fuses MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 23 of 1708

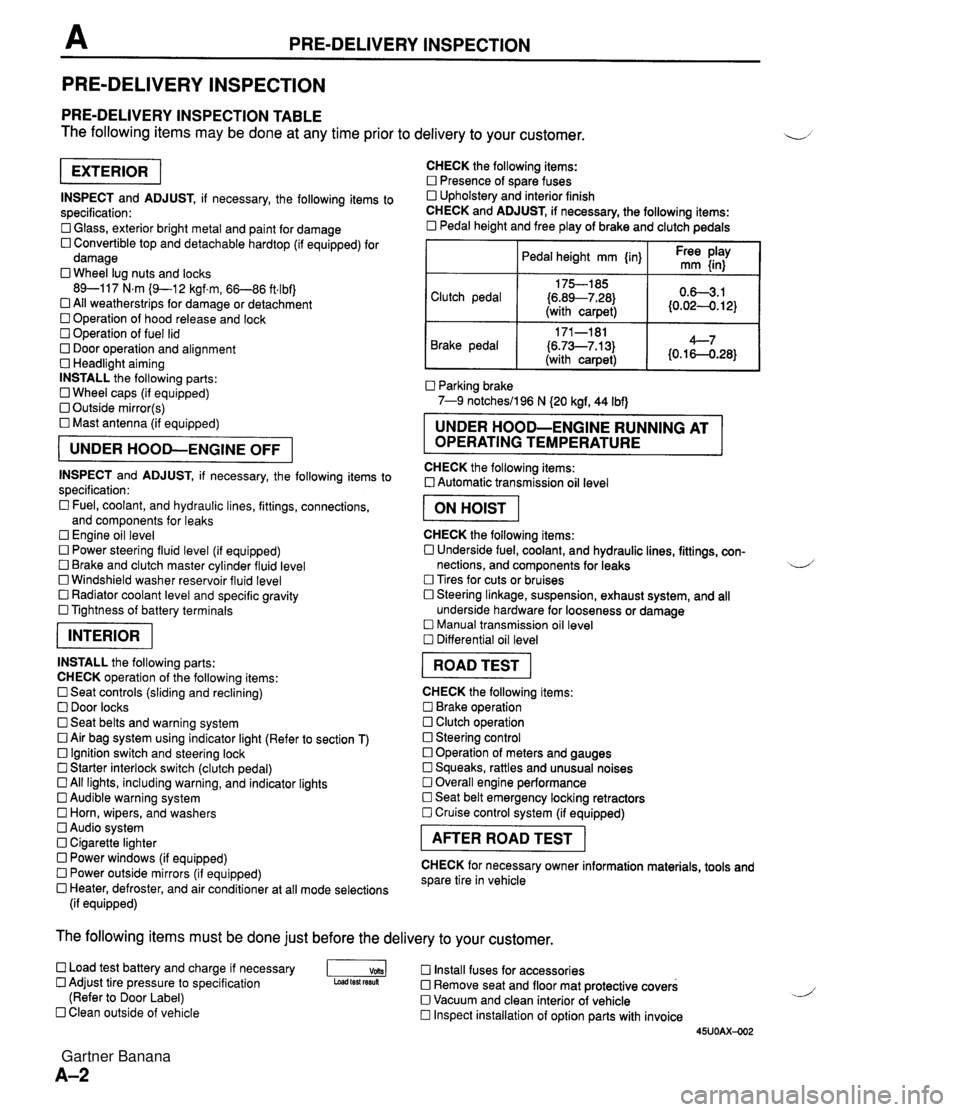

PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION TABLE The following items may be done at any time prior to delivery to your customer. INSPECT and ADJUST, if necessary, the following items to specification: 0 Glass, exterior bright metal and paint for damage 0 Convertible top and detachable hardtop (if equipped) for damage 0 Wheel lug nuts and locks 89-117 N.m (9-1 2 kgf.m, 66-86 ft4bf) 0 All weatherstrips for damage or detachment Operation of hood release and lock Operation of fuel lid 0 Door operation and alignment Headlight aiming INSTALL the following parts: Wheel caps (if equipped) 0 Outside mirror(s) 0 Mast antenna (if equipped) UNDER HOOD-ENGINE OFF INSPECT and ADJUST, if necessary, the following items to specification : Fuel, coolant, and hydraulic lines, fittings, connections, and components for leaks Engine oil level 0 Power steering fluid level (if equipped) Brake and clutch master cylinder fluid level 0 Windshield washer reservoir fluid level 0 Radiator coolant level and specific gravity 0 Tightness of battery terminals pKiq INSTALL the following parts: CHECK operation of the following items: 0 Seat controls (sliding and reclining) 0 Door locks 0 Seat belts and warning system 0 Air bag system using indicator light (Refer to section T) Ignition switch and steering lock 0 Starter interlock switch (clutch pedal) All lights, including warning, and indicator lights 0 Audible warning system 0 Horn, wipers, and washers Audio system 0 Cigarette lighter Power windows (if equipped) 0 Power outside mirrors (if equipped) 0 