Clock MERCEDES-BENZ E-Class SEDAN 2017 W213 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E-Class SEDAN, Model: MERCEDES-BENZ E-Class SEDAN 2017 W213Pages: 446, PDF Size: 6.23 MB

Page 98 of 446

RSecurethel oad using thet ie-down eyes and

distribut ethe load evenly.

Interior stow agec om partments

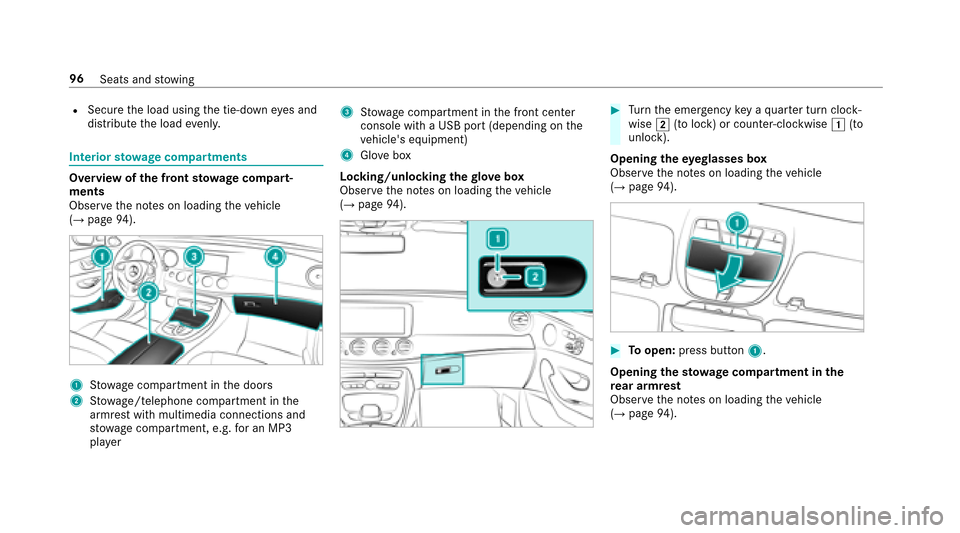

Overvie wofthe front stowage compa rt‐

ments

Observ ethe no tesonl oading thev ehicle

(

→pag e94).

1St ow agec ompartment in thed oors

2Stow age/telephonec ompartment inthe

armres twithm ultimedia connections and

stow agec ompartment ,e.g.f or an MP3

pla yer

3Stow agec ompartment in thef ront center

console wit haUSB por t(depending on the

ve hicle's equipment)

4Glo vebox

Locking/unlocking theg love box

Obser vethen otes on loading thev ehicle

(

→pag e94).

#Turn thee mer gency keyaq uartert urnc lock‐

wise 2(tol ock) or counter-clockwise 1(to

unlock).

Opening thee yeglasses box

Obser vethen otes on loading thev ehicle

(

→pag e94).

#Toopen: press button 1.

Opening thes towa ge compa rtmen tint he

re ar armrest

Observ ethe no tesonl oading thev ehicle

(

→pag e94).

96

Seats and stowing

Page 142 of 446

*NO

TEDo no toverfill thef uel tank as this

ma ydamag ethe fuel sy stem.

#Onl yfillthef uel tank unti lthe pump

nozzle switches off.

* NO

TEDo no toverfill thef uel tank as oth‐

erwise fuel could spr ayout when the

pum pnozzle is remo ved.

#Onl yfillthef uel tank unti lthe pump

nozzle switches off.

Re quirement:

The vehicle mus tbeunlocked.

% Do no tget intot he vehicle again during the

re fueling process. Otherwise, electros tatic

ch arge could buil dupagain.

