MERCEDES-BENZ G-Class 2014 W463 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2014, Model line: G-Class, Model: MERCEDES-BENZ G-Class 2014 W463Pages: 354, PDF Size: 7.63 MB

Page 331 of 354

If "P" precedes the size description: light

truck tires according to U.S. manufacturing

standards.

If "T" precedes the size description: these are

compact emergency spare wheels at high tire

pressure, to be used only temporarily in an

emergency.

Tire width: tire width0043shows the nominal

tire width in millimeters.

Height-width ratio: height-width ratio0044is

the ratio between tire height and tire width.

The aspect ratio is calculated by dividing the

tire width by the tire height. The resulting

quotient is given as a percentage.

Tire code: tire code0087shows the tire type.

"R" represents radial tires; "D" represents

diagonal tires; "B" represents diagonal radial

tires.

Optionally, tires with a maximum speed of

over 149 mph (240 km/h) may have "ZR" in

the size description, depending on the

manufacturer (e.g. 245/40 ZR 18).

Rim diameter: rim diameter0085is the

diameter of the bead seat, not the diameter

of the rim flange. The rim diameter is

specified in inches (in).

Load bearing index: 0084load bearing index

0083 (also load index) is a numerical code that

specifies the maximum load-bearing capacity

of a tire.

Do not overload the tires by exceeding the

specified load limit. The maximum

permissible load can be found on the

vehicle's Tire and Loading Information

placard on the B-pilla ron the driver's side

(Y page 322).

Example:

Load-bearing index 91 indicates a maximum

load of 1356 lbs (615 kg) that the tires can

bear. For further information on the maximum

tire load in kilograms and pounds, see

(Y page 331).

For further information on the load bearing

index, see "Load index" (Y page 330).Speed rating:

speed rating0084specifies the

approved maximum speed of the tire.

i Tire data is vehicle-specific and may

deviate from the data in the example.

Regardless of the speed rating, always

observe the speed limits. Drive carefully and

adapt your driving style to the traffic

conditions.

i Since 2009, tires in Europe which

correspond to the noise limitations of

Directive ECE-R 117 show an >>S<<

(Sound) mark. This identification follows

the type approval number and has no

connection with the speed rating.

Summer tires Index Speed rating

Q up to 100 mph (160 km/h)

R up to 106 mph (170 km/h)

S up to 112 mph (180 km/h)

T up to 118 mph (190 km/h)

H up to 130 mph (210 km/h)

V up to 149 mph (240 km/h)

W up to 168 mph (270 km/h)

Y up to 186 mph (300 km/h)

ZR...Y up to 186 mph (300 km/h)

ZR...(..Y) over 186 mph (300 km/h)

ZR over 149 mph (240 km/h)

R

Optionally, tires with a maximum speed of

over 149 mph (240 km/h) may have "ZR"

in the size description, depending on the

manufacturer (e.g. 245/40 ZR18).

The service specification is made up of

load-bearing index 0083and speed rating

0084.

R If the size description of your tire includes

"ZR" and there are no service Tire labeling

329Wheels and tires Z

Page 332 of 354

specifications, ask the tire manufacturer in

order to find out the maximum speed.

If a service specification is available, the

maximum speed is limited according to the

speed rating in the service specification.

Example: 245/40 ZR 18 97 Y.In this

example, "97 Y" is the service specification.

The letter "Y" represents the speed rating

and the maximum speed of the tire is

limited to 186 mph(300 km/h).

R The size description for all tires with

maximum speeds of over 186 mph

(300 km/h) must include "ZR" andthe

service specification must be given in

parentheses. Example:

275/40 ZR 18 (99 Y). The speed rating "(Y)"

indicates that the maximum speed of the

tire is over 186 mph (300 km/h). Ask the

tire manufacturer about the maximum

speed.

All-weather tires and winter tires Index Speed rating

Q M+S

4 up to 100 mph (160 km/h)

T M+S

4 up to 118 mph (190 km/h)

H M+S

4 up to 130 mph (210 km/h)

V M+S

4 up to 149 mph (240 km/h)

i

Not all tires with the M+S marking provide

the driving characteristics of winter tires.

In addition to the M+S marking, winter tires

also have the 004Dsnowflake symbol on

the tire wall. Tires with this marking fulfill

the requirements of the Rubber

Manufacturers Association (RMA) and the

Rubber Association of Canada (RAC).

These tires have been developed

specifically for driving on snow.

When the electronic speed limiter is set, your

vehicle is prevented from exceeding 130 mph

(210 km/h). The speed rating of tires mounted at the

factory may be higher than the maximum

speed that the electronic speed limiter

permits.

Make sure that your tires have the required

speed rating, e.g. when buying new tires. The

required speed rating for your vehicle can be

found in the "Tires" section (Y

page 340).

