brake MERCEDES-BENZ A-CLASS HATCHBACK 2018 Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: A-CLASS HATCHBACK, Model: MERCEDES-BENZ A-CLASS HATCHBACK 2018Pages: 609, PDF Size: 10.73 MB

Page 474 of 609

R

When replacing with tyres that do not

fe ature run-flat characteristics: vehicles

with MOExtended tyres are not equipped

with a TIREFIT kit at thefa ctor y.Equip the

ve hicle with a TIREFIT kit af terre placing with

tyres that do not feature run-flat characteris‐

tics, e.g. winter tyres.

Fo r more information on wheels and tyres, con‐

ta ct a qualified specialist workshop.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (→ page 459)

R Tyre pressure table (→ page 460)

R Notes on the emer gency spa rewheel

(→ page 477) Note

s on inter changing wheels &

WARNING Risk of inju rythro ugh dif fer‐

ent wheel sizes

Inter changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions may se

verely impair the driving characteris‐

tics.

The disk brakes or wheel suspension compo‐

nents may also be damaged. #

Rotate front and rear wheels on lyifthe

wheels and tyres are of the same

dimensions. Inter

changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions can

re nder thege neral operating pe rmit in valid.

The wear pat tern s on the front and rear wheels

dif fer:

R Front wheels wear more on the shoulder of

th e tyre

R Rear wheels wear more in the cent reofthe

tyre

On vehicles with the same front and rear wheel

size, you can inter change the wheels every

5,000 to10,000 km, depending on thewe ar.

Ensure the direction of rotation is maintained for

th e wheels. It is imperative

toobser vethe instructions and

saf ety no tes on "Wheel change" when doing so. Note

s onstoring wheels R

Afterre moving wheels, store them in a cool,

dry and preferably dark place.

R Protect the tyres from conta ct withoil,

grease or fuel. Overview of

the ty re-change tool kit Apart from some countr

y-specific variants, vehi‐

cles are not equipped with a tyre-change tool kit.

Fo r more information on which tyre-changing

to ol kits are requ ired and appr ovedfo r per form‐

ing a wheel change on your vehicle, consult a

qu alified specialist workshop.

Yo urequ irethefo llowing tools, for ins tance, to

ch ange a wheel:

R Jack

R Chock

R Wheel wrench

R Cent ring pin Wheels and tyres

471

Page 475 of 609

%

The jack weighs appr oximately 3.4 kg.

The maximum load capacity of the jack can

be found on thest icke r af fixe dto the jac k.

The jack is maintenance-free. If there is a

malfunction, please conta ct aqualified spe‐

cialist workshop.

The tyre-change tool kit is located in tool bag 1

in the load compartment. 1

Tool bag

To ol bag 1contains:

R Jack

R Gloves

R Wheel wrench R

Centring pin

R Folding chock

R Ratchet for jack

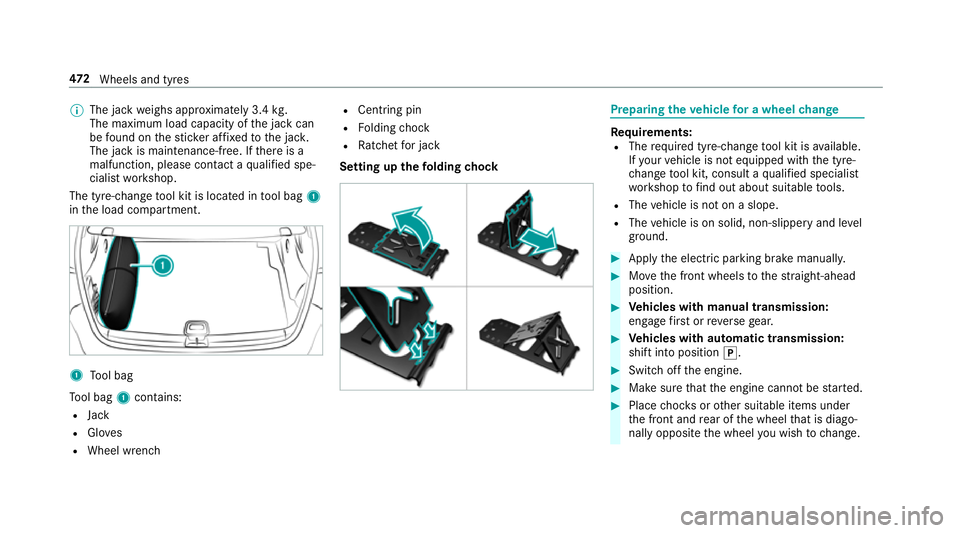

Setting up thefo lding chock Prepa

ring theve hicle for a wheel change Re

quirements:

