lock MERCEDES-BENZ C-CLASS COUPE 2011 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: C-CLASS COUPE, Model: MERCEDES-BENZ C-CLASS COUPE 2011Pages: 373, PDF Size: 8.17 MB

Page 321 of 373

R

If TIREFIT is swallowed, immediately rinse

yourm outh out thoroughly and drink plenty

of water.

R Do not induce vomiting. Consult a doctor

immediately.

R Do not inhale TIREFIT fumes.

i If TIREFIT leaks out, allow it to dry. It can

then be removed like a layer of film.

If you get TIREFIT on your clothing, have it

cleaned as soon as possible with perchloro-

ethylene.

Your vehicle is provided with one of two dif-

ferent TIREFIT kits:

R Version 1: the tyre inflation compressor

and the tyre filler bottle both have their own

fixed hoses.

R Version 2: the tyre inflation compressor

and the tyre filler bottle do not come with

a fixed hose. This is in the housing of the

tyre inflation compressor.

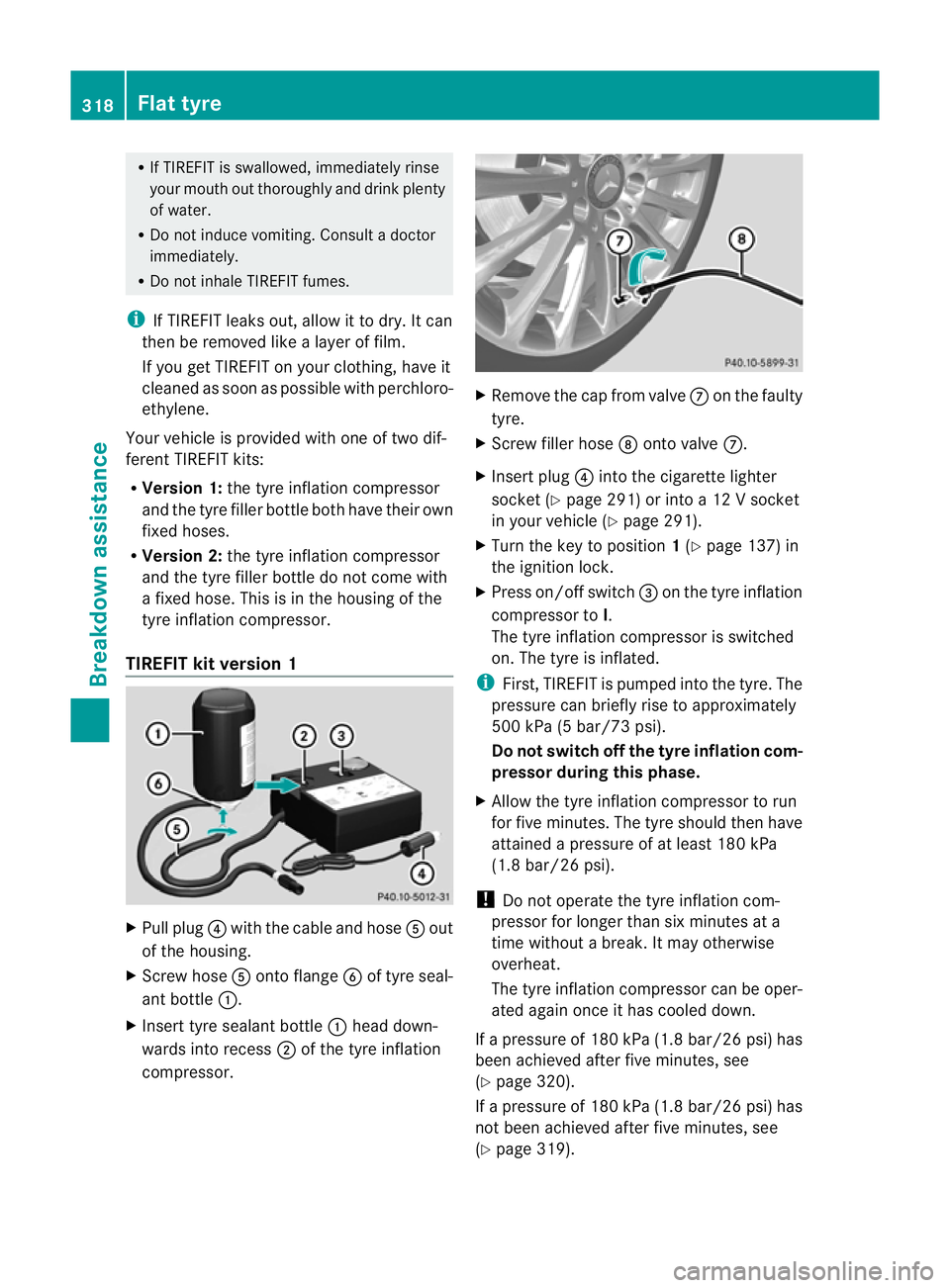

TIREFIT kit version 1 X

Pull plug ?with the cable and hose Aout

of the housing.

X Screw hose Aonto flange Bof tyre seal-

ant bottle :.

