wheel bolts MERCEDES-BENZ AMG GT ROADSTER 2018 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: AMG GT ROADSTER, Model: MERCEDES-BENZ AMG GT ROADSTER 2018Pages: 409, PDF Size: 7.66 MB

Page 264 of 409

#

Alw ays switch off the windscreen wip‐

ers and the ignition before cleaning the

windscreen or wiper blades. &

WARNING Risk of bu rning from theta il‐

pipe or tailpipe trim

The tailpipe and tailpipe trim can become

ve ry hot. If you come into contact with these

car parts, you could burn yourself. #

Alw ays be particular lycareful when in

th e vicinity of theta ilpipe and tailpipe

trims and supervise children very

closely when in this area. #

Before any con tact, allow the car parts

to cool down. Obser

vethefo llowing information: Note

s on cleaning and car eA voiding vehicle damage

Wheels/rims Usewate r and acid-free wheel cleaners. R

Do not use acidic wheel cleaners toremo vebrake dust.

This could damage wheel bolts and brake components.

R Toavoid cor rosion of the brake discs and brakepads, drive

th eve hicle for a few minutes af ter cleaning before parking

it. The brake discs and brakepads warm up and dry out.

Wi ndo ws

Clean windowsinside and outside with a damp clo thand with

a cleaning agent recommended for Mercedes-Benz. Do not use dry clo

ths or abrasive or sol vent-based cleaning

agents toclean the inside of windo ws.

Wi per blades

Fold out the wiper blades and clean them using a damp clo th.D o not clean the wiper blades too of ten. Maintenance and care

261

Page 302 of 409

R

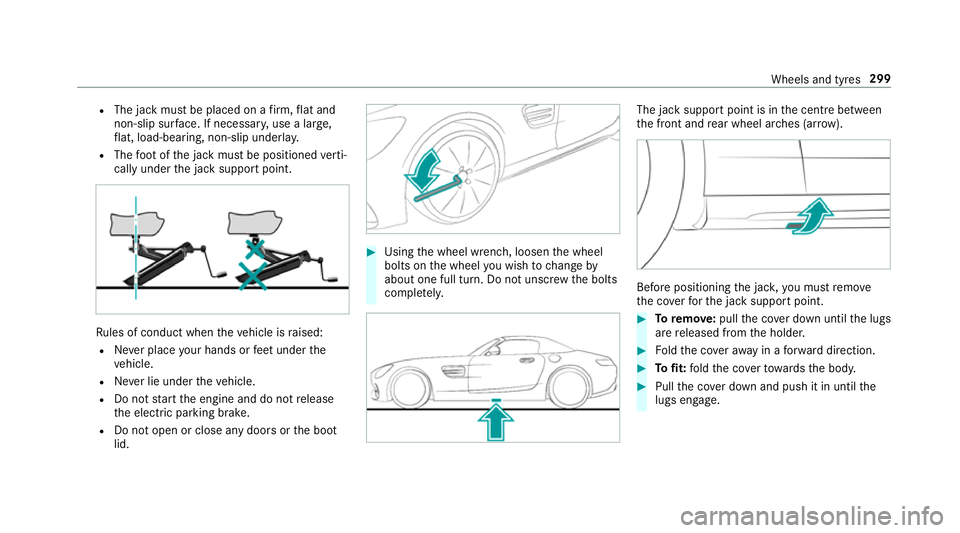

The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

fl at, load-bearing, non-slip unde rlay.

R The foot ofthe jack must be positioned verti‐

cally under the jack support point. Ru

les of conduct when theve hicle is raised:

R Never place your hands or feet under the

ve hicle.

R Never lie under theve hicle.

R Do not start the engine and do not release

th e electric parking brake.