R The requ ired tyre-change tool kit is available.

If yo ur vehicle is not equipped with the tyre-

ch ange tool kit, consult a qualified specialist

wo rkshop tofind out about suitable tools.

R The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Apply the electric parking brake manually. #

Movethe front wheels tothest ra ight-ahead

position. #

Vehicles with manual transmission:

engage firs t or reve rsege ar. #

Vehicles with automatic transmission:

shift into position j. #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

Place choc ks orother suitable items under

th e front and rear of the wheel that is diago‐

nally opposite the wheel you wish tochange. 472

Wheels and tyres

Page 477 of 609

Ru

les of conduct when theve hicle is raised:

R Never place your hands or feet under the

ve hicle.

R Do not lie under theve hicle.

R Do not start the engine and do not release

th e electric parking brake.

R Do not open or close any doors or theta il‐

ga te. #

Using the wheel wrench, loosen the wheel

bolts on the wheel you wish tochange by

about one full turn. Do not unscr ewthe bolts

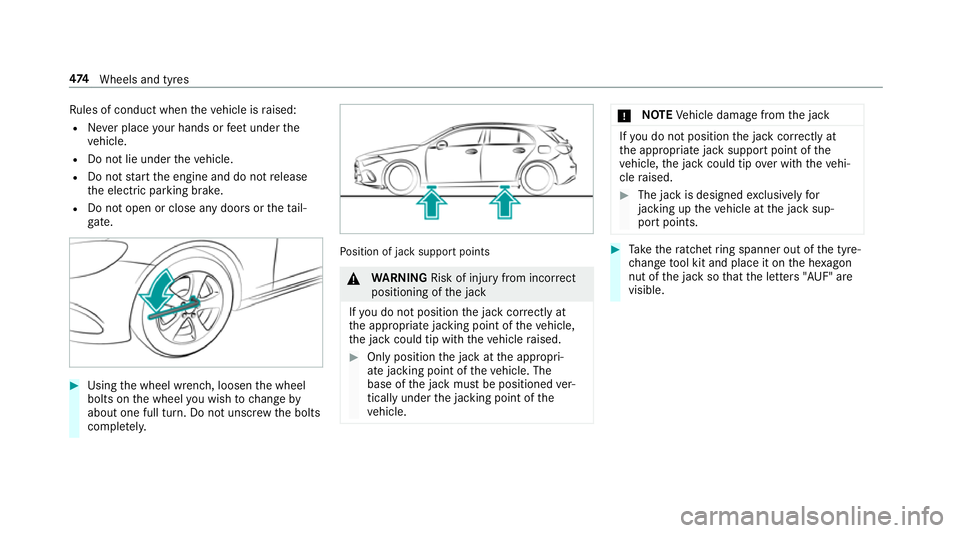

comple tely. Po

sition of jack support points &

WARNING Risk of inju ryfrom incor rect

positioning of the jack

If yo u do not position the jack cor rectly at

th e appropriate jacking point of theve hicle,

th e jack could tip with theve hicle raised. #

Only position the jack at the appropri‐

ate jacking point of theve hicle. The

base of the jack must be positioned ver‐

tically under the jacking point of the

ve hicle. *

NO

TEVehicle damage from the jack If