Further information about reading tire data

can be obtained from any qualified specialist

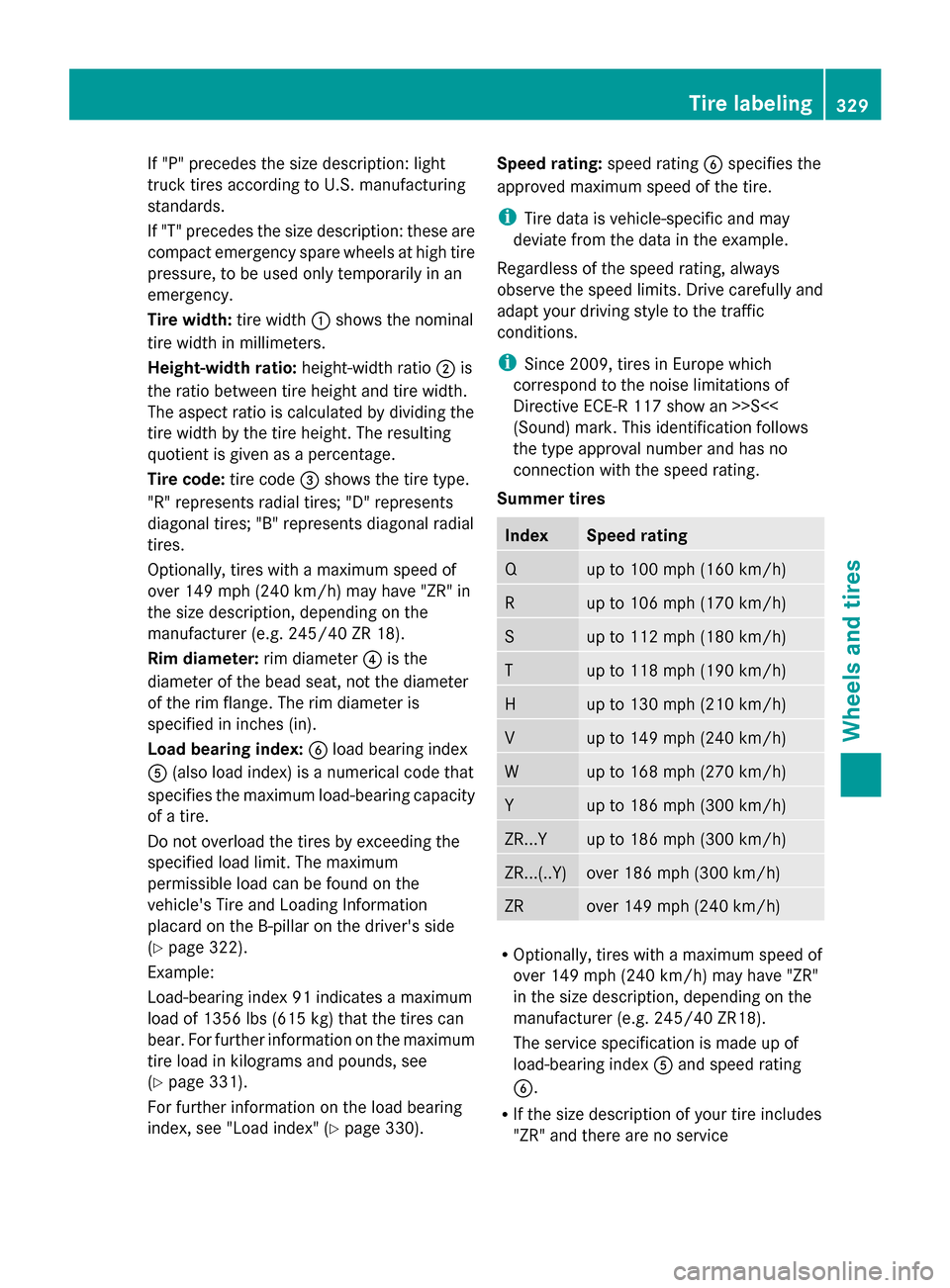

workshop. Load index

In addition to the load bearing index, load

rating

0043may be imprinted after the letters

that identify speed rating 0084on the sidewall

of the tire (Y page 328).

R If no specification is given: no text (as in the

example above), represents a standard

load (SL) tire

R XL or Extra Load: represents a reinforced

tire

R Light Load: represents a light load tire

R C, D, E: represents a load range that

depends on the maximum load that the tire

can carry at a certain pressure

i Tire data is vehicle-specific and may

deviate from the data in the example.

