service MERCEDES-BENZ A-CLASS HATCHBACK 2008 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2008, Model line: A-CLASS HATCHBACK, Model: MERCEDES-BENZ A-CLASS HATCHBACK 2008Pages: 305, PDF Size: 5.43 MB

Page 242 of 305

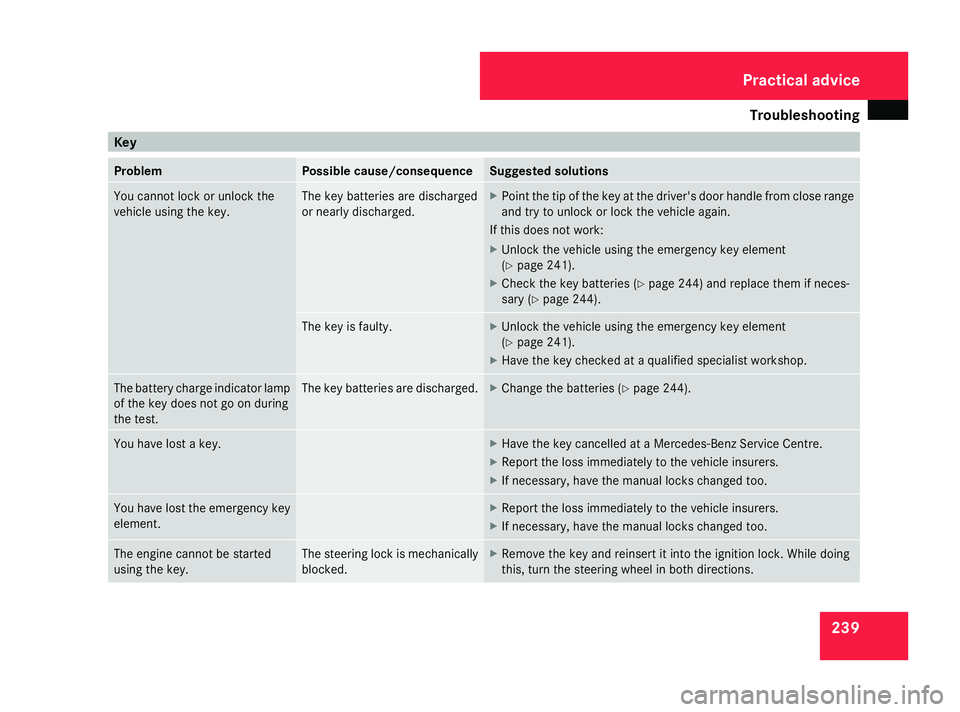

Troubleshooting

239Key

Problem Possible cause/consequence Suggested solutions

You cannot lock or unlock the

vehicle using the key. The key batteries are discharged

or nearl

y discharged. X

Point the tip of the key at the driver's door handle from close range

and try to unlock or lock the vehicle again.

If this does not work:

X Unlock the vehicle using the emergency key element

(Y page 241).

X Check the key batteries (Y page 244) and replace them if neces-

sary ( Ypage 244). The key is faulty. X

Unlock the vehicle using the emergency key element

(Y page 241).

X Have the key checked at a qualified specialist workshop. The battery charge indicator lamp

of the key does not go on during

the test. The key batteries are discharged. X

Change the batteries ( Ypage 244). You have lost a key. X

Have the key cancelled at a Mercedes-Benz Service Centre.

X Report the loss immediately to the vehicle insurers.

X If necessary, have the manual locks changed too. You have lost the emergency key

element. X

Report the loss immediately to the vehicle insurers.

X If necessary, have the manual locks changed too. The engine cannot be started

using the key. The steering lock is mechanically

blocked. X

Remove the key and reinsert it into the ignition lock. While doing

this, turn the steering wheel in both directions. Practical advice

169_AKB; 2; 4, en-GB

wdomann

,V ersion: 2.10.6

2008-07-16T08:52:06+02:00 - Seite 239 ZDateiname: 6515_0315_02_buchblock.pdf; preflight

Page 247 of 305

Changing the batteries

244 Changing the batteries

Notes

It is advisable to have the batteries replaced

at a qualified specialist workshop, e.g. at a

Mercedes-Benz Service Centre. G

Risk of poisoning

Batteries contain toxic and caustic sub-

stances. For this reason, keep batteries

away from children.

