power steering fluid MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 12 of 1164

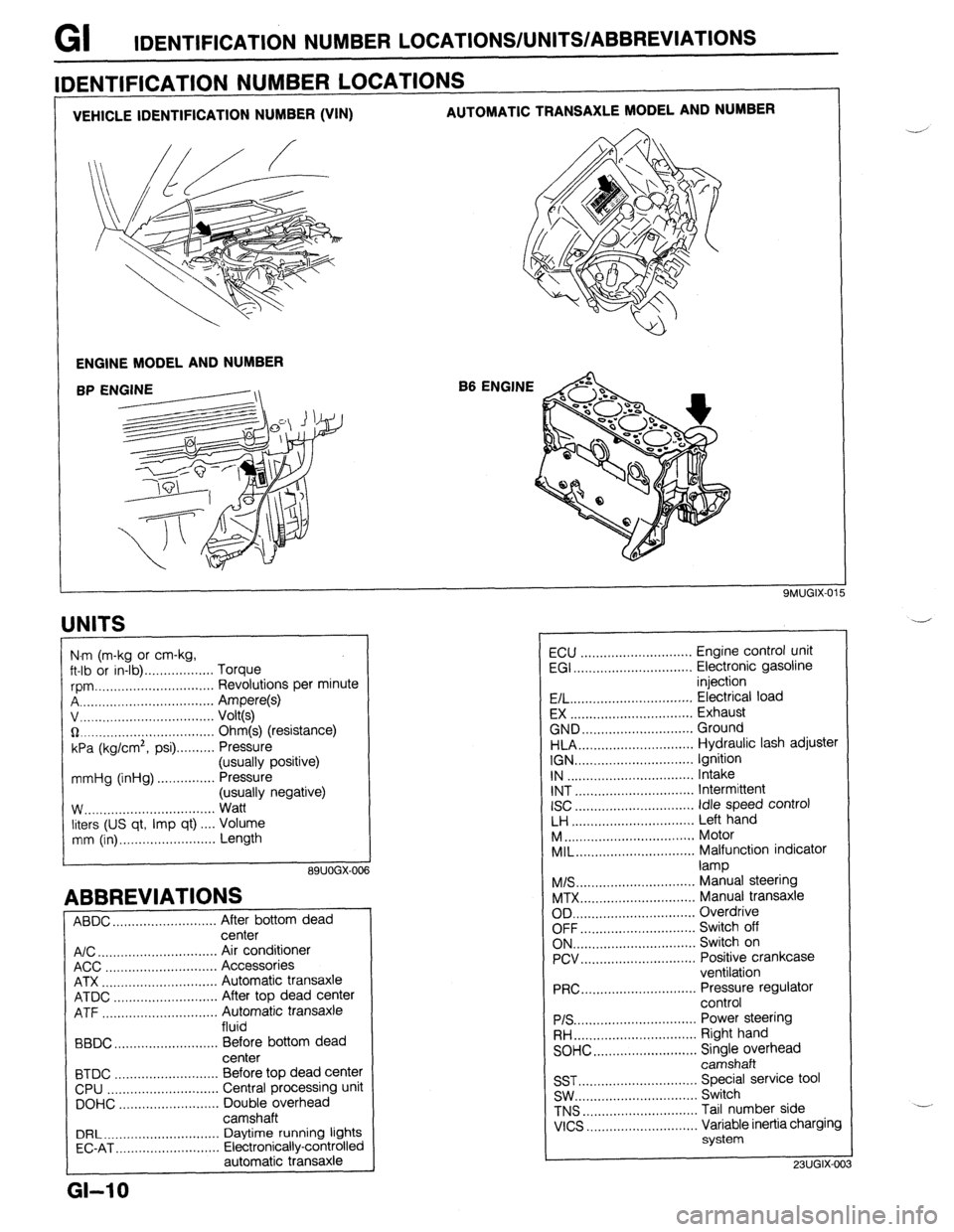

GI IDENTIFICATION NUMBER LOCATIONS/UNITS/ABBREVlATlONS

VEHICLE IDENTIFICATION NUMBER (VIN) AUTOMATIC TRANSAXLE MODEL AND NUMBER

ENGINE MODEL AND NUMBER

B6 ENGINE

IDENTIFICATION NUMBER LOCATIONS

UNITS

I

N.m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . . . . . . . . . . . . . . Torque

rpm ._..,,,.............,.......... Revolutions per minute

A . . . . . . . . . . . . . . . . . Ampere(s)

v, . . . . . . . . . . . . . .

