ESP MERCEDES-BENZ B-CLASS HATCHBACK 2015 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: B-CLASS HATCHBACK, Model: MERCEDES-BENZ B-CLASS HATCHBACK 2015Pages: 293, PDF Size: 10.83 MB

Page 276 of 293

Country Radio type approval number

Jordan Model: Gen Alpha Wal 2 TPMS

transmitter

Type Approval Number:

TRC/LPD/2012/114

Model: Gen Gamma Gen

4 433.92 Mhz.

Type Approval Number:

TRC/LPD/2012/190

Model: Corax 3 MRXMC34MA4

Type Approval Number:

TRC/LPD/2011/158

Type Number: LPD Morocco MR7319 ANRT 2012/

11/07/2012

MR7672 ANRT 2012/

23/11/2012

MR6706 ANRT 2011

Moldova 1024

Philip-

pines No: ESD-1206394C

No: ESD-1306871C

Serbia И 011 12

Singapore Compliance with IDA Standard

DA- 103365

South

Africa TA-2012/719

TA-2012/1540

TA-2011/1370

Changing a wheel

Flat tyre

You can find information on what to do in the

event of a flat tyre in the "Breakdown assis-

tance" section (Y page 249). Information on

driving with MOExtended tyres in the event of a flat tyre can be found under "Breakdown assis-

tance" (Y page 250). Interchanging the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if the wheels or tyres have different dimensions.

The wheel brakes or suspension components may also be damaged. There is a risk of acci-

dent.

Interchange front and rear wheels only if the

wheels and tyres are of the same dimensions.

! On vehicles fitted with a tyre pressure mon-

itor, electronic components are located in the wheel.

Tyre-fitting tools should not be applied in thearea of the valve, as this could damage the

electronic components.

Only have tyres changed at a qualified spe-

cialist workshop.

Interchanging the front and rear wheels of dif-

fering dimensions can render the general oper-

ating permit invalid.

Observe the instructions and safety notes in the "Changing a wheel" section (Y page 273).

The wear patterns on the front and rear tyres

differ depending on the operating conditions.

Interchange the wheels before a clear wear pat-

tern has formed on the tyres. Front tyres typi-

cally wear more on the shoulders and the rear

tyres in the centre.

On vehicles that have the same size front and

rear wheels, you can interchange the wheels

every 5,000 to 10,000 km depending on the

degree of tyre wear. Ensure the direction of

rotation is maintained.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is

interchanged. Check the tyre pressure and reac-

tivate the tyre pressure monitor if necessary. Direction of rotation

Tyres with a specified direction of rotation have additional benefits, e.g. if there is a risk of aqua-

planing. These advantages can only be gained if the tyres are fitted corresponding to the direc-

tion of rotation.