X Insert tyre sealant bottle :head down-

wards into recess ;of the tyre inflation

compressor. X

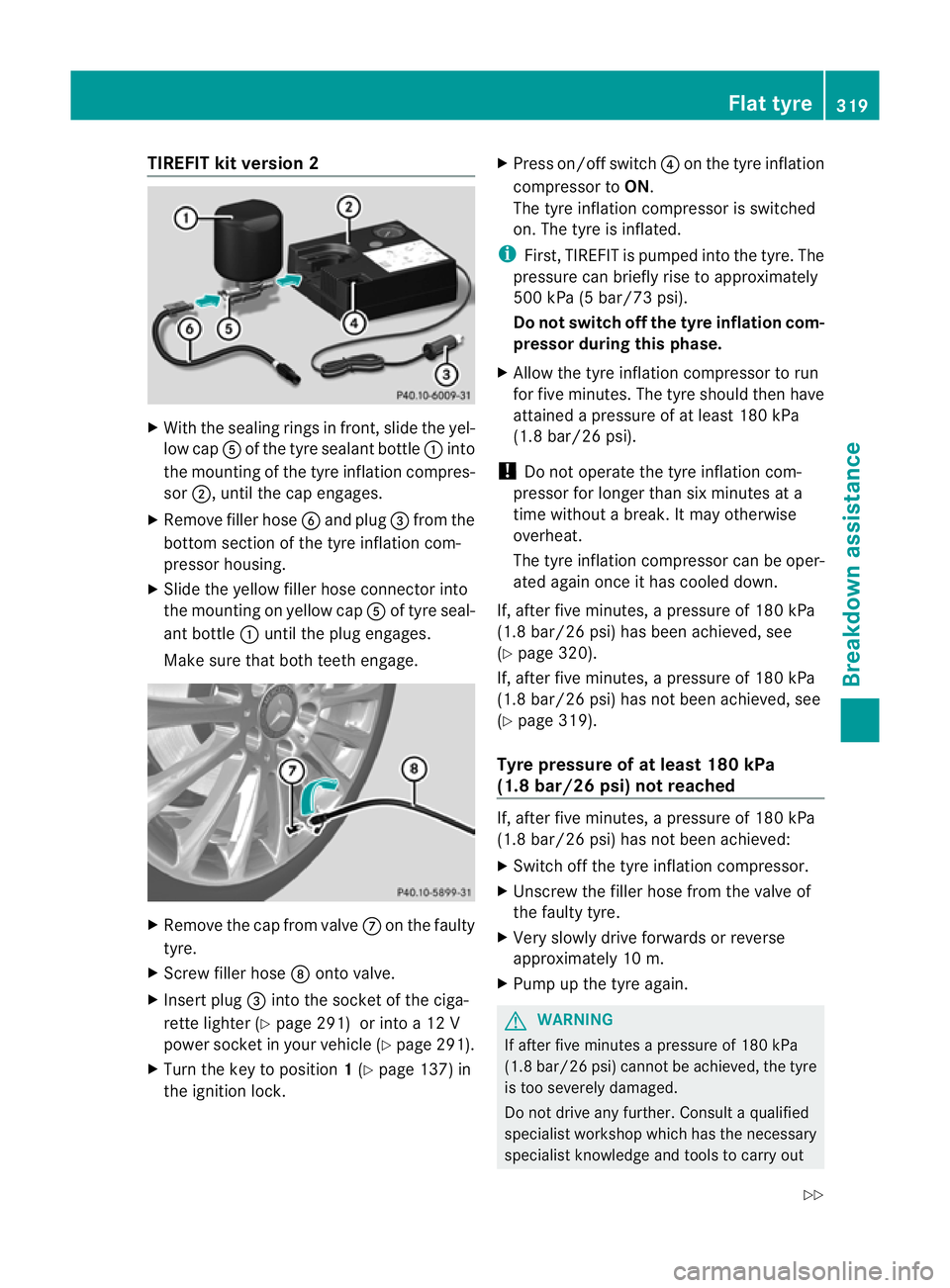

Remove the cap from valve Con the faulty

tyre.

X Screw filler hose Donto valve C.

X Insert plug ?into the cigarette lighter

socket (Y page 291) or into a 12 V socket

in your vehicle (Y page 291).

X Turn the key to position 1(Y page 137) in

the ignition lock.

X Press on/offs witch=on the tyre inflation

compressor to I.

The tyre inflatio ncompressor is switched

on. The tyre is inflated.

i First, TIREFIT is pumped into the tyre. The

pressure can briefly rise to approximately

500 kPa (5 bar/73 psi).

Do not switch off the tyre inflation com-

pressor during this phase.

X Allow the tyre inflation compressor to run

for five minutes. The tyre should then have

attained a pressure of at least 180 kPa

(1.8 bar/26 psi).

! Do not operate the tyre inflation com-

pressor for longer than six minutes at a

time without a break. It may otherwise

overheat.

The tyre inflation compressor can be oper-

ated again once it has cooled down.

If a pressure of 180 kPa (1.8 bar/26 psi) has

been achieved after five minutes, see

(Y page 320).

If a pressure of 180 kPa (1.8 bar/26 psi) has

not been achieved after five minutes, see

(Y page 319). 318

Flat tyreBreakdown assistance

Page 322 of 373

TIREFI

Tkit version 2 X

With the sealing rings in front, slide the yel-

low cap Aof the tyre sealant bottle :into

the mounting of the tyre inflation compres-

sor ;, until the cap engages.

X Remove filler hose Band plug =from the

bottom section of the tyre inflation com-

pressor housing.

X Slide the yellow filler hose connector into

the mounting on yellow cap Aof tyre seal-

ant bottle :until the plug engages.

Make sure that both teeth engage. X

Remove the cap from valve Con the faulty

tyre.

X Screw filler hose Donto valve.

X Insert plug =into the socket of the ciga-

rette lighter (Y page 291) or into a 12 V

power socket in your vehicle (Y page 291).

X Turn the key to position 1(Y page 137) in

the ignition lock. X

Press on/off switch ?on the tyre inflation

compressor to ON.

The tyre inflation compressor is switched

on. The tyre is inflated.

i First, TIREFIT is pumped into the tyre .The

pressure can briefly rise to approximately

500 kPa (5 bar/73 psi).

Do not switch off the tyre inflation com-

pressor during this phase.

X Allow the tyre inflation compressor to run

for five minutes. The tyre should then have

attained a pressure of at least 180 kPa

(1.8 bar/26 psi).

! Do not operate the tyre inflation com-

pressor for longer than six minutes at a

time without a break. It may otherwise

overheat.

The tyre inflation compressor can be oper-

ated again once it has cooled down.

If, after five minutes, a pressure of 180 kPa

(1.8 bar/26 psi) has been achieved, see

(Y page 320).

