lock MERCEDES-BENZ E-CLASS CABRIOLET 2017 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E-CLASS CABRIOLET, Model: MERCEDES-BENZ E-CLASS CABRIOLET 2017Pages: 521, PDF Size: 10.64 MB

Page 400 of 521

R

Centring pin

R Folding wheel chock

R Ratchet for jack

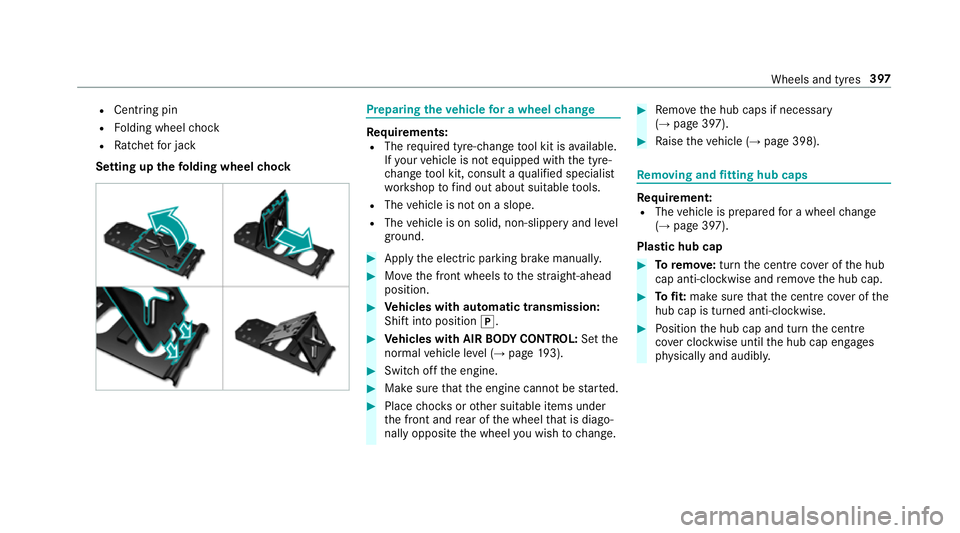

Setting up thefo lding wheel chock Prepa

ring theve hicle for a wheel change Re

quirements:

R The requ ired tyre-change tool kit is available.

If yo ur vehicle is not equipped with the tyre-

ch ange tool kit, consult a qualified specialist

wo rkshop tofind out about suitable tools.

R The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Apply the electric parking brake manually. #

Movethe front wheels tothest ra ight-ahead

position. #

Vehicles with automatic transmission:

Shift into position j. #

Vehicles with AIR BODY CONT ROL:Set the

normal vehicle le vel (→ page 193). #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

Place choc ks orother suitable items under

th e front and rear of the wheel that is diago‐

nally opposite the wheel you wish tochange. #

Remo vethe hub caps if necessary

(→ page 397). #

Raise theve hicle (→ page 398). Re

moving and fitting hub caps Re

quirement:

R The vehicle is prepared for a wheel change

(→ page 397).

Pla stic hub cap #

Toremo ve:turn the cent recover of the hub

cap anti-clockwise and remo vethe hub cap. #

Tofit: make sure that the cent recover of the

hub cap is turned anti-clockwise. #

Position the hub cap and turn the cent re

co ver clockwise until the hub cap engages

ph ysically and audibly. Wheels and tyres

397

Page 401 of 521

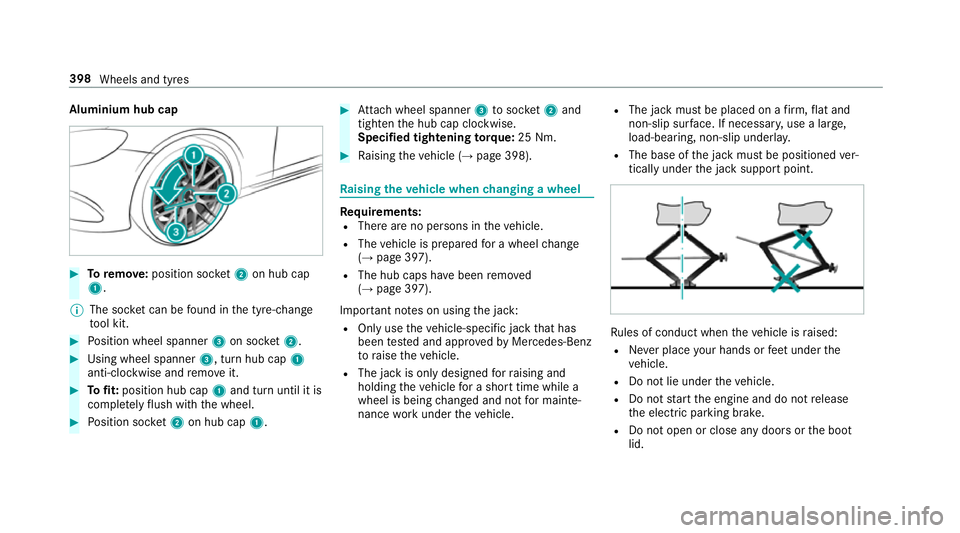

Aluminium hub cap

#

Toremo ve:position soc ket2 on hub cap

1.