Heater, defroster, and air conditioner at all mode selections (if equipped) CHECK the following items: Presence of spare fuses 0 Upholstery and interior finish CHECK and ADJUST, if necessary, the following items: 0 Pedal height and free play of brake and clutch pedals I Pedal height mm {in} I Ft: $iy I Clutch pedal {6.89--7.28) (with carpet) Parking brake 7-9 notchesil96 N (20 kgf, 44 Ibf) 0.63.1 (0.024. 12) Brake pedal RUNNING AT OPERATING TEMPERATURE CHECK the following items: 0 Automatic transmission oil level 171-181 (6.73--7.13) (with carpet) I ON HOIST I 4--7 {0.16-0.28} CHECK the following items: 0 Underside fuel, coolant, and hydraulic lines, fittings, con- nections, and components for leaks 4 Tires for cuts or bruises 0 Steering linkage, suspension, exhaust system, and all underside hardware for looseness or damage Manual transmission oil level Differential oil level I ROAD TEST I CHECK the following items: Brake operation Clutch operation 0 Steering control 0 Operation of meters and gauges Squeaks, rattles and unusual noises 0 Overall engine performance Seat belt emergency locking retractors 0 Cruise control system (if equipped) I AFTER ROAD TEST I CHECK for necessary owner information materials, tools and spare tire in vehicle The following items must be done just before the delivery to your customer. 0 Load test battery and charge if necessary -1 Install fuses for accessories Adjust tire pressure to specification Load test fesuk 0 Remove seat and floor mat protective covers (Refer to Door Label) 0 Vacuum and clean interior of vehicle Clean outside of vehicle Inspect installation of option parts with invoice 45UOAX-002 Gartner Banana

