MERCEDES-BENZ CL500 2002 C215 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2002, Model line: CL500, Model: MERCEDES-BENZ CL500 2002 C215Pages: 430

Page 341 of 430

338 Engine compartment

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

The engine oil level can be checked by either the oil

dipstick or via the multifunction display in the

instrument cluster, see page 157.

Wipe the oil dipstick clean prior to checking the engine

oil level. Fully insert dipstick in tube, and remove after

three seconds to obtain accurate reading.

The oil level must be between the lower

mark (min) and the upper mark (max)

on the oil dipstick.

Unscrew the oil filler cap and add oil carefully if you

need to top up the oil.

CL 500 and CL 55 AMG:

Fill quantity between upper and lower dipstick marking

level is approximately 2.1 US qt (2.0 l).

CL 600:

Follow the message appearing on the engine oil level

indicator display (page 157) as to quantity to be added.

Re-install oil filler cap.

Do not overf ill the engine.

Excessive oil must be drained

or siphoned. It could cause damage to engine and

catalytic converter not covered by the Mercedes-Benz

Limited Warranty.See malfunction and warning messages on page 303 if

an engine oil level display appears on the multifunction

display when the engine is running.

Note:

See page 157 for engine oil level indicator.

Automatic transmission fluid level

The transmission has a permanent fill of automatic

transmission fluid.

Regular automatic transmission fluid level checks and

changes are not required. For this reason the dipstick is

omitted.

If you notice fluid leaks or gear shifting malfunctions,

have your authorized Mercedes-Benz Center check the

transmission fluid level.

Active body control (ABC) fluid level

Regular fluid level check is not required.

If you notice fluid leaks or malfunctions, have your

authorized Mercedes-Benz Center check the

ABC-system.

J_OM_215.book Seite 338 Mittwoch, 30. Mai 2001 2:01 14

Page 342 of 430

339 Engine compartment

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

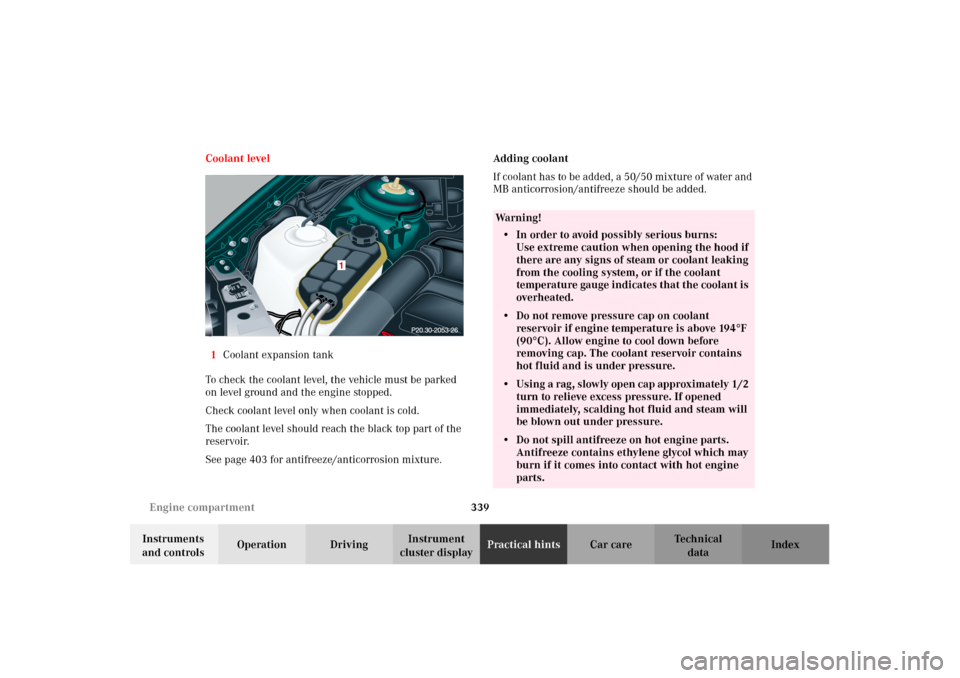

cluster displayPractical hintsCar care Index Coolant level

1Coolant expansion tank

To check the coolant level, the vehicle must be parked

on level ground and the engine stopped.

Check coolant level only when coolant is cold.

The coolant level should reach the black top part of the

reservoir.

See page 403 for antifreeze/anticorrosion mixture.Adding coolant

If coolant has to be added, a 50/50 mixture of water and

MB anticorrosion/antifreeze should be added.

1

Wa r n i n g !