4 Or M+S004D for winter tires.330

Tire labelingWheels and tires

Page 333 of 354

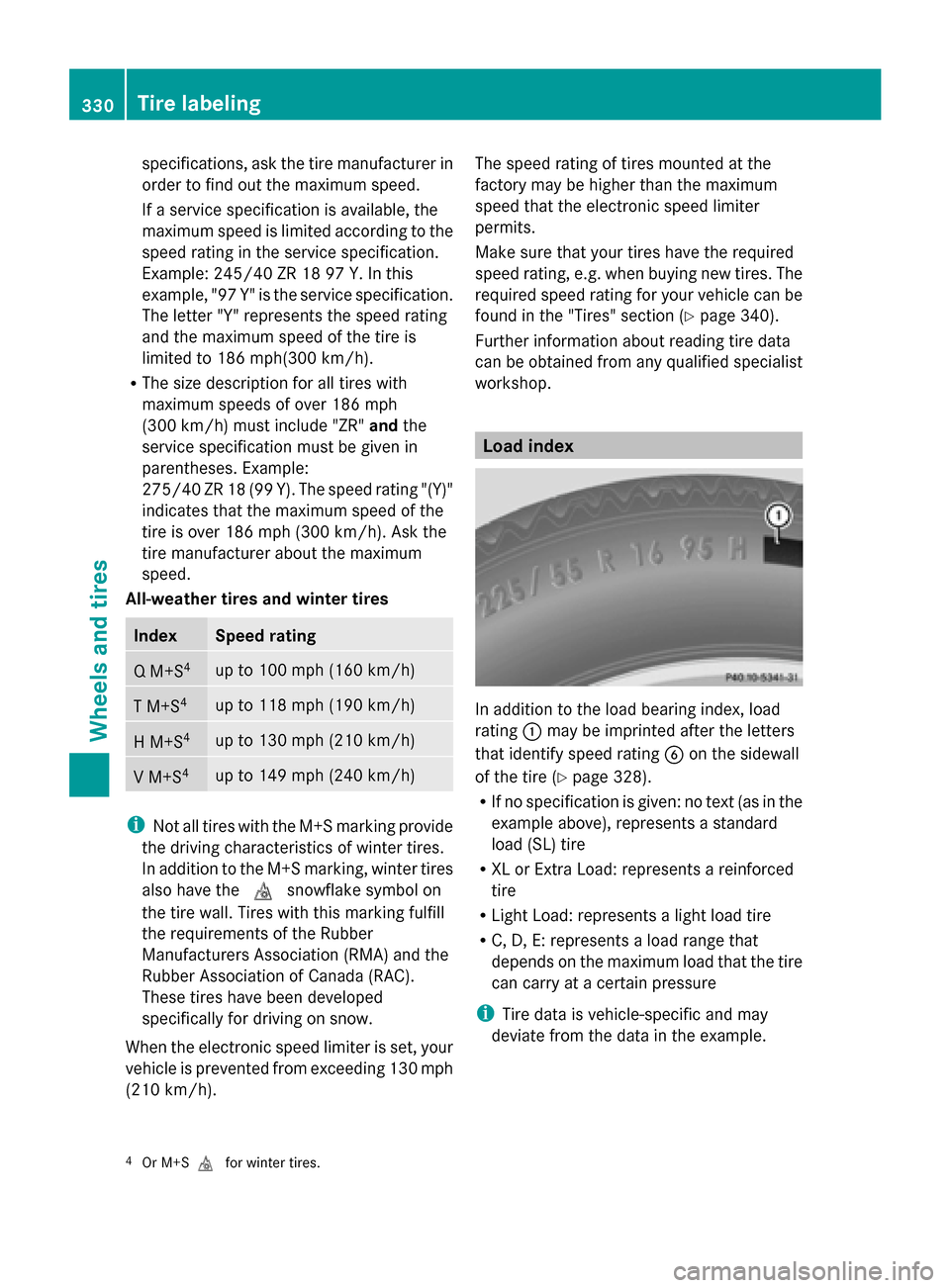

Maximum load rating

Maximum tire load

0043is the maximum

permissible weight for which the tire is

approved.

Do not overload the tires by exceeding the

specified load limit. The maximum

permissible load can be found on the

vehicle's Tire and Loading Information

placard on the B-pillar on the driver's side

(Y page 322).