Page 324 of 1708

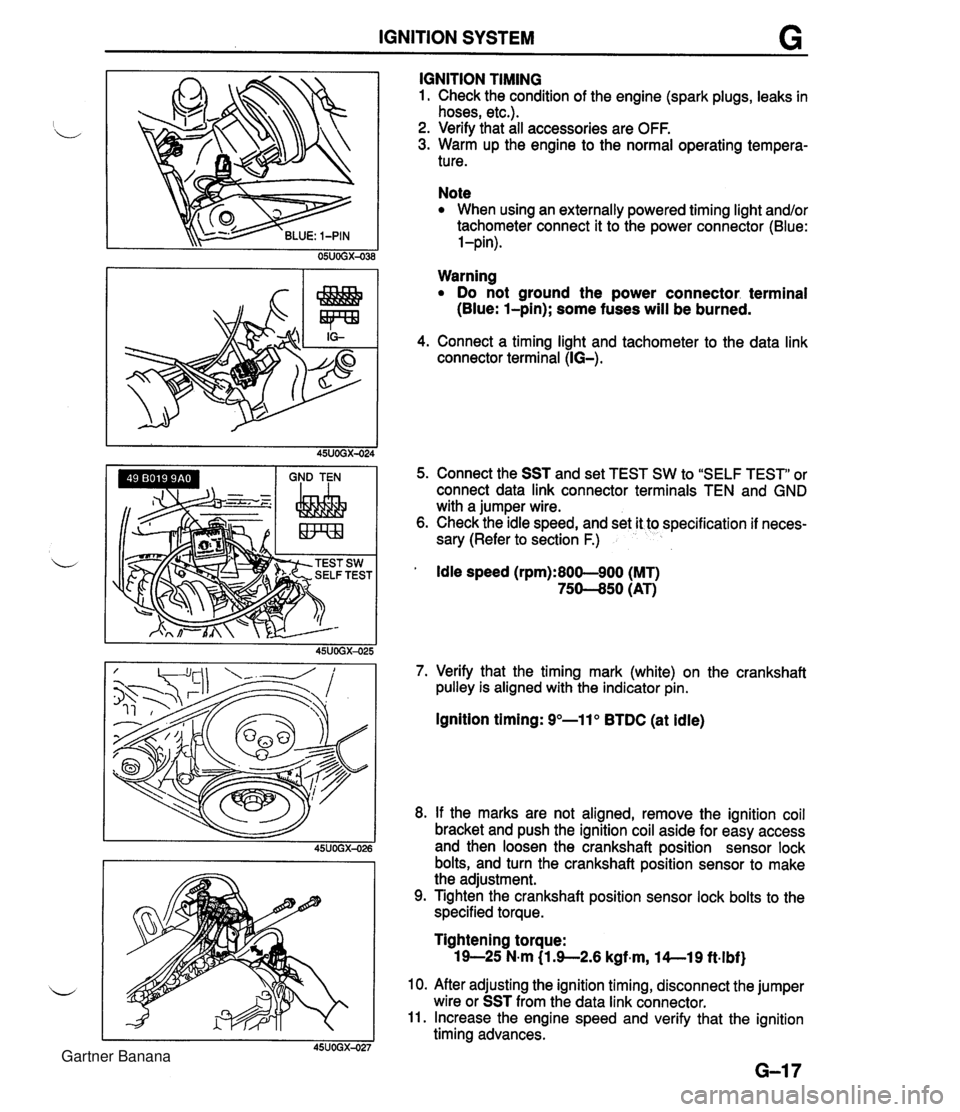

IGNITION SYSTEM G GND TEN I I I IGNITION TIMING 1. Check the condition of the engine (spark plugs, leaks in hoses, etc.). 2. Verify that all accessories are OFF. 3. Warm up the engine to the normal operating tempera- ture. Note When using an externally powered timing light and/or tachometer connect it to the power connector (Blue: l-pin). Warning Do not ground the power connector. terminal (Blue: l-pin); some fuses will be burned. 4. Connect a timing light and tachometer to the data link connector terminal (IG-). 5. Connect the SST and set TEST SW to "SELF TEST" or connect data link connector terminals TEN and GND with a jumper wire. 6. Check the idle speed, and set it to specification if neces- sary (Refer to section F.) ' Idle speed (rpm):800-900 (MT) 75-50 (AT) 7. Verify that the timing mark (white) on the crankshaft pulley is aligned with the indicator pin. Ignition timing: 9"-11" BTDC (at idle) 8. If the marks are not aligned, remove the ignition coil bracket and push the ignition coil aside for easy access and then loosen the crankshaft position sensor lock bolts, and turn the crankshaft position sensor to make the adjustment. 9. Tighten the crankshaft position sensor lock bolts to the specified torque. Tightening torque: 19-25 N-m (1 3-2.6 kgf~m, l4--19 ft.lbf) 10. After adjusting the ignition timing, disconnect the jumper wire or SST from the data link connector. 11. Increase the engine speed and verify that the ignition timing advances. Gartner Banana