If, after five minutes, a pressure of 180 kPa

(1.8 bar/26 psi) has not been achieved, see

(Y page 319).

Tyre pressure of at least 180 kPa

(1.8 bar/26 psi) not reached If, after five minutes, a pressure of 180 kPa

(1.8 bar/26 psi) has not been achieved:

X

Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre.

X Very slowly drive forwards or reverse

approximately 10 m.

X Pump up the tyre again. G

WARNING

If after five minutes apressure of 180 kPa

(1.8 bar/26 psi) cannot be achieved, the tyre

is too severely damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the necessary

specialist knowledge and tools to carry out Flat tyre

319Breakdown assistance

Z

Page 323 of 373

the work required. Mercedes-Benz recom-

mends tha tyou use a Mercedes-Benz Service

Centre for this purpose. In particular, work

relevant to safety or on safety-related sys-

tems must be carried out at a qualified spe-

cialist workshop.

Tyre pressure of 180 kPa (1.8 bar/

26 psi) is reached X

Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre.

! After use, excess TIREFIT may run out of

the filler hose. This may cause stains.

Therefore, place the filler hose in the plastic

bag which contained the TIREFIT kit.

X Stow the tyre sealant bottle, the tyre infla-

tion compressor and the warning triangle.

X Pull away immediately. G

WARNING

Do not exceed the maximum speed of

80 km/h.

The "max. 80 km/h" label must be affixed in

the driver's field of vision.

The vehicle's handling characteristics may be

affected.

X Stop after driving for approximately ten

minutes and check the tyre pressure with

the tyre inflation compressor. G

WARNING

If the tyre pressure is less than 130 kPa

(1.3 bar/20 psi), the tyre is too severely dam-

aged. Do not drive any further. Consult a

qualified specialist workshop which has the

necessary specialist knowledge and tools to

carry out the work required. Mercedes-Benz

recommends that you use aMercedes-Benz

Service Centre for this purpose. In particular,

work relevant to safety or on safety-related

systems must be carried out at a qualified

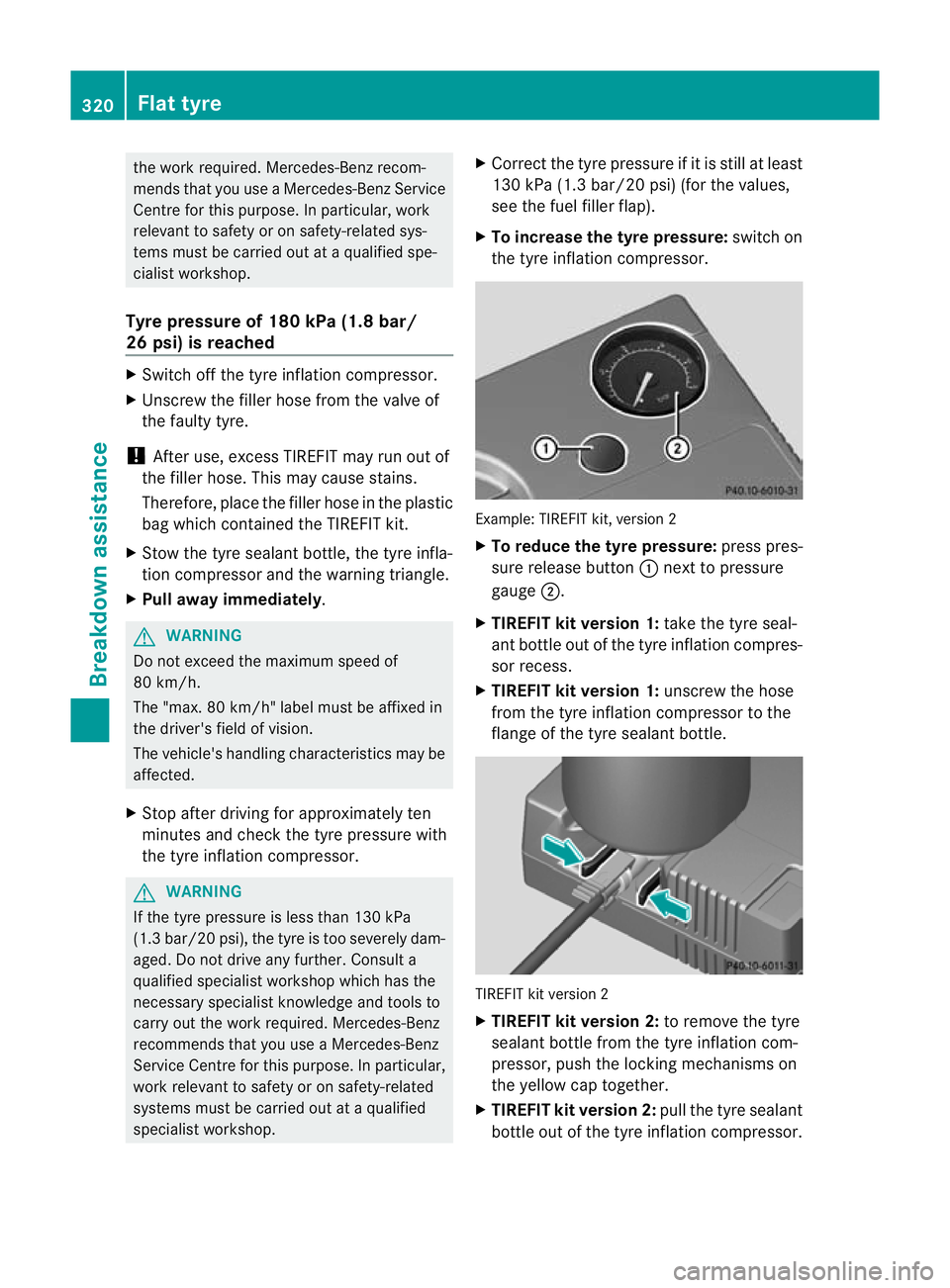

specialist workshop. X

Correct the tyre pressure if it is still at least

130 kPa (1.3 bar/20 psi) (for the values,

see the fuel filler flap).

