clock MERCEDES-BENZ E-CLASS ESTATE 2017 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E-CLASS ESTATE, Model: MERCEDES-BENZ E-CLASS ESTATE 2017Pages: 585, PDF Size: 11.8 MB

Page 444 of 585

R

Centring pin

R Folding wheel chock

R Ratche tfor jack

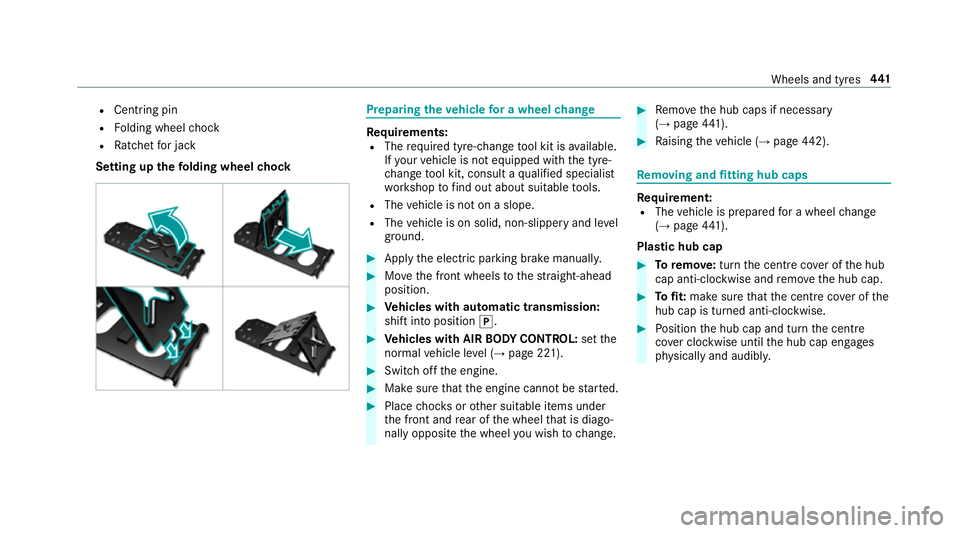

Setting up thef olding wheel chock Prepa

ring thev ehicle foraw heelchange Re

quirements:

R The requ ired tyre-chang etool kit is available.

If yo ur vehicle is no tequipped wit hthe tyre-

ch ang etool kit, consult aqualified specialist

wo rkshop tofind ou tabout suitable tools.

R The vehicle is no tonaslope.

R The vehicle is on solid, non-slipper yand le vel

ground. #

Apply thee lectric parking brak emanually. #

Movethef ront wheels tothes traight-ahead

position. #

Vehicles with automatic transmission:

shif tint op osition j. #

Vehicles with AIRB ODYC ONT ROL:setthe

normal vehicle le vel(→pag e221). #

Swit chofft he engine. #

Mak esuret hat thee ngine cann otbe star ted. #

Place choc ks orother suitable items under

th ef ront and rear of thew heel that is diago‐

nall yopposit ethe wheel youw ish tochange. #

Remo vetheh ub caps if necessary

(→ pag e441). #

Raising thev ehicle (→ page442). Re

moving and fittin ghub caps Re

quirement:

R The vehicle is prepared foraw heelchange

(→ pag e441).