An arrow on the sidewall of the tyre indicates its

correct direction of rotation. Changing a wheel

273Wheels and tyres Z

Page 279 of 293

X

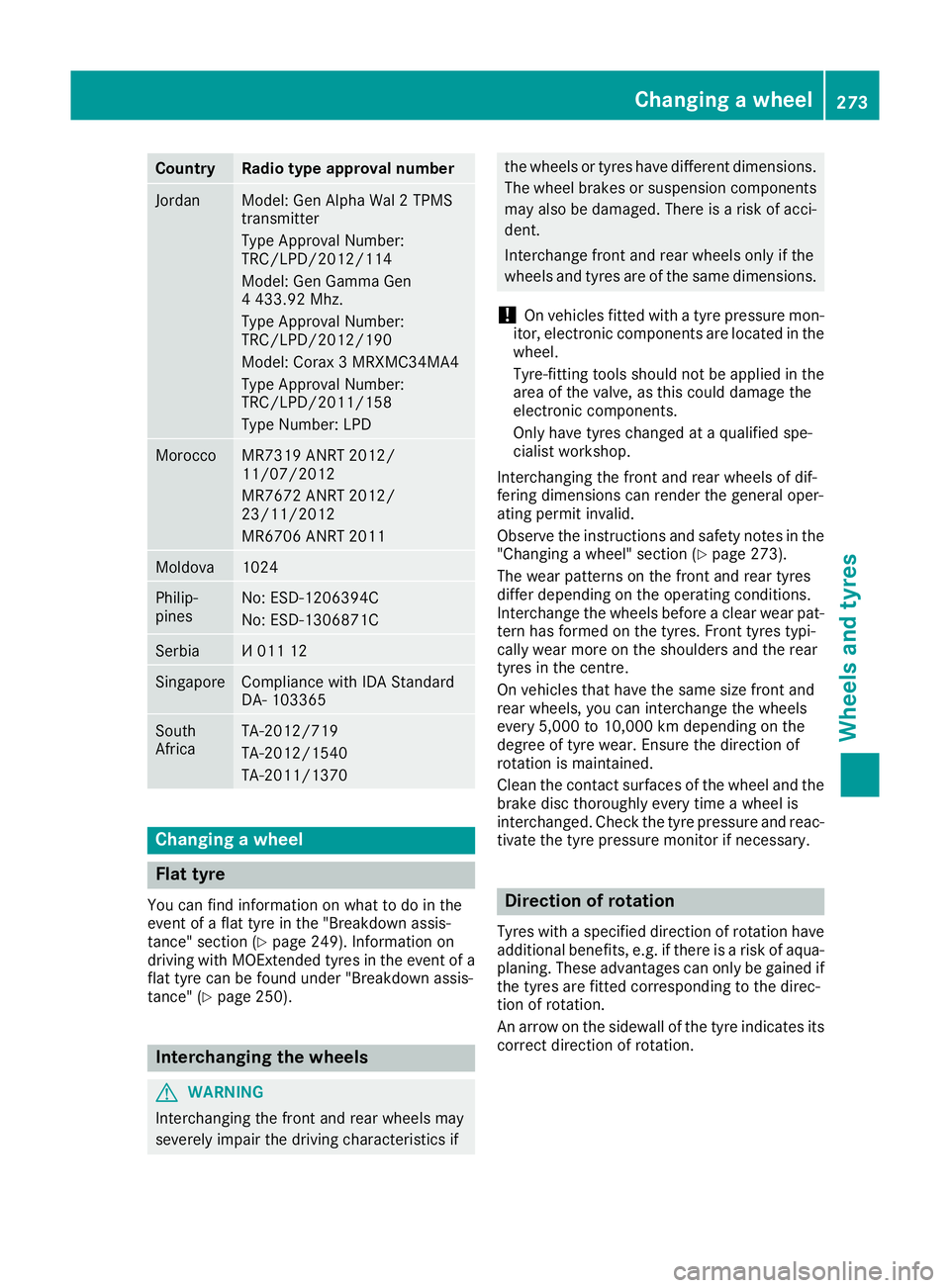

Take ratchet ring spanner ?out of the vehi-

cle tool kit and place it on the hexagon nut of

jack =so that the letters AUFare visible.

X Position jack =at jacking point ;. X

Make sure that the base of the jack is posi-

tioned vertically under the jacking point.

X Turn ratchet ring spanner ?until jack =sits

completely on jacking point ;and the base

of the jack lies evenly on the ground.

X Turn ratchet ring spanner ?until the tyre is

raised a maximum of 3 cm from the ground.

Removing a wheel !

Do not place wheel bolts in sand or dirt. The

threads of the wheel bolts and wheel hubs

could otherwise be damaged when the bolts

are tightened.

X Unscrew the wheel bolts.

X Remove the wheel.

Fitting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Observe the instructions and safety notes on

"Changing a wheel" (Y page 273).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective

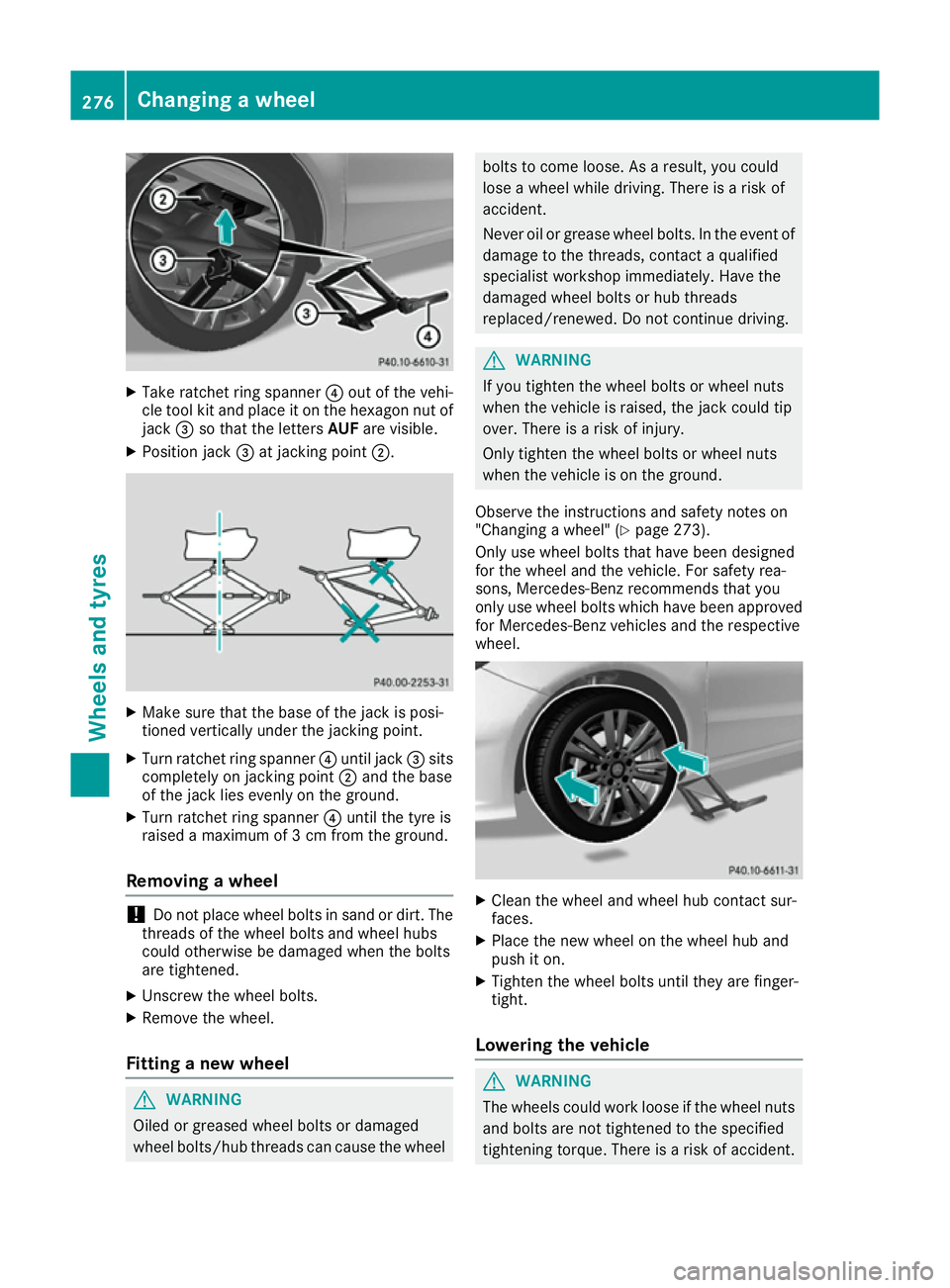

wheel. X

Clean the wheel and wheel hub contact sur-

faces.