X To increase the tyre pressure: switch on

the tyre inflation compressor. Example: TIREFIT kit, version 2

X

To reduce the tyre pressure: press pres-

sure release button :next to pressure

gauge ;.

X TIREFIT kit version 1: take the tyre seal-

ant bottle out of the tyre inflation compres-

sor recess.

X TIREFIT kit version 1: unscrew the hose

from the tyre inflation compressor to the

flange of the tyre sealant bottle. TIREFIT kit version 2

X

TIREFIT kit version 2: to remove the tyre

sealant bottle from the tyre inflation com-

pressor, push the locking mechanisms on

the yellow cap together.

X TIREFIT kit version 2: pull the tyre sealant

bottle out of the tyre inflation compressor. 320

Flat tyreBreakdown assistance

Page 325 of 373

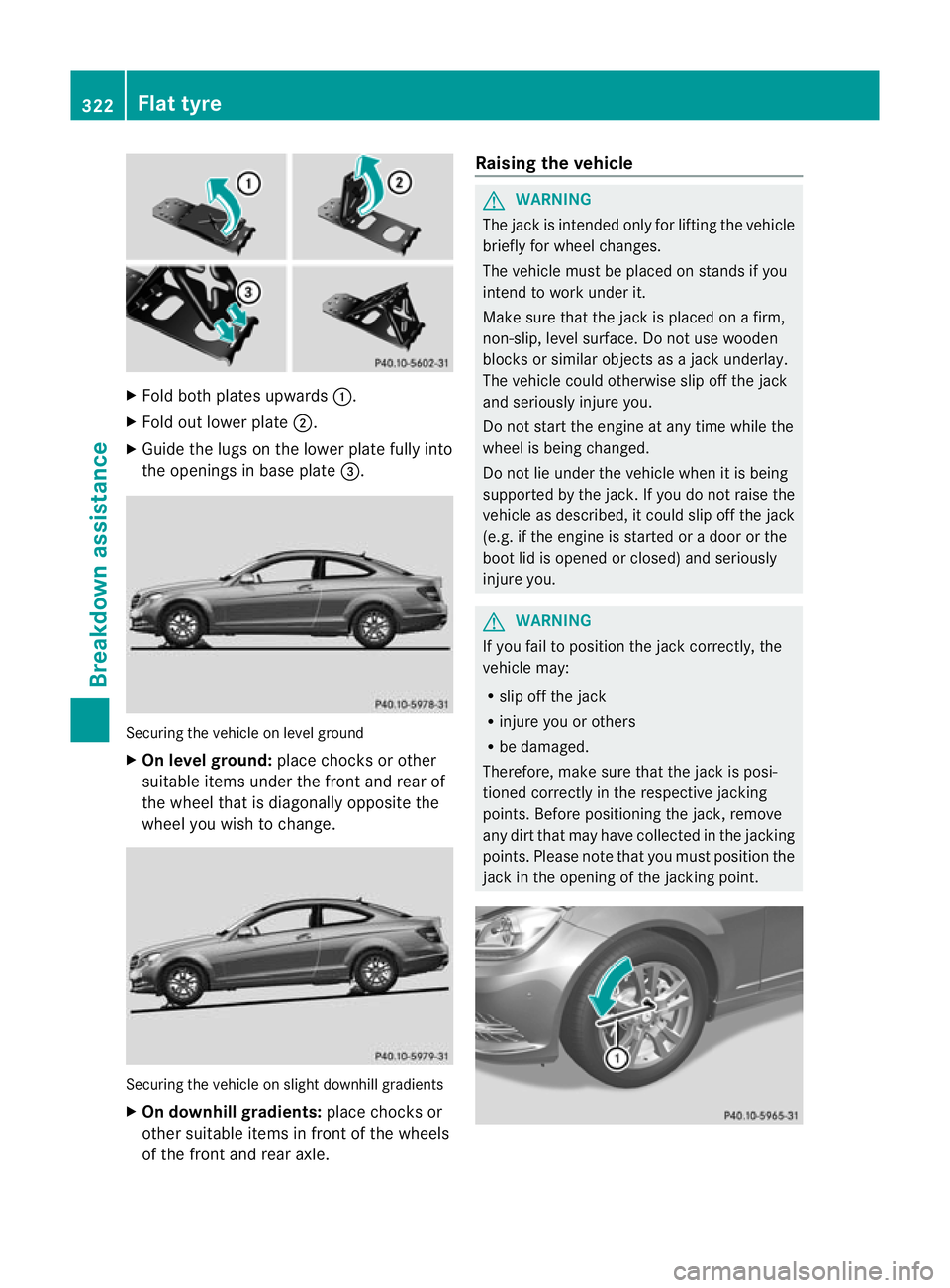

X

Fold both plates upwards :.

X Fold ou tlower plate ;.

X Guide the lugs on the lower plate fully into

the openings in base plate =.Securing the vehicle on level ground

X

On level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change. Securing the vehicle on slight downhill gradients

X

On downhill gradients: place chocks or

other suitable items in front of the wheels

of the front and rear axle. Raising the vehicle G

WARNING

The jack is intended only for lifting the vehicle

briefly for wheel changes.

The vehicle must be placed on stands if you

intend to work under it.

Make sure that the jack is placed on a firm,

non-slip, level surface. Do not use wooden

blocks or similar objects as a jack underlay.

The vehicle could otherwise slip off the jack

and seriously injure you.

Do not start the engine at any time while the

wheel is being changed.

Do not lie under the vehicle when it is being

supported by the jack.Ify ou do not raise the

vehicle as described, it could slip off the jack

(e.g. if the engine is started or a door or the

boot lid is opened or closed) and seriously

injure you. G

WARNING

If you fail to position the jack correctly, the

vehicle may:

R slip off the jack

R injure you or others

R be damaged.