If a battery is swallowed, consult a doctor

immediately. H

Environmental note

Do not dispose of batteries with the house-

hold rubbish, as they contain highly toxic

substances.

Take discharged batteries to a qualified

specialist workshop, e.g. a Mercedes-Benz

Service Centre, or to a special collection

point for old batteries. Key

Checking the batteries X

Press the jork button.

The batteries are in order if the battery

charge indicator lamp lights up briefly.

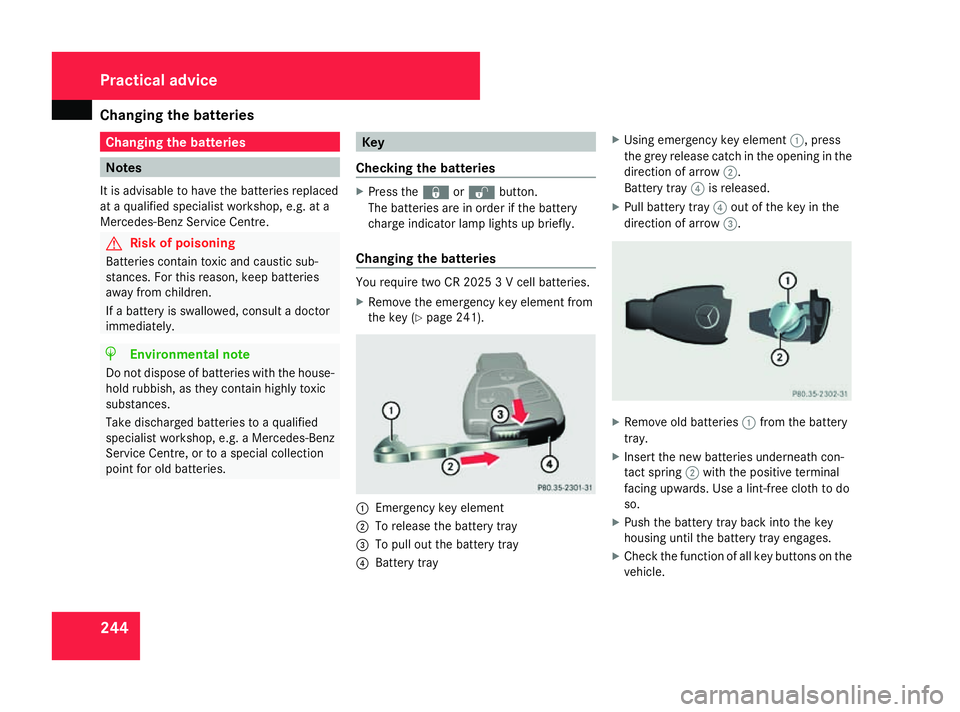

Changing the batteries You require two CR 2025 3 V cell batteries.

X

Remove the emergency key element from

the key (Y page 241). 1

Emergency key element

2 To release the battery tray

3 To pull out the battery tray

4 Battery tray X

Using emergency key element 1, press

the grey release catch in the opening in the

direction of arrow 2.

Battery tray 4is released.

X Pull battery tray 4out of the key in the

direction of arrow 3. X

Remove old batteries 1from the battery

tray.

X Insert the new batteries underneath con-

tact spring 2with the positive terminal

facing upwards. Use a lint-free cloth to do

so.

X Push the battery tray back into the key

housing until the battery tray engages.

X Check the function of all key buttons on the

vehicle. Practical advice

169_AKB; 2; 4, en-GB

wdomann

,V ersion: 2.10.6

2008-07-16T08:52:06+02:00 - Seite 244 Dateiname: 6515_0315_02_buchblock.pdf; preflight