Obser vethen otes on operating fluids

(

→pag e344). Re

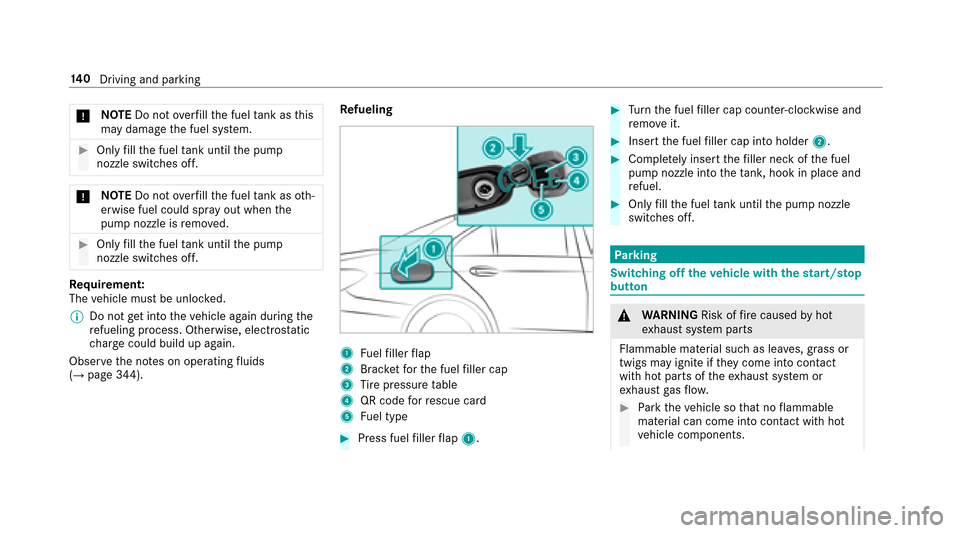

fueling

1Fuelfiller flap

2Brac ketfor thef uel filler cap

3Ti re pressur etable

4QR code forr escue card

5Fu el type

#Press fuel filler flap 1.

#Turn thef uel filler cap coun ter-clockwise and

re mo veit.

#Inser tthe fuel filler cap int oholder 2.

#Comple tely inse rtthef iller nec kofthe fuel

pum pnozzle int othe tank ,h oo kinp lace and

re fuel.

#Onl yfillthef uel tank unti lthe pum pnozzle

switches off.

Pa rking

Switching of fthe vehicl ewiththes tart/ stop

button

& WARNING Risk offire caused byhot

ex haus tsystemp arts

Flammable material suc hasleaves, grass or

twigs ma yignit eift heyc ome int ocontact

wi th hotp arts of thee xhaust system or

ex haus tgas flow .

#Park thev ehicle so that no flammable

material can com eintoc ontact wi thhot

ve hicle components.

14 0

Driving and pa rking

Page 284 of 446

#Allow thee ngine tocool of fand thor‐

oughl yclean thee ngine oil from compo‐

nen tparts befor estartin gt he vehicle.

* NO

TEEngine damag ecaused byan

incor rect oil filter ,incor rect oil or addi‐

tives

#Do no tuse engine oil soroilfilters

whic hdon otcor respond tothes pecifi‐

cation sexplicit lyprescribed fort he

service inter vals.

#Do no talter thee ngine oil or oil filter in

order toachie velonger chang einter vals

th an prescri bed.

#Do notuse additives.

#Followt he instructions in thes ervice

inter vald ispla yregarding theo il

ch ange.

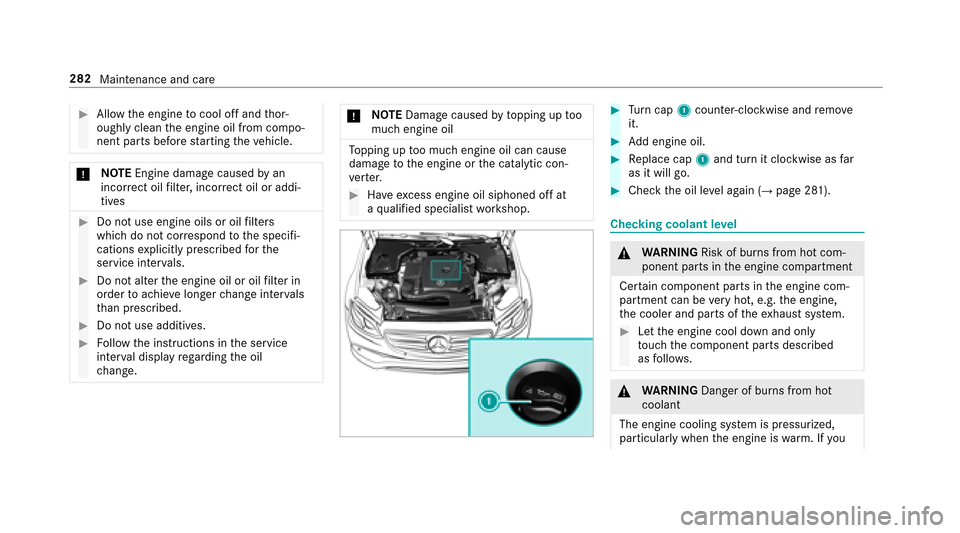

* NO

TEDama gecaused bytopping up too

muc hengine oil

Topping up toom uche ngine oil can cause

damag etothe engine or thec atalytic con‐

ve rter.