yo u do not position the jack cor rectly at

th e appropriate jack support point of the

ve hicle, the jack could tip over with theve hi‐

cle raised. #

The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points. #

Take thera tchet ring spanner out of the tyre-

ch ange tool kit and place it on the he xagon

nut of the jack so that the letters "AUF" are

visible. 474

Wheels and tyres

Page 478 of 609

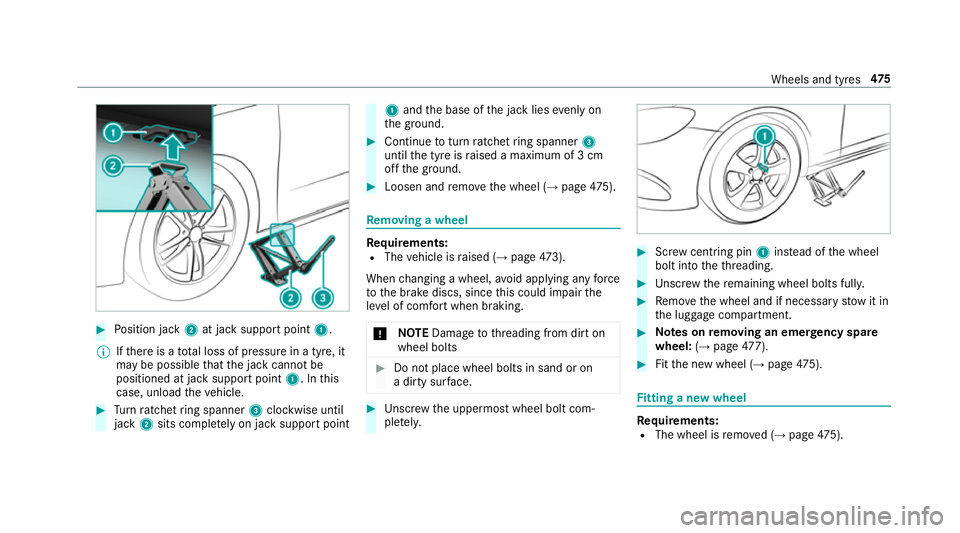

#

Position jack 2at jack support point 1.

% Ifth ere is a total loss of pressure in a tyre, it

may be possible that the jack cann otbe

positioned at jack support point 1. Inthis

case, unload theve hicle. #

Turn ratchet ring spanner 3clockwise until

jack 2sits comple tely on ja cksupport point 1

and the base of the jack lies evenly on

th e ground. #

Continue toturn ratchet ring spanner 3

until the tyre is raised a maximum of 3 cm

off the ground. #

Loosen and remo vethe wheel (→ page475). Re

moving a wheel Re

quirements:

R The vehicle is raised (→ page473).

When changing a wheel, avoid applying any force

to the brake discs, since this could impair the

le ve l of com fort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on

a dirty sur face. #

Unscr ew the uppermost wheel bolt com‐

ple tely. #

Screw centring pin 1instead of the wheel

bolt into theth re ading. #

Unscr ew there maining wheel bolts fully. #

Remo vethe wheel and if necessary stowit in

th e luggage compartment. #

Note s onremoving an eme rgency spa re

wheel: (→page 477). #

Fitth e new wheel (→ page475). Fi

tting a new wheel Re

quirements:

R The wheel is remo ved (→ page 475). Wheels and

tyres475

Page 488 of 609

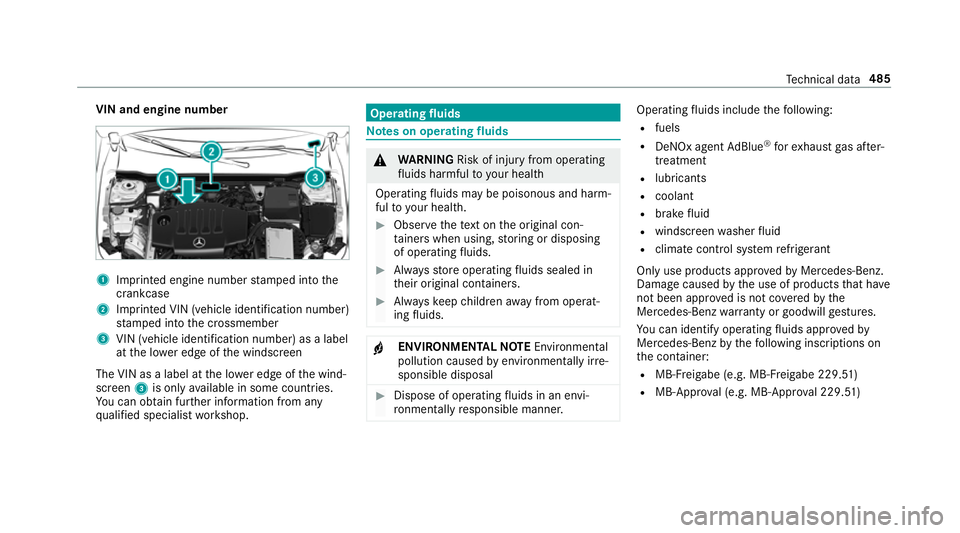

VIN and engine number

1

Imprinted engine number stamped into the

crankcase

2 Imprinted VIN (vehicle identification number)

stamped into the crossmember

3 VIN (vehicle identification number) as a label

at the lo wer edge of the windscreen

The VIN as a label at the lo wer edge of the wind‐

screen 3is only available in some countries.

Yo u can obtain fur ther information from any

qu alified specialist workshop. Operating

fluids Note

s on operating fluids &

WARNING Risk of inju ryfrom operating

fl uids harmful to your health

Operating fluids may be poisonous and harm‐

ful to yo ur health. #

Obser vethete xt on the original con‐

ta iners when using, storing or disposing

of operating fluids. #

Alw aysst ore operating fluids sealed in

th eir original conta iners. #

Alw ayske ep children away from operat‐

ing fluids. +

ENVIRONMEN

TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal #

Dispose of operating fluids in an envi‐

ro nmentally responsible manner. Operating

fluids include thefo llowing:

R fuels

R DeNOx agent AdBlue ®

forex haust gas af ter‐

treatment

R lubri cants

R coolant

R brake fluid

R windsc reen washer fluid

R climate cont rol sy stem refrigerant

Only use products app rove dby Mercedes-Benz.

Damage caused bythe use of products that ha ve

not been appr oved is not co veredby the

Mercedes-Benz warranty or goodwill gestures.

Yo u can identify operating fluids appr ovedby

Mercedes-Benz bythefo llowing insc ript ions on

th e conta iner:

R MB- Freigabe (e.g. MB-Fr eigabe 229.51 )

R MB-Appr oval (e.g. MB-App rova l 229.51) Te

ch nical da ta485

Page 495 of 609

Re

placement amount Mode

lR eplacement

amount

A 16 0

A 180

A 200 5.1 litres

A 18 0 d

A 250 5.5 litres

All other models 6.5 litresNote

s on brake fluid Obser

vethe no tes on operating fluids

(→ page 485). &

WARNING Risk of an accident due to

va pour poc kets form ing in the brake sys‐

tem

The brake fluid cons tantly absorbs moi sture

from the air. This lo wersthe boiling point of

th e brake fluid. If the boiling point is too lo w, va

pour poc kets may form inthe brake sys‐

te m when the brakes are applied hard.

This impairs the braking ef fect. #

Have the brake fluid rene we d at the

specified inter vals. Ha

ve the brake fluid regularly replaced at a

qu alified specialist workshop.

Only use brake fluid appr ovedby Mercedes-Benz

according toMB-F reigabe or MB-Appr oval 33 1.0.

Yo u can obtain fur ther information on brake fluid

in thefo llowing places:

