inflation pressure MERCEDES-BENZ E-CLASS CABRIOLET 2018 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: E-CLASS CABRIOLET, Model: MERCEDES-BENZ E-CLASS CABRIOLET 2018Pages: 498, PDF Size: 6.28 MB

Page 336 of 498

If a pressure losswarning message appears in

th e multifunction display:

RCheck the tire for dama ge.

RIf driving on, obser vethefo llowing no tes.

Driving distance possible in limp-home mode

af te r the pressure loss warning:

Load condition Driving distance pos‐

sible in limp-homemode

Pa rtially laden 50 miles (80 km)

Fu lly laden 19miles (30 km)

RThe driving dis tance possible in li mp-home

mode may vary depending on the driving

st yle.

RMaximum permissible speed 50 mph

(80 km/h).

If a tire has gone flat and cannot be replaced

with an MOEx tended tire, you can use a stand‐

ard tire as a temp orary measure.

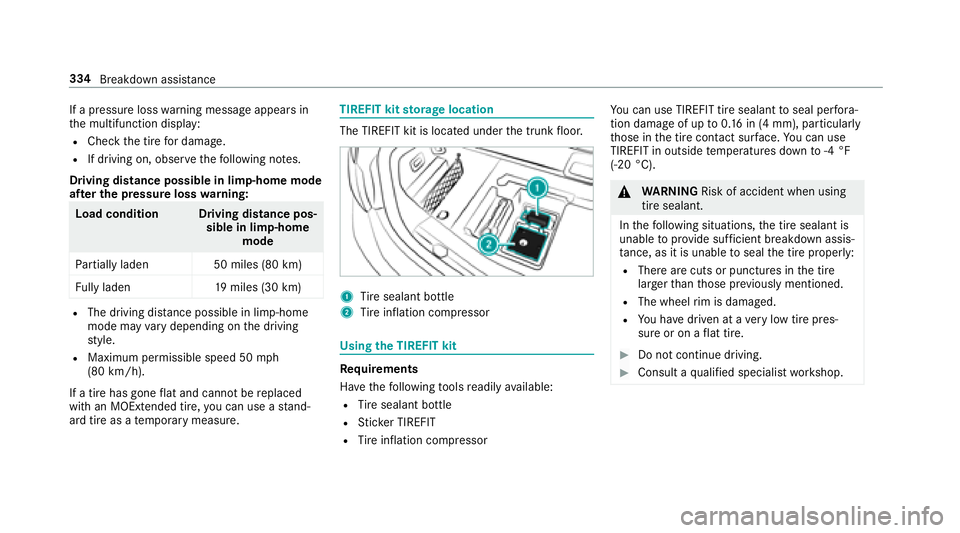

TIREFIT kit storage location

The TIREFIT kit is located under the trunk floor.

1Ti re sealant bottle

2Tire inflation compressor

Using the TIREFIT kit

Re quirements

Ha ve thefo llowing tools readily available:

RTire sealant bottle

RSticke r TIREFIT

RTire inflation compressor Yo

u can use TIREFIT tire sealant toseal per fora ‐

tion damage of upto0.16 in (4 mm), particularly

th ose in the tire conta ct surface.You can use

TIRE FIT in outside temp eratures down to-4 °F

(-20 °C).

0071 WARNING Risk of accident when using

tire sealant.

In thefo llowing situations, the tire sealant is

unable toprov ide suf ficient breakdown assis‐

ta nce, as it is unable toseal the tire properly:

RThere are cuts or punctures in the tire

lar gerth an those pr eviously mentioned.

RThe wheel rim is dama ged.

RYo u ha vedriven at a very low tire pres‐

sure or on a flat tire.

00BBDo not continue driving.

00BBConsult a qualified specialist workshop.