Volt(s)

$2 _....._..,......................... Ohm(s) (resistance)

kPa (kg/cm2,

psi) . . . . . . . . . . Pressure

(usually positive)

mmHg (inHg) . . . . . . . . . . . . . . . Pressure

(usually negative)

W.. . . . . . . . . . . .

Watt

liters (US qt, Imp qt) ,... Volume

mm (in) ..,......,...,........... Length

89UOGX-00

ABBREVIATIONS

ABDC . . . . . . . . . . . . . . . . . . . . .

After bottom dead

center

A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air conditioner

ACC ..,.,...... 3 . . . . . . . . . . . . . . . . . Accessories

ATX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic transaxle

ATDC ..,,...,...,............... After top dead center

ATF . . . . . . . . . . . . . . . . . Automatic transaxle

fluid

BBDC ,,..,.......,...,......,... Before bottom dead

center

BTDC .,......,...............,.. Before top dead center

CPU ..,,.......,...,..........,.. Central processing unit

DOHC ..,...,..,............,,.. Double overhead

camshaft

DRL ____.......................... Daytime running lights

EC-AT .,_.......,............,,.. Electronically-controlled

automatic transaxle

L

GI-10

ECU ............................. Engine control unit

EGI ............................... Electronic gasoline

injection

E/L.. .............................. Electrical load

EX ................................ Exhaust

GND.. ........................... Ground

HLA.. ............................ Hydraulic lash adjuster

IGN ............................... Ignition

IN ................................. Intake

INT ............................... Intermittent

ISC

............................... idle speed control

LH ................................ Left hand

M..

................................ Motor

MIL..

............................. Malfunction indicator

lamp

M/S..

............................. Manual steering

MTX.. ............................ Manual transaxle

OD ................................ Overdrive

OFF.. ............................ Switch off

ON.. .............................. Switch on

PCV.. ............................ Positive crankcase

ventilation

PRC..

............................ Pressure regulator

control

PIS ................................ Power steering

RH..

.............................. Right hand

SOHC.. .........................

