torque specifications MAZDA MX-5 1997 Factory Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1997, Model line: MX-5, Model: MAZDA MX-5 1997Pages: 514, PDF Size: 17.89 MB

Page 10 of 514

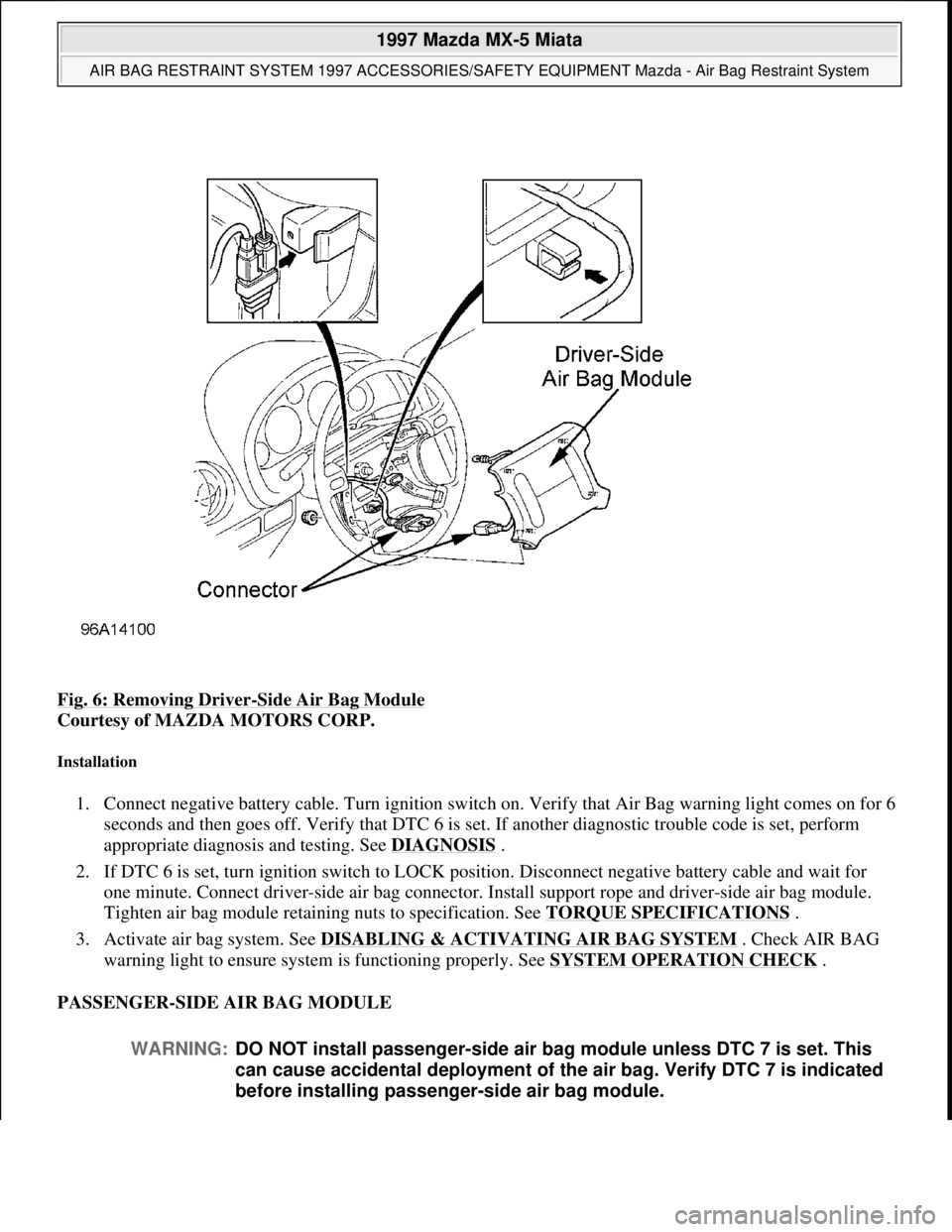

Fig. 6: Removing Driver-Side Air Bag Module

Courtesy of MAZDA MOTORS CORP.

Installation

1. Connect negative battery cable. Turn ignition switch on. Verify that Air Bag warning light comes on for 6

seconds and then goes off. Verify that DTC 6 is set. If another diagnostic trouble code is set, perform

appropriate diagnosis and testing. See DIAGNOSIS

.

2. If DTC 6 is set, turn ignition switch to LOCK position. Disconnect negative battery cable and wait for

one minute. Connect driver-side air bag connector. Install support rope and driver-side air bag module.

Tighten air bag module retaining nuts to specification. See TORQUE SPECIFICATIONS

.