Page 248 of 305

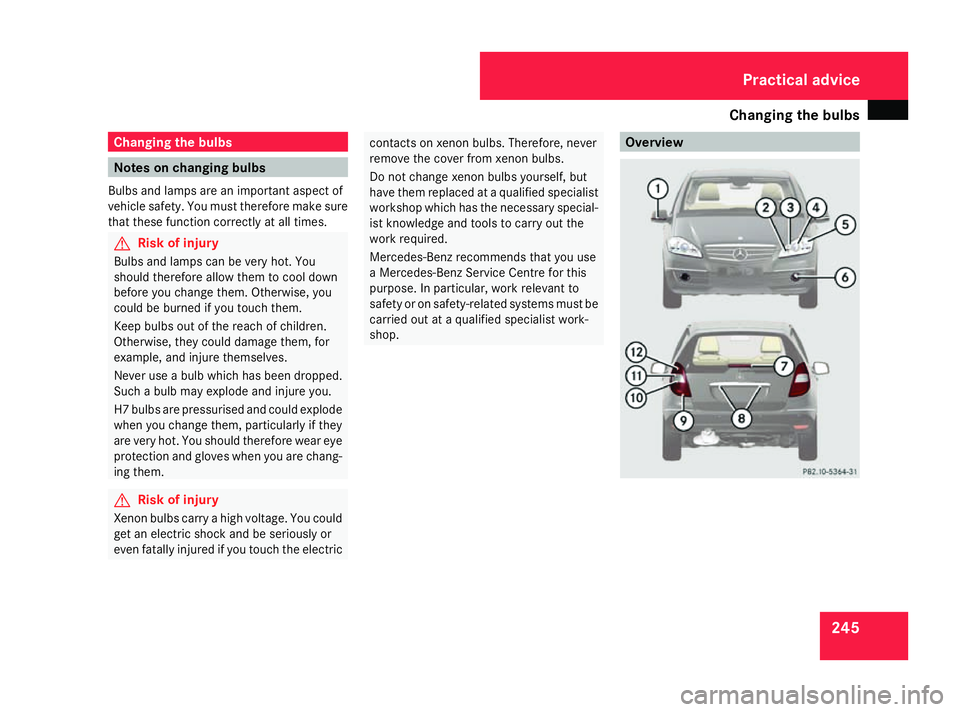

Changing the bulbs

245Changing the bulbs

Notes on changing bulbs

Bulbs and lamps are an important aspect of

vehicle safety. You must therefore make sure

that these function correctly at all times. G

Risk of injury

Bulbs and lamps can be very hot. You

should therefore allow them to cool down

before you change them. Otherwise, you

could be burned if you touch them.

Keep bulbs out of the reach of children.

Otherwise, they could damage them, for

example, and injure themselves.

Never use a bulb which has been dropped.

Such a bulb may explode and injure you.

H7 bulbs are pressurised and could explode

when you change them, particularly if they

are very hot. You should therefore wear eye

protection and gloves when you are chang-

ing them. G

Risk of injury

Xenon bulbs carry a high voltage. You could

get an electric shock and be seriously or

even fatally injured if you touch the electric contacts on xenon bulbs. Therefore, never

remove the cover from xenon bulbs.

Do not change xenon bulbs yourself, but

have them replaced at a qualified specialist

workshop which has the necessary special-

ist knowledge and tools to carry out the

work required.

Mercedes-Benz recommends that you use

a Mercedes-Benz Service Centre for this

purpose. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist work-

shop. Overview Practical advice

169_AKB; 2; 4, en-GB

wdomann

, Version: 2.10.6 2008-07-16T08:52:06+02:00 - Seite 245 ZDateiname: 6515_0315_02_buchblock.pdf; preflight

Page 249 of 305

Changing the bulbs

246

Front bulbs Bulb Type

1

Additional turn

signal lamp

LEDs

29 2

Parking lamp/

side lamp W 5 W

3

Main-beam

headlamps

30

/

cornering

light* 31 H7 55 W

4

Dipped-beam

headlamps

H7 55 W

30

or

D1S 35 W* 32 5

Turn signal lamp PY 21 W

6

Front foglamps* H11 55 W

33 Rear bulbs

Bulb Type

7

Third brake

lamp

LED

29 8

Licence plate

lamp C 5 W

9

Rear foglamp P 21 W

Tail lamp P 4 W

a

Turn signal lamp PY 21 W

b

Reversing lamp P 21 W

c

Brake lamp P 21 W

Before changing bulbs

You can replace the following bulbs:

R

Dipped-beam headlamps (halogen head-

lamps)

R Main-beam headlamps (halogen head-

lamps) R

Side lamp/parking lamp (halogen head-

lamps)

R Cornering light* (vehicles with bi-xenon

headlamps*)

R Front turn signal lamp

R Brake lamp

R Reversing lamp

R Rear foglamp/tail lamp

R Turn signal lamp (rear)

R Licence plate lamp

Observe the following points:

R Use only the bulb types specified here.

R To prevent a short-circuit, switch off the

lights before changing a bulb.

R Only hold bulbs with a clean, lint-free cloth.