#Ha ve excess engine oil siphonedo ffat

aq ualified specialis tworks hop.

#Tu rn cap 1counter-clockwise and remo ve

it.

#Ad de ngin eoil.

#Replace cap 1and tur nitclockwise as far

as it will go.

#Chec kthe oil le vela ga in (→pag e281).

Checking coolant le vel

&

WARNING Risk of burn sfromh otcom‐

ponent parts in thee ngine compartment

Cer tain component parts in thee ngine com‐

partmen tcan be very hot, e.g. thee ngine,

th ec ooler and parts of thee xhaust system.

#Le tthe engine cool down and only

to uc ht he component parts described

as follo ws .

&

WARNING Danger of burn sfromh ot

coolant

The engine cooling sy stem is pressurized,

particularly when thee ngine is warm.Ify ou

282

Maintenance and care

Page 285 of 446

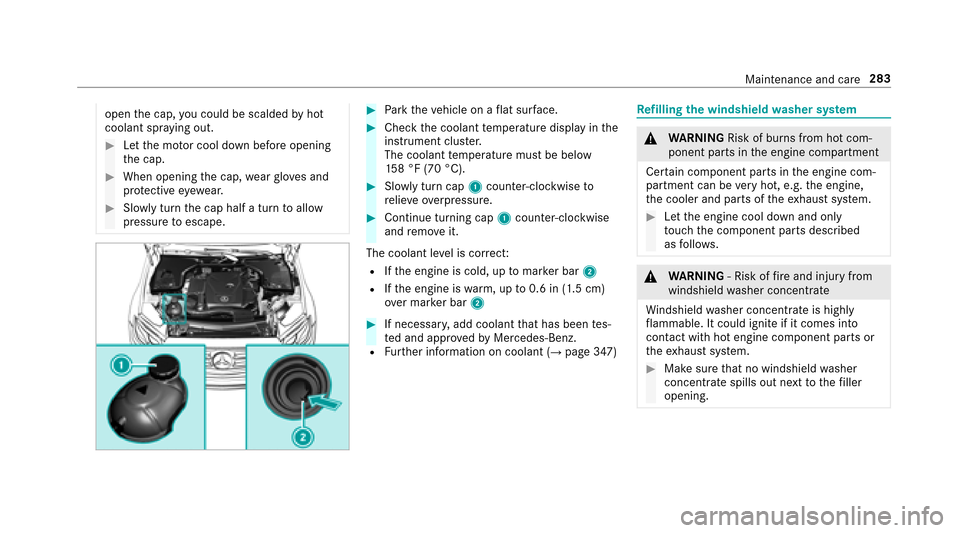

openthec ap, youc ould be scalded byhot

coolant spr aying out.

#Le tthe mo torc ool down befor eopening

th ec ap.

#When opening thec ap, wearglove sand

pr otectiv eeyewe ar.

#Slowl yturnt he cap half aturntoa llow

pressur etoescape.

#Park thev ehicle on aflat sur face.

#Chec kthe coolant temp eratur edispla yint he

instrument clus ter.

The coolant temp eratur emustbeb elow

15 8°F( 70 °C).

#Slowly tur ncap 1 counter-clockwise to

re lie ve ove rpressure.

#Continue turning cap 1counter-clockwise

and remo veit.

The coolan tleve lisc orrect:

RIfth ee ngine is cold, up tomar kerb ar2

RIfth ee ngine is warm,upt o0.6 in (1.5 cm)

ove rmarke rb ar2

#If necessar y,add coolant that has been tes‐

te da nd appr ovedbyM ercedes-Benz.

RFurther information on coolant (→pag e347)

Re filling thew indshield washer sy stem

&

WARNING Risk of burn sfromh otcom‐

ponent parts in thee ngine compartment

Cer tain component parts in thee ngine com‐

partmen tcan be very hot, e.g. thee ngine,

th ec ooler and parts of thee xhaust system.

#Le tthe engine cool down and only

to uc ht he component parts described

as follo ws .