R inthe Mercedes-Benz Specifications for

Operating Fluids

- at http://be vo.mercedes-benz.com

- inthe Mercedes-Benz BeVo App

R at a qualified specialist workshop Coolant

Note

s on coolant

Obser vethe no tes on operating fluids

(→ page 485). &

WARNING Risk offire ‑ and inju ryfrom

antifreeze

If antifreeze comes into contact with hot

component parts in the engine compart‐

ment, it may ignite. #

Allow the engine tocool down before

yo uto p up the antif reeze. #

Make sure that no antifreeze spills out

next tothefiller opening. #

Thoroughly clean the antif reeze from

component parts before starting the

ve hicle. *

NO

TEDama gecaused byincor rect cool‐

ant #

Only add coolant that has been pre‐

mixed with therequ ired antifreeze pro‐

te ction. 492

Tech nical da ta

Page 499 of 609

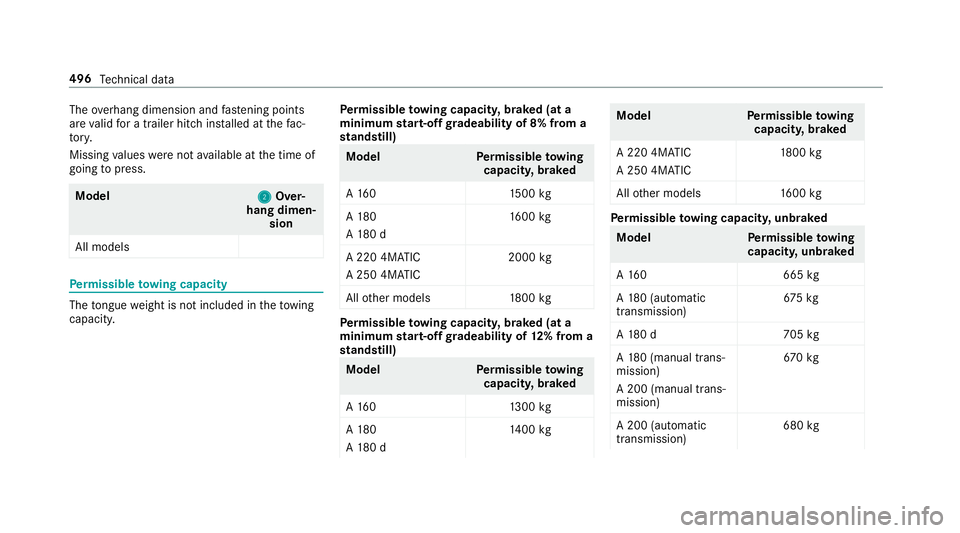

The

overhang dimension and fastening points

are valid for a trailer hitch ins talled at thefa c‐

to ry.

Missing values werenot available at the time of

going topress. Model

2

2Over‐

hang dimen‐ sion

All models Pe

rm issible towing capacity The

tongue weight is not included in theto wing

capacity. Pe

rm issible towing capacit y,braked (at a

minimum start-off gradeability of 8% from a

st andstill) Model

Perm issible towing

capacit y,braked

A 16 01 500kg

A 180

A 18 0 d 16

00 kg

A 220 4MATIC

A 250 4MATIC 2000

kg

All other models 1800 kg Pe

rm issible towing capacit y,braked (at a

minimum start-off gradeability of 12% from a

st andstill) Model

Perm issible towing

capacit y,braked

A 16 01 300kg

A 180

A 18 0 d 14

00 kg Model

Perm issible towing

capacit y,braked

A 220 4MATIC

A 250 4MATIC 18

00 kg

All other models 1600 kg Pe

rm issible towing capacit y,unbraked Model

Perm issible towing

capacit y,unbraked

A 16 06 65kg

A 18 0 (au tomatic

transmission) 67

5kg

A 18 0d7 05kg

A 18 0 (manual trans‐

mission)