Page 846 of 1708

BODY ELECTRICAL SYSTEM ................................... INDEX T- 2 ........................... SWITCHES T- 2 FUSES AND RELAYS .................. T- 3 .............................. LIGHTS T- 4 CRUISE CONTROL SYSTEM ........... T- 5 ...................... AUDIO SYSTEM T- 6 SRS AIR BAG SYSTEM ................ T- 7 ............................... OUTLINE T- 8 TROUBLESHOOTING GUIDE ........... T- 8 ELECTRICAL SYMBOLS ............... T- 9 ................................... FUSE T- 10 STRUCTURAL VIEW ................... T- 10 ...................... SPECIFICATIONS T- 11 ........................ DESCRIPTION T- 12 ....................... REPLACEMENT T- 12 ....................... RELAY .. ....... T- 13 STRUCTURAL VIEW ................... T- 13 ........................ DESCRIPTION T- 13 RETRACTABLE HEADLIGHT RELAY .... T- 14 ....................... FLASHER UNIT T- 14 ........................... TNS RELAY T- 15 .......................... HORN RELAY T- 15 COOLANT FAN RELAY ................. T- 15 REAR WINDOW DEFROSTER RELAY ... T- 16 HEADLIGHT RELAY ................... T- 16 ................................ SWITCH T- 17 ................... STRUCTURAL VIEW T- 17 ........................ DESCRIPTION T- 17 .................... IGNITION SWITCH T- 18 COMBINATION SWITCH ............... T- 19 RETRACTOR SWITCH AND HAZARD WARNING ............................. SWITCH T- 21 ................. INSTRUMENT CLUSTER T- 22 ................... STRUCTURAL VIEW T- 22 ........................ DESCRIPTION T- 22 .................... CIRCUIT DIAGRAM T- 23 ................. TROUBLESHOOTING T- 24 ............ REMOVAL / INSTALLATION T- 29 ........... DISASSEMBLY 1 ASSEMBLY T- 29 ...................... SPEEDOMETER T- 30 ........................ TACHOMETER T- 30 WATER TEMPERATURE GAUGE ....... T- 30 ......................... FUEL GAUGE T- 31 OIL PRESSURE GAUGE ............... T- 31 .................... PRINTED CIRCUIT T- 32 VEHICLE SPEED SENSOR ............. T- 32 WATER TEMPERATURE SENDER UNlT . T- 32 FUEL GAUGE SENDER UNlT ...................... (IN FUEL TANK) T- 32 OIL PRESSURE SENSOR .............. T- 33 ............... SPEEDOMETER CABLE T- 33 WARNING LIGHT AND SENDER UNIT ..... T- 34 ................... STRUCTURAL VIEW T- 34 CIRCUIT DIAGRAM .................... T- 35 ................. TROUBLESHOOTING T- 36 BRAKE FLUID LEVEL SENSOR ......... T- 39 PARKING BRAKE SWITCH ............. T- 39 ..................... BUCKLE SWITCH T- 39 ...................... LIGHTING SYSTEM T- 40 ................... STRUCTURAL VIEW T- 40 ......................... HEADLIGHTS T- 41 ......................... STOPLIGHTS T- 53 TURN AND HAZARD WARNING LIGHTS . T- 57 ..................... BACK-UP LIGHTS T- 66 TAILLIGHTS. SIDE MARKER LIGHTS. PARKING LIGHTS AND LICENSE PLATE LIGHTS . T- 69 DAYTIME RUNNING LIGHTS (DRL) .................... (CANADA SPEC.) T- 72 ........... REAR COMBINATION LIGHT T- 76 .................... INTERIOR LIGHTS T- 78 ................ ILLUMINATION LIGHTS T- 82 .................................. HORN T- 84 ................... STRUCTURAL VIEW T- 84 .................... CIRCUIT DIAGRAM T- 85 ................. TROUBLESHOOTING T- 86 ............ REMOVAL 1 INSTALLATION T- 87 ............ REAR WINDOW DEFROSTER T- 89 ................... STRUCTURAL VIEW T- 89 ........................ DESCRIPTION T- 89 ................. TROUBLESHOOTING T- 90 ................ REPAIRING FILAMENT T- 93 ............. CRUISE CONTROL SYSTEM T- 94 ................... STRUCTURAL VIEW T- 94 .................... CIRCUIT DIAGRAM T- 95 ................. TROUBLESHOOTING T- 96 ....... SELF-DIAGNOSTIC INSPECTION T-100 ............... CRUISE CONTROL UNIT T-103 .................... ACTUATOR CABLE T-104 ..................... CLUTCH SWITCH T-105 .......... STOP LIGHTIBRAKE SWITCH T-105 ...... CRUISE CONTROL MAIN SWITCH T-106 ........... CRUISE CONTROL SWITCH T-106 ............. VEHICLE SPEED SENSOR T-106 ........................... ACTUATOR T-107 a .................................. AUDIO T-108 ................... STRUCTURAL VIEW T-108 ................... SYSTEM DIAGRAM T-109 ............................ FEATURES T-110 FUNCTION AND OPERATING ......................... PROCEDURE 1-111 ............. OPERATION DESCRIPTION T-113 .................. ANTITHEFT SYSTEM T-120 ................. TROUBLESHOOTING T-122 ............ REMOVAL I INSTALLATION T-145 .................... POWER ANTENNA T-149 ......................... INSPECTION T-153 CONNECTOR TERMINAL .................... SPECIFICATIONS T-154 SRS AIR BAG SYSTEM .................. T-156 PREPARATION ........................ T-156 ................... STRUCTURAL VIEW T-156 .......... COMPONENT DESCRIPTION T-157 SYSTEM DIAGRAM ................... T-158 ................. SERVICE WARNINGS T-159 GENERAL PROCEDURES ............. T-160 TROUBLESHOOTING ................. T-160 DRIVER-SIDE AIR BAG MODULE ....... T-206 PASSENGER-SIDE AIR BAG MODULE . . T-207 DIAGNOSTIC MODULE ................ T-208 CLOCK SPRING ....................... T-209 CRASH SENSOR (D-SENSOR) ......... T-210 CRASH SENSOR (S-SENSOR) ......... T-213 AIR BAG MODULE DISPOSAL . .. PROCEDURE ........................ T-215 INSPECTION OF SST (DEPLOYMENT TOOL) ............... T-217 Gartner Banana

