AFTER WARM-UP Fuel pressure not held in fuel line after engine stops 0 Hi](/img/28/57072/w960_57072-174.png)

F TROUBLESHOOTING GUIDE [TROUBLESHOOTING HINTS] D AirIFuel mixture too rich 7 Q Vaoor lock CRANKS NORMALLY BUT HARD TO START - AFTER WARM-UP Fuel pressure not held in fuel line after engine stops 0 High RVP (winter) fuel used in warm weather ACTION DESCR'PnON Fuel injection control malfunction Fuel injector fuel leakage Check if "00" is displayed on Self-Diagnosis Check- er with ignition switch ON uar page F-79 Engine cranks at normal speed but requires excessive cranking time (more than 5 sec.) before starting after run- ning and hot soaked Battery in normal condition Engine starts normally when cold 1 Check if PCME terminal voltages are OK (2D,2R and 2Q) page F-145 INSPECTION Run engine at idle and check if fuel line pressure is held after ignition switch turned OFF page F-109 Fuel line pressure: More than 147 kPa (1.5 kgf/cm2, 21 psi} for 5 min. INSTALL CLAPS Try known good PCME and check if condition im- proves US page F-144 Yes - No Yes - No Yes No - Yes Go to next step Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage page F-145 Specification: Battery positive voltage (Ignition switch ON) 0 If OK, replace PCME @sf page F-143 G If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Go to next step Check for cause (Refer to "Check Point for Each Termi- nal") page F-148 Go to next step Block outlet of pressure regulator and check if fuel line pressure is held after ignition switch is turned OFF page F-117 If OK, replace pressure regulator page F-118 Q If not OK, check fuel pump hold pressure I@? page F-115 If fuel pump is OK, check fuel injector for fuel leakage page F-120 Replace PCME Change fuel to another brand Gartner Banana

Page 221 of 1708

TROUBLESHOOTING GUIDE INSPECTION Check if PCME terminal voltages are OK (20,2N, 20,2P, 2Q, 2R, 2U and 2V) page F-146 Check if fuel cut operation is OK during decelera- tion Fuel cut: Above 1,900 rpm after warm-up Check for correct ignition timing at idle page F-76 Ignition timing: 10" 2 lo BTDC Check for correct fuel line pressure at idle page 6118 Fuel line pressure: 216-264 kPa i2.2-2.7 kgf/cm2, 32-48 psi) INSTALL CLAPS ' Run engine at idle and check if fuel line pressure is held after ignition switch turned OFF page F-109 Fuel line pressure: More than 147 kPa {I .5 kgf/cm2, 21 psi) for 5 mln. PRESSURE IGNITION 5 MIN. TIME SWITCH OFF Yes - No Yes No Yes No Yes No - Yes No ACTION Go to next step Check for cause (Refer to "Check Point for Each Terrni- nal") paae F-148 Go to next step Try known good PCME @ page F-144 Go to next step Adjust page M6 Go to next step High pressure Check if vacuum hose to pressure regulator is damaged or poorly connected o If OK, replace pressure regulator * page F-119 O If not OK, repair or replace hose So to next step Check fuel injector for fuel leakage page F-120 Change fuel to another brand Gartner Banana

Page 685 of 1708

P BRAKE SYSTEM k FIRST PEDAL VACUUM GAUG DEPRESSION FORCE GAUGE POWER BRAKE UNIT Quick Inspection, On-vehicle Power brake unit function check (Simple method) ii Step 1 1. With the engine stopped, depress the pedal a few times. 2. With the pedal depressed, start the engine. 3. If immediately after the engine starts the pedal moves down slightly, the unit is operating. Step 2 1. Start the engine and let it run 1 or 2 minutes. 2. Stop the engine. 3. Depress the pedal with the usual force. 4. If the first pedal stroke is long and becomes shorter with subsequent strokes, the unit is operating. 5. If a problem is found, inspect for damage or improper connection of the check valve or vacuum hose. Repair if necessary, and inspect it once again. Step 3 1. Start the engine. 2. Depress the pedal with the usual force. 3. Stop the engine with the pedal depressed. 4. Hold the pedal down for about 30 seconds. 5. If the pedal height does not change, the unit is operating. ,, 6. If there is a problem, check for damage or improper con- nection of the check valve or vacuum hose. Repair if necessary, and check once again. If the nature of the problem is still not clear after following the 3 steps above, follow the more detailed check described in "Method using tester," below. (Method using tester) Connect the SST, vacuum gauge, and pedal depression force gauge as shown in the figure. After bleeding the air from the SST, conduct the test as described in the 3 steps below. Inspection using gauges Connect the SST gauges, a vacuum gauge (A), and a pedal depression gauge (B) as shown. Bleed the air from the SST gauges before performing the following tests. a) Checking for vacuum loss Unloaded condition 1. Start the engine. 2. Stop the engine when the vacuum gauge indicates 66.7 kPa (500 mmHg, 19.7 inHg). 3. Observe the vacuum gauge for 15 seconds. If the gauge indicates 63.4-66.6 kPa (475-500 mmHg, ,, 18.7-19.7 inHg), the unit is operating. Gartner Banana