334

Breakdown assis tance

Page 338 of 498

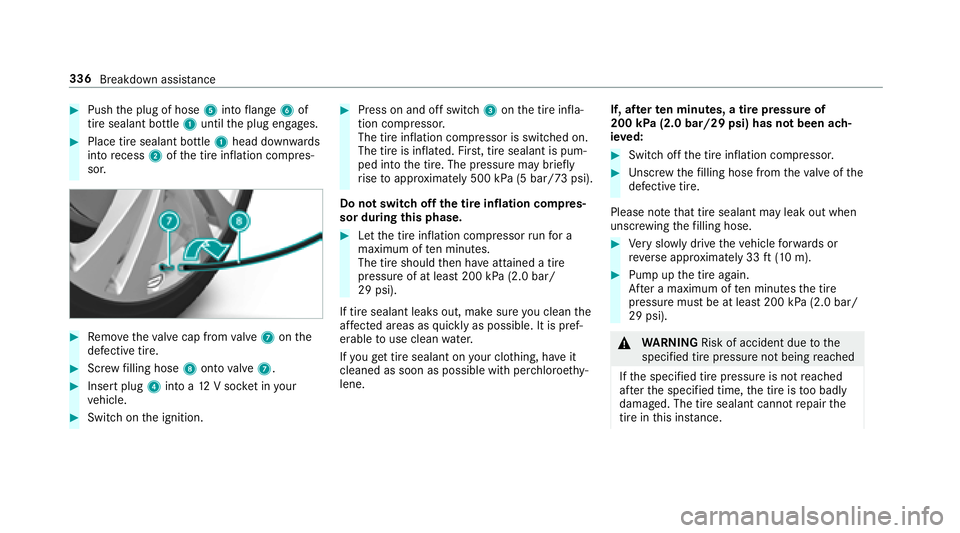

00BBPushthe plug of hose 5into flange 6of

tire sealant bottle 1until the plug engages.

00BBPlace tire sealant bottle 1head down wards

into recess 2ofthe tire inflation compres‐

sor.

00BBRe mo vetheva lve cap from valve 7 onthe

defective tire.

00BBScr ew filling hose 8onto valve 7.

00BBInsert plug 4into a 12V soc ket in your

ve hicle.

00BBSwitch on the ignition.

00BBPress on and off switch 3onthe tire infla‐

tion compressor.

The tire inflation compressor is switched on.

The tire is inflated. Fir st, tire sealant is pum‐

ped into the tire. The pressure may brief ly

ri se toappr oximately 500 kPa (5 bar/73 psi).

Do not switch off the tire inflation compres‐

sor du ring this phase.

00BBLet the tire inflation compressor runfo r a

maximum of ten minu tes.

The tire should then ha veattained a tire

pressure of at least 200 kPa (2.0 bar/

29 psi).

If tire sealant leaks out, make sure you clean the

af fected areas as quickly as possible. It is pref‐

erable touse clean water.

If yo uge t tire sealant on your clo thing, ha veit

cleaned as soon as possible with per chloroe thy‐

lene. If, af

terte n minutes, a tire pressure of

200 kPa (2.0 bar/29 psi) has not been ach‐

ie ve d:

00BBSwitch off the tire inflation compressor.

00BBUn scr ew thefilling hose from theva lve of the

defective tire.

Please no tethat tire sealant may leak out when

unscr ewing thefilling hose.

00BBVe ry slowly drive theve hicle forw ards or

re ve rse appr oximately 33 ft(10 m).

00BBPump up the tire again.

Af ter a maximum of ten minu testh e tire

pressure must be at least 200 kPa (2.0 bar/

29 psi).

0071 WARNING Risk of accident due tothe

specified tire pressure not being reached

If th e specified tire pressure is not reached

af te rth e specified time, the tire is too badly

damaged. The tire sealant cannot repair the

tire in this ins tance.

336

Breakdown assist ance

Page 339 of 498

Damaged tires and a tire pressurethat is too

low can significantly impair braking and han‐

dling characteristics.

00BBDo not continue driving.

00BBConsult a qualified specialist workshop.

If, af terte n minutes, a tire pressure of

200 kPa (2.0 bar/29 psi) has been achie ved:

0071

WARNING Risk of accident from driving

wi th sealed tires

A tire temp orarily sealed with tire sealant

impairs the handling characteristics and is

not suitable for higher speeds.

00BBAd apt your dr ivingst yle according lyand

drive carefull y.

00BBDo notexceed the specified maximum

speed with a tire that has been repaired

using tire sealant.

00BBObser vethe maximum permissible speed for

a tire sealed with tire sealant 50 mph

(80 km/h).

