change wheel MERCEDES-BENZ CLS 2017 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: CLS, Model: MERCEDES-BENZ CLS 2017Pages: 334, PDF Size: 10.18 MB

Page 304 of 334

Restarting the tire pressure monitor When you restart the tire pressure monitor, all

existing warning messages are deleted and the

warning lamps go out. The monitor uses the cur-

rently set tire pressures as the reference values

for monitoring. In most cases, the tire pressure

monitor will automatically detect the new refer-

ence values after you have changed the tire

pressure. However, you can also define refer-

ence values manually as described here. The tire

pressure monitor then monitors the new tire

pressure values. X

Set the tire pressure to the value recommen-

ded for the corresponding driving situation on

the Tire and Loading Information placard on

the driver's side B-pillar ( Y

page 295).

You can find more tire pressure values for

various operating conditions in the tire pres-

sure table inside the fuel filler flap

( Y

page 295).X

Make sure that the tire pressure is correct on

all four wheels. X

Make sure that the SmartKey is in position 2

in the ignition lock. X

Press the �Y or �e button on the steering

wheel to select the Service menu.X

Press the �c or �d button to select

Tire Pressure .X

Press the �v button.

The multifunction display shows the current

tire pressure for the individual tires or the

Tire pressures will be displayed

after driving a few minutes message.X

Press the �d button.

The Use Current Pressures as New Ref‐

erence Values message appears in the mul-

tifunction display.

If you wish to confirm the restart: X

Press the �v button.

The Tire Press. Monitor Restarted mes-

sage appears in the multifunction display.

After driving for a few minutes, the system

checks whether the current tire pressures are

within the specified range. The new tire pres-

sures are then accepted as reference values

and monitored.

If you wish to cancel the restart: X

Press the �8 button.

The tire pressure values stored at the last

restart will continue to be monitored. Radio type approval for the tire pres-

sure monitor Country Radio type approval number

USA FCC ID: MRXMW2433A

FCC ID: MRXGG4

FCC ID: MRXMC34MA4

Canada IC: 2546A-MW2433A

IC: 2546A-GG4

IC: 2546A-MC34MA4

Loading the vehicle

Instruction labels for tires and loads

G WARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair the

steering and driving characteristics and lead

to brake failure. There is a risk of accident.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load.

Two instruction labels on your vehicle show the

maximum possible load.

(1) The Tire and Loading Information placard is

on the B-pillar on the driver's side. The Tire

and Loading Information placard shows the

maximum permissible number of occu-

pants and the maximum permissible vehicle

load. It also contains details of the tire sizes

and corresponding pressures for tires

mounted at the factory.

(2) The vehicle identification plate is on the B-

pillar on the driver's side. The vehicle iden-

tification plate informs you of the gross

vehicle weight rating. It is made up of the

vehicle weight, all vehicle occupants, the

fuel and the cargo. You can also find infor-

mation about the maximum gross axle

weight rating on the front and rear axle.

The maximum gross axle weight rating is

the maximum weight that can be carried by

one axle (front or rear axle). Never exceed

the maximum load or the maxi mum g ross

a

xle weight rating for the front or rear axle.302

Loading the vehicle

Wheels and tires

Page 316 of 334

must be positioned vertically, directly under

the jacking point of the vehicle.

! The jack is designed exclusively for jacking

up the vehicle at the jacking points. Other-

wise, your vehicle could be damaged.

Observe the following when raising the vehicle: R

To raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised. R

The jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle. R

Avoid changing the wheel on uphill and down-

hill slopes. R

Before raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised. R

The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats. R

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height. R

Make sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm). R

Never place your hands and feet under the

raised vehicle. R

Do not lie under the vehicle. R

Do not start the engine when the vehicle is

raised. R

Do not open or close a door or the trunk lid

when the vehicle is raised. R

Make sure that no persons are present in the

vehicle when the vehicle is raised.