R Do not open or close any doors or the boot

lid. #

Using the wheel wrench, loosen the wheel

bolts on the wheel you wish tochange by

about one full turn. Do not unscr ewthe bolts

comple tely. The jack support point is in

the cent rebetween

th e front and rear wheel ar ches (ar row). Before positioning

the jac k,you must remo ve

th e co verfo rth e jack support point. #

Toremo ve:pull the co ver down until the lugs

are released from the holder. #

Foldthe co veraw ay in a forw ard direction. #

Tofit: fold the co verto wa rdsth e body. #

Pull the co ver down and push it in until the

lugs engage. Wheels and tyres

299

Page 304 of 409

*

NO

TEDama getothre ading from dirt on

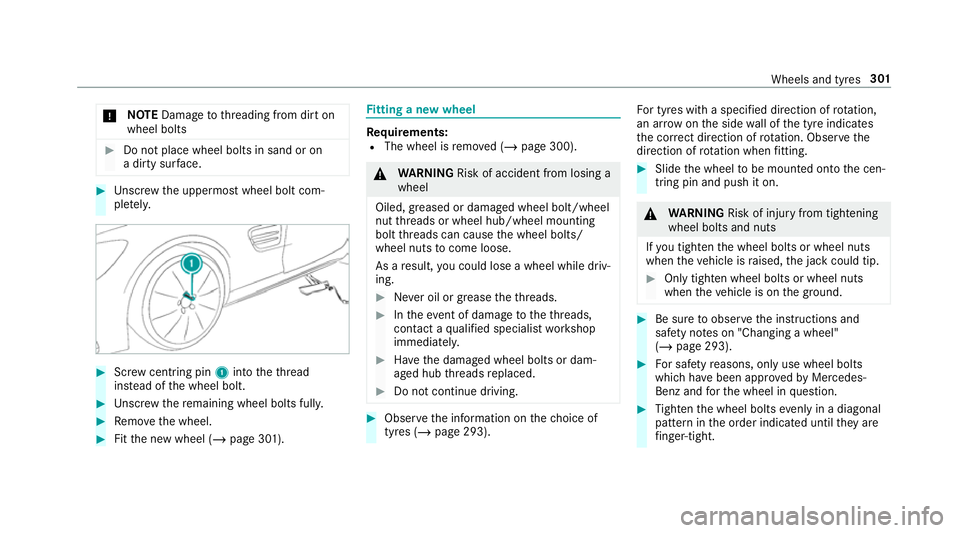

wheel bolts #

Do not place wheel bolts in sand or on

a dirty sur face. #

Unscr ew the uppermost wheel bolt com‐

ple tely. #

Screw centring pin 1into theth re ad

ins tead of the wheel bolt. #

Unscr ew there maining wheel bolts fully. #

Remo vethe wheel. #

Fitthe new wheel (/ page 301). Fi

tting a new wheel Re

quirements:

R The wheel is remo ved (/ page 300). &

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can cause the wheel bolts/

wheel nuts tocome loose.

As a result, you could lose a wheel while driv‐

ing. #

Never oil or grease theth re ads. #

Intheeve nt of dama getotheth re ads,

con tact a qualified specialist workshop

immediatel y. #

Have the damaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do not continue driving. #

Obser vethe information on thech oice of

tyres (/ page 293). Fo

r tyres with a specified direction of rotation,

an ar row on the side wall of the tyre indicates

th e cor rect di rection of rotation. Obse rvethe

direction of rotation when fitting. #

Slide the wheel tobe mounted onto the cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

Be sure toobser vethe instructions and

saf ety no tes on "Changing a wheel"

(/ page 293). #

For saf etyre asons, on lyuse wheel bolts

which ha vebeen appr ovedby Mercedes-

Benz and forth e wheel in question. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated until they are

fi nger-tight. Wheels and tyres

301

Page 305 of 409

#

Unscr ew the cent ring pin. #

Tighten the last wheel bolt until it is finger-

tight. #

Ifth e collapsible emer gency spa rewheel has

been fitted, infla tethe collapsible emer gency

spa rewheel (/ page 304). #

Lowe rth eve hicle (/ page 302). Lo

weri ngtheve hicle af ter a wheel change Re

quirements:

R The new wheel has been fitted

(/ page 301).

* NO

TEDama getothe emer gency spa re

wheel when lo wering theve hicle Lo

we ring theve hicle without pr eviously

inflating the emer gency collapsible spa re

wheel can damage its rim. #

Inflate the emer gency collapsible spa re

wheel using the tyre inflation compres‐

sor before lo wering theve hicle. #

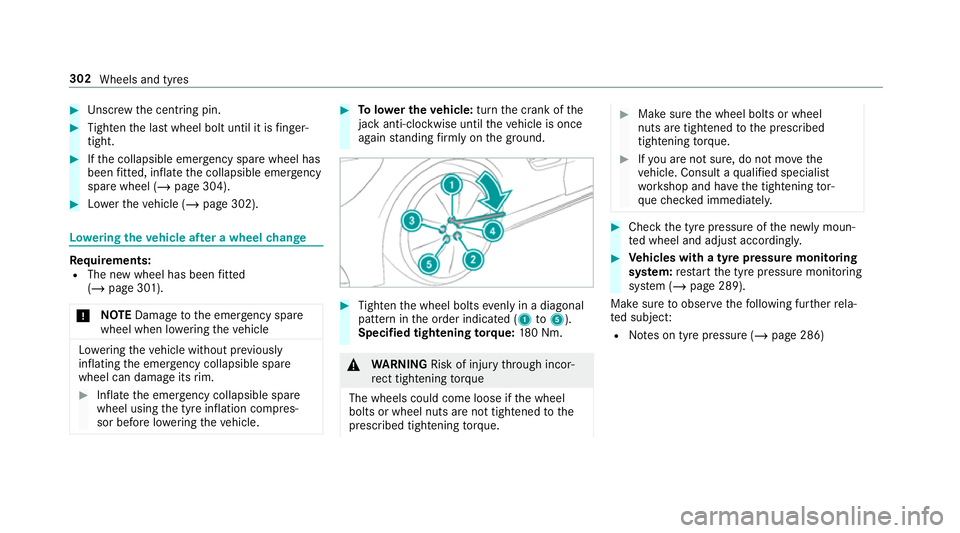

Tolowe r the vehicle: turnthe crank of the

jack anti-clo ckwise until theve hicle is once

again standing firm lyon the ground. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated (1 to5 ).

Specified tightening torq ue: 180 Nm. &

WARNING Risk of inju rythro ugh incor‐

re ct tigh tening torque

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened tothe

prescribed tightening torque. #

Makesure the wheel bolts or wheel

nuts are tightened tothe prescribed

tightening torque. #

Ifyo u are not sure, do not mo vethe

ve hicle. Consult a qualified specialist

wo rkshop and ha vethe tightening tor‐

qu ech ecked immediately. #

Check the tyre pressure of the newly moun‐

te d wheel and adjust according ly. #

Vehicles with a tyre pressure monitoring

sy stem: restart the tyre pressure monitoring

sy stem (/ page 289).

Make sure toobser vethefo llowing fur ther rela‐

te d subjec t:

R Notes on tyre pressure (/ page 286)302

Wheels and tyres