X Place the new wheel on the wheel hub and

push it on.

X Tighten the wheel bolts until they are finger-

tight.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident. 276

Changing a wheelWheels and tyres

Page 280 of 293

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

X Place the ratchet ring spanner onto the hex-

agon nut of the jack so that the letters ABare

visible.

X Turn the ratchet ring spanner until the vehicle

is once again standing firmly on the ground.

X Place the jack to one side. X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (: toA).

The specified tightening torque is 130 Nm.

X Turn the jack back to its initial position.

X Stow the jack and the rest of the vehicle tools

in the vehicle again.

X Check the air pressure of the newly fitted

wheel and adjust accordingly.

Observe the recommended tyre pressure

(Y page 269).

If you are driving with the emergency spare

wheel fitted, the tyre pressure monitor cannot

function reliably. Only restart the tyre pressure

monitor when the defective wheel has been

replaced with a new wheel. All fitted wheels

must be equipped with functioning sensors.

Vehicles with a tyre pressure monitor: all fit-

ted wheels must be equipped with functioning

sensors. Wheel and tyre combinations

General notes

! For safety reasons, Mercedes-Benz recom-

mends that you only use tyres and wheels

which have been approved by Mercedes-Benz specifically for your vehicle. These are specially adapted to the control

systems, such as ABS or ESP

®

and are

marked as follows:

R MO = Mercedes-Benz Original

R MOE = Mercedes-Benz Original Extended

(tyres featuring run-flat characteristics)

R MO1 = Mercedes-Benz Original (only cer-

tain AMG tyres)

Mercedes-Benz Original Extended tyres may

only be used on wheels that have been spe-

cifically approved by Mercedes-Benz.

Only use tyres, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when

driving with a load, tyre dimension variations

could cause the tyres to come into contact

with the bodywork and axle components. This

could result in damage to the tyres or the

vehicle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tyres, wheels or accessories other than those tested and

approved.

Further information about wheels, tyres and

approved combinations can be obtained from

any qualified specialist workshop.

! Retreaded tyres are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tyres. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tyres are fitted. Do not fit used tyres if you

have no information about their previous

usage.

! Large wheels: the lower the section width

for a certain wheel size, the lower the ride

comfort is on poor road surfaces. Roll comfort and suspension comfort are reduced and therisk of damage to the wheels and tyres as a

result of driving over obstacles increases.

Overview of abbreviations used in the following tyre tables:

R BA: both axles

R FA: front axle

R RA: rear axle

The recommended tyre pressures for various

operating conditions can be found in the tyre

pressure table on the charge socket flap. For

further information on tyre pressure, see Wheel and tyre combinations

277Wheels and tyres Z

Page 284 of 293

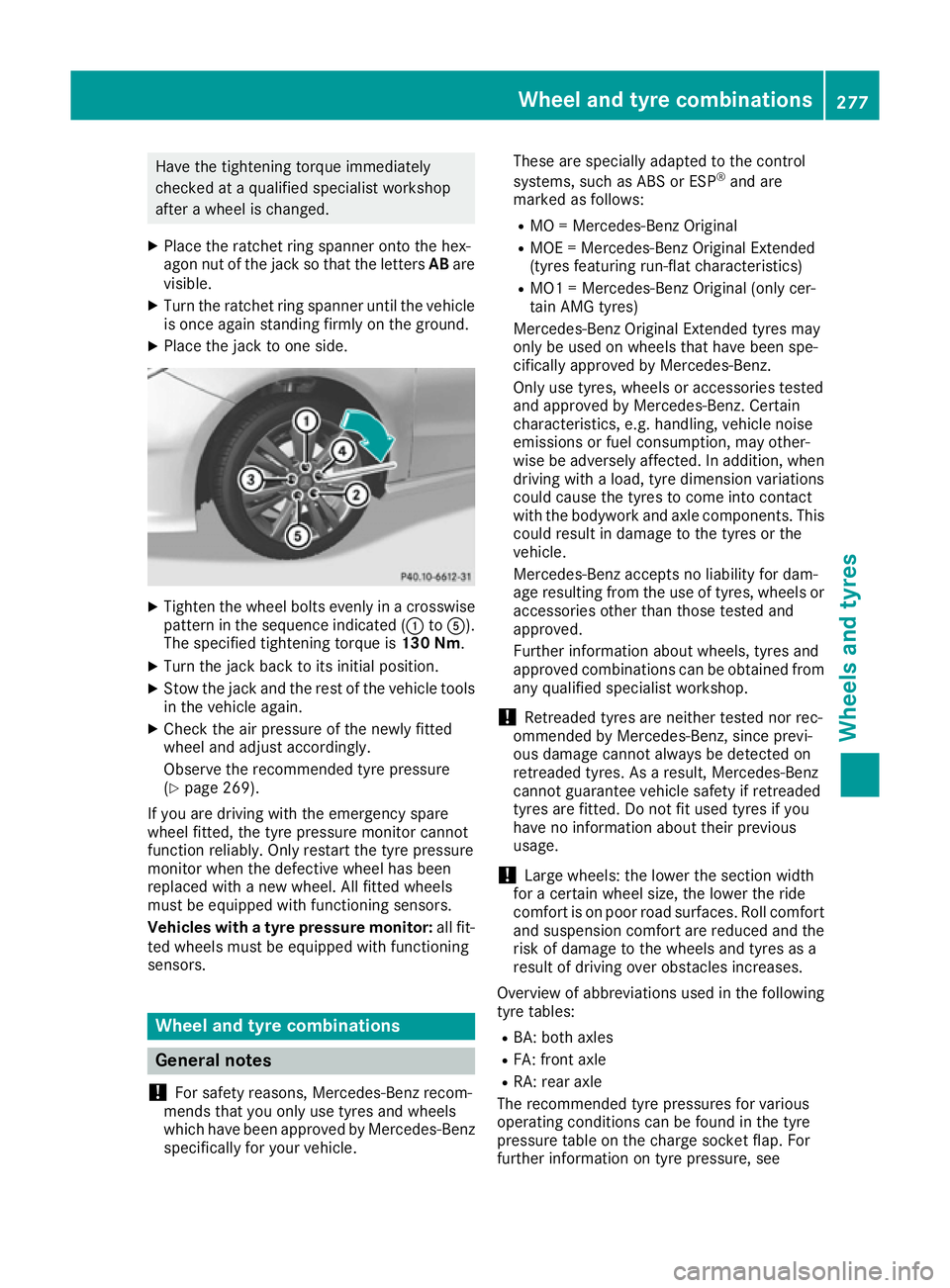

Approved aerial positions

:

Front roof area

; Rear roof area

= Rear wing

i On the rear wing, it is recommended that

you position the aerial on the side of the vehi-

cle closest to the centre of the road.

Use Technical Specification ISO/TS 21609

(Road Vehicles – "EMC guidelines for fitting

aftermarket radio frequency transmitting equip- ment") when retrofitting RF (radio frequency)

transmitters. Comply with the legal require-

ments for add-on parts.

If your vehicle has fittings for two-way radio

equipment, use the power supply or aerial con-

nections intended for use with the basic wiring.

Be sure to observe the manufacturer's addi-

tional instructions when installing.

Deviations with respect to wavebands, maxi-

mum transmission outputs or aerial positions

must be approved by Mercedes-Benz.

The maximum transmission output (PEAK) at the base of the aerial must not exceed the followingvalues: Waveband Maximum

transmission output Short wave

3 - 54 MHz 100 W

4 m waveband

74 - 88 MHz 30 W

2 m waveband

144 - 174 MHz 50 W

Trunked radio/Tetra

380 - 460 MHz 10 W Waveband Maximum

transmission output 70 cm waveband

400 - 460 MHz 35 W

Mobile communications

(2G/3G/4G) 10 W

The following can be used in the vehicle without

restrictions:

R RF transmitters with a maximum transmis-

sion output of up to 100 mW

R RF transmitters with transmitter frequencies

in the 380 - 410 MHz waveband and a maxi-

mum transmission output of up to 2 W

(trunked radio/Tetra)

R Mobile telephones (2G/3G/4G)

There are no restrictions when positioning the

aerial on the outside of the vehicle for the fol-

lowing wavebands:

R Trunked radio/Tetra

R 70 cm waveband

R 2G/3G/4G Identification plates

Vehicle identification plate with vehi-

cle identification number (VIN)