R Do not work with wet or greasy fingers.

R If the new bulb still does not light up, con-

sult a qualified specialist workshop, e.g. a

Mercedes-Benz Service Centre.

29 LEDs must not be replaced, as they are designed to have an unlimited service life.

30 Vehicles with halogen headlamps.

31 Vehicles with bi-xenon headlamps*

32 Vehicles with xenon headlamps*: always have these bulbs changed at a qualified specialist workshop, e.g. a Mercedes-Benz Service Centre.

33 These bulbs must be replaced at a qualified specialist workshop, e.g. a Mercedes-Benz Service Centre. Practical advice

* optional

169_AKB; 2; 4, en-GB

wdomann

,V ersion: 2.10.6

2008-07-16T08:52:06+02:00 - Seite 246 Dateiname: 6515_0315_02_buchblock.pdf; preflight

Page 250 of 305

Changing the bulbs

247

i

Due to the location of the bulbs in the

front headlamps, it is best to have these

changed at a qualified specialist workshop,

e.g. a Mercedes-Benz Service Centre.

i Have the headlamp setting checked reg-

ularly at a qualified specialist workshop,

e.g. a Mercedes-Benz Service Centre. Changing the front bulbs

Opening/closing the cover in the front

wheel arch X

To open: turn the front wheels inwards.

X Unscrew retaining screw 1.

X Fold the cover down. X

To close: fold the cover upwards.

X Screw in retaining screw 1.

Removing/fitting the washer fluid res-

ervoir You must remove the washer fluid reservoir

from the engine compartment before you can

replace the bulbs in the front left-hand head-

lamp. X

To remove: turn retaining screw 1anti-

clockwise.

X Remove washer fluid reservoir 2from

bracket 3.

X Put washer fluid reservoir 2to one side

and leave the lines and hoses connected.

Make sure that no washer fluid escapes. X

To fit: guide the lower retaining lug into the

rubber grommet on the longitudinal mem-

ber and fit washer fluid reservoir 2into

bracket 3.

X Turn retaining screw 1clockwise.

Replacing the bulbs in the dipped-beam

headlamp (halogen headlamps) X

Switch off the lights.

X Open the cover in the front wheel arch

(Y page 247).

X Open the bonnet.

X Left-hand headlamps: remove the washer

fluid reservoir (Y page 247).

X Press retaining lug :down and remove

housing cover 2.

X Pull connector =from bulb holder 4. Practical advice

169_AKB; 2; 4, en-GB

wdomann

,V ersion: 2.10.6

2008-07-16T08:52:06+02:00 - Seite 247 ZDateiname: 6515_0315_02_buchblock.pdf; preflight

Page 256 of 305

Flat tyre

253Flat tyre

Flat tyre equipment variants

Your vehicle may be equipped with:

R a TIREFIT kit (Y page 200)

R a "Minispare" emergency spare

wheel* (Y page 201)

R a spare wheel* (Y page 201)

R the MOExtended run-flat sys-

tem* (Y page 262) Preparing the vehicle

i Vehicle preparation is not necessary on

vehicles with MOE tyres*.

X Stop your vehicle as far away from traffic

as possible on solid, non-slippery, level

ground.

X Switch on the hazard warning lamps.

X Apply the handbrake.

Vehicles with manual transmission X

Shift to either first or reverse gear. Vehicles with AUTOTRONIC* X

Move the selector lever to P.

For all vehicles X

All occupants must get out of the vehicle.

Make sure that they are not endangered as

they do so.

X Make sure that no one is near the danger

area whilst a wheel is being changed. Any-

one who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Switch off the engine.

X Remove the key from the ignition lock.

X Get out of the vehicle.

X Close the driver’s door.

X Place the warning triangle (Y page 200) at

a suitable distance. Observe legal require-

ments. Using the TIREFIT kit

You can use the TIREFIT kit to seal small

punctures, particularly those in the tyre tread.

You can use TIREFIT in outdoor temperatures

down to -20 °C. G

Risk of accident

In the following situations, your safety is at

particular risk and tyre sealant is unable to

provide breakdown assistance:

R if there are cuts or punctures in the tyre

greater than 4 mm

R if the wheel rim is damaged

R if you have driven at very low tyre pres-

sures or on a flat tyre

Do not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required.