Page 848 of 1708

INDEX T FUSES AND RELAYS 1. Main fuse block 7. Rear window defroster timer unit Replacement ............... page T-12 8. Coolant fan relay .................. 2. Fuse box No.1 and No.2 Inspection page T-15 Replacement ............... page T-12 9. Horn relay .................. 3. Headlight relay inspection page T-15 .................. Inspection page T-16 10. Flasher unit .................. 4. TNS relay Inspection page T-14 .................. Inspection page T-15 11. Rear window defroster relay u .................. 5. Retractable headlight relay Inspection page T-15 .................. Inspection page T-14 6. EGI main relay ................... Inspection section F Gartner Banana

Page 857 of 1708

T FUSE DESCRIPTION Main Fuse Block The main fuse block is located on the right side of the engine compartment and contains nine fuses and two relays. -1 Fuse Box Fuse block No.1 is located above the dead pedal of the driver side. The fuse box cover shows the speci- fied fuse locations. A circuit breaker is included in the fuse box to protect the heater blower motor circuit. Fuse block No.2 is located to the side of the battery in the trunk compartment. 45UOTX-016 REPLACEMENT Caution Determine and correct the cause of a burnt fuse before replacing it. If the fuse is replaced before doing this, it may burn again. Plate type 1. Disconnect the negative battery cable. 2. Replace the failed fuse with the fuse puller. 3. Reconnect the negative battery cable. Cartridge-type 80A fuse (Black) 1. Disconnect the negative battery cable. 2. Remove the fuse block mounting nuts, and remove the service cover. 3. Remove the fuse installation bolts, and pull out the fuse. 4. Install the new fuse and the fuse installation bolts. 5. Install the main fuse block. 6. Reconnect the negative battery cable. Gartner Banana