3. Activate air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Check AIR BAG

warning light to ensure system is functioning properly. See SYSTEM OPERATION CHECK

.

PASSENGER-SIDE AIR BAG MODULE

WARNING:DO NOT install passenger-side air bag module unless DTC 7 is set. This

can cause accidental deployment of the air bag. Verify DTC 7 is indicated

before installing passenger-side air bag module.

1997 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1997 ACCESSORIES/SAFETY EQUIPMENT Mazda - Air Bag Restraint System

Microsoft

Sunday, July 05, 2009 1:40:47 PMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 12 of 514

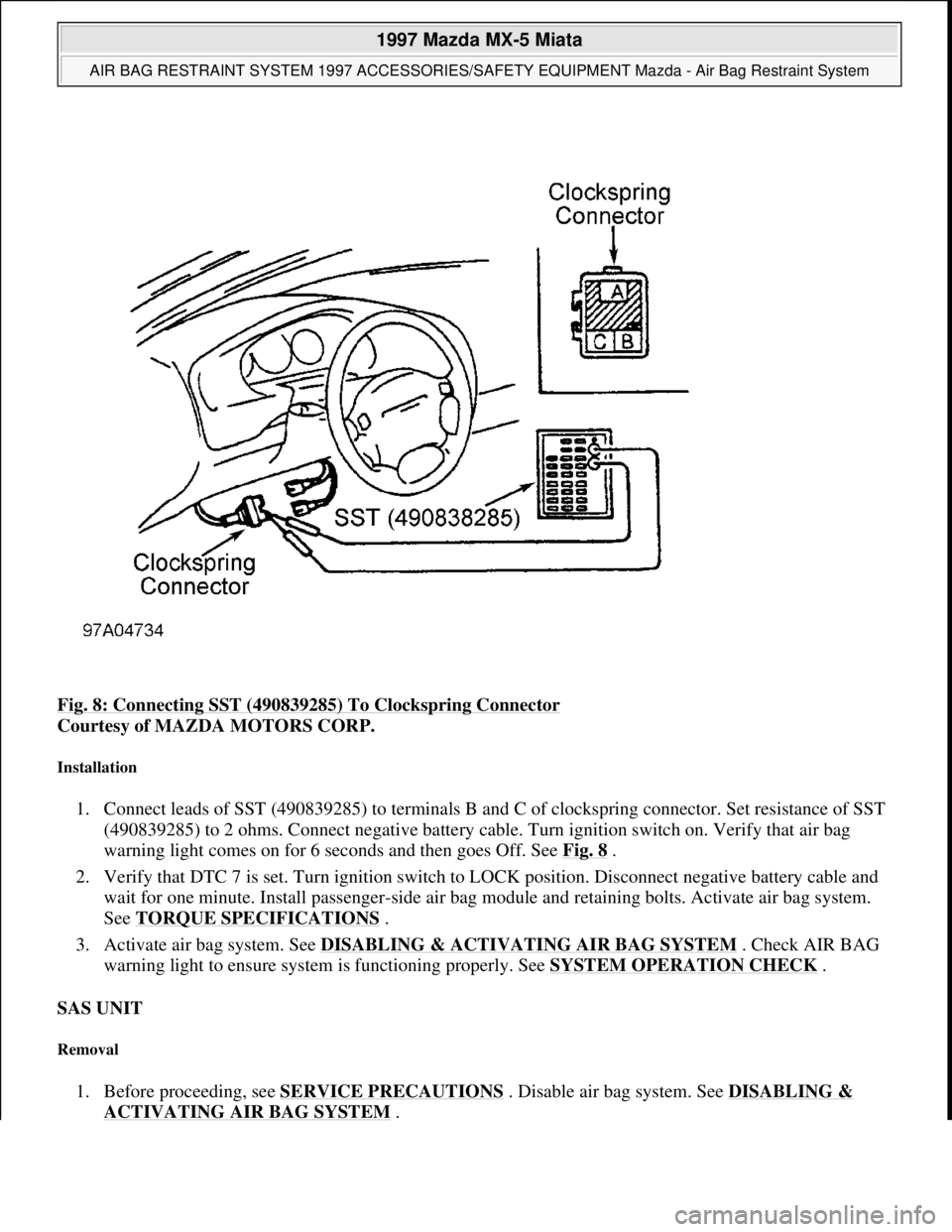

Fig. 8: Connecting SST (490839285) To Clockspring Connector

Courtesy of MAZDA MOTORS CORP.

Installation

1. Connect leads of SST (490839285) to terminals B and C of clockspring connector. Set resistance of SST

(490839285) to 2 ohms. Connect negative battery cable. Turn ignition switch on. Verify that air bag

warning light comes on for 6 seconds and then goes Off. See Fig. 8

.