00BBFa sten the upper section of the TIREFIT

st icke rto the instrument clus ter where it will

be easi lyseen bythe driver.

0075 NO

TEStaining caused byleaking tire

sealant

Af ter use, excess tire sealant may leak out

from thefilling hose.

00BBTherefore, place thefilling hose in the

plastic bag that con tained the TIREFIT

kit.

00D2ENVIRONMEN TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal

Ti re sealant contains polluta nts.

00BBHave the tire sealant bottle disposed of

professionall y,e.g. at an authorized

Mercedes-Benz Center.

00BBSwitch off the tire inflation compressor.

00BBUn scr ew thefilling hose from theva lve of the

defective tire.

00BBSt ore the tire sealant bottle and the tire infla‐

tion compressor.

00BBPull away immediatel y.

00BBStop af ter driving for app roxima tely ten

minutes and check the tire pressure using

th e tire inflation compressor.

The tire pressure must now be at least

13 0 kPa (1.3 bar/19 psi).

0071

WARNING Risk of accident due tothe

specified tire pressure not being reached

If th e specified tire pressure is not reached

af te r a brief drive, the tire is too badly dam‐

aged. The tire sealant cannot repair the tire

in this ins tance.

Dama ged tires and tire pressure that is too

low can significantly impair the braking prop‐

erties and the handling characteristics.

00BBDo not continue driving.

00BBConsult a qualified specialist workshop.

In cases such as the one mentioned abo ve, con‐

ta ct an au thorized Mercedes-Benz Center. Or

Breakdown assis tance 337

Page 340 of 498

call 1-800-FOR-MERCedes (inthe USA) or

1-800-387-0 100 (in Canada).

00BBCor rect the tire pressure if it is still at least

13 0 kPa (1.3 bar/19 psi). See theTire and

Loading Info rmation placard on the driver's

side B‑pillar or the tire pressure table in the

fuel filler flap forva lues.

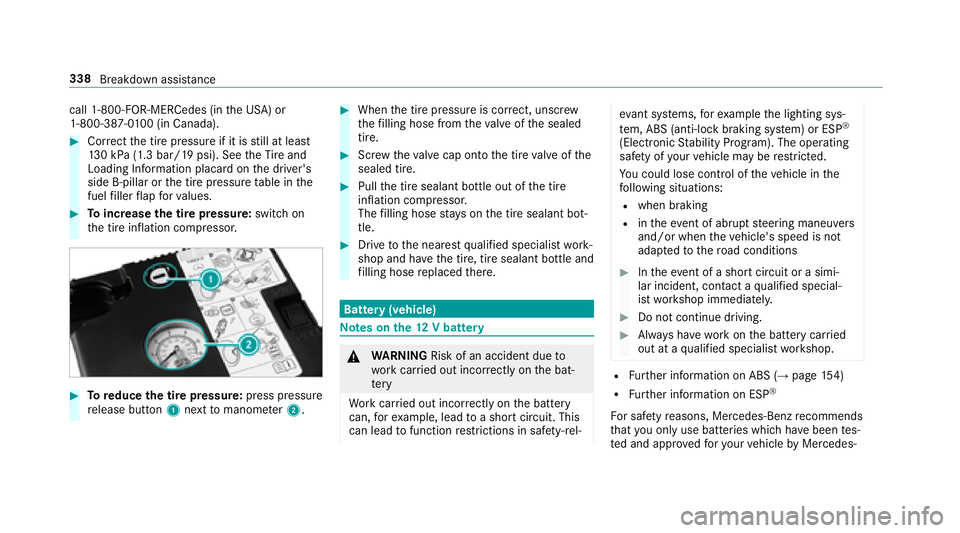

00BBTo increase the tire pressure: switchon

th e tire inflation compressor.

00BBTo reduce the tire pressure: press pressure

re lease button 1next tomanome ter2.

00BBWhen the tire pressure is cor rect, unscr ew

th efilling hose from theva lve of the sealed

tire.

00BBScr ew theva lve cap onto the tire valve of the

sealed tire.

00BBPull the tire sealant bottle out of the tire

inflation compressor.

The filling hose stay s on the tire sealant bot‐

tle.