z;;kiprhead

SST ............................... Special service tool

SW.. .............................. Switch

TNS

.............................. Tail number side

VICS

............................. Variable inertia charging

system

23UGIX-00

Page 20 of 1164

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 28 of 1164

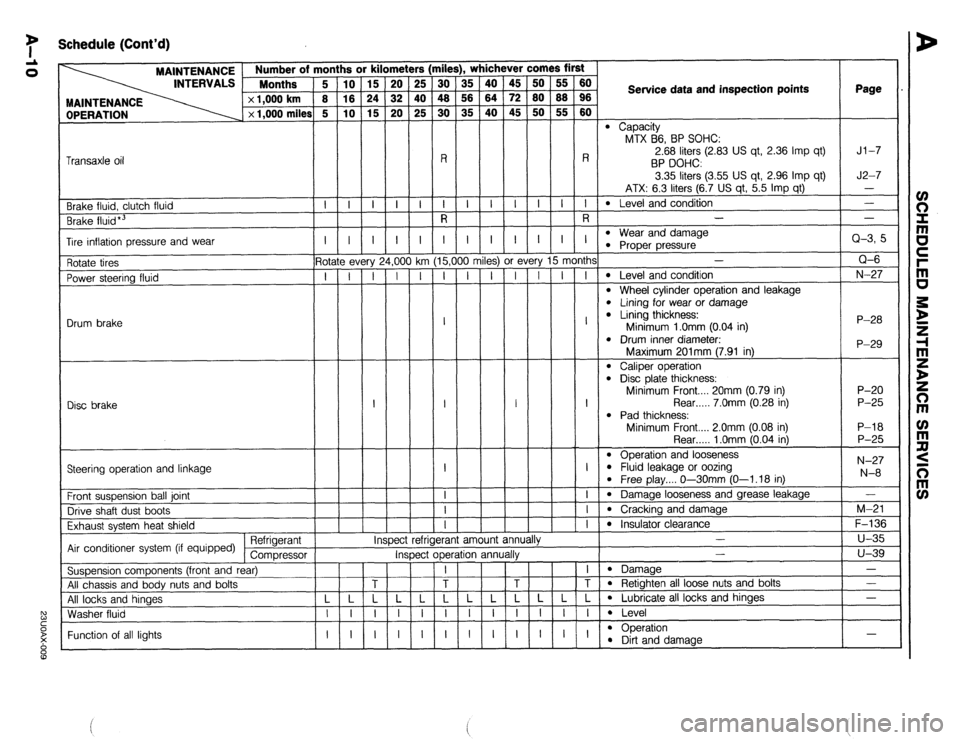

7 Schedule (Cont’d)

rile

iii

48

30

-

R

I

R !rs

25

40

25

-

-i- , whichever comes first

OPERATION MAINTENANCE Number of m

INTERVALS Months

x 1,000 km

x 1,000 miles

ii

is

G

-

i-

-

-

I

5-

T

-

-

-

-

-

-

- ii

z

ro

-

I-

-

-

I

- 45

72

45

-

-i-

-

-

I

-

ry 15 month:

I I I

A

t

A

j

milt Service data and inspection points Page

l Capacity

MTX B6, BP SOHC:

2.68 liters (2.83 US qt, 2.36 Imp qt)

BP DOHC

3.35 liters (3.55 US qt, 2.96 Imp qt)

ATX: 6.3 liters (6.7 US qt, 5.5 Imp qt)

l Level and condition

- Jl-7

J2-7

- Transaxle oil

l Wear and damaae -i- -i- -i- -

Brake fluid, clutch fluid

Brake fluid*3 -

Q-3, 5

Q-6

N-27

P-28

P-29 I I

- I

1,oo

-i

-

-

-

-

-

-

- I

G

T

-

-

-

-

-

-

- I

15,(

I Tire inflation pressure and wear l Proper pressure-

-

l Level and condition

l Wheel cylinder operation and leakage l Lining for wear or damage l Lining thickness:

Minimum 1 .Omm (0.04 in)

l Drum inner diameter. 3s) or f

I I

I

:t r

- Rotate tires

Power steering fluid

Drum brake ? every

I I

Disc brake I I

Maximum 201mm (7.91 in)

l Caliper operation l Disd plate thickness:

Minimum Front.... 20mm (0.79 in)

Rear . . . . . 7.0mm (0.28 in)

l Pad thickness:

Minimum Front.... 2.0mm (0.08 in) P-20

P-25

P-l 8

P-25

N-27

N-8 Rear . . . . . 1 .Omm (0.04 in)

l Operation and looseness l Fluid leakage or oozina

l Free play.... O--3OmmjO-1.18 in)

l Damage looseness and grease leakage

l Cracking and damage

l Insulator clearawp .-v

-

Steering operation and linkage

I

-i-

-I-

-i- Front suspension ball joint

Drive shaft dust boots

Exhaust system heat shield

Air conditioner system (if equipped) Refrigerant

Compressor

Suspension components (front and rear)

All chassis and body nuts and bolts

All locks and hinaes

Washer fluid -

M-21

F-136

u-35

u-39

-

- IY efrigerant amount ann

*. I# mspec

Inspect operation annualry -

l Damaae

l Retighten all loose nuts and bolts

l Lubricate all locks and hinges

l Level

l ODeration - Function of all lights l !%t and damage -

Page 625 of 1164

N

STEERING SYSTEM

INDEX ......................................................

MANUAL STEERING ............................... ;I g

ENGINE SPEED SENSING POWER

STEERING (ESPS) ................................. N- 3

OUTLINE ..................................................