2. Verify that DTC 7 is set. Turn ignition switch to LOCK position. Disconnect negative battery cable and

wait for one minute. Install passenger-side air bag module and retaining bolts. Activate air bag system.

See TORQUE SPECIFICATIONS

.

3. Activate air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Check AIR BAG

warning light to ensure system is functioning properly. See SYSTEM OPERATION CHECK

.

SAS UNIT

Removal

1. Before proceeding, see SERVICE PRECAUTIONS . Disable air bag system. See DISABLING &

ACTIVATING AIR BAG SYSTEM.

1997 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1997 ACCESSORIES/SAFETY EQUIPMENT Mazda - Air Bag Restraint System

Microsoft

Sunday, July 05, 2009 1:40:47 PMPage 12 © 2005 Mitchell Repair Information Company, LLC.

Page 13 of 514

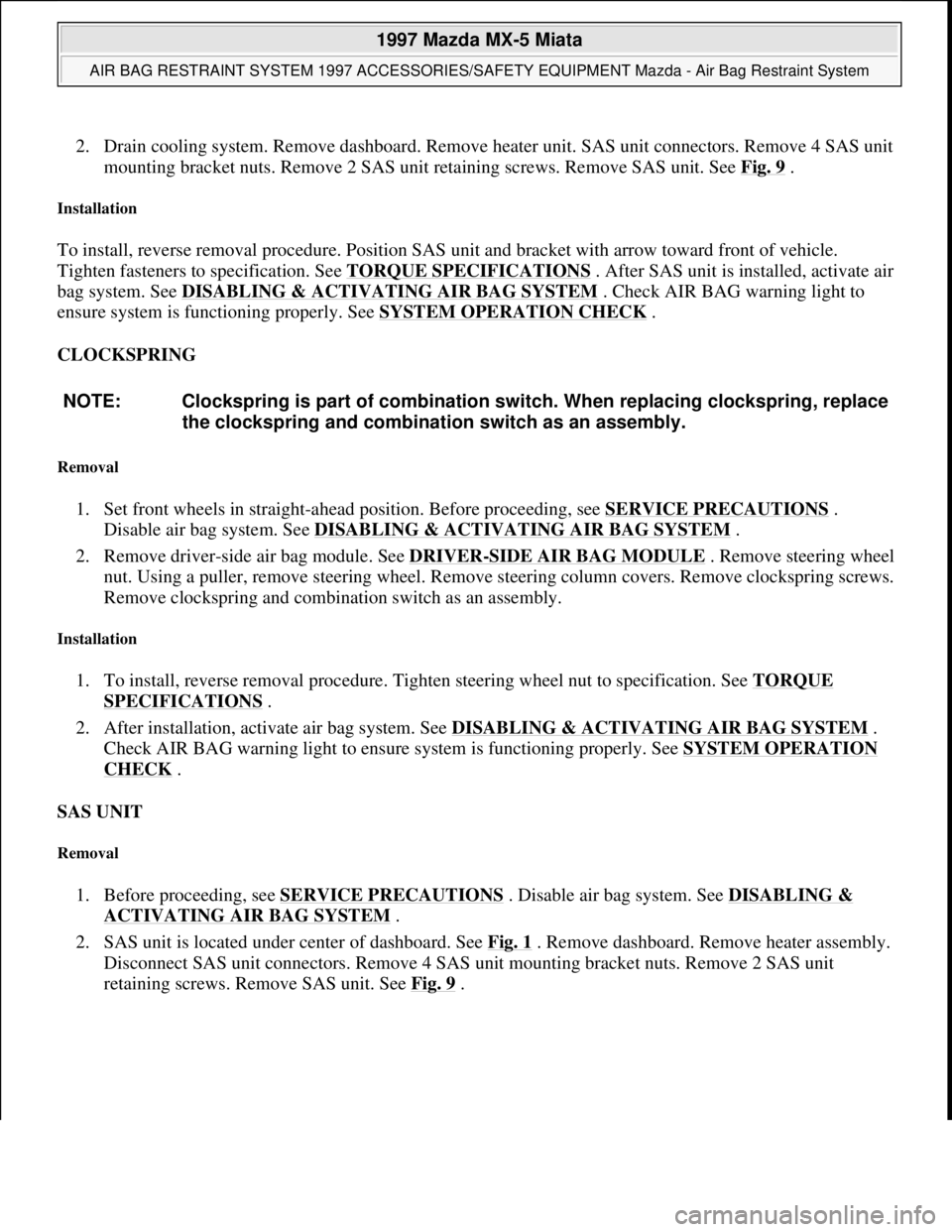

2. Drain cooling system. Remove dashboard. Remove heater unit. SAS unit connectors. Remove 4 SAS unit

mounting bracket nuts. Remove 2 SAS unit retaining screws. Remove SAS unit. See Fig. 9

.