• In order to avoid possibly serious burns:

Use extreme caution when opening the hood if

there are any signs of steam or coolant leaking

from the cooling system, or if the coolant

temperature gauge indicates that the coolant is

overheated.• Do not remove pressure cap on coolant

reservoir if engine temperature is above 194

°F

(90

°C). Allow engine to cool down before

removing cap. The coolant reservoir contains

hot fluid and is under pressure.

• Using a rag, slowly open cap approximately 1/2

turn to relieve excess pressure. If opened

immediately, scalding hot fluid and steam will

be blown out under pressure.• Do not spill antifreeze on hot engine parts.

Antifreeze contains ethylene glycol which may

burn if it comes into contact with hot engine

parts.

J_OM_215.book Seite 339 Mittwoch, 30. Mai 2001 2:01 14

Page 343 of 430

340 Engine compartment

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

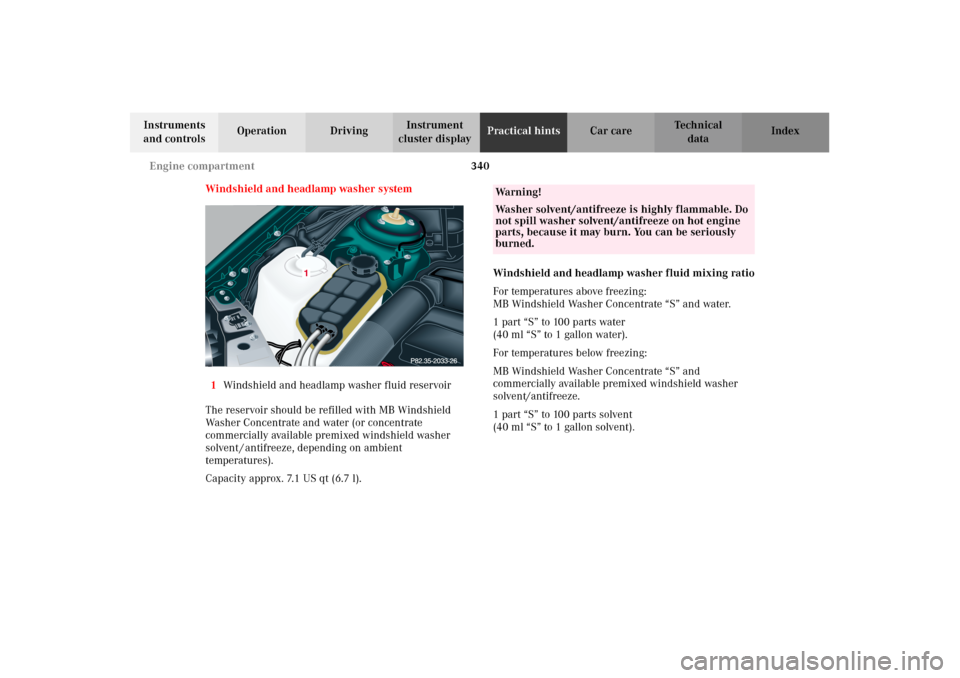

Windshield and headlamp washer system

1Windshield and headlamp washer fluid reservoir

The reservoir should be refilled with MB Windshield

Washer Concentrate and water (or concentrate

commercially available premixed windshield washer

solvent / antifreeze, depending on ambient

temperatures).

Capacity approx. 7.1 US qt (6.7 l).Windshield and headlamp washer fluid mixing ratio

For temperatures above freezing:

MB Windshield Washer Concentrate “S” and water.

1 part “S” to 100 parts water

(40 ml “S” to 1 gallon water).

For temperatures below freezing:

MB Windshield Washer Concentrate “S” and

commercially available premixed windshield washer

solvent/antifreeze.

1 part “S” to 100 parts solvent

(40 ml “S” to 1 gallon solvent).

1

Wa r n i n g !

Washer solvent/antifreeze is highly flammable. Do

not spill washer solvent/antifreeze on hot engine

parts, because it may burn. You can be seriously

burned.