Mercedes-Benz recommends that you use

a Mercedes-Benz Service Centre for this

purpose. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist work-

shop. Practical advice

* optional

169_AKB; 2; 4, en-GB

wdomann,

Version: 2.10.6 2008-07-16T08:52:06+02:00 - Seite 253 ZDateiname: 6515_0315_02_buchblock.pdf; preflight

Page 259 of 305

Flat tyre

256 ommends that you use a Mercedes-Benz

Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

qualified specialist workshop.

If a tyre pressure of 1.8 bar is reached:

X Press on/off switch 4on the electric air

pump to 0.

The electric air pump is switched off.

X Disconnect the electric air pump and stow

it away.

X Fold up the warning triangle and stow it

away.

X Pull away immediately.

This distributes the TIREFIT more evenly

around the tyre.

X Stop after driving for approximately ten

minutes and check the tyre pressure with

the electric air pump. G

Risk of accident

If the tyre pressure is now lower than

1.3 bar, the tyre is too badly damaged. Do

not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required. Mercedes-Benz rec-

ommends that you use a Mercedes-Benz Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

qualified specialist workshop.

X If the tyre pressure is still at least 1.3 bar,

correct it (see fuel filler flap for values).

To increase the tyre pressure: switch on

the electric air pump.

To reduce the tyre pressure: open pres-

sure release screw aon pressure

gauge b.

X Drive to the nearest workshop and have the

tyre changed there.

X Have the TIREFIT kit replaced as soon as

possible at a qualified specialist workshop,

e.g. at a Mercedes-Benz Service Centre. G

Risk of accident

Do not exceed the maximum speed of

80 km/h.

The "max. 80 km/h "sticker must be affixed

within the driver's field of vision.

The vehicle's handling characteristics may

be affected. H

Environmental note

Have the used TIREFIT kit disposed of pro-

fessionally, e.g. at a Mercedes-Benz

Service Centre.

X Have the TIREFIT kit replaced every four

years at a qualified specialist workshop,

e.g. a Mercedes-Benz Service Centre.

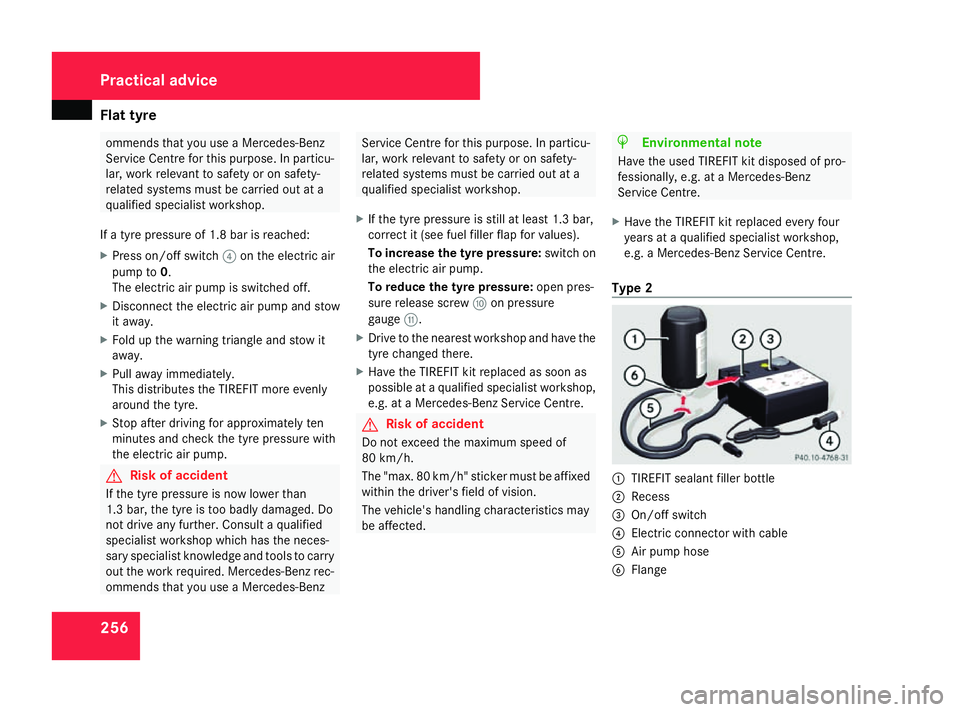

Type 2 1

TIREFIT sealant filler bottle

2 Recess

3 On/off switch

4 Electric connector with cable

5 Air pump hose

6 Flange Practical advice

169_AKB; 2; 4, en-GB

wdomann,

Version: 2.10.6 2008-07-16T08:52:06+02:00 - Seite 256Dateiname: 6515_0315_02_buchblock.pdf; preflight