Therefore, make sure that the jack is posi-

tioned correctly in the respective jacking

points. Before positioning the jack, remove

any dirt that may have collected in the jacking

points. Please note that you must position the

jack in the opening of the jacking point. 322

Flat tyreBreakdown assistance

Page 326 of 373

X

Using wheel wrench :, loosen the bolts on

the wheel you wish to change by abouto ne

full turn. Do not unscrew the bolts com-

pletely.

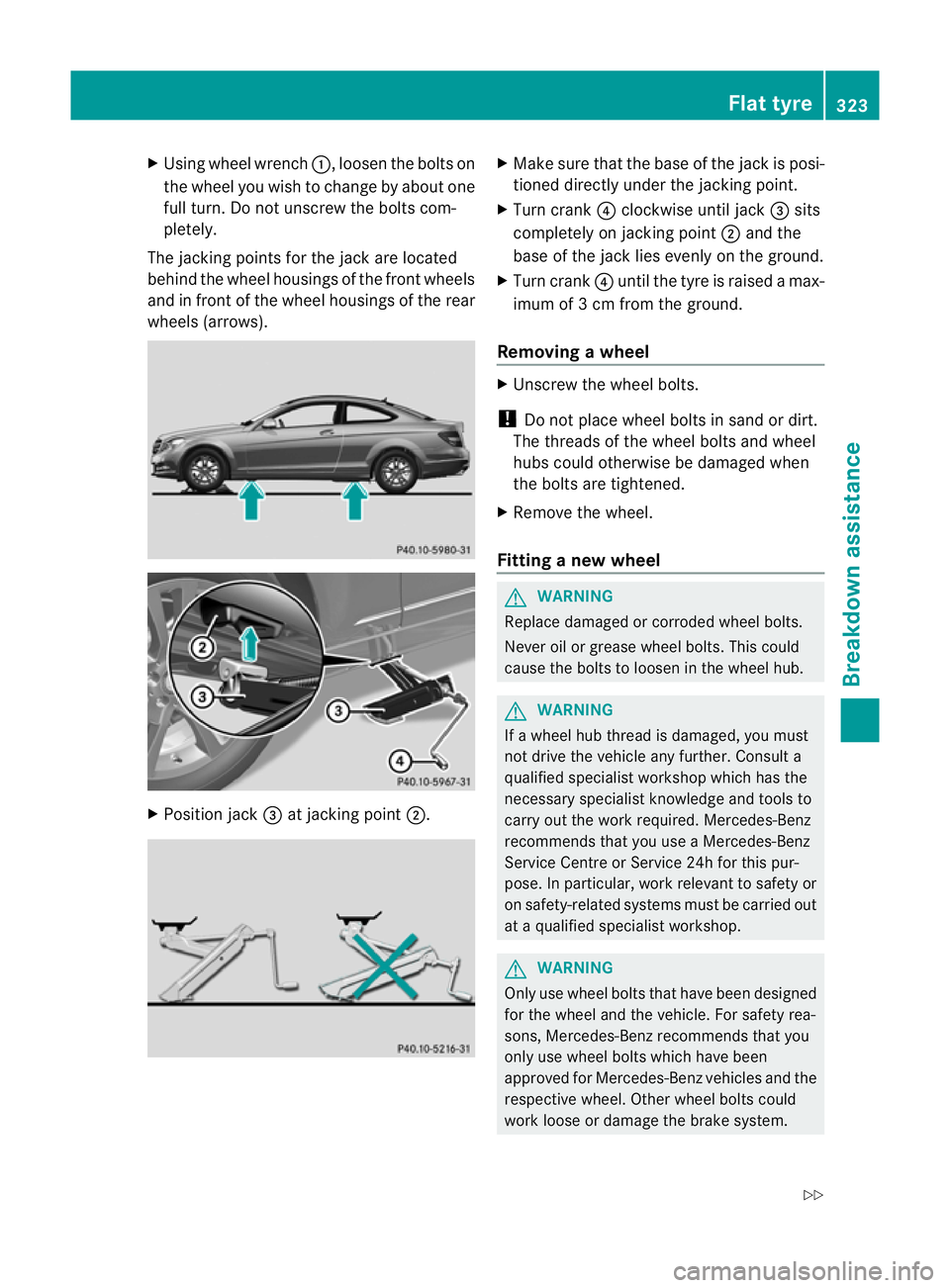

The jacking points for the jack are located

behind the wheel housings of the front wheels

and in front of the wheel housings of the rear

wheels (arrows). X

Positio njack =at jacking point ;. X

Make sure that the base of the jac kis posi-

tioned directly under the jacking point.

X Turn crank ?clockwise until jack =sits

completely on jacking point ;and the

base of the jack lies evenly on the ground.

X Turn crank ?until the tyre is raised a max-

imum of 3 cm from the ground.

Removing awheel X

Unscrew the wheel bolts.

! Do not place wheel bolts in sand or dirt.

The threads of the wheel bolts and wheel

hubs could otherwise be damaged when

the bolts are tightened.

X Remove the wheel.

Fitting anew wheel G

WARNING

Replace damaged or corroded wheel bolts.