Installation

To install, reverse removal procedure. Position SAS unit and bracket with arrow toward front of vehicle.

Tighten fasteners to specification. See TORQUE SPECIFICATIONS

. After SAS unit is installed, activate air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Check AIR BAG warning light to

ensure system is functioning properly. See SYSTEM OPERATION CHECK

.

CLOCKSPRING

Removal

1. Set front wheels in straight-ahead position. Before proceeding, see SERVICE PRECAUTIONS .

Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

2. Remove driver-side air bag module. See DRIVER

-SIDE AIR BAG MODULE . Remove steering wheel

nut. Using a puller, remove steering wheel. Remove steering column covers. Remove clockspring screws.

Remove clockspring and combination switch as an assembly.

Installation

1. To install, reverse removal procedure. Tighten steering wheel nut to specification. See TORQUE

SPECIFICATIONS .

2. After installation, activate air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

Check AIR BAG warning light to ensure system is functioning properly. See SYSTEM OPERATION

CHECK .

SAS UNIT

Removal

1. Before proceeding, see SERVICE PRECAUTIONS . Disable air bag system. See DISABLING &

ACTIVATING AIR BAG SYSTEM .

2. SAS unit is located under center of dashboard. See Fig. 1

. Remove dashboard. Remove heater assembly.

Disconnect SAS unit connectors. Remove 4 SAS unit mounting bracket nuts. Remove 2 SAS unit

retainin

g screws. Remove SAS unit. See Fig. 9. NOTE: Clockspring is part of combination switch. When replacing clockspring, replace

the clockspring and combination switch as an assembly.

1997 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1997 ACCESSORIES/SAFETY EQUIPMENT Mazda - Air Bag Restraint System

Microsoft

Sunday, July 05, 2009 1:40:47 PMPage 13 © 2005 Mitchell Repair Information Company, LLC.