&

WARNING ‑Riskoff irea nd injur yfrom

windshield washer concentrate

Wi ndshield washer concentrat eishighly

fl ammable. It coul dignit eifitc omes into

con tact wi thhote ngine component parts or

th ee xhaust system.

#Mak esuret hat no windshield washer

concentrat espills out next tothef iller

opening.

Maintenance and care 283

Page 309 of 446

*NO

TEDama getothed rive trai ndueto

incor rect positioning

#Do no tposition thev ehicle abo vethe

connection point of thet ranspor tvehi‐

cle.

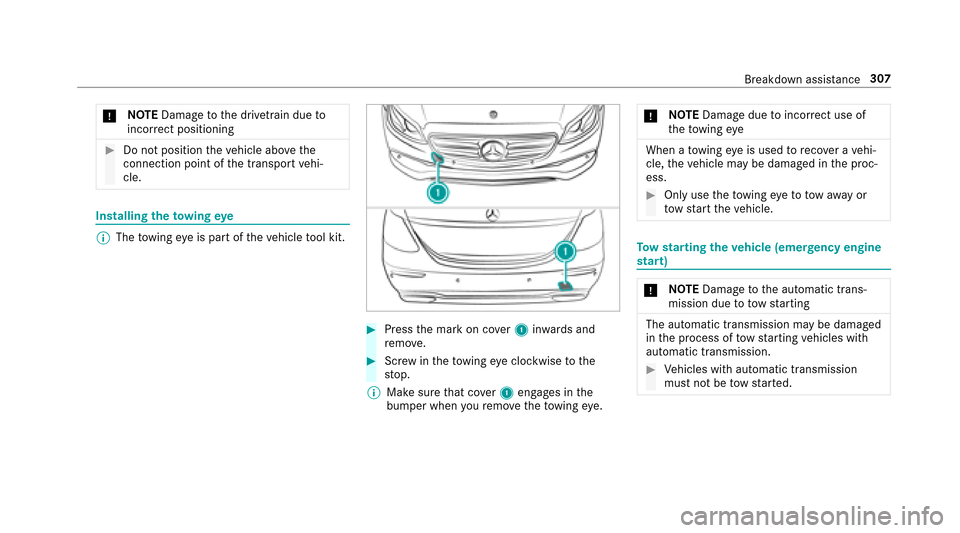

Installing thet ow ing eye

%

The towing eyeisp artoft hevehicle tool kit.

#Press them arkonc over 1 inwa rdsa nd

re mo ve.

#Scr ew inthet ow ing eye clockwise tothe

st op.

% Mak esuret hat co ver1 engages in the

bumper when your emo vethet ow ing eye. *

NO

TEDama gedue toincor rect us eof

th et ow ing eye

When atow ing eyeisu sedtoreco verav ehi‐

cle, thev ehicle ma ybedamaged in thep roc‐

ess.

#Onl yusethet ow ing eyetot owaway or

to ws tart thev ehicle.

Tows tarting thev ehicle (emer gency engine

st art)

* NO

TEDama getothea utomatic trans‐

mission due to towstarting

The automatic transmissionm aybe damaged

in thep rocess of tows tartin gv ehicles with

automatic transmission.

#Ve hicles wit hautomatic transmission

mus tnotbe tows tarted.

Breakdown assis tance 307

Page 336 of 446

Notesons toring wheels

RAf terr emoving wheels, stor et hem in acool,

dr ya nd preferably dar kplace.

RProtect thet ires from conta ct withoil, grease

or fuel.

Preparing thev ehicle foraw heelchange

Prerequisi tesRThe requ ired tire-chang etool kit is available.

If yo ur vehicle is no tequipped wit hthe tire-

ch ang etool kit, consult aqualified specialis t

wo rkshop tofind outa boutsuitable tools.

RThe vehicle is no tonaslope.

RThevehicle is on solid, non-slipper yand le vel

ground .

#Applythee lectric parking brak emanually.

#Movethef ront wheels tothes traight-ahead

position.

#Ve hicles with automatic transmission:

shif tint op osition j.

#Vehicles with AI RBODYC ONT ROL:setthe

normal vehicle le vel(→pag e171).

#Switc hoffthee ngine.

#Mak esuret hat thee ngine cannot bestar ted.

#Place choc ks orother suitable items under

th ef ront and rear of thew heel that is diago‐

nall yopposit ethe wheel youw ish tochange.

#Re mo vetheh ub caps if necessary

(→pag e334).