SPECIFICATIONS .................................... ;I ::

MANUAL STEERING ..................................

PREPARATION ....................................... ;I ;

TROUBLESHOOTING GUIDE.. .................. N- 5

BOOT ................................................... N- 6

STEERING WHEEL AND COLUMN.. .......... N- 6

STEERING GEAR AND LINKAGE .............. N-13

ENGINE SPEED SENSING POWER

STEERING .............................................. N-23

PREPARATION ....................................... N-23

TROUBLESHOOTING GUIDE.. .................. N-25

AIR BLEEDING ....................................... N-26

STEERING WHEEL AND COLUMN.. .......... N-26

POWER STEERING FLUID.. ...................... N-27

STEERING GEAR AND LINKAGE .............. N-30

POWER STEERING OIL PUMP.. ................ N-37

DRIVE BELT ........................................... N-41

23UONX-001

Page 627 of 1164

INDEX

ENGINE SPEED SENSING POWER STEERING (ESPS)

FLUID

ATF M STEERING WHEEL PLAY

O-30mm (O-l .18 in)

SPECIFICATION

-IIt or Dexron@lI

I T nFFl FCTIC-IN

--. --w. .-.. NEW: 8.0-9.0mm (0.31-0.35 in)

USED: 9.0-lO.Omm (0.35-0.39 in)

LIMIT: 11.5mm (0.45 in)

23UONX-00

1. Boot

4. Drive belt

Removal / installation

.................. page N- 6 Inspection ................................... page N-41

2. Steering gear and linkage Adjustment .................................

page N-42

Removal / Installation.. ................ page N-30 Replacement .............................. page N-42

Disassembly / Inspection.. ..........

page N-31 5. Power steering fluid

Assembly..

.................................. page N-34 Air bleeding ................................ page N-26

3. Power steering oil pump Inspection.. .................................

page N-27

Removal I Installation

.................. page N-37 6. Steering wheel and column

Disassembly / Inspection I Inspection (On-vehicle).

.............. page N-26

Assembly ..................................

page N-38 Removal / Installation..

................ page N- 9

Disassembly / Assembly ............. page

N-l 0

Inspection ................................... page N-l 1

N-3

Page 628 of 1164

OUTLINE, MANUAL STEERING

OUTLINE

SPECIFICATIONS

Item

Steering wheel

Steering shaft and joint

Steering gear Outer diameter mm (in)

Lock-to-lock turns

Shaft

Joint

Power assist

Gear

Gear ratio

Rack stroke mm (in)

Power steering fluid

Fluid capacity liter (US qt, Imp qt) Manual steering Power steering 370 (14.6)

4.3 3.0

Collapsible

2cross joint

-

Engine speed sensing

Rack-and-pinion

a0 (infinite)

140 (5.51)

-

ATF Dexron@lI or M-III

-

0.8 (0.85, 0.70)

23UONX-00

MANUAL STEERING

PREPARATION

SST

49 0118 850C

Puller, ball joint For 49 1243 785

removal of tie rod

end Installer, dust

boot

49 0180 5108

Attachment,

steering worm

bearing preload

measuring For

measurement of

pinion preload 49 F032 308

Installer For

installation of dust

boot

For

installation of

oil seal

93GONX-OC

N-94

Page 648 of 1164

N ENGINE SPEED SENSING POWER STEERING

19 1232 670A

Gauge set,

Dower steering

49 HO32 301

wrench

49 8032 304

Adapter

49 8032 307

Wrench, outer

box

49 8032 308

Remover body,

rod seal

49 8032 319

Protector body,

rod seal

49 9200 020

Tension gauge,

V-ribbed belt For

measurement of

fluid pressure

For

removal of

tie-rod

For

measurement of

fluid pressure

For

removal and

installation of

outer box

For

removal of oil

seal

For

installation of

inner guide 81 oil

seal

For

measurement of

drive belt tension 49 1232 673

Valve body

(Part of

49 1232 670A)

49 1232 672

Gauge

(Part of

49 1232 670A)

49 HO02 671

Adapter

49 8032 313

Protector, outer

box

49 8032 318

Guide, rod seal

49 0118 850C

Puller, ball joint

I

-

For

measurement of

fluid pressure

For

measurement of

fluid pressure

For

measurement of

fluid pressure

For

installation of

outer box

For

installation of

inner guide & oil

seal

For

removal of

tie rods end

23UONX-0.