Page 14 of 514

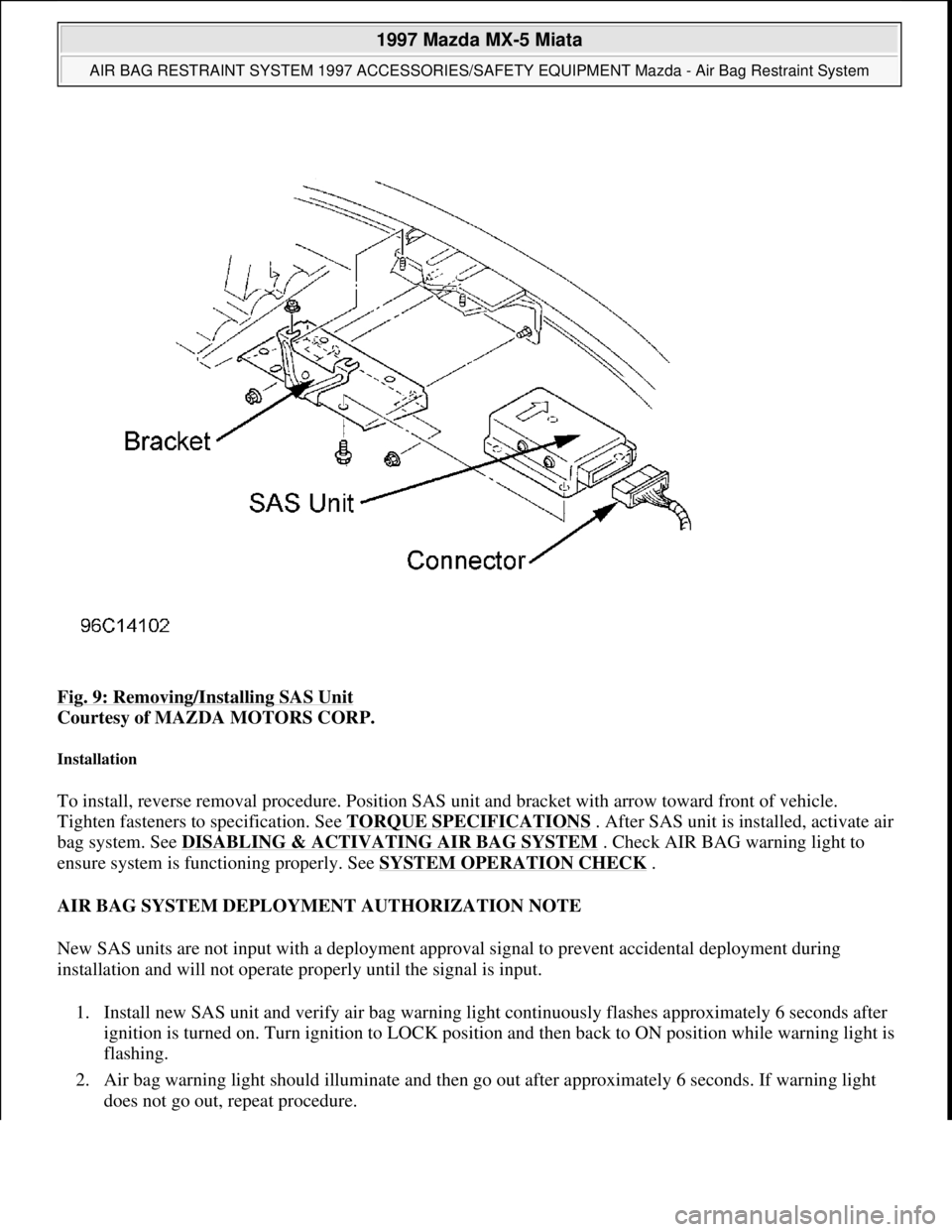

Fig. 9: Removing/Installing SAS Unit

Courtesy of MAZDA MOTORS CORP.

Installation

To install, reverse removal procedure. Position SAS unit and bracket with arrow toward front of vehicle.

Tighten fasteners to specification. See TORQUE SPECIFICATIONS

. After SAS unit is installed, activate air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Check AIR BAG warning light to

ensure system is functioning properly. See SYSTEM OPERATION CHECK

.

AIR BAG SYSTEM DEPLOYMENT AUTHORIZATION NOTE

New SAS units are not input with a deployment approval signal to prevent accidental deployment during

installation and will not operate properly until the signal is input.

1. Install new SAS unit and verify air bag warning light continuously flashes approximately 6 seconds after

ignition is turned on. Turn ignition to LOCK position and then back to ON position while warning light is

flashing.

2. Air bag warning light should illuminate and then go out after approximately 6 seconds. If warning light

does not go out, repeat procedure.

1997 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1997 ACCESSORIES/SAFETY EQUIPMENT Mazda - Air Bag Restraint System

Microsoft

Sunday, July 05, 2009 1:40:47 PMPage 14 © 2005 Mitchell Repair Information Company, LLC.

Page 19 of 514

4. Disconnect SAS unit connector. Check wiring between terminal K of SAS unit connector and terminal C

of passenger-side air bag module connector for short to ground, short to power or open circuit. If wiring

is OK, replace SAS unit. See SAS UNIT

under REMOVAL & INSTALLATION. If wiring is not OK,

replace wiring harness between passenger-side air bag module and SAS unit. Perform SYSTEM

OPERATION CHECK .

WIRE REPAIR

DO NOT repair air bag system wiring. If a problem is found with air bag system wiring, replace faulty wiring.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAM

ApplicationFt. Lbs. (N.m)

Passenger-Side Air Bag Module Retaining Bolts13-20 (18-27)

Steering Wheel Nut29-36 (39-49)

INCH Lbs. (N.m)

Driver-Side Air Bag Module Retaining Nuts35-52 (4.0-5.8)

SAS Unit Retaining Nuts61-86 (6.7-9.8)

1997 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1997 ACCESSORIES/SAFETY EQUIPMENT Mazda - Air Bag Restraint System

Microsoft

Sunday, July 05, 2009 1:40:48 PMPage 19 © 2005 Mitchell Repair Information Company, LLC.

Page 42 of 514

2. Disconnect ABS control module electrical connector. Remove ABS control module mounting bolts/nuts.

Remove ABS control module. To install, reverse removal procedure. Tighten ABS control module

mounting bolts/nuts to 61-87 INCH lbs. (6.9-9.8 N.m).

HYDRAULIC UNIT

Removal & Installation

1. Disconnect negative battery cable. Disconnect hydraulic unit electrical connector. Using Flare Nut

Wrench (49-0259-770B), disconnect brakelines from hydraulic unit. Note location of brakelines for

installation reference. Disconnect electrical connectors. Remove hydraulic unit mounting bolts and nuts.

2. Remove hydraulic unit. To install, reverse removal procedure. Tighten mounting bolts and nuts to

specification. See TORQUE SPECIFICATIONS

. Add fluid and bleed air from system. See

BLEEDING BRAKE SYSTEM

.

FRONT WHEEL SPEED SENSOR ROTOR

Removal

Raise and support vehicle. Remove front wheel assemblies. Remove brake caliper and wire aside. Remove

rotor. Remove grease cap and wheel bearing lock nut. Remove wheel hub. Using Puller (49-0839-425C) and

Attachment (49-F027-007), remove wheel speed sensor rotor from hub.