% The soc ket can be found in the tyre-change

to ol kit. #

Position wheel spanner 3on soc ket2. #

Using wheel spanner 3, turn hub cap1

anti-clo ckwise and remo veit. #

Tofit: position hub cap 1and turn until it is

comple tely flush with the wheel. #

Position soc ket2 on hub cap 1. #

Attach wheel spanner 3tosoc ket2 and

tighten the hub cap clockwise.

Specified tightening torq ue: 25 Nm. #

Raising theve hicle (→ page 398). Ra

ising theve hicle when changing a wheel Re

quirements:

R There are no persons in theve hicle.

R The vehicle is prepared for a wheel change

(→ page 397).

R The hub caps ha vebeen remo ved

( → page 397).

Impor tant no tes on using the jack:

R Only use theve hicle-specific jack that has

been tested and appr ovedby Mercedes-Benz

to raise theve hicle.

R The jack is only designed forra ising and

holding theve hicle for a short time while a

wheel is being changed and not for mainte‐

nance workunder theve hicle. R

The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

load-bearing, non-slip underla y.

R The base of the jack must be positioned ver‐

tically under the jack support point. Ru

les of conduct when theve hicle is raised:

R Never place your hands or feet under the

ve hicle.

R Do not lie under theve hicle.

R Do not start the engine and do not release

th e electric parking brake.

R Do not open or close any doors or the boot

lid. 398

Wheels and tyres

Page 403 of 521

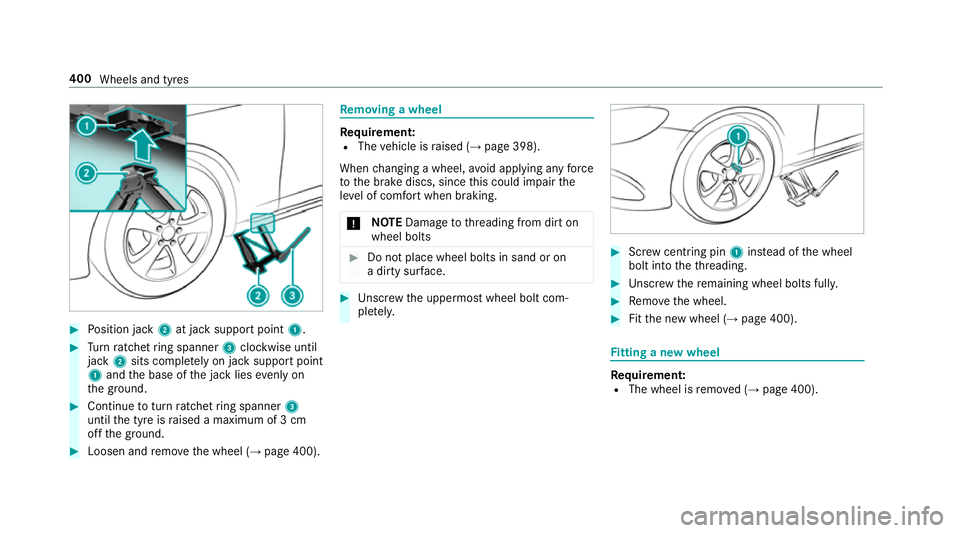

#

Position jack 2at jack support point 1.#

Turn ratchet ring spanner 3clockwise until

jack 2sits comple tely on ja cksupport point

1 and the base of the jack lies evenly on

th e ground. #

Continue toturn ratchet ring spanner 3

until the tyre is raised a maximum of 3 cm

off the ground. #

Loosen and remo vethe wheel (→ page 400). Re

moving a wheel Re

quirement:

R The vehicle is raised (→ page 398).

When changing a wheel, avoid applying any force

to the brake discs, since this could impair the

le ve l of com fort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on

a dirty sur face. #

Unscr ew the uppermost wheel bolt com‐

ple tely. #

Screw centring pin 1instead of the wheel

bolt into theth re ading. #

Unscr ew there maining wheel bolts fully. #

Remo vethe wheel. #

Fitthe new wheel (→ page 400). Fi

tting a new wheel Re

quirement:

R The wheel is remo ved (→ page 400). 400

Wheels and tyres

Page 404 of 521

&

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can cause the wheel bolts/

wheel nuts tocome loose.