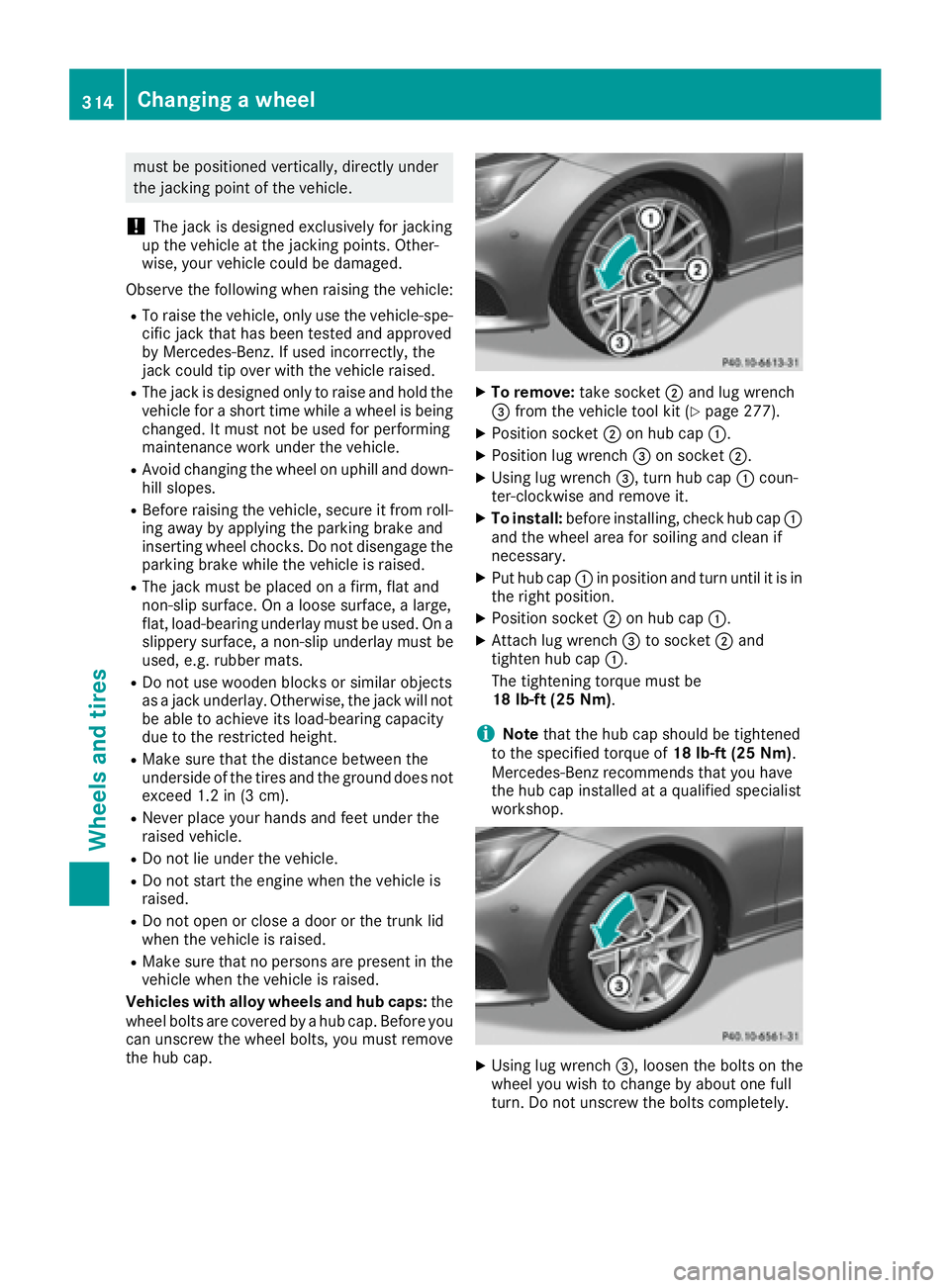

Vehicles with alloy wheels and hub caps: the

wheel bolts are covered by a hub cap. Before y ou

ca n unscrew the wheel bolts, you must remove

the hub cap. X

To remove: take socket �D and lug wrench

�

Page 318 of 334

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

( Y

page 312).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

! Mercedes-AMG vehicles with ceramic-

brake disc: during removal and repositioning

of the wheel, the wheel rim can strike the

ceramic-brake disc and damage it. Therefore,

you should proceed carefully and get a sec-

ond person assist to you. Alternatively, you

can use a second alignment bolt.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

X

Clean the wheel and wheel hub contact sur-

faces. X

Slide the wheel to be mounted onto the align-

ment bolt and push it on. X

Tighten the wheel bolts until they are finger-

tight. X

Unscrew the alignment bolt. X

Tighten the last wheel bolt until it is finger-

tight. X

Vehicles with a collapsible spare wheel:

inflate the collapsible spare wheel

( Y

page 319).

Only then lower the vehicle. Lowering the vehicle

G WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Vehicles with a collapsible spare wheel:

before lowering the vehicle, inflate the col-

lapsible spare wheel with the tire inflation

compressor. The wheel rim could otherwise

be damaged. X

Turn the crank of the jack counter-clockwise

until the vehicle is once again standing firmly

on the ground. X

Place the jack to one side.

X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated ( �C to �