Page 260 of 305

Flat tyre

257

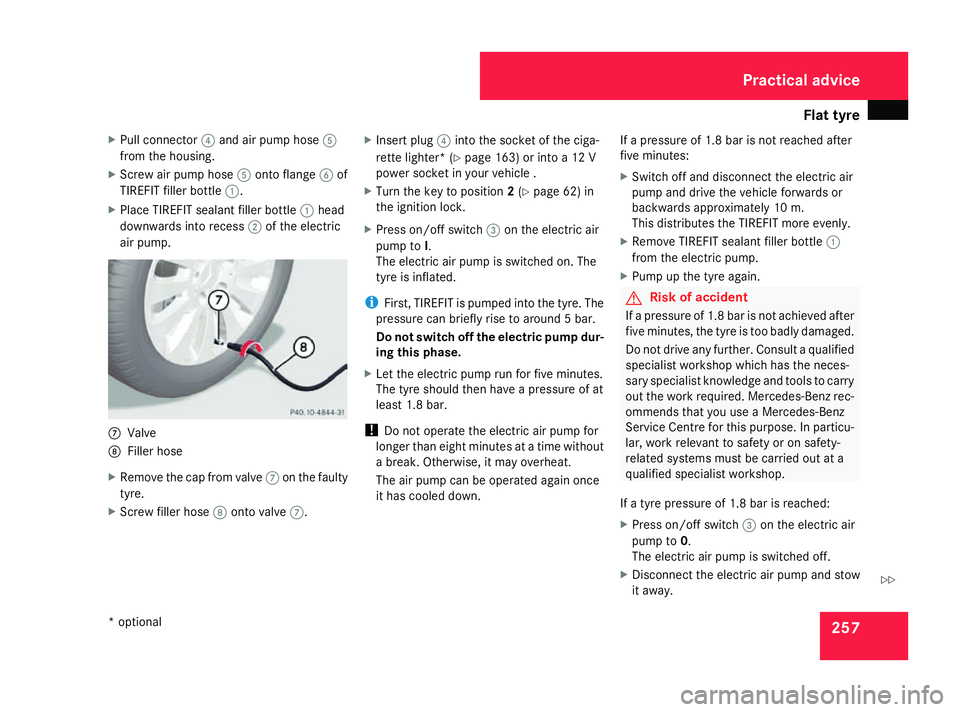

X

Pull connector 4and air pump hose 5

from the housing.

X Screw air pump hose 5onto flange 6of

TIREFIT filler bottle 1.

X Place TIREFIT sealant filler bottle 1head

downwards into recess 2of the electric

air pump. 7

Valve

8 Filler hose

X Remove the cap from valve 7on the faulty

tyre.

X Screw filler hose 8onto valve 7. X

Insert plug 4into the socket of the ciga-

rette lighter* (Y page 163) or into a 12 V

power socket in your vehicle .

X Turn the key to position 2(Y page 62) in

the ignition lock.

X Press on/off switch 3on the electric air

pump to I.

The electric air pump is switched on. The

tyre is inflated.

i First, TIREFIT is pumped into the tyre. The

pressure can briefly rise to around 5 bar.

Do not switch off the electric pump dur-

ing this phase.

X Let the electric pump run for five minutes.

The tyre should then have a pressure of at

least 1.8 bar.

! Do not operate the electric air pump for

longer than eight minutes at a time without

a break. Otherwise, it may overheat.

The air pump can be operated again once

it has cooled down. If a pressure of 1.8 bar is not reached after

five minutes:

X Switch off and disconnect the electric air

pump and drive the vehicle forwards or

backwards approximately 10 m.

This distributes the TIREFIT more evenly.

X Remove TIREFIT sealant filler bottle 1

from the electric pump.

X Pump up the tyre again. G

Risk of accident

If a pressure of 1.8 bar is not achieved after

five minutes, the tyre is too badly damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required. Mercedes-Benz rec-

ommends that you use a Mercedes-Benz

Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

qualified specialist workshop.

If a tyre pressure of 1.8 bar is reached:

X Press on/off switch 3on the electric air

pump to 0.