Installation

To install, reverse removal procedure. Tighten bolts and nuts to specification. See TORQUE

SPECIFICATIONS .

REAR WHEEL SPEED SENSOR ROTOR

Removal

Raise and support vehicle. Remove rear wheel assemblies. Remove brake caliper and wire aside. Remove wheel

bearing lock nut. Remove lower control arm-to-rear steering knuckle bolt and nut. Remove drive axle. DO NOT

disassemble drive axle assembly to remove sensor rotor. Replace drive axle assembly.

Installation

To install, reverse removal procedure. Tighten bolts and nuts to specification. See TORQUE

SPECIFICATIONS .

WHEEL SPEED SENSOR

Removal & Installation

Raise and support vehicle. Remove wheel assemblies. Disconnect wheel speed sensor electrical connector.

Remove wheel speed sensor mounting bolt. Remove wheel speed sensor from vehicle. To install, reverse

1997 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1997 BRAKES Mazda - Anti-Lock

Microsoft

Sunday, July 05, 2009 1:48:49 PMPage 21 © 2005 Mitchell Repair Information Company, LLC.

Page 43 of 514

removal procedure. Tighten mounting bolt to specification. See TORQUE SPECIFICATIONS.

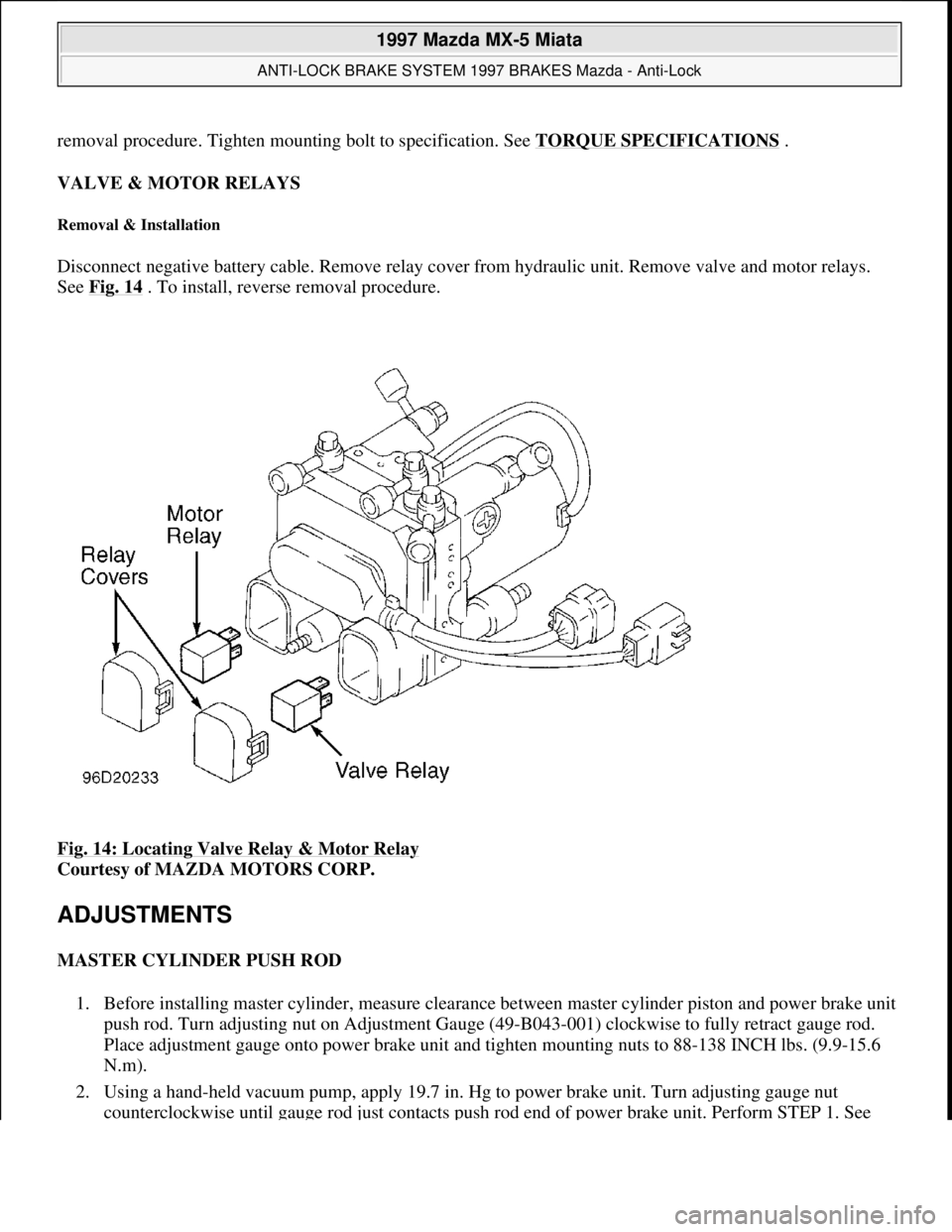

VALVE & MOTOR RELAYS

Removal & Installation

Disconnect negative battery cable. Remove relay cover from hydraulic unit. Remove valve and motor relays.