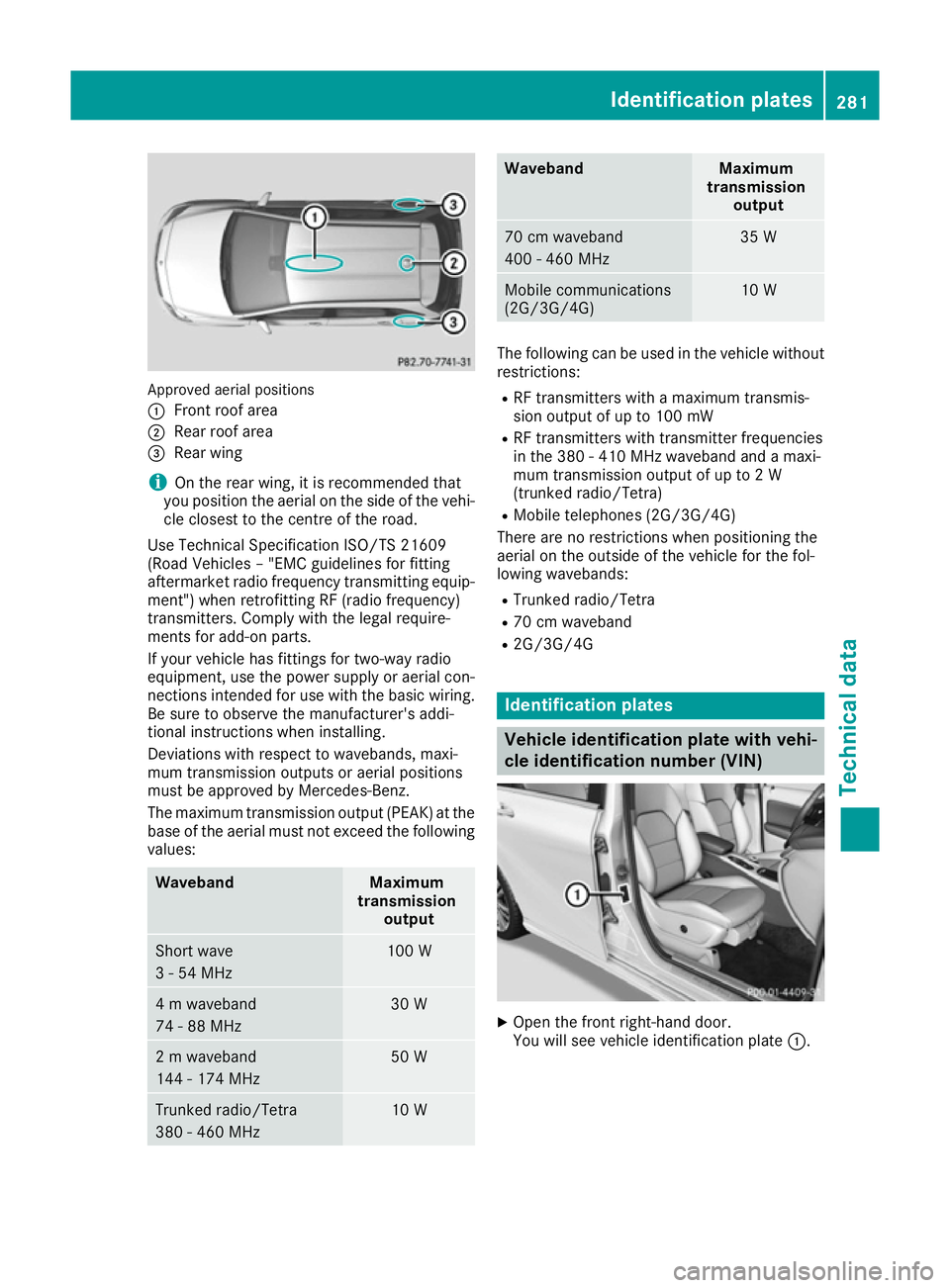

X

Open the front right-hand door.