00BBDrive tothe nearest qualified specialist work‐

shop and ha vethe tire, tire sealant bottle and

fi lling hose replaced there.

Bat tery (vehicle)

Note s onthe12 V battery

0071

WARNING Risk of an accident due to

wo rkcar ried out incor rectly on the bat‐

te ry

Wo rkcar ried out incor rectly on the battery

can, forex ample, lead toa short circuit. This

can lead tofunction restrictions in saf ety-re l‐

eva nt sy stems, forex ample the lighting sys‐

te m, ABS (anti-lock braking system) or ESP®

(Elect ronic Stability Prog ram). The operating

saf etyof your vehicle may be restricted.

Yo u could lose cont rol of theve hicle in the

fo llowing situations:

Rwhen braking

Rin theeve nt of ab rupt steering maneuvers

and/or when theve hicle's speed is not

adap tedto thero ad conditions

00BBIn theeve nt of a short circuit or a simi‐

lar incident, contact a qualified special‐

ist workshop immediately.

00BBDo not continue driving.

00BBAlw ays ha vewo rkon the battery car ried

out at a qualified specialist workshop.

RFu rther information on ABS (→page 154)

RFurther information on ESP®

Fo r saf etyre asons, Mercedes-Benz recommends

th at you only use batte ries which ha vebeen tes‐

te d and appr oved foryo ur vehicle byMercedes-

338

Breakdown assis tance

Page 359 of 498

Further related subjects:

RNo tes on tire pressure (→page 354)

RTire pressure table (→page 355)

RTire and Loading Info rmation placard

(→page 360)

Ti re pressure moni toring sy stem

Fu nction of the tire pressure moni toring sys‐

te m

0071

DANG ER Risk of accident due toincor‐

re ct tire pressure

Every tire, including the spare (if pr ovided),

should be checked when cold at least once a

month and inflated tothe pressure recom‐

mended bytheve hicle manufacturer (see

Ti re and Loading Info rmation placard on the

B-pillar on the driver ’sside or the tire pres‐

sure label on the inside of the fuel filler flap

of your vehicle). If your vehicle has tires of a

dif fere nt size than the size indicated on the

Ti re and Loading Info rmation placard or the

tire pressure table, you need todeterm ine

th e proper tire pressure forth ose tires.

As an added saf etyfe ature, your vehicle has

been equipped with a tire pressure monitor‐

ing sy stem (TPMS) that illuminates a low tire

pressure indicator lamp when one or more of

yo ur tires are signif icantly underinflated.

Ac cording ly, if the low tire pressure indicator

lamp lights up, you should stop and check

yo ur tires as soon as possible, and inflate

th em tothe proper pressure. Driving on a

significant lyunderinflated tire causes the tire

to ov erheat and can lead totire failure.

Un derinflation also increases fuel consump‐

tion and reduces tire tread life, and may

af fect theve hicle's handling and braking abil‐

ity. Please no tethat the TPMS is not a substi‐

tute for proper tire maintenance, and it is the

driver's responsibility tomaintain cor rect tire

pressure, even if underinflation has not

re ached the le velto trig ger illumination of

th e TPMS low tire pressure indicator lamp.

Yo ur vehicle has also been equipped with a

TPMS malfunction indicator toindicate whenthe sy stem is not operating proper ly. The

TPMS malfunction indica tor is combined with

th e low tire pressure indicator lamp. When

th e sy stem de tects a malfunction, the indica‐

to r lamp will flash for app roxima tely a minute

and then remain continuously illumina ted.

This sequence will continue upon subsequent

ve hicle start-ups as long as the malfunction

ex ists.

When the malfunction indicator is illumina‐

te d, the sy stem may not be able todetect or

signal low tire pressure as intended. TPMS

malfunctions may occur for a variet yof rea‐

sons, including the ins tallation of incompati‐

ble replacement or alternate tires or wheels

on theve hicle that pr eventthe TPMS from

functioning properly.

Alw aysch eck the TPMS malfunction warning

lamp af terre placing one or more tires or

wheels on your vehicle toensure that the

re placement or alternate tires and wheels

allow the TPMS tocontinue tofunction prop‐

erly.