See Fig. 14

. To install, reverse removal procedure.

Fig. 14: Locating Valve Relay & Motor Relay

Courtesy of MAZDA MOTORS CORP.

ADJUSTMENTS

MASTER CYLINDER PUSH ROD

1. Before installing master cylinder, measure clearance between master cylinder piston and power brake unit

push rod. Turn adjusting nut on Adjustment Gauge (49-B043-001) clockwise to fully retract gauge rod.

Place adjustment gauge onto power brake unit and tighten mounting nuts to 88-138 INCH lbs. (9.9-15.6

N.m).

2. Using a hand-held vacuum pump, apply 19.7 in. Hg to power brake unit. Turn adjusting gauge nut

counterclockwise until

gauge rod just contacts push rod end of power brake unit. Perform STEP 1. See

1997 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1997 BRAKES Mazda - Anti-Lock

Microsoft

Sunday, July 05, 2009 1:48:49 PMPage 22 © 2005 Mitchell Repair Information Company, LLC.

Page 46 of 514

With engine off, depress pedal a few times to eliminate vacuum. Depress brake pedal by hand and check pedal

free play. See BRAKE PEDAL FREE PLAY SPECIFICATIONS

table. Adjust play by loosening push rod

lock nut. Turn push rod until correct free play is obtained. Tighten push rod lock nut to 18-25 ft. lbs. (24-34

N.m).

BRAKE PEDAL FREE PLAY SPECIFICATIONS

PARKING/EMERGENCY BRAKE

1. Depress brake pedal several times. Pull parking brake lever with a force of 44 lbs. (20 kg). If stroke is 7-9

notches, parking brake is properly adjusted. If stroke is not 7-9 notches, raise and support rear of vehicle.

Release parking brake lever.

2. Rotate cable adjusting nut at lever end of cable, located under console cover, until stroke is within

specification. Ensure rear brakes do not drag. Ensure parking brake warning light illuminates when brake

lever is pulled one notch.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

ApplicationIn. (mm)

Miata.16-.28 (4-7)

ApplicationFt. Lbs. (N.m)

Brake Caliper Mounting Bolts37-50 (50-68)

Brakeline Nuts10-16 (14-22)

Hydraulic Unit Brakeline Union Bolts18-26 (24-35)

Hydraulic Unit Mounting Bolts/Nuts14-18 (19-24)

I-Arm-To-Rear Steering Knuckle Bolt (RX7)44-54 (59-73)

Lower Control Arm-To-Rear Steering Knuckle Nut47-54 (64-73)

Push Rod Lock Nut18-25 (24-34)

Stoplight Switch Lock Nut10-13 (14-18)

Wheel Bearing Lock Nut

Front123-159 (167-216)

Rear159-217 (216-294)

Wheel Lug Nuts66-86 (89-117)

Wheel Speed Sensor Mounting Bolt12-16 (16-22)

INCH Lbs. (N.m)

ABS Control Unit Mounting Bolts/Nuts61-87 (6.9-9.8)

1997 Mazda MX-5 Miata

ANTI-LOCK BRAKE SYSTEM 1997 BRAKES Mazda - Anti-Lock

Microsoft

Sunday, July 05, 2009 1:48:49 PMPage 25 © 2005 Mitchell Repair Information Company, LLC.

Page 64 of 514

1. Inspect ATF level and condition. Correct as needed. If fluid level and condition is okay, check line

pressure. See LINE PRESSURE TEST under TESTING in MAZDA NC4A-EL OVERHAUL article.

Follow repair recommendations if line pressure is not within specifications. If line pressure is okay, go to

next step.

2. Inspect lock-up solenoid. See SOLENOID VALVES

under COMPONENT TESTING. Repair as

needed. If solenoid valve is okay, go to next step.

3. Inspect lock-up control valve in valve body. If valve is okay, go to next step.

4. Using an EC-AT tester connected to TCM, ensure that engine speed and turbine speed during TCC lock-

up in 4th gear are the same. If speeds are different, replace torque converter. If speeds are the same, go to

next step.

5. Clear DTC. See CLEARING CODES

. Retrieve DTC. If DTC P0740 is still present, replace TCM. If

code is no longer present and symptom still exists, problem may be caused by intermittent TCC slippage.