Never oil or grease wheel bolts. This could

cause the bolts to loose ninthe wheel hub. G

WARNING

If a wheel hub thread is damaged, you must

not drive the vehicle any further. Consult a

qualified specialist workshop which has the

necessary specialist knowledge and tools to

carry out the work required. Mercedes-Benz

recommends that you use aMercedes-Benz

Service Centre or Service 24h for this pur-

pose. In particular, work relevant to safety or

on safety-related systems must be carried out

at a qualified specialist workshop. G

WARNING

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel. Other wheel bolts could

work loose or damage the brake system. Flat tyre

323Breakdown assistance

Z

Page 327 of 373

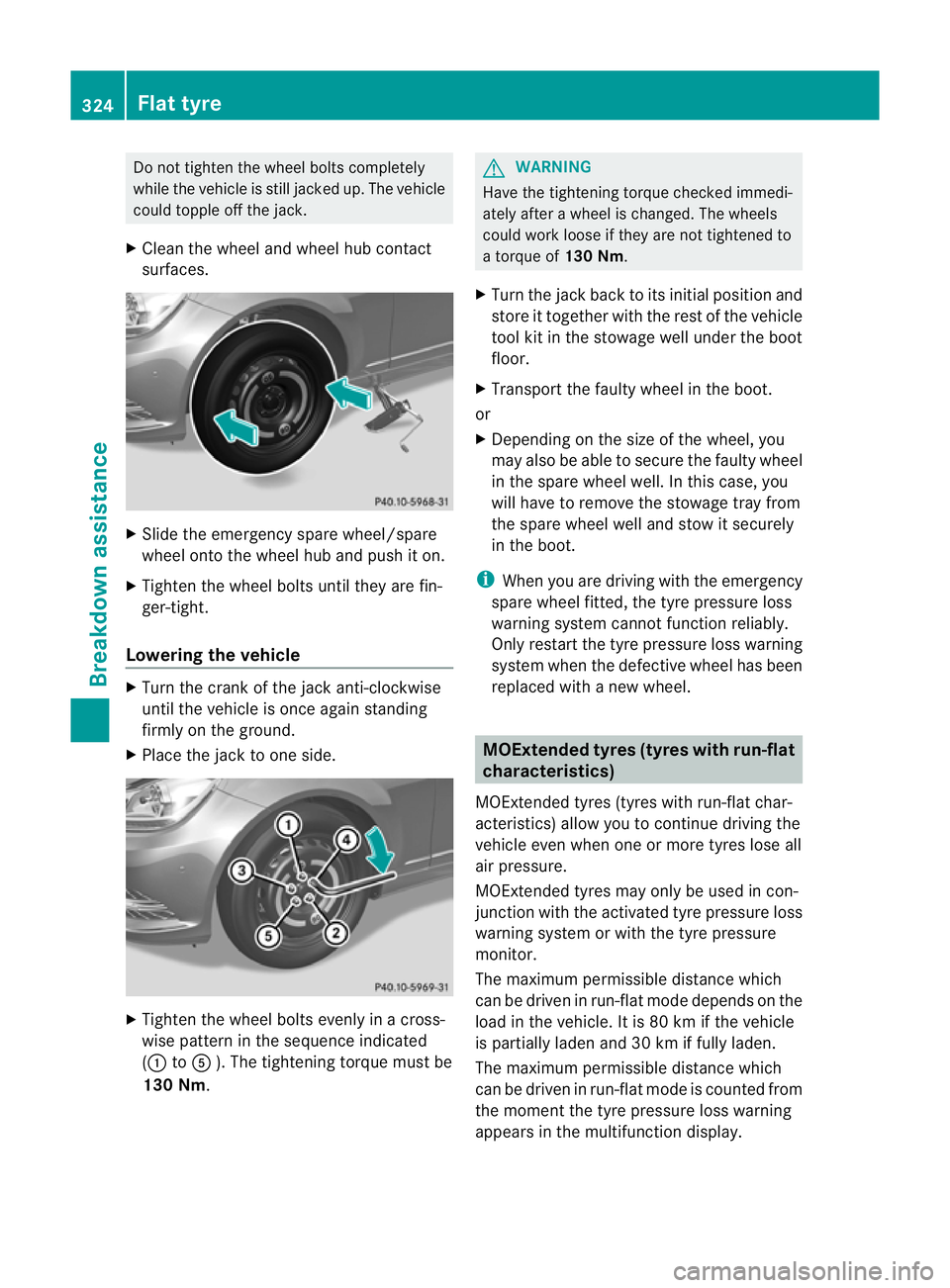

Do not tighte

nthe wheel bolts completely

while the vehicle is still jacked up. The vehicle

could topple off the jack.

X Cleant he wheel and wheel hub contact

surfaces. X

Slide the emergency spare wheel/spare

wheel onto the wheel hub and push it on.

X Tighten the wheel bolts until they are fin-

ger-tight.

Lowering the vehicle X

Turn the crank of the jack anti-clockwise

until the vehicle is once again standing

firmly on the ground.

X Place the jack to one side. X

Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indicated

(: toA ). The tightening torque must be

130 Nm. G

WARNING

Have the tightening torque checked immedi-

ately after a wheel is changed. The wheels

could work loose if they are not tightened to

a torque of 130 Nm.

X Turn the jack back to its initial position and

store it together with the rest of the vehicle

tool kit in the stowage well under the boot

floor.

X Transport the faulty wheel in the boot.

or

X Depending on the size of the wheel, you

may also be able to secure the faulty wheel

in the spare wheel well. In this case, you

will have to remove the stowage tray from

the spare wheel well and stow it securely

in the boot.

i When you are driving with the emergency

spare wheel fitted, the tyre pressure loss

warning system cannot function reliably.

Only restart the tyre pressure loss warning

system when the defective wheel has been

replaced with a new wheel. MOExtended tyres (tyres with run-flat

characteristics)

MOExtended tyres (tyres with run-flat char-

acteristics) allow you to continue driving the

vehicle even when one or more tyres lose all

air pressure.

MOExtended tyres may only be used in con-

junction with the activated tyre pressure loss

warning system or with the tyre pressure

monitor.

The maximum permissible distance which

can be driven in run-flat mode depends on the

load in the vehicle. It is 80 km if the vehicle

is partially laden and 30 km if fully laden.