As a result, you could lose a wheel while driv‐

ing. #

Never oil or grease theth re ads. #

Intheeve nt of damage totheth re ads,

con tact a qualified specialist workshop

immediatel y. #

Have the damaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do not continue driving. #

Obser vethe information on thech oice of

tyres (→ page 392).

Fo r tyres with a specified direction of rotation,

an ar rowonthe side wall of the tyre indicates

th e cor rect di rection of rotation. Obse rvethe

direction of rotation when fitting. #

Slide the wheel tobe mounted onto the cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

For saf etyre asons, on lyuse wheel bolts

which ha vebeen appr ovedfo r Mercedes-

Benz and the wheel in question. #

Tighten the wheel bolts until they are finger-

tight. #

Unscr ew the cent ring pin. #

Tighten the last wheel bolt until it is finger-

tight. #

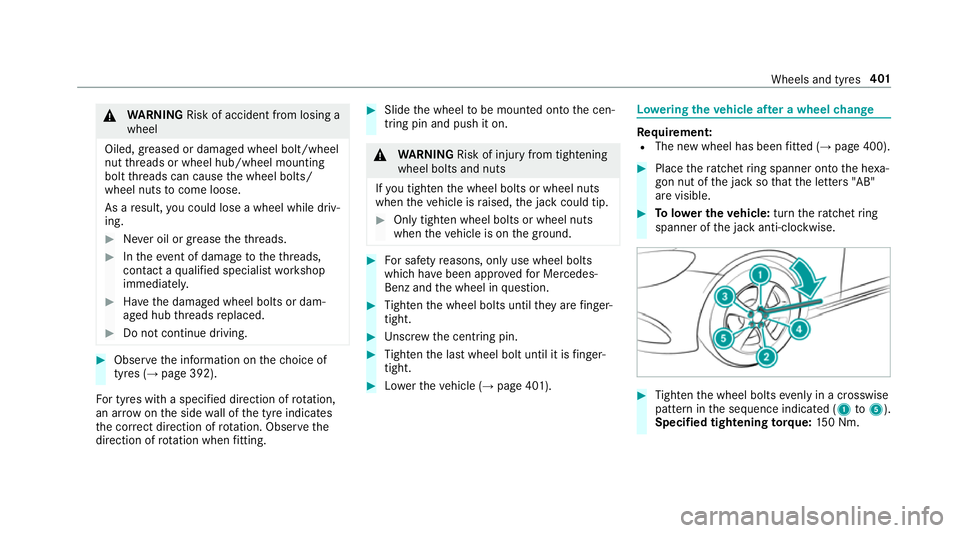

Lowe rth eve hicle (→ page 401). Lo

weri ngtheve hicle af ter a wheel change Re

quirement:

R The new wheel has been fitted (→ page 400). #

Place thera tchet ring spanner onto the he xa‐

gon nut of the jack so that the letters "AB"

are visible. #

Tolowe r the vehicle: turnthera tchet ring

spanner of the jack anti-clockwise. #

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (1 to5 ).

Specified tightening torq ue: 150 Nm. Wheels and tyres

401

Page 418 of 521

Ha

ve the coolant regularly changed at a qualified

specialist workshop.

The proportion of cor rosion inhibitor/antifreeze

concentrate in the engine cooling sy stem should

be:

R A minimum of 50% (antifreeze pr otection

down toappr oximately -37 °C).

R A maximum of 55% (antifreeze pr otection

down to-45 °C). Note

s on windscreen washer fluid Obser

vethe no tes on operating fluids

(→ page 408). &

WARNING ‑ Risk of fire and injury due to

windscreen washer concentrate

Wi ndsc reen washer concentrate is highly

fl ammable. It could ignite if it comes into

con tact wi thhot engine component parts or

th eex haust sy stem. #

Make sure that no windsc reen washer

concentrate spills out next tothefiller

opening. *

NO

TEDama getotheex terior lighting

due tounsuitable windsc reen washer

fl uid Uns

uitable windsc reen washer fluids may

damage the plastic sur face of theex terior

lighting. #

Only use windscreen washer fluids

which are also suitable for use on plas‐

tic sur faces, e.g. MB SummerFit or MB

Wi nterFit. *

NO

TEBlocked spr aynozzles caused by

mixing windscreen washer fluids #

Do not mix MB SummerFit and MB Win‐

te rFit with other windscreen washer flu‐

ids. Do not use distilled or de-ionised

water asthefill

le ve l sensor may be triggered er roneously.

Re commended windscreen washer fluid:

R Abo vefreezing point: e.g. MB SummerFit

R Below freezing point: e.g. MB WinterFit Fo

rth e cor rect mixing ratio referto the informa‐

tion on the antif reeze reser voir.