Further investigation may be required. See MAZDA NC4A-EL OVERHAUL article.

DTC P0750: 1-2 SHIFT SOLENOID MALFUNCTION

Possible Causes:

Short or open circuit between TCM and solenoid.

TCM malfunction.

Shift solenoid malfunction.

Diagnosis & Repair Procedure

1. Ensure all connections are clean and tight. Repair as needed. Turn ignition on. Access TCM connectors.

Using voltmeter, backprobe harness connectors. DO NOT disconnect connectors. Go to next step.

2. Measure voltage between ground and terminal No. 2E (Blue/Yellow wire) on TCM connector. During

test drive, voltage should be less than one volt when solenoid is off and battery voltage when solenoid is

on. See SOLENOID OPERATION

table under TCM OUTPUT DEVICES. If voltage is within

specification, go to step 5 . If voltage is not within specification, go to next step.

3. Turn ignition off. Disconnect TCM harness connector. Measure resistance between ground and terminal

No. 2E. If resistance is 13-27 ohms at 68°F (20°C), go to step 5 . If resistance is not 13-27 ohms at 68°F

(20°C), go to next step.

4. Inspect 1-2 shift solenoid and related circuits. See SOLENOID VALVES

under COMPONENT

TESTING. Repair as needed. If solenoid valve and related circuits are okay, go to next step.

5. Clear DTC and road test vehicle. Retrieve DTC. If DTC P0750 is still present, replace TCM. If code is no

longer present, system is okay.

DTC P0755: 2-3 SHIFT SOLENOID MALFUNCTION

Possible Causes:

Short or open circuit between TCM and solenoid.

TCM malfunction.

1997 Mazda MX-5 Miata

1997 AUTOMATIC TRANSMISSIONS NC4A-EL Electronic Controls

Microsoft

Sunday, July 05, 2009 1:35:04 PMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 66 of 514

Condition

Vehicle speed sensor signal is not input to TCM. Possible causes are:

Vehicle speed sensor malfunction.

Vehicle speedometer sensor malfunction.

Damaged circuits or connectors between sensors and TCM.

Diagnosis & Repair Procedure

1. Ensure all connections are clean and tight. Repair as needed. Turn ignition on. Using voltmeter,

backprobe TCM harness connector. DO NOT disconnect connector. Test drive vehicle.

2. Measure voltage between ground and terminal No. 1P (Green/Red wire) on TCM harness connector.

During test drive voltage should be about 4 volts. When parked, voltage should be less than 1.5 or 7-9

volts. If voltage is within specifications, go to step 5 . If voltage is not within specifications, go to next

step.

3. Turn ignition off. Disconnect negative battery cable. Remove instrument cluster. Disconnect TCM

harness connectors. Ensure continuity exists on Green/Red wire between terminal No. 1P on TCM

connector and terminal No. 2F on instrument cluster harness left connector. Repair as needed. If

continuity exists, go to next step.

4. With combination meter removed, measure voltage between terminals No. 2F and 2D on combination

meter connector using analog voltmeter. Raise and support vehicle. Rotate rear wheels. If voltage pulse is

present, go to next step. If voltage pulse is not present, inspect speedometer cable. Replace as needed. If

cable is okay, replace combination meter or circuit board (as applicable).

5. Clear codes and road test vehicle. Retrieve DTC. If DTC 1720 is still present, replace TCM. If code is no

longer present, problem may be caused by poor connection. Repair as needed.

DTC P1743: TORQUE CONVERTER CLUTCH (TCC) SOLENOID MALFUNCTION

Possible Causes:

Short or open circuit between TCM and solenoid.

TCM malfunction.

Lock-up solenoid malfunction.

Diagnosis & Repair Procedure

1. Ensure all connections are clean and tight. Repair as needed. Turn ignition on. Access TCM connectors.

Using voltmeter, backprobe harness connectors. DO NOT disconnect connectors. Go to next step.

2. Measure voltage between ground and terminal No. 2K (Yellow/Black wire). Battery voltage should be

present with solenoid on and zero volts with solenoid off. If voltage is within specifications, go to step 5 .

If voltage is not within specifications, go to next step.

3. Turn ignition off. Disconnect TCM harness connector. Measure resistance between ground and terminal

No. 2K. If resistance is 13-25 ohms at 68°F (20°C), go to step 5 . If resistance is not 13-25 ohms at 68°F

(20°C),

go to next step.

1997 Mazda MX-5 Miata

1997 AUTOMATIC TRANSMISSIONS NC4A-EL Electronic Controls

Microsoft

Sunday, July 05, 2009 1:35:04 PMPage 18 © 2005 Mitchell Repair Information Company, LLC.