Page 891 of 1708

T LIGHTING SYSTEM I Symptom: Retractable headlight actuators do not operate (Both sides). I Activate the headlight switch and retractor switch and follow the approximate action. d Switch I Headlight switch ON / 'RECTOR Retractor rnotor(s) operate Retractor switch ON Step 1 1. Check RETRACTOR 30A and HEAD 30A fuses in the main fuse block. 2. If a fuse is burned, replace it. Check and repair the wire harness, if necessary. 3. If the fuses are OK, go to Step 2. Actlon Yes No Step 2 1. Disconnect the negative battery cable. 2. Retract the headlights fully by using the manual knobs. 3. Disconnect the retractable headlight actuator connec- tors. 4. Reconnect the negative battery cable. 5. Turn on the headlight switch and retractor switch. 6. Measure the voltage at the following terminal wires of the retractable headlight actuator connectors. Begin troubleshooting from Step 5 Next, turn ON retractor switch 45UOTX-087 Yes No B+: Batterv ~ositive voltage Begin troubleshooting from Step 4 Begin troubleshooting from Step 1 . . - Step 3 1. Disconnect the retractable headlight actuator connec- tors. 2. Check for continuity between the A terminal wire of the retractable headlight actuator connectors and ground. Retractable headlight actuator Left and Right I~ontinui~l headlight actuator Action Voltage (RN) Repair wiring harness (Retractable headlight actuator - GND) Left and Right Check retractable headlight actuator (Refer to oaon T-51) Action B+ Other Go to Step 3 Go to Step 4 Gartner Banana

Page 936 of 1708

REAR WINDOW DEFROSTER T u Symptom: Rear window defroster does not operate. 9MUOTX-232 Step 1 1. Check the following fuses. I Fuse Amperage I Location I 2. If all the fuses are OK, go to Step 2. 3. If a fuse is burned out, replace it. Check and repair the wire harness, if necessary. R.DEF HEATER -- M: Continuity 20A 30A Step 2 1. Disconnect the rear window defroster relay. 2. Apply battery positive voltage and check for continuity between terminals of the relay. B+: Battery positive voltage 3. If correct install the rear window defroster relay and go to Step 3. 4. If not as specified, replace the rear window defroster relay. Fuse box No.2 Main fuse block Step 1 2 C Terminal D 0 GND B 0 B+ A 0 C 0 Gartner Banana

Page 1069 of 1708

TROUBLESHOOTING u 7- Symptom: Magnetic clutch does not operate I Normal operation of magnetic clutch The PCME controls the operation of the condenser fan and magnetic clutch, depending on engine load. (Refer to section F.) The magnetic clutch is supplied with battery positive voltage as follows: 1. The ACS and fan switch are turned on. 2. The PCME receives a signal that the ACS and fan switch are on and creates a ground circuit. 3. The A/C relay is magnetized and the contact is closed. 4. Battery positive voltage is applied to the magnetic clutch and the clutch locks. WIPER 20A AD FAN 20A FUSE BLOCK MAIN FUSE BLOCK Step 1 1. Check the following fuses. I Fuse I Amperage I Location I I I . - I WIPER I 20A 1 In fuse block I I AD FAN I 20A 1 In main fuse block I 2. If the fuses are OK, go to Step 2. 3. If a fuse is burned, check for a short circuit in the harness before replacing it. Step 2 1. Run the engine at idle. 2. Turn on the ACS and fan switch. 3. Measure the voltage at the A terminal wire of the mag- netic clutch connector. B+: Battery positive voltage I Terminal I Voltage I Action 1 Step 3 1. Start the engine. 2. Turn on the fan switch and ACS. 3. Measure the voltage at terminal C and A of the A/C relay connector. B+: Batterv positive voltaae - -- A 1 Terminal I V0lta0e 1 Action I I C I Other I Repair wiring harness (AD FAN 20A fuse - AIC relay) I B+ Other I 1. -. B+ I GO to step 4 Replace magnetic clutch Go to Step 3 I A 1 Other I Repair wiring harness (WIPER 20A fuse - AIC relay) I Gartner Banana