A 200 (manual trans‐

mission) 67

0kg

A 200 (automatic

transmission) 680

kg 496

Tech nical da ta

Page 500 of 609

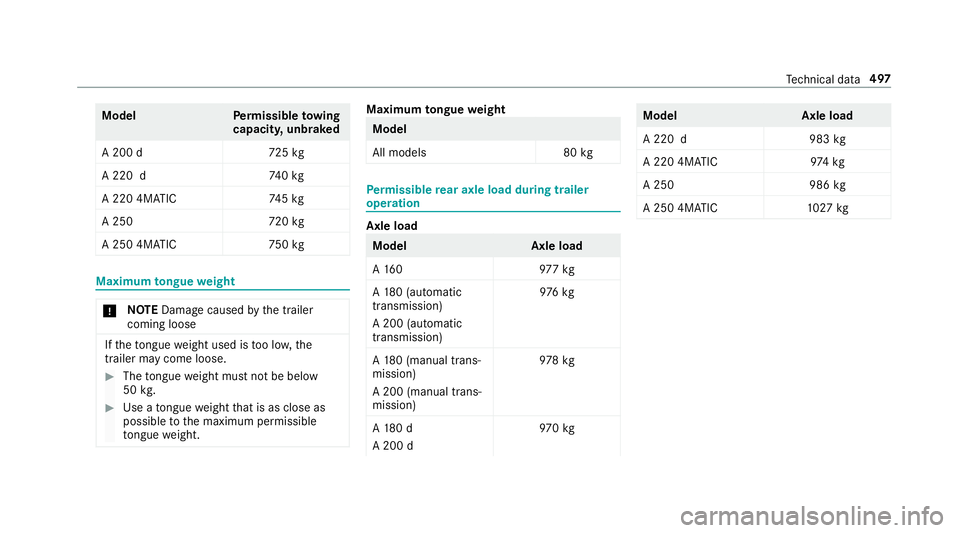

Model

Perm issible towing

capacit y,unbraked

A 200 d7 25kg

A 220 d7 40kg

A 220 4MATIC 745kg

A 250 720kg

A 250 4MATIC 750kg Maximum

tongue weight *

NO

TEDama gecaused bythe trailer

coming loose If

th eto ngue weight used is too lo w,the

trailer may come loose. #

The tongue weight must not be below

50 kg. #

Use a tongue weight that is as close as

possible tothe maximum permissible

to ngue weight. Maximum

tongue weight Model

All models

80kg Pe

rm issible rear axle load during trailer

operation Axle load

Model

Axle load

A 16 09 77kg

A 18 0 (au tomatic

transmission)

A 200 (auto matic

transmission) 97

6kg

A 18 0 (manual trans‐

mission)

A 200 (manual trans‐

mission) 978

kg

A 18 0 d

A 200 d 97

0kg Model

Axle load

A 220 d9 83kg

A 220 4MATIC 974kg

A 250 986kg

A 250 4MATIC 1027 kg Te

ch nical da ta497

Page 502 of 609

Saf

ety sy stems Display messages

Possible causes/consequences and M

MSolutions

÷ currently unavailable See

Owner's Manual *

ESP ®

is temp orarily una vailable.

Other drive sy stems and driving saf ety sy stems may also be malfunctioning. &

WARNING Risk of skidding if ESP ®

is malfunctioning

If ESP ®

is malfunctioning, ESP ®

cannot car ryout vehicle stabilisation. In addition, other driving saf ety sy stems

are switched off. #

Drive on carefull y. #

Have ESP ®

ch ecked at a qualified specialist workshop. #

Carefully drive on a suitable stre tch of road, making slight steering mo vements at a speed abo ve30 km/h. #

Ifth e display message does not disappear, consult a qualified specialist workshop immediately. Drive carefully.

Brake immediately *

Ve hicles with manual transmission: a malfunction has occurred while the HOLD function was activated.

A tone may also sound at regular inter vals. If you attem pttolock theve hicle, theto ne becomes louder.

Yo u cannot start the engine. #

Immediately depress the brake pedal firm lyuntil the display message disappears.

Yo u can restart the engine. Display messages and

warning/indicator lamps 499

Page 503 of 609

Display messages

Possible causes/consequences and M

MSolutions

! Turn on the ignition to

release the parking brake *

The red! indicator lamp is lit.

Yo u ha veattem ptedto release the electric parking brake with the ignition switched off. #

Switch the ignition on.

! Parking brake See Owner's

Manual *

The yellow ! indicator lamp is lit. The elect ric pa rking brake is malfunctioning.

To appl y: #

Switch off the ignition and switch it back on. #

Apply the electric parking brake manually (→ page183).

If it is not possible toapply the electric parking brake: #

Consult a qualified specialist workshop. #

Where necessar y,also safeguard the par kedve hicle against rolling away.

The yellow ! indicator lamp and there d! indicator lamp are lit. The elect ric pa rking brake is malfunction‐

ing.

To release: #

Swit choff the ignition and switch it back on. #

Release the electric parking brake manually (→ page183).

or #

Release the electric parking brake automatically (→ page182). 500

Displaymessa ges and warning/indicator lamps