#Raise thev ehicle (→pag e335).

Removing and mounting hub caps

Requirements

#The vehicle is prepared foraw heelc hange

(→pag e334).

Plast ic hub cap

#Toremo ve:tur nthe center co veroft he hub

cap counter-clockwise and remo vetheh ub

cap.

#To mount: makesurethat thec enter co ver

of theh ub cap is turned counter-clockwise.

#Position theh ub cap and tur nthe center

co verc lockwise until theh ub cap engages

ph ysicall yand audibly.

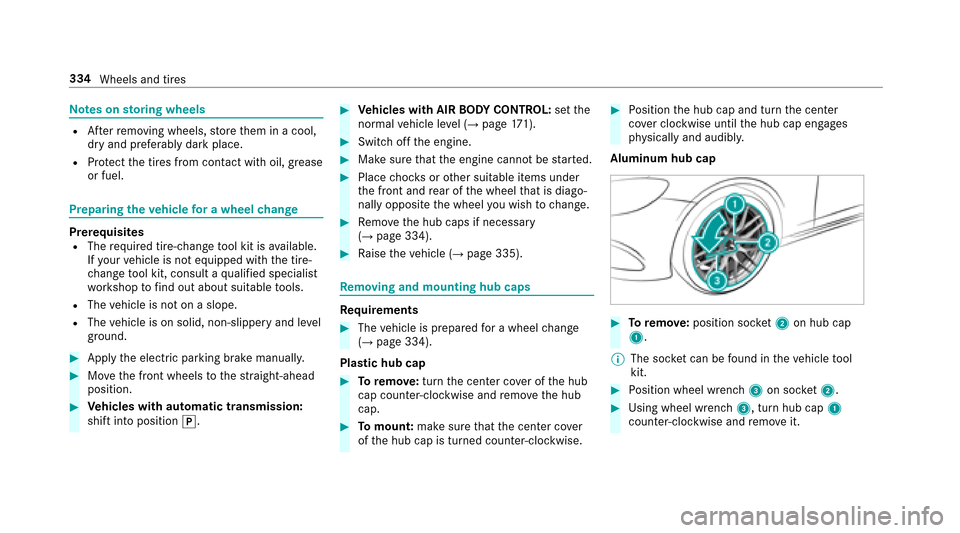

Aluminum hub cap

#To remo ve:positio nsocket2 on hubc ap

1.

% The soc ketc an be found in thev ehicle tool

kit.

#Po sition wheel wrench 3on soc ket2.

#Using whee lwrench 3,t urnh ub cap 1

counter-clo ckwise and remo veit.

334

Wheels and tires

Page 337 of 446

#Tomount: positionhub cap 1and turn

unti litisc ompletelyf lush wit hthe wheel.

#Position soc ket2 on hubc ap1.

#Position wheel wrench 3on soc ket2 and

tighten theh ub cap clockwise.

Specified tightening torq ue: 18lb-ft

(25 Nm).

#Ra ise thev ehicle (→pag e335).

Raising thev ehicle when changing awheel

RequirementsRTher eareno persons in thev ehicle.

RThe vehicle is prepared foraw heelc hange

(→pag e334).

RThe hub caps ha vebeen remo ved

(→pag e334).

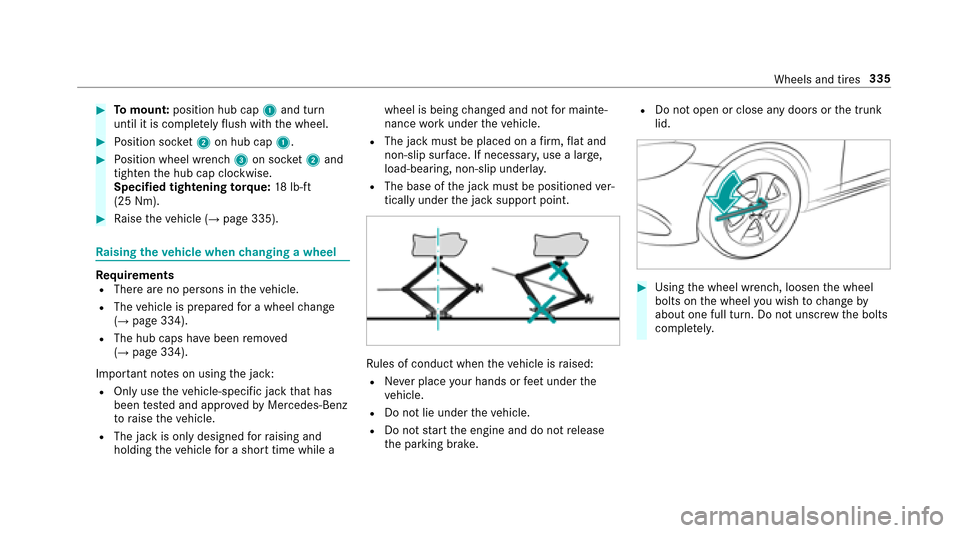

Impor tant no tesonu singthej ack:

ROnl yusethev ehicle-specific jac kthat has

been tested and appr ovedbyM ercedes-Benz

to raise thev ehicle.

RThe jac kisonlyd esigned forr aising and

holdingt hevehicle foras horttime while a whee

lisbeing changed and no tfor mainte‐

nance workunder thev ehicle.

RThe jac kmustbep laced on afirm, flat and

non-slip sur face. If necessar y,use alarge ,

load-bearing, non-slip underla y.

RThe base ofthej ackm ustbep ositioned ver‐

tically under thej acks uppor tpoint.

Rules of conduct when thev ehicle is raised:

RNe verp lace your hands or feet under the

ve hicle.

RDo no tlie under thev ehicle.

RDo no tstar tthe engine and do no trelease

th ep arking brake.

RDo no topen or close an ydoor sort he trunk

lid.

#Using thew heel wrench, loosen thew heel

bolts on thew heel youw ish tochang eby

about onef ull turn. Do no tunscr ewtheb olts

comple tely.

Wheels and tires 335

Page 338 of 446

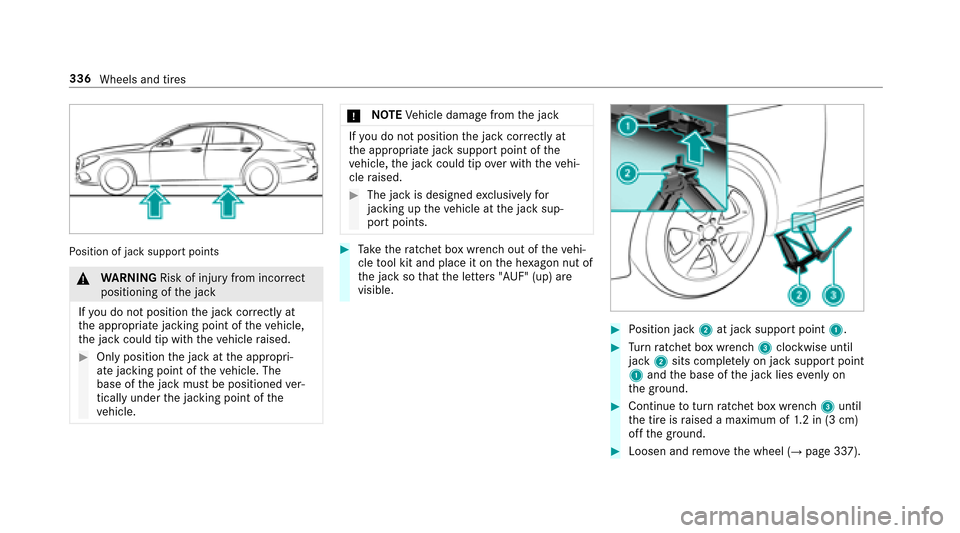

Position of jac ksuppor tpoints

&

WARNING Risk of injury from incorrect

positioning of thej ack

If yo udon otpositio nthe jac kcorrectly at

th ea ppropriat ejacking point of thev ehicle,

th ej ackc ould tip wit hthe vehicle raised.

#Onl yposition thej ackatt he appropri‐

at ej acking point of thev ehicle. The

base of thej ackm ustbep ositioned ver‐

tically under thej acking point of the

ve hicle.

* NO

TEVehicle damag efromt he jack

Ifyo udon otpositio nthe jac kcorrectl ya t

th ea ppropriat ejacks uppor tpoint of the

ve hicle, thej ackc ould tip overwitht he vehi‐

cle raised.

#The jac kisdesigned exclusively for

jacking up thev ehicle at thej acks up‐

por tpoints.

#Take ther atche tbox wrenc houtofthev ehi‐

cle tool kit and place it on theh exagon nut of

th ej acksot hatthel ette rs "AUF" (up) are

visible.