The maximum permissible distance which

can be driven in run-flat mode is counted from

the moment the tyre pressure loss warning

appears in the multifunction display. 324

Flat tyreBreakdown assistance

Page 330 of 373

X

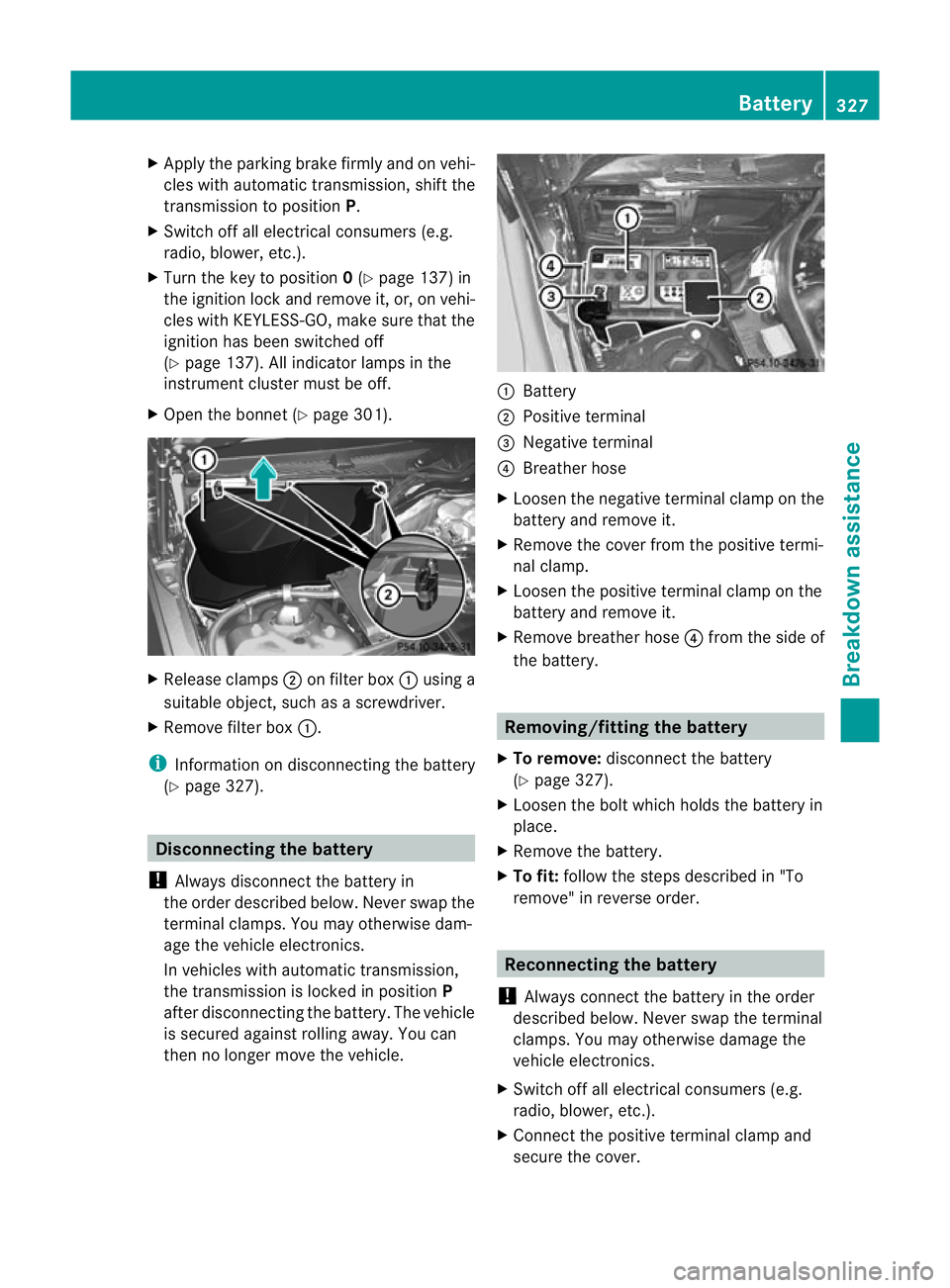

Apply the parking brake firmly and on vehi-

cles with automatic transmission, shift the

transmission to position P.

X Switch off all electrical consumers (e.g.

radio, blower, etc.).

X Turn the key to position 0(Y page 137) in

the ignition lock and remove it, or, on vehi-

cles with KEYLESS-GO ,make sure that the

ignition has been switched off

(Y page 137). All indicator lamps in the

instrument cluster must be off.

X Open the bonnet (Y page 301).X

Release clamps ;on filter box :using a

suitable object, such as a screwdriver.

X Remove filter box :.

i Information on disconnecting the battery

(Y page 327). Disconnecting the battery

! Always disconnect the battery in

the order described below. Never swap the

terminal clamps. You may otherwise dam-

age the vehicle electronics.

In vehicles with automatic transmission,

the transmission is locked in position P

after disconnecting the battery. The vehicle

is secured against rolling away. You can

then no longer move the vehicle. :

Battery

; Positive terminal

= Negative terminal

? Breather hose

X Loosen the negative terminal clamp on the

battery and remove it.

X Remove the cover from the positive termi-

nal clamp.

X Loosen the positive terminal clamp on the

battery and remove it.

X Remove breather hose ?from the side of

the battery. Removing/fitting the battery

X To remove: disconnect the battery

(Y page 327).

X Loosen the bolt which holds the battery in

place.

X Remove the battery.

X To fit: follow the steps described in "To

remove" in reverse order. Reconnecting the battery

! Always connect the battery in the order

described below. Never swap the terminal

clamps. You may otherwise damage the

vehicle electronics.

X Switch off all electrical consumers (e.g.

radio, blower, etc.).

X Connect the positive terminal clamp and

secure the cover. Battery

327Breakdown assistance Z

Page 331 of 373

X

Connect the negative terminal clamp.

X Put the filter box back in place, then clip in

and close the retaining clamps.

X Close the bonnet.

i If the power supply has been interrupted,

e.g. if the battery has been reconnected,

you must carry out th efollowing tasks:

R set the clock; see the separate operating

instructions.

R reset the function for automatically fold-

ing the exterior mirrors in/out by folding

the mirrors out once (Y page 104).Charging the battery

G

WARNING

Only charge the battery in a well-ventilated

area. As the battery is being charged, gases

can escape and generate minor explosions.