Page 746 of 1708

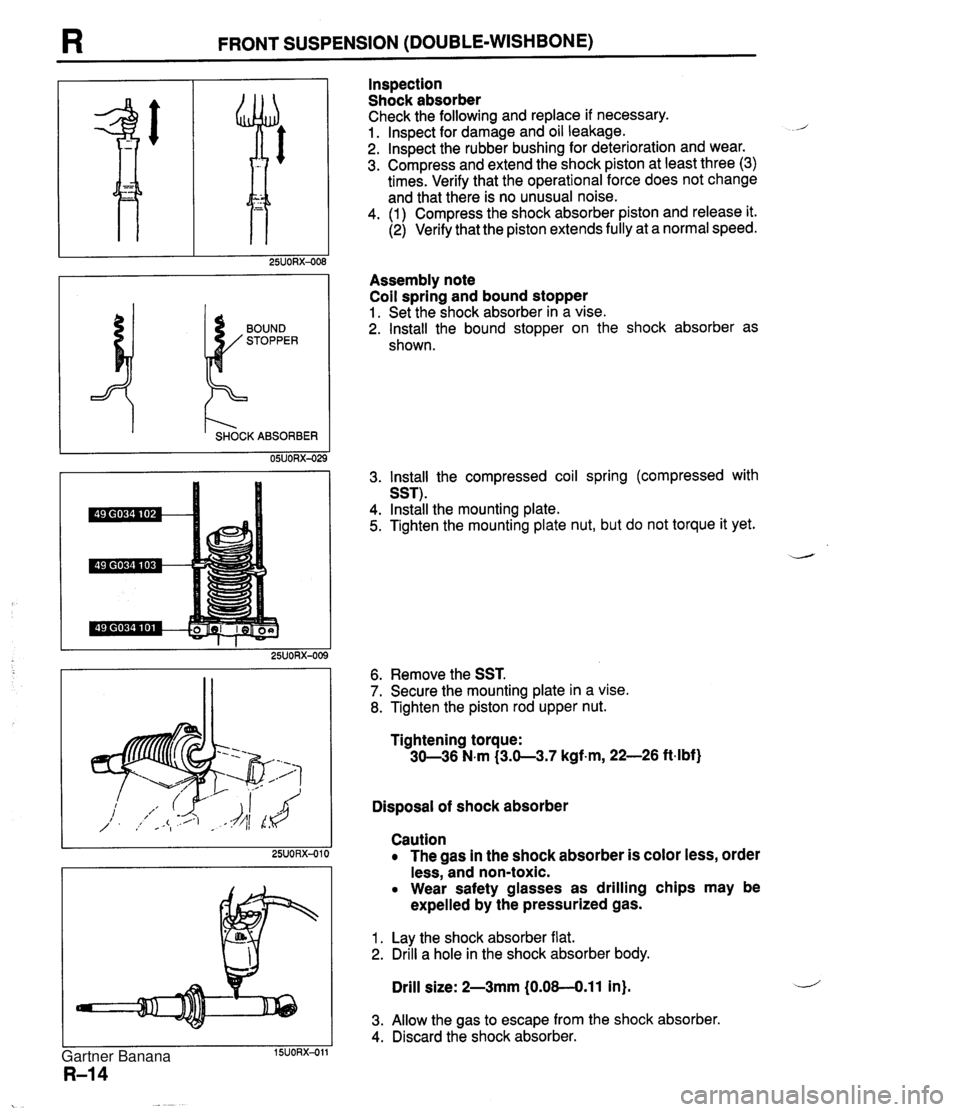

I3 FRONT SUSPENSION (DOUBLE-WISHBONE) I t'- SHOCK ABSORBER 05UORX-02 Inspection Shock absorber Check the following and replace if necessary. 1. lnspect for damage and oil leakage. 2. lnspect the rubber bushing for deterioration and wear. 3. Compress and extend the shock piston at least three (3) times. Verify that the operational force does not change and that there is no unusual noise. 4. (1) Compress the shock absorber piston and release it. (2) Verify that the piston extends fully at a normal speed. Assembly note Coil spring and bound stopper 1. Set the shock absorber in a vise. 2. Install the bound stopper on the shock absorber as shown. 3. lnstall the compressed coil spring (compressed with SST). 4. Install the mounting plate. 5. Tighten the mounting plate nut, but do not torque it yet. 6. Remove the SST. 7. Secure the mounting plate in a vise. 8. Tighten the piston rod upper nut. Tightening torque: 30-36 N.m (3.0-3.7 kgf.m, 22-26 ftdbf) Disposal of shock absorber Caution The gas in the shock absorber is color less, order less, and non-toxic. Wear safety glasses as drilling chips may be expelled by the pressurized gas. 1. Lay the shock absorber flat. 2. Drill a hole in the shock absorber body. Drill size: 2-3mm (0.08-0.11 in). 3. Allow the gas to escape from the shock absorber. 4. Discard the shock absorber. Gartner Banana

Page 956 of 1708

AUDIO T FUNCTION AND OPERATING PROCEDURE RADIO ONIOFF VOLUME - I I APC 00 W~AL AUTO M -- TUNE MANUAUSEEK - TUNE (UP) - HOUR SET MANUAUSEEK - TUNE (DOWN) - MINUTE SET - SCAN - DOLBY - CLOCKIDISPLAY MODE CHANGE (PUSHING THlS ALTERNATES DISPLAY MODE TYPE 1 AMaFM RADIO UNIT PRESET CHANNELS AMIFM AUTO MEMORY - 6 I I I I I 1 I I RADIO OR TIME) BASS - TREBLE ILLUMINATION ONIOFF REVERSE) (PUSHING THlS ALTERNATES ON - OFF ILLUMINATION) HEAD - RESTRAINT SPEAKER VOLUME COMPACT DISC (CD) PLAYER BALANCE REWIND STOP - FAST - PLAY - I EJECT FORWARD PROGRAM "OGRAM rrApE CONTROL RESET BU7TON I I FAST - REPEAT FORWARD I EJECT - RELOAD I +RACKSEARCH I I REVERSE SCAN PLAY - STOP I DISPLAY Gartner Banana

Page 960 of 1708