J_OM_215.book Seite 340 Mittwoch, 30. Mai 2001 2:01 14

Page 344 of 430

341 Spare wheel

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

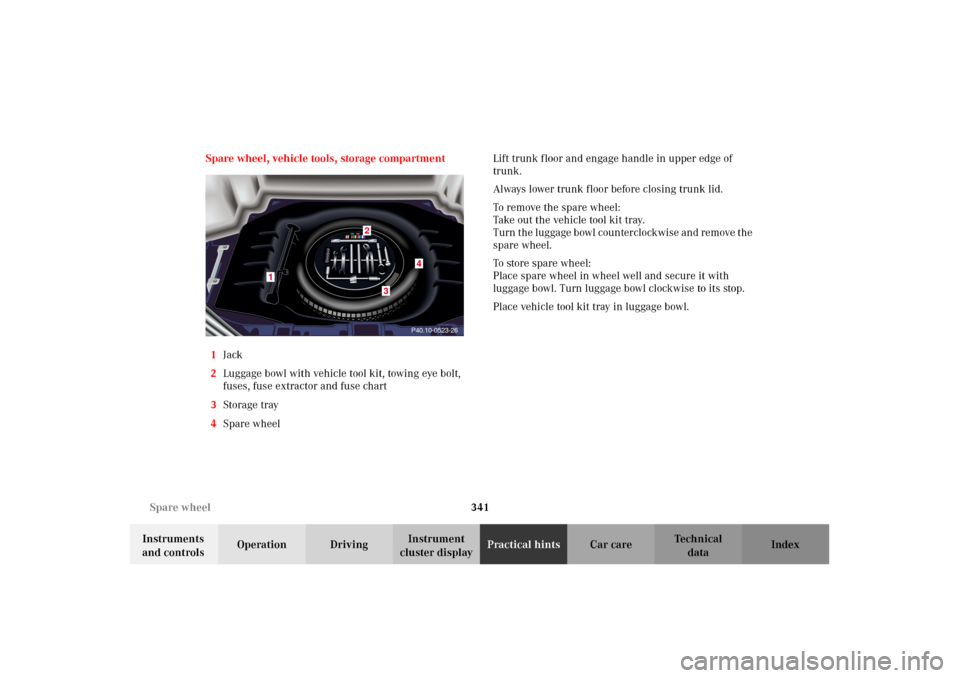

cluster displayPractical hintsCar care Index Spare wheel, vehicle tools, storage compartment

1Jack

2Luggage bowl with vehicle tool kit, towing eye bolt,

fuses, fuse extractor and fuse chart

3Storage tray

4Spare wheel Lift trunk floor and engage handle in upper edge of

trunk.

Always lower trunk floor before closing trunk lid.

To remove the spare wheel:

Take out the vehicle tool kit tray.

Turn t he luggage b owl coun ter clock wise an d re move t he

spare wheel.

To store spare wheel:

Place spare wheel in wheel well and secure it with

luggage bowl. Turn luggage bowl clockwise to its stop.

Place vehicle tool kit tray in luggage bowl.

P40.10-0523-26

1

4

3

2

J_OM_215.book Seite 341 Mittwoch, 30. Mai 2001 2:01 14

Page 345 of 430

342 Jack

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Jack

To prepare the jack for use:

Remove the jack from the spare wheel well under the

trunk floor, push the crank handle up and turn

clockwise until it engages (operational position).Storing the jack in the trunk:

Retract the jack arm to the base of the jack, push the

crank handle up and turn counterclockwise to the end

of the stop (storage position).

P58.10-2001-26

Wa r n i n g !

The jack is designed exclusively for jacking up the

vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack

only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported

by the ja ck. Keep ha nd s an d feet away from the area

under the lifted vehicle. Always firmly set parking

brake and block wheels before raising vehicle with

jack.Do not d i sen ga ge park in g b ra ke whi l e the vehic l e is

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before

working under the vehicle.

J_OM_215.book Seite 342 Mittwoch, 30. Mai 2001 2:01 14

Page 346 of 430

343 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Wheels

Replace rims or tires with the same designation,

manufacturer and type as shown on the original part.

See your authorized Mercedes-Benz Center for further

information.

See your authorized Mercedes-Benz Center for

information on tested and recommended rims and tires

for summer and winter operation. They can also offer

advice concerning tire service and purchase.

Tire replacement

Front and rear tires should be replaced in sets. Rims

and tires must be of the correct size and type. For

dimensions, see “Technical Data”.

We recommend that you break in new tires for approx.

60 miles (100 km) at moderate speed.It is imperative that the wheel mounting bolts be

fastened to a tightening torque of 110 ft.lb. (150 Nm)

whenever wheels are mounted.

For rim and tire specifications, refer to “Technical Data”.

Wa r n i n g !

Worn, old tires can cause accidents. If the tire tread

is badly worn, or if the tires have sustained

damage, replace them.When replacing rims, use only genuine

Mercedes-Benz wheel bolts specified for the

particular rim type. Failure to do so can result in

the bolts loosening and possibly an accident.