N-24

Page 650 of 1164

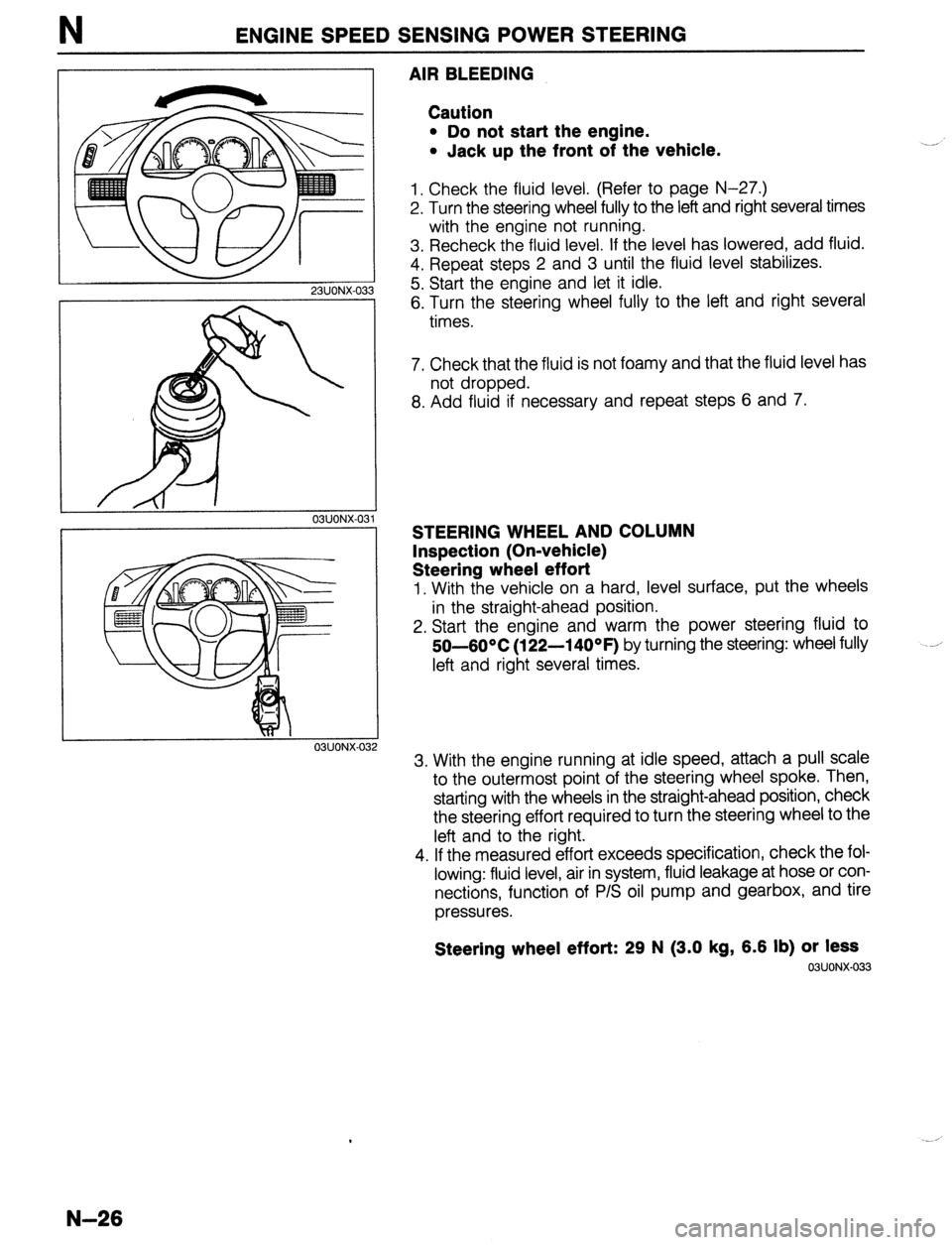

ENGINE SPEED SENSING POWER STEERING

23UONX-03

03UONX-032

AIR BLEEDING

Caution

l Do not start the engine.

l Jack up the front of the vehicle.