Plastic hub cap #

Toremo ve: turnthe centre coveroft he hub

cap anti-clockwise and remo vetheh ub cap. #

Tofit: mak esuret hat thec ent recoveroft he

hub cap is turned anti-clockwise. #

Position theh ub cap and tur nthe centre

co verc lockwise until theh ub cap engages

ph ysicall yand audibly. Wheels and tyres

441

Page 445 of 585

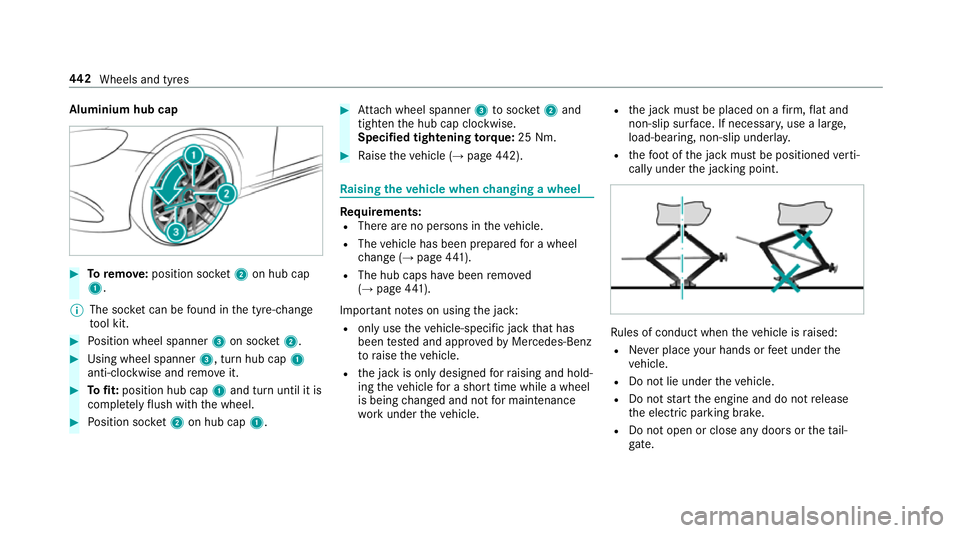

Aluminiu

mhubcap #

Toremo ve: positio nsocket 2on hu bcap

1.

% The soc ketc an be found in thet yre-change

to ol kit. #

Position wheel spanner 3on soc ket2. #

Using whee lspa nner 3,turnh ub cap 1

anti-clo ckwise and remo veit. #

Tofit: position hub cap 1and tur nuntil it is

comple tely flush wit hthe wheel. #

Position soc ket2on hu bcap 1. #

Attach wheel spanner 3tosoc ket 2and

tighten theh ub cap clockwise.

Specified tightening torq ue: 25 Nm. #

Raise thev ehicle (→ page442). Ra

ising thev ehicle when changing awheel Re

quirements:

R Ther eareno persons in thev ehicle.

R The vehicle has been prepared foraw heel

ch ang e(→pag e441).

R Theh ub cap shave been remo ved

( → pag e441).

Impor tant no tesonu singthej ack:

R onlyusethev ehicle-specific jac kthat has

been tested and appr ovedbyM ercedes-Benz

to raise thev ehicle.

R thej ackiso nlyd esigned forr aising and hold‐

ing thev ehicle foras horttime while awheel

is being changed and no tfor maintenance

wo rkunder thev ehicle. R

thej ackm ustbep laced on afirm, flat and

non-slip sur face. If necessar y,use alarge,

load-bearing, non-slip underla y.

R thef ootoft he jac kmustbep ositioned verti‐

call yunder thej acking point. Ru

les of conduct when thev ehicle is raised:

R Neverp lace your hands or feet under the

ve hicle.

R Do no tlie under thev ehicle.

R Do no tstar tthe engine and do no trelease

th ee lectric parking brake.

R Do no topen or close an ydoor sort hetail‐

ga te. 442

Wheels and tyres

Page 447 of 585

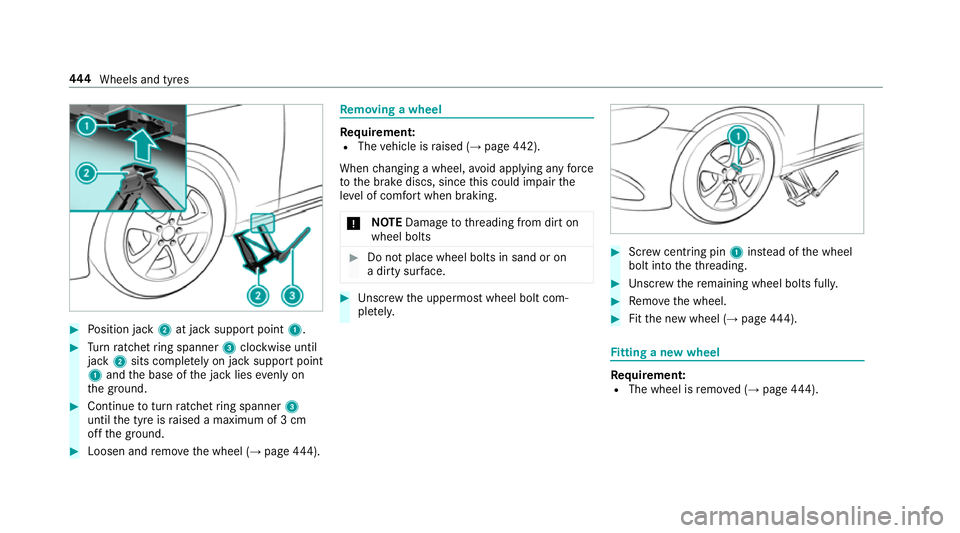

#

Position jack 2at jac ksuppor tpoint 1. #

Turn ratche tring sp anner 3clockwise until

jack 2sitsc omple tely on ja cksuppor tpoint

1 and theb ase of thej ackl ies evenlyon

th eg round. #

Continue totur nratche tring sp anner 3

unti lthe tyr eisraised amaximum of 3cm

of ft he ground. #

Loosen and remo vethew heel (→ page444). Re

moving awheel Re

quirement:

R The vehicle is raised (→ page442).