J_OM_215.book Seite 343 Mittwoch, 30. Mai 2001 2:01 14

Page 347 of 430

344 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Rotating wheels

The wheels can be rotated according to the degree of

tire wear while retaining the same direction of travel.

Rotating, however, should be carried out as

recommended by the tire manufacturer, before the

characteristic tire wear pattern (shoulder wear on front

wheels and tread center wear on rear wheels) becomes

visible, as otherwise the driving properties deteriorate.

Notes:

Thoroughly clean the inner side of the wheels any time

you rotate the wheels or wash the vehicle underside.

The use of retread tires is not recommended. Retread

tires may adversely affect the handling characteristics

and safety of the vehicle.

Dented or bent rims can cause tire pressure loss and

damage to the tire beads. For this reason, check rims for

damage at regular intervals. The rim flanges must be

checked for wear before a tire is mounted. Remove

burrs, if any.

Check and ensure proper tire inflation pressure after

rotating the wheels. For tire inflation pressure see

inside of fuel filler flap and also page 351.Spare wheel

Spare wheel CL 500 and CL 600

(except Sport Package)

Important!

The spare wheel rim is mounted with a full size tire of

the same type as on the vehicle, and is fully functional.

However, that spare wheel rim is weight optimized and

has a limited service life of 12 000 miles (20 000 km)

use before a standard wheel rim must replace it.

In the case of a flat tire, you may temporarily use the

spare wheel.

Do not operate vehicle with more than one spare wheel

mounted.

Wa r n i n g !

The spare wheel rim is for temporary use only. Use

for over a total of 12 000 miles (20 000 km)

(aggregate of all uses) may cause wheel rim failure

leading to an accident and possible injuries.

J_OM_215.book Seite 344 Mittwoch, 30. Mai 2001 2:01 14

Page 348 of 430

345 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Spare wheel CL 55 AMG and Sport Package

Important!

The spare wheel rim size is 7

1/2J x 17 H 2 with tire size

225/55 R17 97H.

The spare wheel rim is weight optimized and has a

limited service life of 12 000 miles (20 000 km) use

before a standard wheel rim must replace it.

In the case of a flat tire, you may temporarily use the

spare wheel, when observing the following restrictions:

•Do not exceed vehicle speed of 50 mph (80 km/h)

•Drive to the nearest tire repair facility to have the

flat tire repaired or replaced as appropriate.

•Do not operate vehicle with more than one spare

wheel mounted.

If the arrow on tire side wall does not point in direction

of vehicle forward movement when using the spare

wheel, observe the following restriction:

Unidirectional tires must always be mounted with arrow

on tire sidewall pointing in direction of vehicle forward

movement.For rim and tire specifications, refer to “Technical Data”.

Wa r n i n g !

The spare wheel rim is for temporary use only. Use

for over a total of 12 000 miles (20 000 km)

(aggregate of all uses) may cause wheel rim failure

leading to an accident and possible injuries.The dimensions of the spare wheel are different

from those of the road wheels. As a result, the

vehicle handling characteristics change when

driving with a mounted spare wheel.The spare wheel should only be used temporarily,

and replaced with a regular road wheel as quick as

possible.

J_OM_215.book Seite 345 Mittwoch, 30. Mai 2001 2:01 14

Page 349 of 430

346 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Changing wheelsMove vehicle to a level area which is a safe distance

from the roadway.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine.

3. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone. When

changing a wheel on a hill, place chocks on the

downhill side blocking both wheels of the other

axle. On an level road, place one chock in front of

and one behind the wheel that is diagonally

opposite to the wheel being changed.

Wa r n i n g !

The jack is designed exclusively for jacking up the

vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack

only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported

by t he j ack . Keep han ds a nd feet away from t he a rea

under the lifted vehicle. Always firmly set parking

brake and block wheels before raising vehicle with

jack.Do n ot d is engage parki n g brake w hil e t he vehi c le i s

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before

working under the vehicle.

J_OM_215.book Seite 346 Mittwoch, 30. Mai 2001 2:01 14

Page 350 of 430

347 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index 4. Remove the two-piece wheel wrench from the

vehicle tool kit and assemble. Using the wrench,

loosen but do not yet remove the wheel bolts.5. Remove the protective cover from the jack support

tube opening by inserting the screwdriver (supplied

in the tool kit) in the opening and prying it out.

The tube openings are located directly behind the

front wheel housings and in front of the rear wheel

housings.

P40.10-2177-26

J_OM_215.book Seite 347 Mittwoch, 30. Mai 2001 2:01 14