This could injure you and other persons or

cause damage to the paintwork or acid cor-

rosion on the vehicle.

You can obtain information about battery

chargers which allow the battery to be

charged while still installed from a qualified

specialist workshop, e.g. aMercedes-Benz

Service Centre. G

WARNING

There is a risk of acid burns during the charg-

ing process due to the gases which escape

from the battery. Do not lean over the battery

during the charging process. G

WARNING

Battery acid is caustic. Avoid contact with the

skin, eyes or clothing.

! Only charge the installed battery with a

battery charger which has been tested and

approved by Mercedes-Benz .These battery

chargers allow the battery to be charged

while still installed. !

Only use battery chargers with a maxi-

mum charging voltage of 14.8 V.

! Only charge the battery using the jump-

start connection point.

The jump-starting connection point is in the

engine compartment (Y page 329).

X Open the bonnet (Y page 301).

X Connect the battery charger to the positive

terminal and earth point in the same order

as when connecting the donor battery in

the jump-starting procedure

(Y page 329).

X Read the battery charger's operating

instructions before charging the battery. 328

BatteryBreakdown assistance

Page 334 of 373

Before towing away, make sure that the steer-

ing can be moved and is not locked.

If you tow or tow-start another vehicle, its

weight must not exceed the maximum per-

missible gross vehicle weigh tofyour vehicle. G

WARNING

The vehicle is braked when the HOLD function

or DISTRONIC PLUS is activated. Therefore,

deactivate HOLD and DISTRONIC PLUS if the

vehicle is to be towed.

It is better to have the vehicle transported

than to have it towed.

! You may tow the vehicle for a maximum

of 50 km. A towing speed of 50 km/hm ust

no tb e exceeded.

For towing distances over 50 km, the entire

vehicle must be lifted up and transported.

! Only secure the tow rope or towing bar to

the towing eyes. The vehicle may otherwise

be damaged.

! Do not use the towing eye for recovery,

as this could damage the vehicle. If in

doubt, recover the vehicle with a crane.

! Pull away smoothly when towing away or

tow-starting a vehicle. If the tractive power

is too high, the vehicles could be damaged.

! On vehicles with KEYLESS-GO, use the

key instead of the Start/Stop button .Turn

the key to position 2in the ignition loc kand

shift the automatic transmission to N.

Then, tur nthe key back to 0and leave it in

the ignition lock.

When towing a vehicle with an automatic

transmission, the transmission must be in

position N.

The battery must be connected and charged.

Otherwise, you:

R cannot turn the key in the ignition lock to

position 2

R cannot shift the transmission to position

N on vehicles with automatic transmission Vehicles with automatic transmission:

release the selector lever lock manually to

move it out of position

P(Y page 152).

i Before the vehicle is towed, switch off the

automatic locking feature (Y page 84). You

could otherwise be locked out when push-

ing or towing the vehicle.

Deactivate tow-away protection

(Y page 73) before the vehicle is towed. Fitting/removing the towing eye

Fitting the towing eye Vehicles with a trailer tow hitch: if you intend

to use the vehicle for towing, fold out the ball

coupling and connect the towbar to it

(Y

page 201).

X Remove the towing eye from the vehicle

tool kit (Y page 315). G

WARNING

The exhaust tail pipe may be hot. You could

burn yourself if you touch the tail pipe. Be

particularly careful when removing the rear

cover.

The mountings for the removable towing eyes

are located in the bumpers. They are at the

front and at the rear, under the covers. Towing and tow-starting

331Breakdown assistance Z

Page 335 of 373

X

Take cover :off the opening.

X Screw the towing eye in clockwise to the

stop and tighten it.

Removing the towing eye X

Loosen the towing eye and unscrew it.

X Attach cover :to the bumper and press

until it engages.

X Place the towing eye in the vehicle tool kit. Towing the vehicle with the rear axle

raised

When towing your vehicle with the rear axle

raised, it is importan tthat you observe the

safety instructions (Y page 330).

! The ignition must be switched off if you

are towing the vehicle with the rear axle

raised. Intervention by ESP ®

could other-

wise damage the brake system.

X Switch on the hazard warning lamps

(Y page 111).

X Turn the key in the ignition lock to position

0and remove the key from the ignition

lock.

X When leaving the vehicle, take the key or

the KEYLESS-GO key with you. Towing the vehicle with both axles on

the ground

It is important that you observe the safety

instructions when towing away your vehicle

(Y page 330). G

WARNING

The power assistance for the steering and the

brake force booster do not work when the

engine is not running. You will then need

much more effort to brake and steer the vehi-

cle. Adapt your style of driving accordingly. X

Switch on the hazard warning lamps

(Y page 111).

i When towing with the hazard warning

lamps switched on, use the combination

switch as usual to signal achange of direc-

tion. In this case, only the turn signals for

the desired direction flash. When the com-

bination switch is reset, the hazard warning

lamps start flashing again.

X Turn the key to position 2in the ignition

lock.

X When the vehicle is stationary, depress the

brake pedal and keep it depressed.

X Vehicles with manual transmission:

depress the clutch pedal.

X Shift to neutral.

or

X Vehicles with automatic transmission:

shift the automatic transmission to posi-

tion N.

X Release the brake pedal.

X Release the parking brake. Transporting the vehicle

The towing eyes or trailer tow hitch can be

used to pull the vehicle onto a trailer or trans-

porter if you wish to transport it.

X Vehicles with manual transmission:

shift to neutral.

X Vehicles with automatic transmission:

turn the key to position 2in the ignition

lock.

X Move the selector lever to N.

As soon as the vehicle is loaded:

X Prevent the vehicle from rolling away by

applying the parking brake.

X Vehicles with manual transmission:

shift to first gear or reverse gear.

X Vehicles with automatic transmission:

move the selector lever to P.332

Towing and tow-startingBreakdown assistance