i The actual values for tires are vehicle-

specific and may deviate from the values in

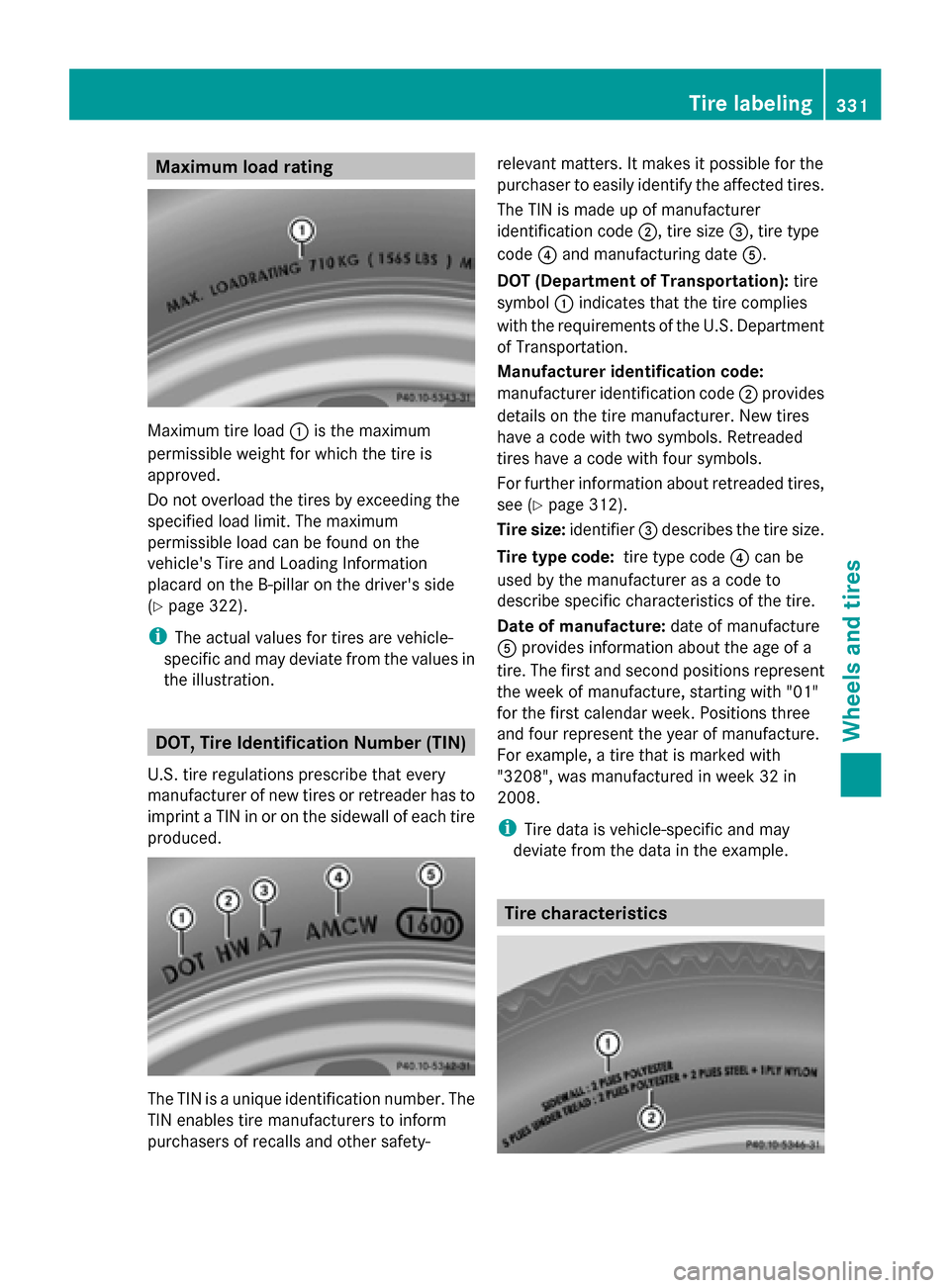

the illustration. DOT, Tire Identification Number (TIN)

U.S. tire regulations prescribe that every

manufacturer of new tires or retreader has to

imprint a TIN in or on the sidewall of each tire

produced. The TIN is a unique identification number. The

TIN enables tire manufacturers to inform

purchasers of recalls and other safety- relevant matters. It makes it possible for the

purchaser to easily identify the affected tires.

The TIN is made up of manufacturer

identification code

0044, tire size0087, tire type

code 0085and manufacturing date 0083.

DOT (Department of Transportation): tire

symbol 0043indicates that the tire complies

with the requirements of the U.S. Department

of Transportation.

Manufacturer identification code:

manufacturer identification code 0044provides

details on the tire manufacturer. New tires

have a code with two symbols. Retreaded

tires have a code with four symbols.

For further information about retreaded tires,

see (Y page 312).

Tire size: identifier0087describes the tire size.

Tire type code: tire type code0085can be

used by the manufacturer as a code to

describe specific characteristics of the tire.

Date of manufacture: date of manufacture

0083 provides information about the age of a

tire. The first and second positions represent

the week of manufacture, starting with "01"

for the first calendar week. Positions three

and four represent the year of manufacture.

For example, a tire that is marked with

"3208", was manufactured in week 32 in

2008.