1. Check the fluid level. (Refer to page N-27.)

2. Turn the steering wheel fully to the left and right several times

with the engine not running.

3. Recheck the fluid level. If the level has lowered, add fluid.

4. Repeat steps 2 and 3 until the fluid level stabilizes.

5. Start the engine and let it idle.

6. Turn the steering wheel fully to the left and right several

times.

7. Check that the fluid is not foamy and that the fluid level has

not dropped.

8. Add fluid if necessary and repeat steps 6 and 7.

STEERING WHEEL AND COLUMN

Inspection (On-vehicle)

Steering wheel effort

1. With the vehicle on a hard, level surface, put the wheels

in the straight-ahead position.

2. Start the engine and warm the power steering fluid to

50-60°C

(122-14OOF) by turning the steering: wheel fully

left and right several times.

3. With the engine running at idle speed, attach a pull scale

to the outermost point of the steering wheel spoke. Then,

starting with the wheels in the straight-ahead position, check

the steering effort required to turn the steering wheel to the

left and to the right.

4. If the measured effort exceeds specification, check the fol-

lowing: fluid level, air in system, fluid leakage at hose or con-

nections, function of P/S oil pump and gearbox, and tire

pressures.

Steering wheel effort: 29 N (3.0 kg, 6.6 lb) or less 03UONX-033

N-26

Page 651 of 1164

ENGINE SPEED SENSING POWER STEERING N

r-

-l

03UONX-034

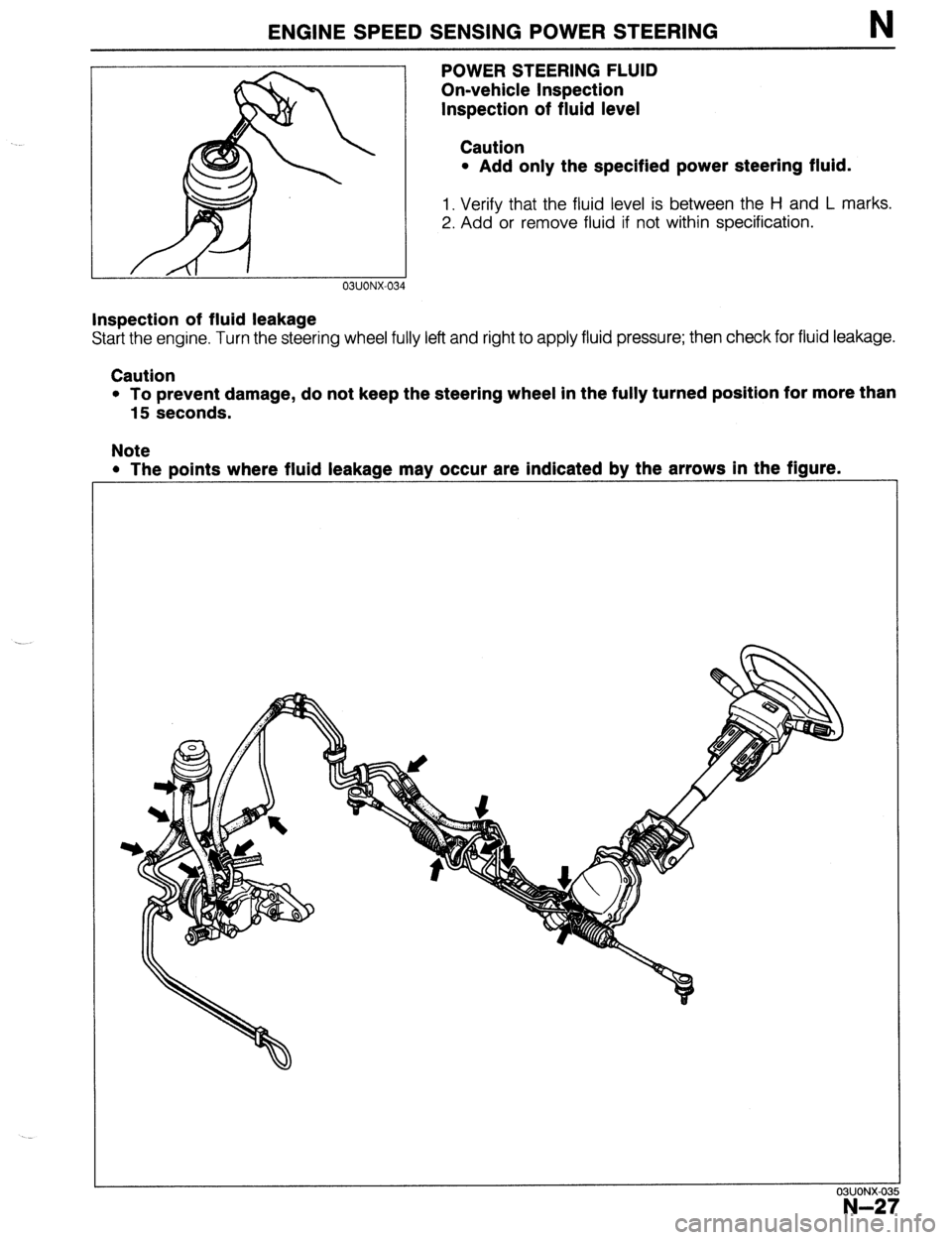

POWER STEERING FLUID

On-vehicle Inspection

Inspection of fluid level

Caution

l Add only the specified power steering fluid.

1. Verify that the fluid level is between the H and L marks.

2. Add or remove fluid if not within specification.

Inspection of fluid leakage

Start the engine. Turn the steering wheel fully left and right to apply fluid pressure; then check for fluid leakage.