You will see vehicle identification plate :. Identification plates

281Technical data Z

Page 285 of 293

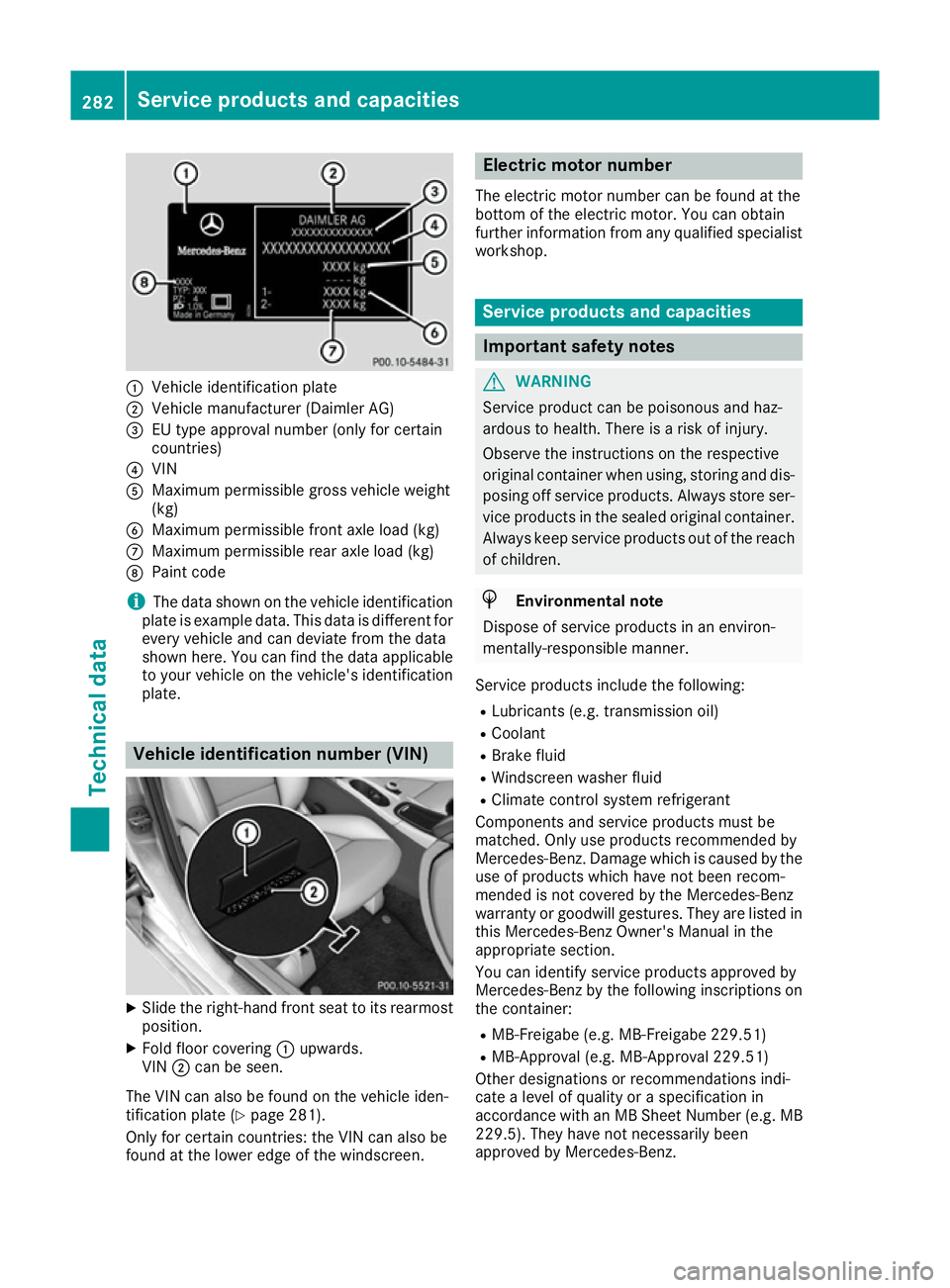

:

Vehicle identification plate

; Vehicle manufacturer (Daimler AG)

= EU type approval number (only for certain

countries)

? VIN

A Maximum permissible gross vehicle weight

(kg)

B Maximum permissible front axle load (kg)

C Maximum permissible rear axle load (kg)

D Paint code

i The data shown on the vehicle identification

plate is example data. This data is different for

every vehicle and can deviate from the data

shown here. You can find the data applicable to your vehicle on the vehicle's identification

plate. Vehicle identification number (VIN)

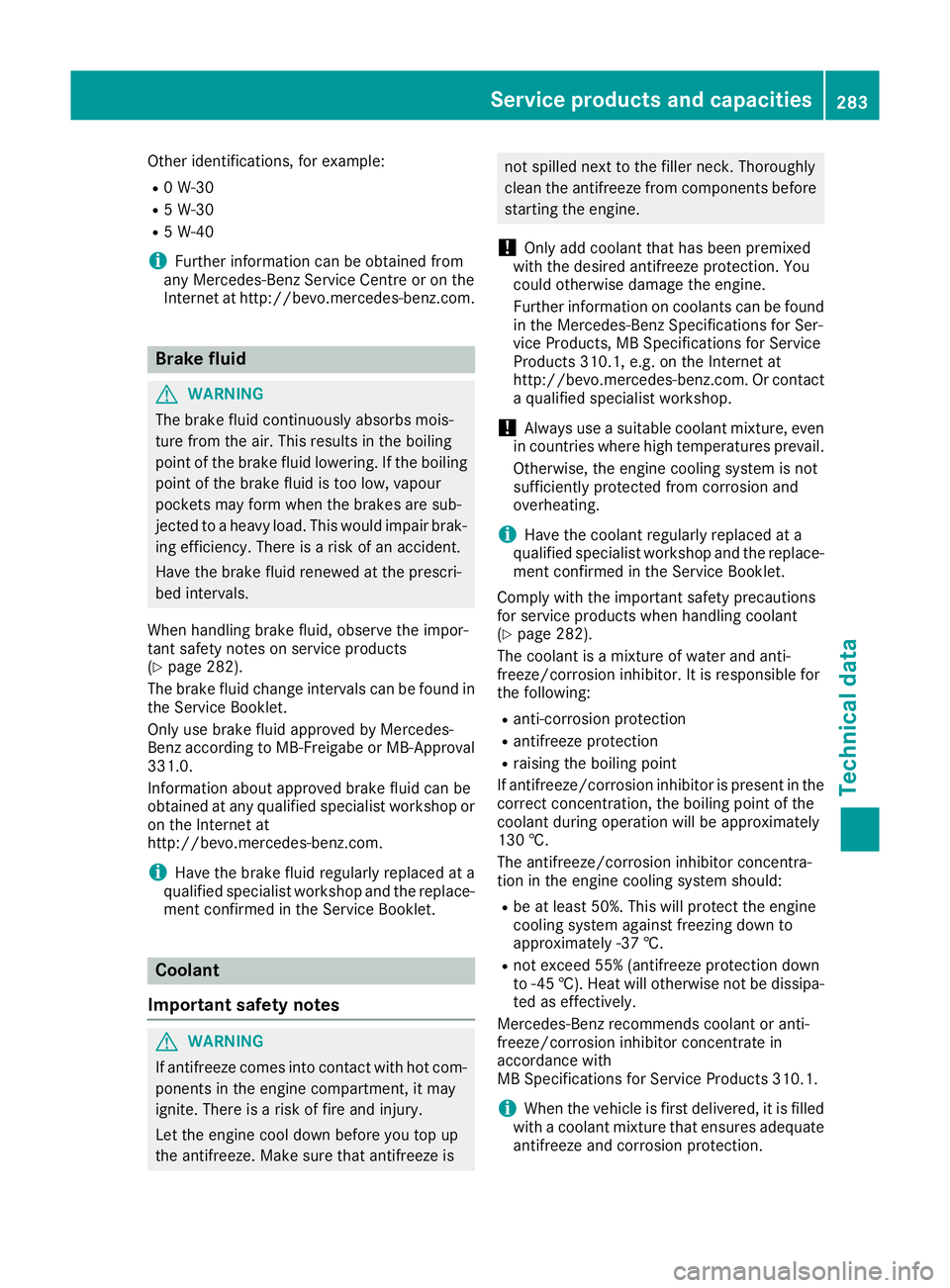

X

Slide the right-hand front seat to its rearmost

position.