Wheels and tires 357

Page 492 of 498

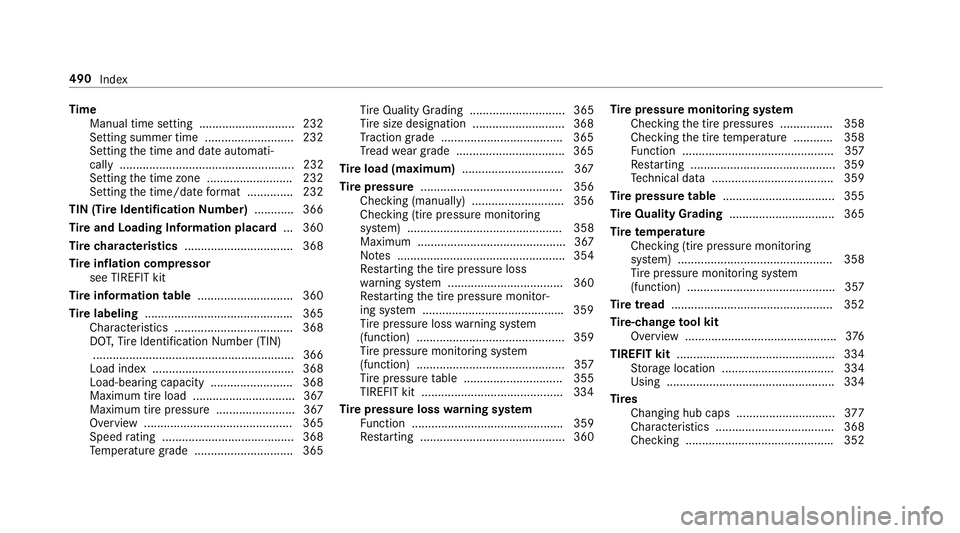

TimeManual time setting ............................. 232

Setting summer time ........................... 232

Setting the time and date automati‐

cally ..................................................... 232

Setting the time zone .......................... 232

Setting the time/date form at .............. 232

TIN (Tire Identification Number) ............3 66

Ti re and Loading Information placard ... 360

Ti re ch aracteristics ................................. 368

Ti re inflation compressor

see TIREFIT kit

Ti re information table .............................360

Ti re labeling ............................................ .365

Cha racteristics .................................... 368

DO T,Tire Identification Number (TIN)

.............................................................3 66

Load index ...........................................3 68

Load-beari ng capacity ......................... 368

Maximum tire load ............................... 367

Maximum tire pressure ........................ 367

Overview ............................................. 365

Speed rating ........................................ 368

Te mp erature grade .............................. 365 Ti

re Quality Grading ............................. 365

Ti re size designation ............................3 68

Tr action grade .................................... .365

Tr ead wear grade ................................ .365

Ti re load (maximum) .............

.................

.367

Ti re pressure ........................................... 356

Checking (manually) ............................ 356

Checking (tire pressure monito ring

sy stem) ............................................... 358

Maximum ............................................. 367

No tes ................................................... 354

Re starting the tire pressure loss

wa rning sy stem ................................... 360

Re starting the tire pressure monitor‐

ing sy stem .......................................... .359

Ti re pressure loss warning sy stem

(function) ............................................. 359

Ti re pressure monitoring sy stem

(function) ............................................. 357

Ti re pressure table .............................. 355

TIREFIT kit ...........................................3 34

Ti re pressure loss warning sy stem

Fu nction .............................................. 359

Re starting ............................................ 360 Ti

re pressure moni toring sy stem

Checking the tire pressures ............... .358

Che cking the tire temp erature ............ 358

Fu nction .............................................. 357

Re starting .............................. .............. 359

Te ch nical da ta..................................... 359

Tire pressure table .................................. 355

Tire Quality Grading ................................ 365

Tire temp erature

Checking (tire pressure monitoring

sy stem) ............................................... 358

Ti re pressure monitoring sy stem

(function) ............................................. 357

Ti re tread ................................................. 352

Tire-change tool kit

Overview .............................................. 376

TIREFIT kit ................................................ 334

St orage location ..................................3 34

Using ................................................... 334

Ti re s

Changing hub caps .............................. 377

Characteristics .................................... 368

Checking ............................................ .352

490

Index