AUDIO Name ;can button 3epeat button rrack search button Press SCAN button and beginning of tunes are played one by one (10 seconds for each) Press button during playback and scanning starts from next tune Press button during scanning and tune being scanned is played Scanning is canceled automatically when all programs in disc have been scanned Illustration Press RPT button during a tune is playing to play it repeatedly Press again to cancel repeat operation and resume normal playback Operation Press button to search for beginning of next or current program 1. PressA(up) button for less than 0.5 second during disc play and be- ginning of next tune is selected and played Tunes are changed one by one with each press of button When pressed during play of last tune, first tune is replayed 2. PressV(down) button for less than 0.5 second during disc play and current tune is replayed from beginning Tunes are changed one by one with each press of button When pressed during play of first tune, last tune is replayed Press button to fast forwardheverse disc 1. Press and hold FF (up) button for more than 0.5 second and disc play position moved ahead at high speed while button pressed When last part of last tune is reached, first tune is selected and disc stops 2. Press and hold REV (down) button for opposite operation of FF button When first part of first tune reached, disc stops reversing and starts playing Clock The clock can be set while the radio or tape/CD player is ON. Illustration Clock button (clock display) HIM button (clock setup) Operation Press button to display present radio frequency or operation mode If power supply to unit is broken (burnt fuse or disconnected battery), clock setup will be canceled When clock button is pushed for 2 seconds, clock display flashes. At this point, press H button to advance hours and M button to advance minutes Press clock button again to return to normal display If clock button is pressed again while clock display is flashing and time has not been adjusted (that is, H and M buttons have not been pressed), min- utes will be set at : 00. If time before adjustment showed 30-59 minutes, time will be set at next hour For example, nn Gartner Banana