X Fold floor covering :upwards.

VIN ;can be seen.

The VIN can also be found on the vehicle iden-

tification plate (Y page 281).

Only for certain countries: the VIN can also be

found at the lower edge of the windscreen. Electric motor number

The electric motor number can be found at the

bottom of the electric motor. You can obtain

further information from any qualified specialist

workshop. Service products and capacities

Important safety notes

G

WARNING

Service product can be poisonous and haz-

ardous to health. There is a risk of injury.

Observe the instructions on the respective

original container when using, storing and dis- posing off service products. Always store ser-

vice products in the sealed original container. Always keep service products out of the reach

of children. H

Environmental note

Dispose of service products in an environ-

mentally-responsible manner.

Service products include the following:

R Lubricants (e.g. transmission oil)

R Coolant

R Brake fluid

R Windscreen washer fluid

R Climate control system refrigerant

Components and service products must be

matched. Only use products recommended by

Mercedes-Benz. Damage which is caused by the

use of products which have not been recom-

mended is not covered by the Mercedes-Benz

warranty or goodwill gestures. They are listed in this Mercedes-Benz Owner's Manual in the

appropriate section.

You can identify service products approved by

Mercedes-Benz by the following inscriptions on

the container:

R MB-Freigabe (e.g. MB-Freigabe 229.51)

R MB-Approval (e.g. MB-Approval 229.51)

Other designations or recommendations indi-

cate a level of quality or a specification in

accordance with an MB Sheet Number (e.g. MB

229.5). They have not necessarily been

approved by Mercedes-Benz. 282

Service products and capacitiesTechnical data

Page 286 of 293

Other identifications, for example:

R 0 W-30

R 5 W-30

R 5 W-40

i Further information can be obtained from

any Mercedes-Benz Service Centre or on the

Internet at http://bevo.mercedes-benz.com. Brake fluid

G

WARNING

The brake fluid continuously absorbs mois-

ture from the air. This results in the boiling

point of the brake fluid lowering. If the boiling

point of the brake fluid is too low, vapour

pockets may form when the brakes are sub-

jected to a heavy load. This would impair brak- ing efficiency. There is a risk of an accident.

Have the brake fluid renewed at the prescri-

bed intervals.

When handling brake fluid, observe the impor-

tant safety notes on service products

(Y page 282).

The brake fluid change intervals can be found in the Service Booklet.

Only use brake fluid approved by Mercedes-

Benz according to MB-Freigabe or MB-Approval

331.0.

Information about approved brake fluid can be

obtained at any qualified specialist workshop or on the Internet at

http://bevo.mercedes-benz.com.

i Have the brake fluid regularly replaced at a

qualified specialist workshop and the replace- ment confirmed in the Service Booklet. Coolant

Important safety notes G

WARNING

If antifreeze comes into contact with hot com- ponents in the engine compartment, it may

ignite. There is a risk of fire and injury.

Let the engine cool down before you top up

the antifreeze. Make sure that antifreeze is not spilled next to the filler neck. Thoroughly

clean the antifreeze from components before

starting the engine.

! Only add coolant that has been premixed

with the desired antifreeze protection. You

could otherwise damage the engine.

Further information on coolants can be found in the Mercedes-Benz Specifications for Ser-

vice Products, MB Specifications for Service

Products 310.1, e.g. on the Internet at

http://bevo.mercedes-benz.com. Or contact

a qualified specialist workshop.

! Always use a suitable coolant mixture, even

in countries where high temperatures prevail.

Otherwise, the engine cooling system is not

sufficiently protected from corrosion and

overheating.

i Have the coolant regularly replaced at a

qualified specialist workshop and the replace- ment confirmed in the Service Booklet.

Comply with the important safety precautions

for service products when handling coolant

(Y page 282).

The coolant is a mixture of water and anti-

freeze/corrosion inhibitor. It is responsible for

the following:

R anti-corrosion protection

R antifreeze protection

R raising the boiling point

If antifreeze/corrosion inhibitor is present in the

correct concentration, the boiling point of the

coolant during operation will be approximately

130 †.

The antifreeze/corrosion inhibitor concentra-

tion in the engine cooling system should:

R be at least 50%. This will protect the engine

cooling system against freezing down to

approximately -37 †.

R not exceed 55% (antifreeze protection down

to -45 †). Heat will otherwise not be dissipa-

ted as effectively.

Mercedes-Benz recommends coolant or anti-

freeze/corrosion inhibitor concentrate in

accordance with

MB Specifications for Service Products 310.1.

i When the vehicle is first delivered, it is filled

with a coolant mixture that ensures adequate

antifreeze and corrosion protection. Service products and capacities

283Technical data Z

Page 287 of 293

i

The coolant is checked at every mainte-

nance interval at a qualified specialist work-

shop. Windscreen washer system and head-

lamp cleaning system

Important safety notes G

WARNING

If windscreen washer concentrate comes into contact with hot components of the engine or

the exhaust system, it can ignite. There is a

risk of fire and injury.

Make sure the windscreen washer concen-

trate does not come into contact with the filler neck.

! Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or MB

WinterFit. Unsuitable washer fluid could dam-

age the plastic lenses of the headlamps.

! Do not use distilled or de-ionised water in

the washer fluid reservoir. Otherwise, the

level sensor may be damaged.

! Only the washer fluids SummerFit and Win-

terFit can be mixed. Otherwise, the spraying

nozzles could become blocked.