When changing awheel, avoid applying an yforce

to theb rake discs, since this could impair the

le ve lofc omfort when braking.

* NO

TEDama getothre adin gfromd irton

wheel bolts #

Do no tplace wheel bolt sinsandoron

ad irty sur face. #

Unscr ew theu ppermos twheel bolt com‐

ple tely. #

Screw centring pin 1instead of thew heel

bolt int othe thre ading. #

Unscr ew ther emaining wheel bolt sfully. #

Remo vethew heel. #

Fitthen ew wheel (→ page444). Fi

ttin gan ewwheel Re

quirement:

R The wheel is remo ved( →pag e444). 444

Wheels and tyres

Page 448 of 585

&

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can caus ethe wheel bolts/

wheel nuts tocome loose.

As aresult, youc ould lose awheel while driv‐

ing. #

Nevero il or grease thet hreads. #

Inthee vent of damag etothethre ads,

con tact aq ualified specialis tworks hop

immediatel y. #

Have thed amaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do no tcontinue driving. #

Obser vethei nformation on thec hoice of

tyres (→ page436).

Fo rtyres wit haspecified direction of rotation,

an ar rowonthes ide wall of thet yrei ndicates

th ec orrect di rection of rotation. Obse rvet he

direction of rotatio nw henf itting. #

Slide thew heel tobe mounted ont othe cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

whee lbolts and nuts

If yo ut ighten thew heel bolts or wheel nuts

when thev ehicle is raised, thej ackc ould tip. #

Onlytighten wheel bolts or wheel nuts

when thev ehicle is on theg round. #

Fors afet yr easons, onl yuse wheel bolts

whic hhaveb een appr ovedbyM ercedes-

Benz and fort he wheel in question. #

Tighten thew heel bolts until they aref inger-

tight. #

Unscr ew thec ent ring pin. #

Tighten thel astw heel bolt until it is finger-

tight. #

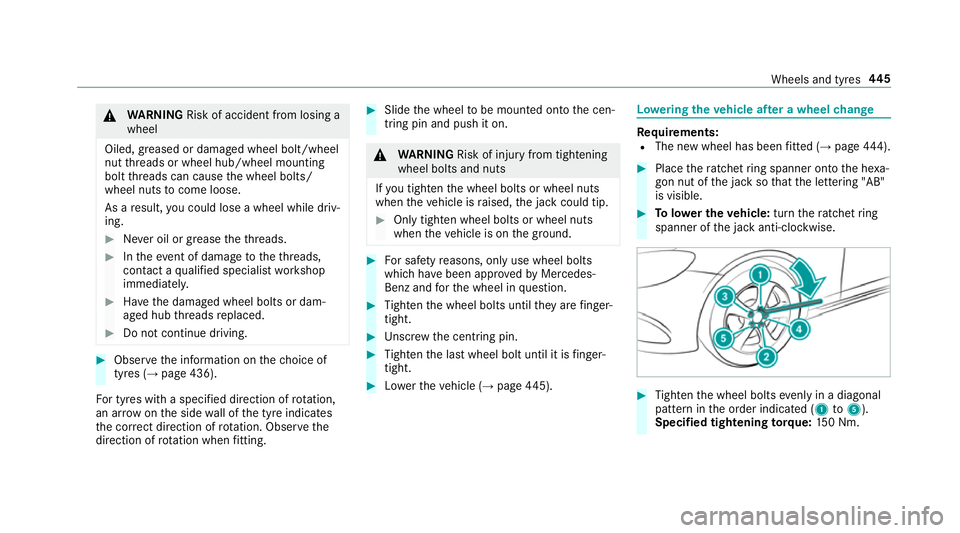

Lowe rthe vehicle (→ page445). Lo

weri ngthev ehicle af teraw heelchange Re

quirements:

R The ne wwheel has been fitted (→ page 444 ). #

Place ther atche tring sp anner ont othe he xa‐

gon nut of thej acksot hatthel ette ring "AB"

is visible. #

Tolowe rthe vehicle: turnthe ratche tring

sp an ner of thej acka nti-clockwise. #

Tighten thew heel bolts evenlyinad iagonal

patter ninthe order indicated (1 to5 ).

Specified tightening torq ue: 150N m. Wheels and tyres

445