i Tire data is vehicle-specific and may

deviate from the data in the example. Tire characteristics Tire labeling

331Wheels and tires Z

Page 334 of 354

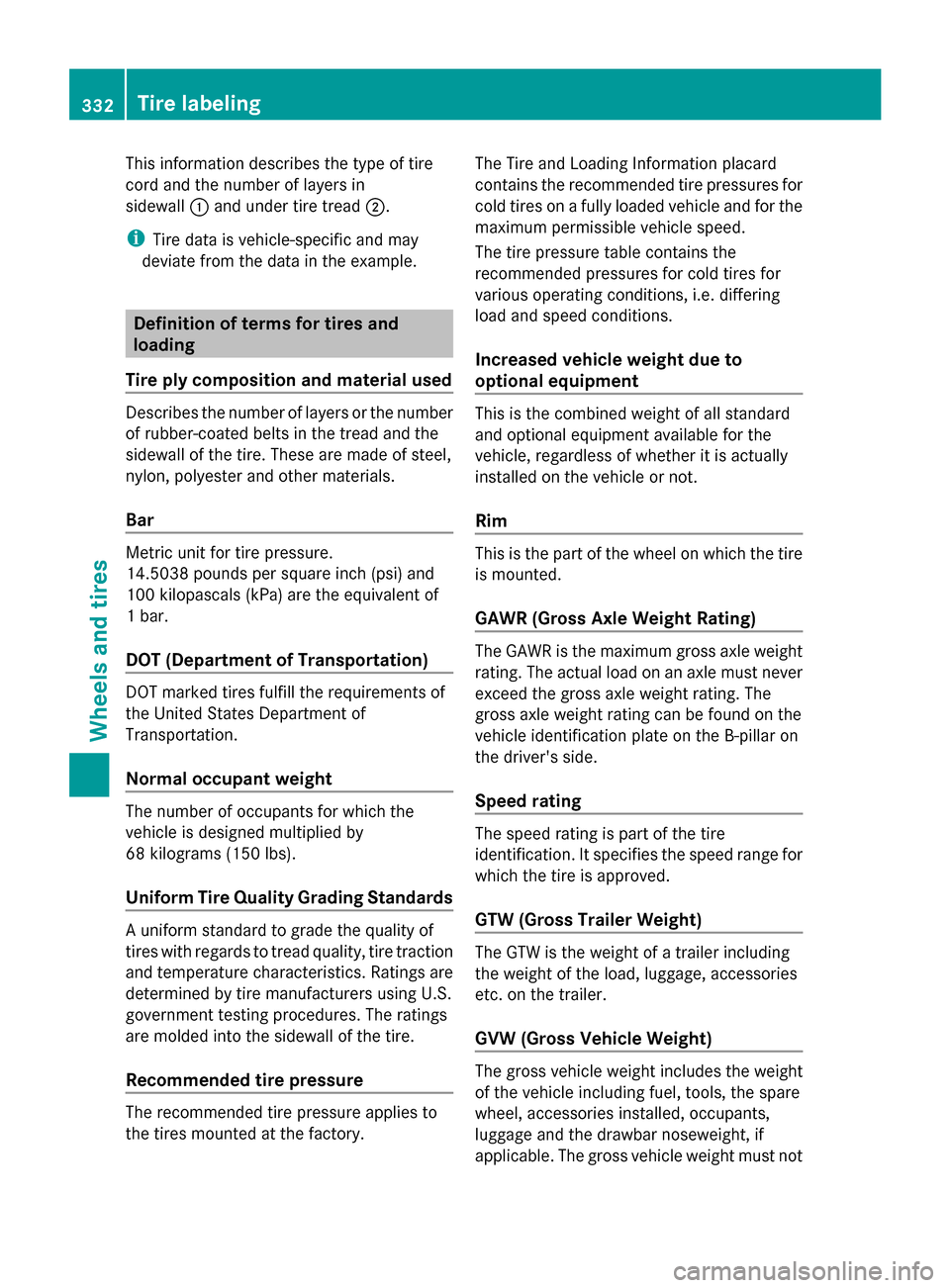

This information describes the type of tire

cord and the number of layers in

sidewall 0043and under tire tread 0044.

i Tire data is vehicle-specific and may

deviate from the data in the example. Definition of terms for tires and

loading

Tire ply composition and material used Describes the number of layers or the number

of rubber-coated belts in the tread and the

sidewall of the tire. These are made of steel,

nylon, polyester and other materials.

Bar Metric unit for tire pressure.

14.5038 pounds per square inch (psi) and

100 kilopascals (kPa) are the equivalent of

1 bar.

DOT (Department of Transportation) DOT marked tires fulfill the requirements of

the United States Department of

Transportation.

Normal occupant weight The number of occupants for which the

vehicle is designed multiplied by

68 kilograms (150 lbs).

Uniform Tire Quality Grading Standards A uniform standard to grade the quality of

tires with regards to tread quality, tire traction

and temperature characteristics. Ratings are

determined by tire manufacturers using U.S.

government testing procedures. The ratings

are molded into the sidewall of the tire.

Recommended tire pressure The recommended tire pressure applies to

the tires mounted at the factory. The Tire and Loading Information placard

contains the recommended tire pressures for

cold tires on a fully loaded vehicle and for the

maximum permissible vehicle speed.

The tire pressure table contains the

recommended pressures for cold tires for

various operating conditions, i.e. differing

load and speed conditions.

Increased vehicle weight due to

optional equipment

This is the combined weight of all standard

and optional equipment available for the

vehicle, regardless of whether it is actually

installed on the vehicle or not.

Rim This is the part of the wheel on which the tire

is mounted.

GAWR (Gross Axle Weight Rating)

The GAWR is the maximum gross axle weight

rating. The actual load on an axle must never

exceed the gross axle weight rating. The

gross axle weight rating can be found on the

vehicle identification plate on the B-pillar on

the driver's side.

Speed rating The speed rating is part of the tire

identification. It specifies the speed range for

which the tire is approved.

GTW (Gross Trailer Weight)

The GTW is the weight of a trailer including

the weight of the load, luggage, accessories

etc. on the trailer.

GVW (Gross Vehicle Weight)

The gross vehicle weight includes the weight

of the vehicle including fuel, tools, the spare

wheel, accessories installed, occupants,

luggage and the drawbar noseweight, if

applicable. The gross vehicle weight must not332

Tire labelingWheels and tires

Page 335 of 354

exceed the gross vehicle weight rating GVWR

as specified on the vehicle identification plate

on the B-pillar on the driver's side.

GVWR (Gross Vehicle Weight Rating) The GVWR is the maximum permissible gross

weight of a fully loaded vehicle (the weight of

the vehicle including all accessories,

occupants, fuel, luggage and the drawbar

noseweight, if applicable). The gross vehicle

weight rating is specified on the vehicle

identification plate on the B-pillar on the

driver's side.

Maximum loaded vehicle weight The maximum weight is the sum of:

R

the curb weight of the vehicle

R the weight of the accessories

R the load limit

R the weight of the factory installed optional

equipment

Kilopascal (kPa) Metric unit for tire pressure. 6.9 kPa

corresponds to 1 psi. Another unit for tire

pressure is bar. 100 kilopascals (kPa) are the

equivalent of 1 bar.