The electric air pump is switched off.

X Disconnect the electric air pump and stow

it away. Practical advice

* optional

169_AKB; 2; 4, en-GB

wdomann

, Version: 2.10.6 2008-07-16T08:52:06+02:00 - Seite 257 ZDateiname: 6515_0315_02_buchblock.pdf; preflight

Page 261 of 305

Flat tyre

258

X

Fold up the warning triangle and stow it

away.

X Pull away immediately.

This distributes the TIREFIT more evenly

around the tyre.

X Stop after driving for approximately ten

minutes and check the tyre pressure with

the electric air pump. G

Risk of accident

If the tyre pressure is now lower than

1.3 bar, the tyre is too badly damaged. Do

not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required. Mercedes-Benz rec-

ommends that you use a Mercedes-Benz

Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

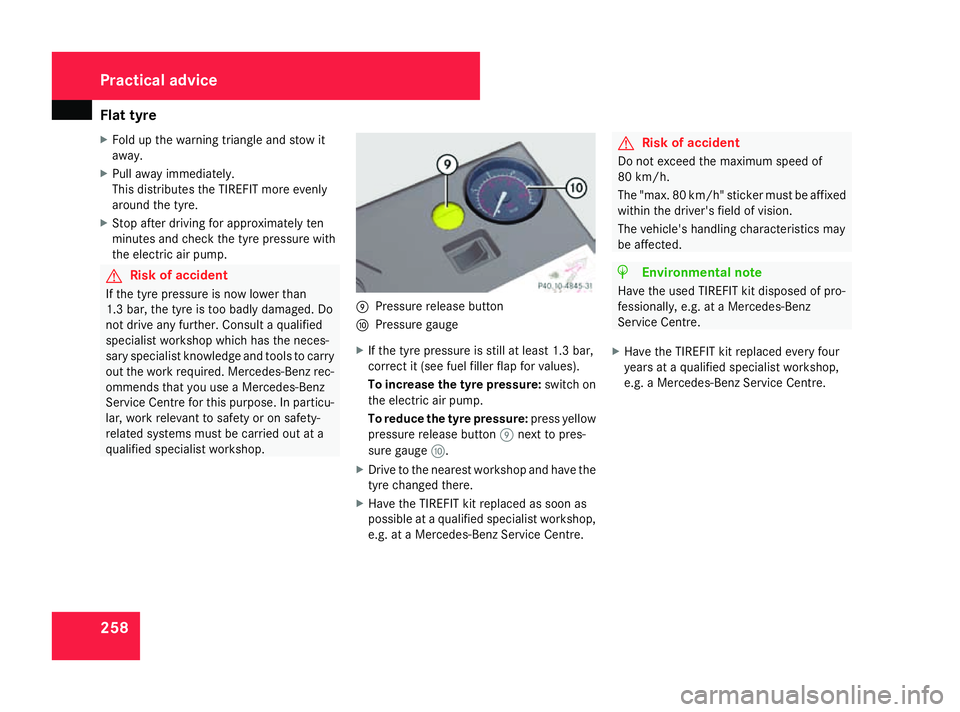

qualified specialist workshop. 9

Pressure release button

a Pressure gauge

X If the tyre pressure is still at least 1.3 bar,

correct it (see fuel filler flap for values).

To increase the tyre pressure: switch on

the electric air pump.

To reduce the tyre pressure: press yellow

pressure release button 9next to pres-

sure gauge a.

X Drive to the nearest workshop and have the

tyre changed there.

X Have the TIREFIT kit replaced as soon as

possible at a qualified specialist workshop,

e.g. at a Mercedes-Benz Service Centre. G

Risk of accident

Do not exceed the maximum speed of

80 km/h.

The "max. 80 km/h "sticker must be affixed

within the driver's field of vision.

The vehicle's handling characteristics may

be affected. H

Environmental note

Have the used TIREFIT kit disposed of pro-

fessionally, e.g. at a Mercedes-Benz

Service Centre.

X Have the TIREFIT kit replaced every four

years at a qualified specialist workshop,

e.g. a Mercedes-Benz Service Centre. Practical advice

169_AKB; 2; 4, en-GB

wdomann,

Version: 2.10.6

2008-07-16T08:52:06+02:00 - Seite 258 Dateiname: 6515_0315_02_buchblock.pdf; preflight

Page 262 of 305

Flat tyre

259Changing a wheel/fitting the spare

wheel*

G

Risk of accident

The wheel dimensions and tyre size of the

"Minispare" emergency spare wheel* may

differ from those of the standard wheels.