Page 965 of 1708

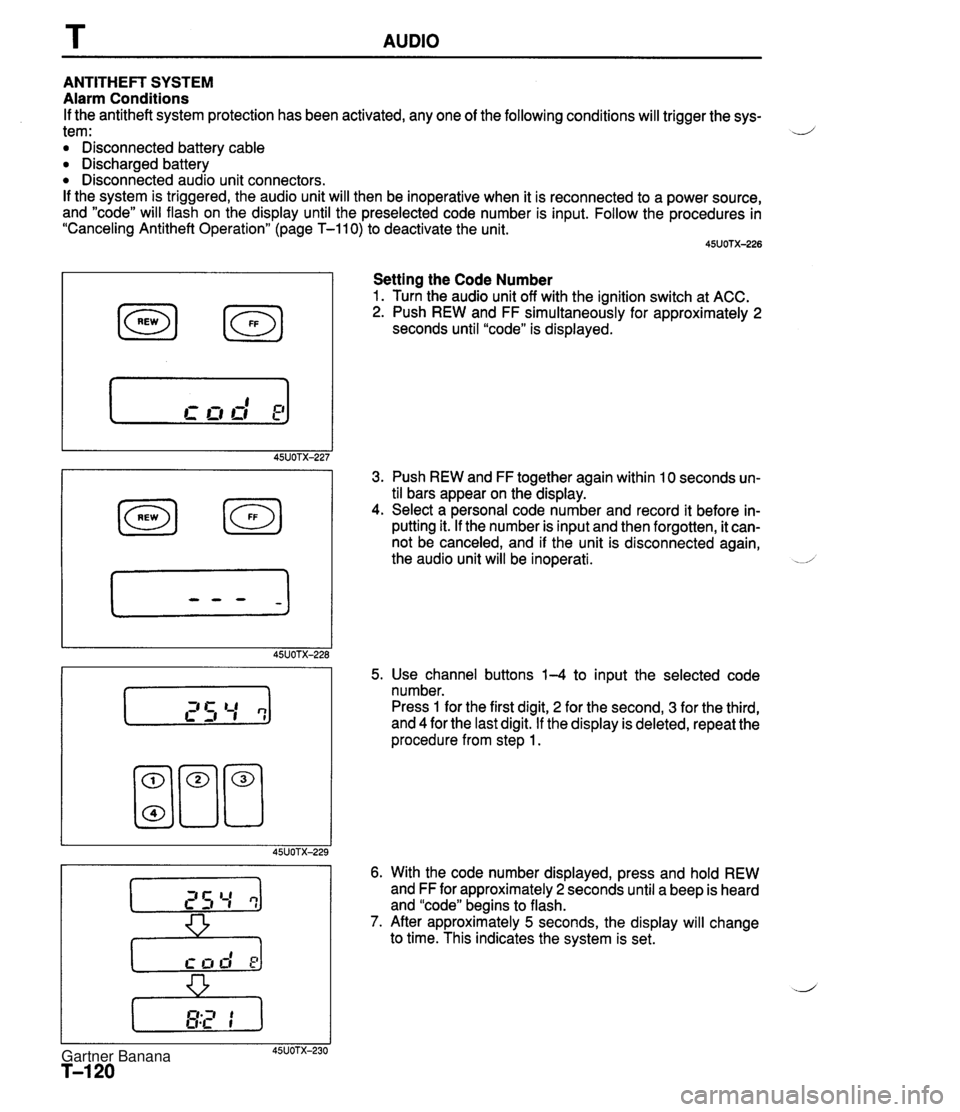

T AUDIO ANTITHEFT SYSTEM Alarm Conditions If the antitheft system protection has been activated, any one of the following conditions will trigger the sys- tem: .--' Disconnected battery cable Discharged battery Disconnected audio unit connectors. If the system is triggered, the audio unit will then be inoperative when it is reconnected to a power source, and "code" will flash on the display until the preselected code number is input. Follow the procedures in "Canceling Antitheft Operation" (page T-110) to deactivate the unit. Setting the Code Number 1. Turn the audio unit off with the ignition switch at ACC. 2. Push REW and FF simultaneously for approximately 2 seconds until "code" is displayed. 3. Push REW and FF together again within 10 seconds un- til bars appear on the display. 4. Select a personal code number and record it before in- putting it. If the number is input and then forgotten, it can- not be canceled, and if the unit is disconnected again, the audio unit will be inoperati. .-/ 5. Use channel buttons 1-4 to input the selected code number. Press 1 for the first digit, 2 for the second, 3 for the third, and 4 for the last digit. If the display is deleted, repeat the procedure from step 1. 6. With the code number displayed, press and hold REW and FF for approximately 2 seconds until a beep is heard and "code" begins to flash. 7. After approximately 5 seconds, the display will change to time. This indicates the system is set. Gartner Banana