Load index In addition to the load-bearing index, the load

index may also be imprinted on the sidewall

of the tire. This specifies the load-bearing

capacity more precisely.

Curb weight The weight of a vehicle with standard

equipment including the maximum capacity

of fuel, oil and coolant. It also includes the air-

conditioning system and optional equipment

if these are installed in the vehicle, but does

not include passengers or luggage. Maximum load rating The maximum tire load is the maximum

permissible weight in kilograms or lbs for

which a tire is approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one

tire.

Maximum load on one tire

Maximum load on one tire. This is calculated

by dividing the maximum axle load of one axle

by two.

PSI (pounds per square inch)

A standard unit of measure for tire pressure.

Aspect ratio

Relationship between tire height and tire

width in percent.

Tire pressure

This is pressure inside the tire applying an

outward force to each square inch of the tire's

surface. The tire pressure is specified in

pounds per square inch (psi), in kilopascal

(kPa) or in bar. The tire pressure should only

be corrected when the tires are cold.

Cold tire pressure

The tires are cold:

R

if the vehicle has been parked without

direct sunlight on the tires for at least three

hours and

R if the vehicle has not been driven further

than 1 mile (1.6 km)

Tread The part of the tire that comes into contact

with the road. Tire labeling

333Wheels and tires Z

Page 336 of 354

Bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from

coming loose from the wheel rim.

Sidewall The part of the tire between the tread and the

bead.

Weight of optional extras The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-

performance battery, are not included in the

curb weight and the weight of the

accessories.

TIN (Tire Identification Number) This is a unique identifier which can be used

by a tire manufacturer to identify tires, for

example for a product recall, and thus identify

the purchasers. The TIN is made up of the

manufacturer's identity code, tire size, tire

type code and the manufacturing date.

Load bearing index The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire.

Traction Traction is the result of friction between the

tires and the road surface.

TWR (Tongue Weight Rating) The TWR specifies the maximum permissible

weight that the ball coupling of the trailer tow

hitch can support. Treadwear indicators Narrow bars (tread wear bars) that are

distributed over the tire tread. If the tire tread

is level with the bars, the wear limit of

00CDin

(1.6 mm) has been reached.

Occupant distribution The distribution of occupants in a vehicle at

their designated seating positions.

Total load limit Nominal load and luggage load plus 150 lbs

(68 kg) multiplied by the number of seats in

the vehicle. Changing a wheel

Flat tire

The "Breakdown assistance" section

(Y page 298) contains information and notes

on how to deal with a flat tire. Rotating the wheels

G

WARNING

Rotate front and rear wheels only if the tires

are of the same dimension.

If your vehicle is equipped with mixed-size

tires (different tire dimensions front vs. rear),

tire rotation is not possible. G

WARNING

Have the tightening torque checked after

changing a wheel. The wheels could come

loose if they are not tightened to a torque of

96 lb-ft (130 Nm).

Only use genuine Mercedes-Benz wheel bolts

specified for your vehicle's rims.

! On vehicles equipped with a tire pressure

monitor, electronic components are

located in the wheel. 334

Changing a wheelWheels and tires

Page 337 of 354

Tire-mounting tools should not be used

near the valve. This could damage the

electronic components.

Only have tires changed at a qualified

specialist workshop.

Rotating front and rear wheels of differing

dimensions can render the general operating

permit invalid.

Always pay attention to the instructions and

safety notices in the section on "Changing a

wheel and mounting a spare wheel"

(Y page 335).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the

intervals in the tire manufacturer's warranty

book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to

6,000 miles(5,000 to 10,000 km), or earlier if

tire wear requires. Do not change the

direction of wheel rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressure and

reactivate the tire pressure monitor

(Y page 319) if necessary. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these

benefits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates

its correct direction of rotation.

You may mount the spare wheel against the

direction of rotation. Adhere to the time

restriction on use as well as the speed

limitation specified on the spare wheel. Storing wheels

Store tires that are not being used in a cool,

dry and preferably dark place. Protect the

tires from oil, grease, gasoline and diesel. Cleaning the wheels

G

WARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior damage

to the tires or chassis components.

Components damaged in this way may fail

unexpectedly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced

immediately. Mounting a wheel

Preparing the vehicle G

WARNING

You must remove the spare wheel from the

spare wheel carrier before lifting the vehicle.

Otherwise the vehicle could fall off the jack

and injure you or others.

X Prepare the vehicle as described

(Y page 298).

X Remove the vehicle tool kit and the jack

(Y page 296).

X Secure the vehicle to prevent it from rolling

away.

X Remove the spare wheel from the spare

wheel bracket (Y page 297).

i Vehicles without a spare wheel or

emergency spare wheel are not equipped

with a tire-change tool kit at the factory. For

more information on which tools are

required to perform a wheel change on your

vehicle e.g. lug wrench or jack, consult an

authorized Mercedes-Benz Center. Changing a wheel

335Wheels and tires Z

Page 338 of 354

Securing the vehicle to prevent it from

rolling away X

On level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change.

X On downhill gradients: place chocks or

other suitable items in front of the wheels

of the front and rear axle.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle.