#Po sition jack 2at jac ksuppor tpoint 1.

#Turn ratche tbox wrench 3clockwise until

jack 2sitsc omple tely on ja cksuppor tpoint

1 and theb ase of thej ackl ies evenlyo n

th eg round.

#Continue totur nratche tbox wrench 3until

th et ireisr aised amaximum of 1.2i n(3c m)

of ft he ground.

#Loosen and remo vethew heel (→pag e337).

336

Wheels and tires

Page 340 of 446

#Slidethew heel tobe mounted ont othe cen‐

te ring pi nand push it on.

&

WARNING Risk of injury from tightening

whee lbolts and nuts

If yo ut ighten thew heel bolts or wheel nuts

when thev ehicle is raised, thej ackc ould tip.

#Onl ytighten wheel bolts or wheel nuts

when thev ehicle is on theg round.

#Fo rs afet yr easons, Mercedes-Benz recom‐

mend sthat youo nly use wheel boltswhich

ha ve been appr oved forM ercedes-Benz vehi‐

cles, as well as fort he wheel in question.

* NO

TEDama getopaintwor kofthe wheel

ri mw hen scr ewing on thef irst whee lbolt

If th ew heel has toom uchp layw hen scr ew‐

ing in thef irst whee lbolt, th ew heel rimp aint

can be dama ged.

#Press thew heel firm lyagains tthe

whee lhub when scr ewing on thef irst

wheel bolt.

#Ti ghten thew heel bolts until they aref inger-

tight.

#Un scr ew thec entering pin.

#Tighten thel astw heel bolt until it is finger-

tight.

#Lo we rthe vehicle(→pag e338).

Loweri ngthev ehicle af teraw heelchange

Re quirementsRThe ne wwheel has been mounted

(→pag e337).

#Place ther atche tbox wrenc hontot he he xa‐

gon nut of thej acksot hatthel ette rs "AB"

ar ev isible.

#To lowe rthe vehicle: turnthe ratche tbox

wrenc hofthe jac kcounter-clockwise.

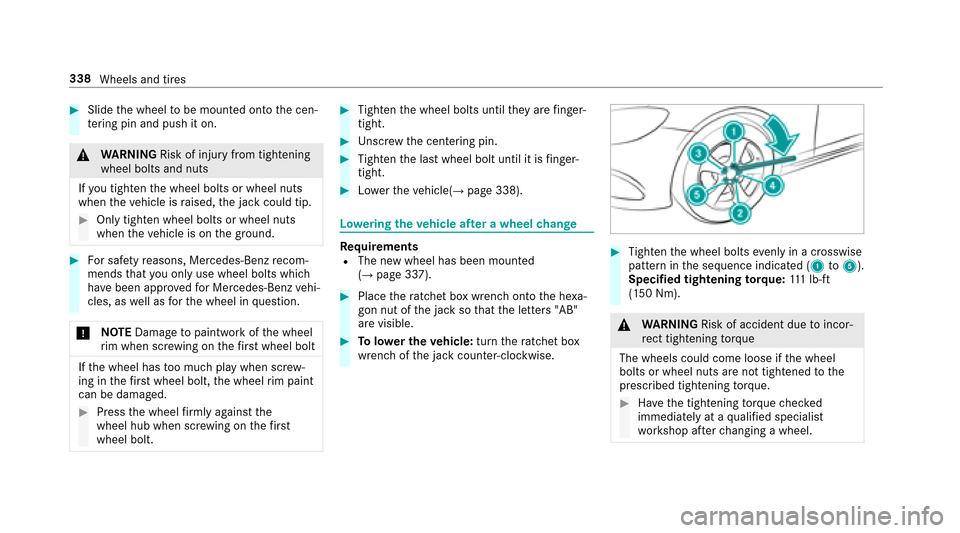

#Tighten thew heel bolts evenlyinac rosswise

patter ninthe sequence indicated (1 to5).

Specified tightening torq ue: 111 lb-ft

(150 Nm).

& WARNING Risk of accident duetoi ncor‐

re ct tigh tening torque

Th ew heelsc ould come loose if thew heel

bolts or wheel nuts ar enottightened tothe

prescribed tightenin gtorque.

#Ha ve thet ightening torque checked

immediatel yataqualified specialist

wo rkshop af terc hanging awheel.

338

Wheels and tires