Caution

+ To prevent damage, do not keep the steering wheel in the fully turned position for more than

15 seconds.

Note

l The points where fluid leakage may occur are indicated by the arrows in the figure.

03UONX-035

N-27

Page 652 of 1164

N ENGINE SPEED SENSING POWER STEERING

03UONXGI

23UONX-03

23UONX-OZ

THERMOMETER

-Y

23UONX-03

Inspection of fluid pressure

1. Assemble the SST as shown in the figure.

Tightening torque:

39-49 Nern (4.0-5.0 m-kg, 29-36 ft-lb)

2. Disconnect the pressure hose on the oil pump side, and

attach the SST.

Note

l Before disconnecting the hose, make marks at the

connections for proper reinstallation.

3. Bleed the air from the system. (Refer to page N-26.)

4. Open the gauge valve fully. Start the engine and turn the

steering wheel fully left and right to raise the fluid tempera-

ture to 50-60°C (122-14OOP).

5. Close the gauge valve completely. Increase the engine

speed to 1,000-l ,500 rpm and measure the fluid pres-

sure generated by the oil pump. If the pressure is below

specification, replace the oil pump assembly.

Oil pump fluid pressure:

7,356 kPa (75 kg/cm2, 1,067 psi)

Caution

l If the valve Is left closed for more than 15 seconds,

the fluid temperature will increase excessively and

adversely affect the oil pump.

6. Open the gauge valve fully again and increase the engine

speed to l,OOO-1,500 rpm.

7. Turn the steering wheel fully to the left and right and meas-

ure the fluid pressure generated by the gear housing. If the

pressure is below specification, replace the gear housing

assembly.

Gear housing fluid pressure:

7,356 kPa (75 kg/cm2, 1,067 psi)

Caution

l If the steering wheel is kept in the fully turned po-

sition for more than 15 seconds, the fluid tempera-

ture will rise excessively.

N-28