Your vehicle's handling characteristics will

change when a "Minispare" emergency

spare wheel* is fitted. Adapt your style of

driving accordingly.

The "Minispare" emergency spare wheel*

may only be used for a short time. Do not

exceed the maximum speed of 80 km/h

and do not deactivate ESP ®

.

Never drive the vehicle with more than one

"Minispare" emergency spare wheel* fit-

ted. G

Risk of accident

Have the "Minispare" emergency spare

wheel* or the spare wheel* replaced with

a new wheel as soon as possible at a quali-

fied specialist workshop which has the nec-

essary specialist knowledge and tools to

carry out the work required. Mercedes-

Benz recommends that you use a

Mercedes-Benz Service Centre for this pur- pose. In particular, work relevant to safety

or on safety-related systems must be car-

ried out at a qualified specialist workshop.

Preparing the vehicle X

Prepare the vehicle as described

(Y page 253).

X If a trailer is coupled, uncouple it.

X Place the wheels in the straight-ahead posi-

tion.

X Take the "Minispare" emergency spare

wheel* or the spare wheel* out of the stow-

age well under the luggage compartment

floor.

X Take the following out of the left-hand

stowage compartment in the luggage com-

partment

R

the vehicle tool kit

R the wheel chock

R the jack

X Secure the vehicle to prevent it from rolling

away.

On level ground: place chocks or similar

items under the front and rear of the wheel

that is diagonally opposite the wheel you

wish to change. X

On downhill gradients: place chocks or

similar behind both wheels of the other

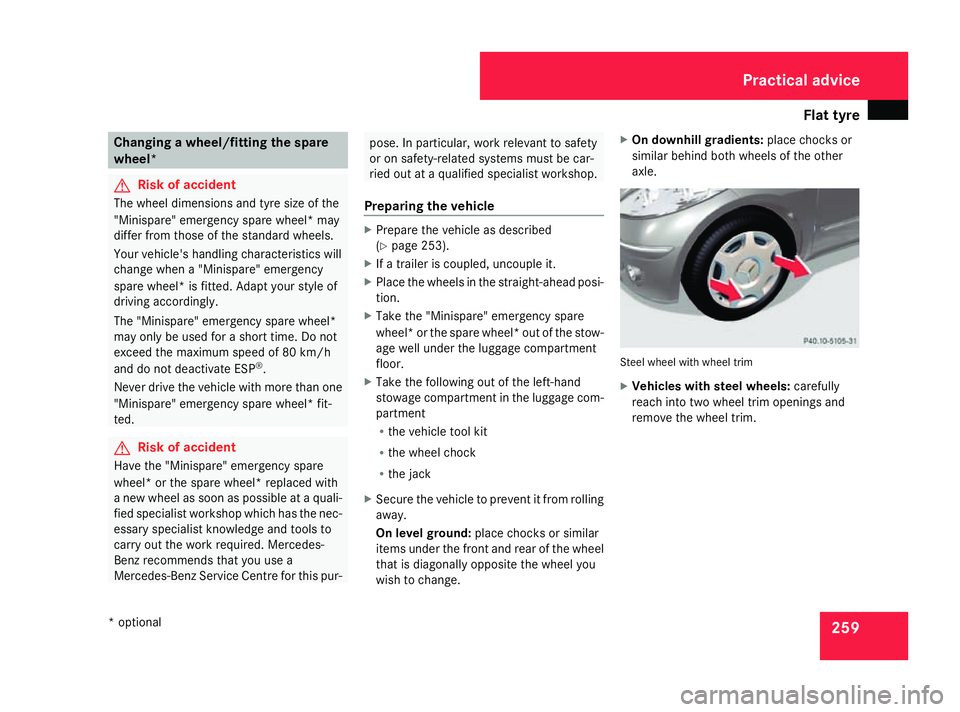

axle. Steel wheel with wheel trim

X

Vehicles with steel wheels: carefully

reach into two wheel trim openings and

remove the wheel trim. Practical advice

* optional

169_AKB; 2; 4, en-GB

wdomann, Version: 2.10.6 2008-07-16T08:52:06+02:00 - Seite 259 ZDateiname: 6515_0315_02_buchblock.pdf; preflight