! The jack is designed exclusively for

jacking up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged.

The following must be observed when raising

the vehicle:

R to raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If used

incorrectly, the jack could tip over with the

vehicle raised.

R the jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for

performing maintenance work under the

vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never

disengage the parking brake while the

vehicle is raised. R

the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

R never place your hands and feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door or the tailgate

when the vehicle is raised.

R make sure that no persons are present in

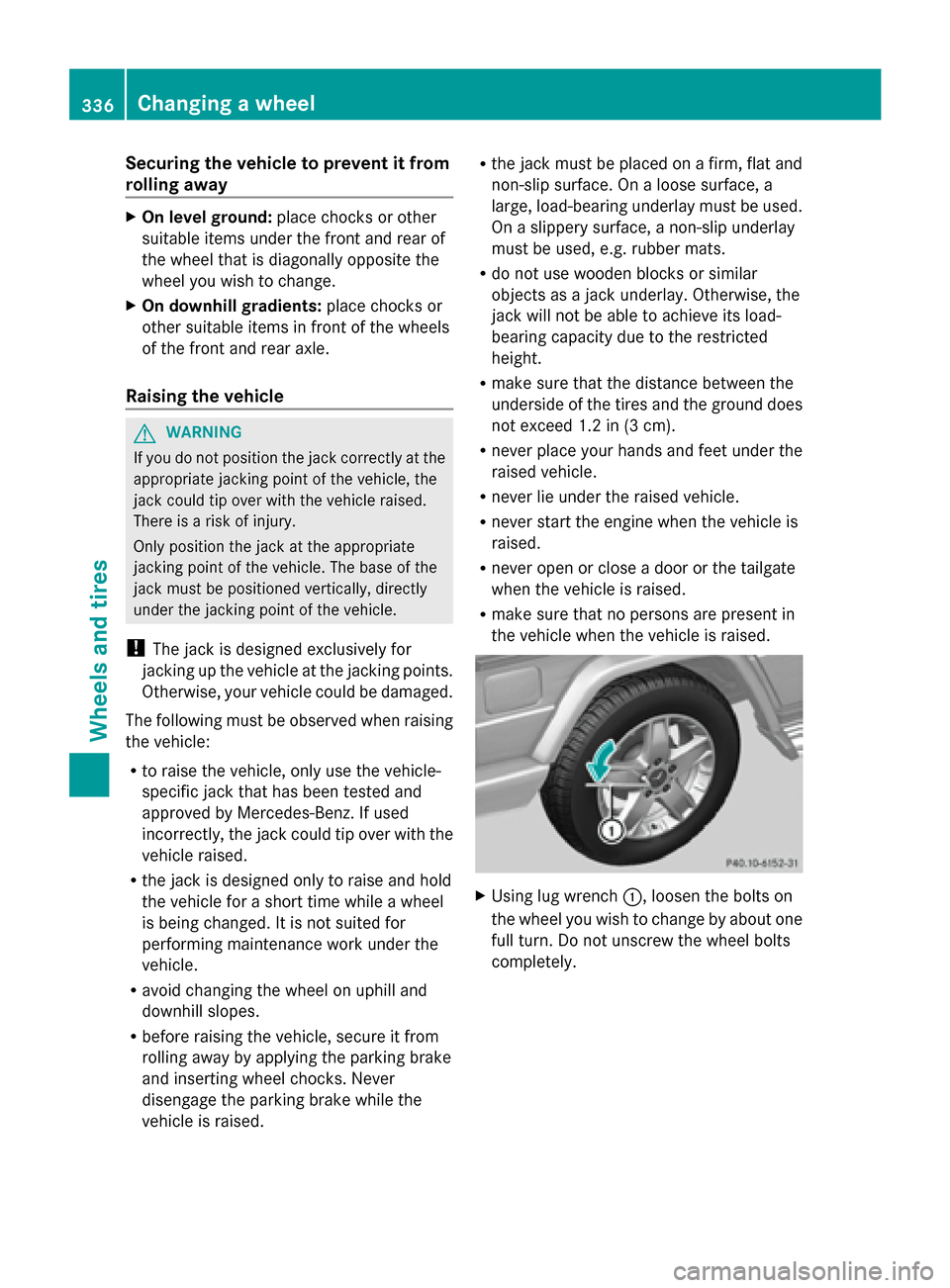

the vehicle when the vehicle is raised. X

Using lug wrench 0043, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the wheel bolts