Mix thewa sher fluid with the windscreen washer

fl uid all year round. Ve

hicle data Ve

hicle dimensions The heights speci

fied may vary as a result of the:

R tyres

R load

R condition of the suspension

R optional equipment Te

ch nical da ta415

Page 450 of 521

Display messages

Possible causes/consequences and M

MSolutions

Key not detected (red dis‐

play message) *T

hekey cannot be de tected and may no longer be in theve hicle.

The key is no lon ger in theve hicle and you swit choff the engine:

R you can no lon gerst art the engine

R you cannot centrally lock theve hicle #

Ensure that theke y is in theve hicle.

If th eke y de tection function has a malfunction due toast ro ng radio signal source: #

Pull over and stop theve hicle safely as soon as possible, paying attention toroad and traf fic conditions. #

Place theke y in thestow age compartment forst arting the engine with theke y .

Place the key in the

marked space See Owner's

Manual *T

hekey de tection function is malfunctioning. #

Change the location of theke y in theve hicle. #

Start theve hicle with theke y in thestow age compartment . Display messages and

warning/indicator lamps 447

Page 452 of 521

Display messages

Possible causes/consequences and M

MSolutions

j Check trailer hitch lock *T

he trailer hitch is not operational. &

WARNING Risk of an accident if the ball neck is not loc ked

If th e ball neck is not in the loc ked position, the trailer may come loose. #

Pull over and stop theve hicle safely as soon as possible, paying attention toroad and traf fic conditions.

Do not continue driving under any circums tances. #

Uncouple the trailer and secure it against rolling away. #

Initiate a new swivelling procedure and do not re-couple the trailer until the display message disappears. #

Stop theve hicle immediately, paying attention toroad and traf fic conditions, and switch off the engine. #

Uncouple the trailer and safeguard it against rolling away. #

Initiate a new swivelling procedure . #

When the display message disappears, couple up the trailer and drive on.

If th e display message does not disappear, the trailer hitch is defective and the ball neck is not loc ked. #

Do not couple up the trailer. Drive on without the trailer. Pay attention tothere duced ground clearance due to

th e unloc ked ball nec k. #

Consult a qualified specialist workshop.

Apply brake to deselect

Park (P) position *

Yo u ha veattem ptedto shift the transmission out of position jand into ano ther transmission position. #

Depress the brake pedal. Display messages and

warning/indicator lamps 449

Page 459 of 521

Display messages

Possible causes/consequences and M

MSolutions

M *T

he engine bonnet is open. &

WARNING Risk of accident due todriving with the engine bonn etunlo cked

An unloc ked engine bonn etmay open up when theve hicle is in motion and block your vie w. #

Never unlock the engine bonn etwhen driving. #

Before every trip, ensure that the engine bonn etis loc ked. #

Pull over and stop theve hicle safely as soon as possible. #

Close the engine bonn et.

C *A

t least one door is open. #

Close all doors. 456

Displaymessa ges and warning/indicator lamps

Page 460 of 521

Display messages

Possible causes/consequences and M

MSolutions

N *T

he boot lid is open. &

WARNING Risk ofexhaust gas poisoning

Combustion engines emit poisonous exhaust gases such as carbon monoxide. Exhaust gases can enter the

ve hicle interior if the boot lid is open when the engine is running, especially if theve hicle is in motion. #

Alw ays switch off the engine before opening the boot lid. #

Never drive with the boot lid open. #

Close the boot lid.

_ Example:Front left seat

backrest not locked *T

he seat backrest of the cor responding front seat is not engaged. #

Push the seat backrest back until it engages.

_

Example:Rear left seat

backrest not locked *T

he cor responding seat backrest of there ar ben chseat is not engaged. #

Foldthe cor responding seat backrest back until it engages. Display messages and

warning/indicator lamps 457

Page 468 of 521

Wa

rning/indicator lamp

Possible causes/consequences and M

MSolutions

J Brake sy stem warning lamp The

red brake sy stem warning lamp is lit while the engine is running.

Po ssible causes:

R The brake forc e boosting is malfunctioning and the braking characteristics may be af fected.

R The reis insuf ficient brake fluid in the brake fluid reser voir. &

WARNING Thereis a risk of an accident if brake forc e boosting is malfunctioning

If brake forc e boosting is malfunctioning, the wheels may lock when braking. Braking characteristics may be

impaired. The braking dis tance may increase in an eme rgency braking situation. #

Pull over and stop theve hicle safely as soon as possible, paying attention toroad and traf fic conditions. Do

not continue driving under any circums tances. #

Consult a qualified specialist workshop. &

WARNING Risk of an accident due tolow brake fluid le vel

If th e brake fluid le vel is too lo w,the braking ef fect and the braking characteristics may be impaired. #

Pull over and stop theve hicle safely as soon as possible, paying attention toroad and traf fic conditions. Do

not continue driving under any circums tances. #

Consult a qualified specialist workshop.

Do not top up the brake fluid. Display messages and

warning/indicator lamps 465