Comply with the important safety notes for ser-

vice products when handling washer fluid

(Y page 282).

At temperatures above freezing:

X Fill the washer fluid reservoir with a mixture of

water and washer fluid, e.g. MB SummerFit.

Mix 1 part MB SummerFit to 100 parts water.

At temperatures below freezing:

X Fill the washer fluid reservoir with a mixture of

water and washer fluid, e.g. MB WinterFit.

For the correct mixing ratio refer to the infor-

mation on the antifreeze reservoir.

i Add washer fluid concentrate, e.g. MB Sum-

merFit or MB WinterFit, to the washer fluid all

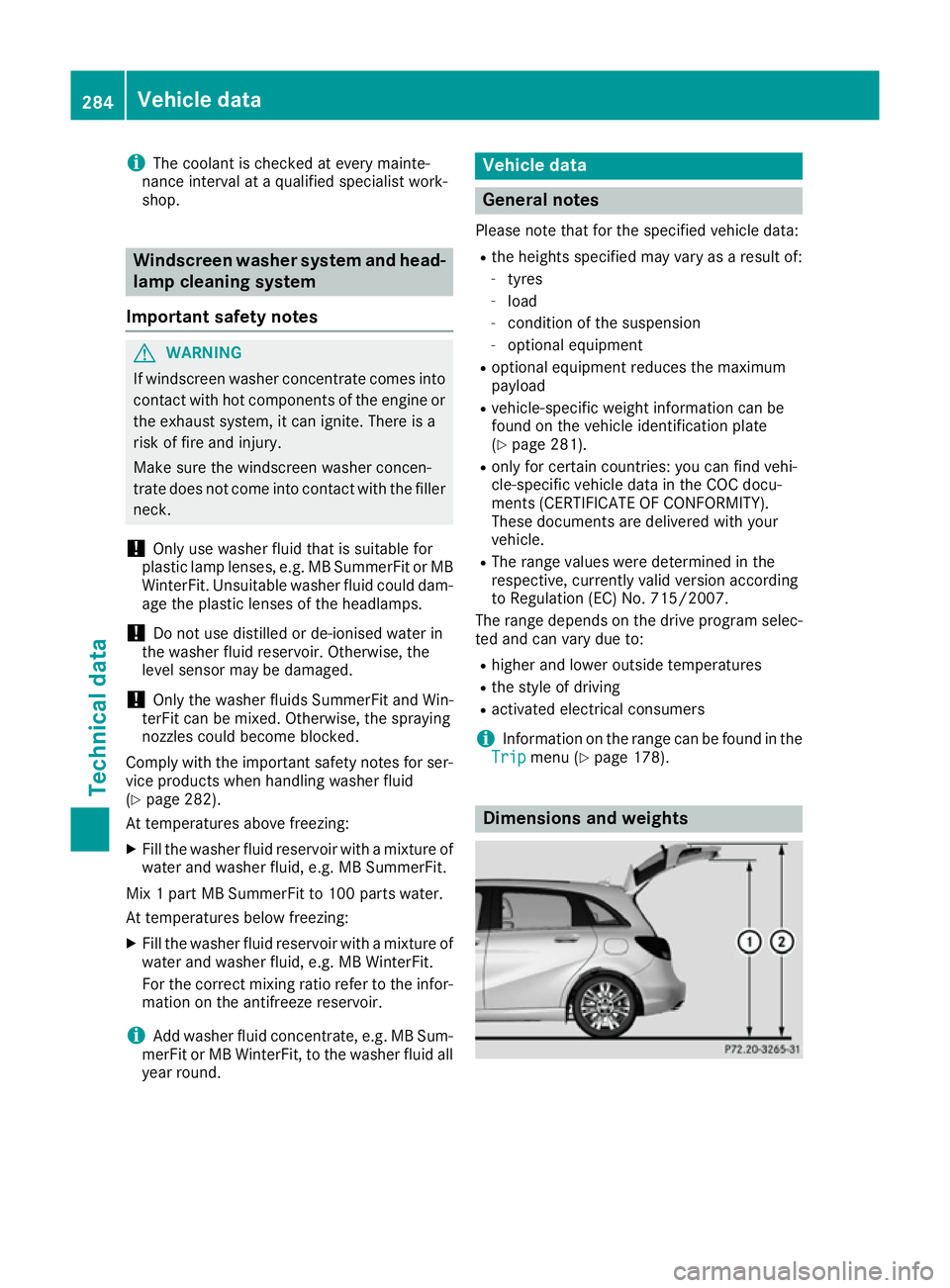

year round. Vehicle data

General notes

Please note that for the specified vehicle data: R the heights specified may vary as a result of:

- tyres

- load

- condition of the suspension

- optional equipment

R optional equipment reduces the maximum

payload

R vehicle-specific weight information can be

found on the vehicle identification plate

(Y page 281).

R only for certain countries: you can find vehi-

cle-specific vehicle data in the COC docu-

ments (CERTIFICATE OF CONFORMITY).

These documents are delivered with your

vehicle.

R The range values were determined in the

respective, currently valid version according

to Regulation (EC) No. 715/2007.

The range depends on the drive program selec-

ted and can vary due to:

R higher and lower outside temperatures

R the style of driving

R activated electrical consumers

i Information on the range can be found in the

Trip Trip menu (Y page 178). Dimensions and weights284

Vehicle dataTechnical data