completely. 336

Changing a wheelWheels and tires

Page 339 of 354

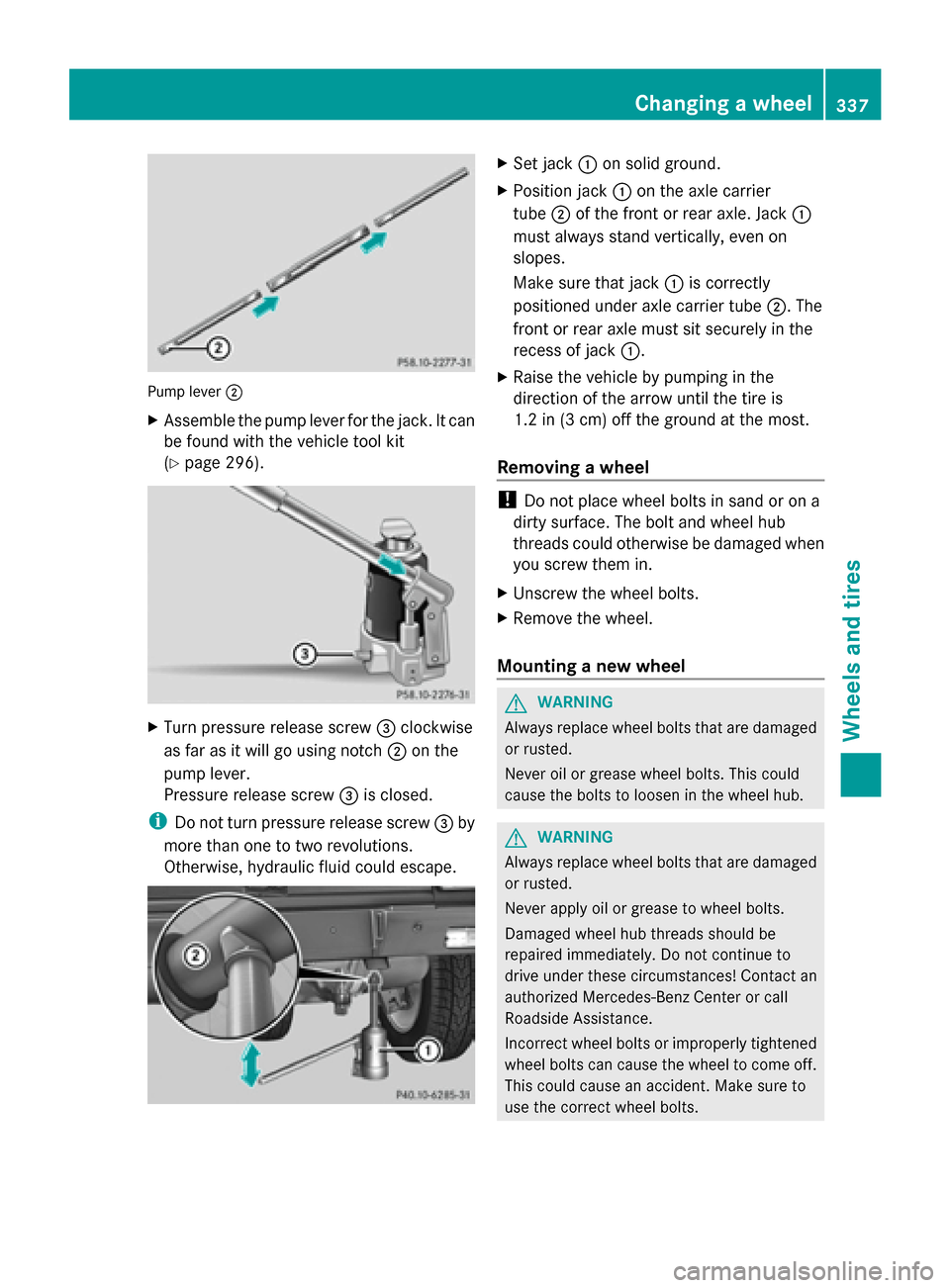

Pump lever

0044

X Assemble the pump lever for the jack. It can

be found with the vehicle tool kit

(Y page 296). X

Turn pressure release screw 0087clockwise

as far as it will go using notch 0044on the

pump lever.

Pressure release screw 0087is closed.

i Do not turn pressure release screw 0087by

more than one to two revolutions.

Otherwise, hydraulic fluid could escape. X

Set jack 0043on solid ground.

X Position jack 0043on the axle carrier

tube 0044of the front or rear axle. Jack 0043

must always stand vertically, even on

slopes.

Make sure that jack 0043is correctly

positioned under axle carrier tube 0044. The

front or rear axle must sit securely in the

recess of jack 0043.

X Raise the vehicle by pumping in the

direction of the arrow until the tire is

1.2 in (3 cm) off the ground at the most.

Removing a wheel !

Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when

you screw them in.

X Unscrew the wheel bolts.

X Remove the wheel.

Mounting a new wheel G

WARNING

Always replace wheel bolts that are damaged

or rusted.

Never oil or grease wheel bolts. This could

cause the bolts to loosen in the wheel hub. G

WARNING

Always replace wheel bolts that are damaged

or rusted.

Never apply oil or grease to wheel bolts.

Damaged wheel hub threads should be

repaired immediately. Do not continue to

drive under these circumstances! Contact an

authorized Mercedes-Benz Center or call

Roadside Assistance.

Incorrect wheel bolts or improperly tightened

wheel bolts can cause the wheel to come off.

This could cause an accident. Make sure to

use the correct wheel bolts. Changing a wheel

337Wheels and tires Z

Page 340 of 354

G

WARNING

Only use genuine Mercedes-Benz wheel bolts.

Other wheel bolts may come loose.

Do not tighten the wheel bolts when the

vehicle is raised. Otherwise, the vehicle could

fall off the jack.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel"

section (Y page 334).

X Clean the wheel and wheel hub contact

surfaces.

X Place the new wheel on the wheel hub and

push it on.

X Tighten the wheel bolts until they are

finger-tight.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

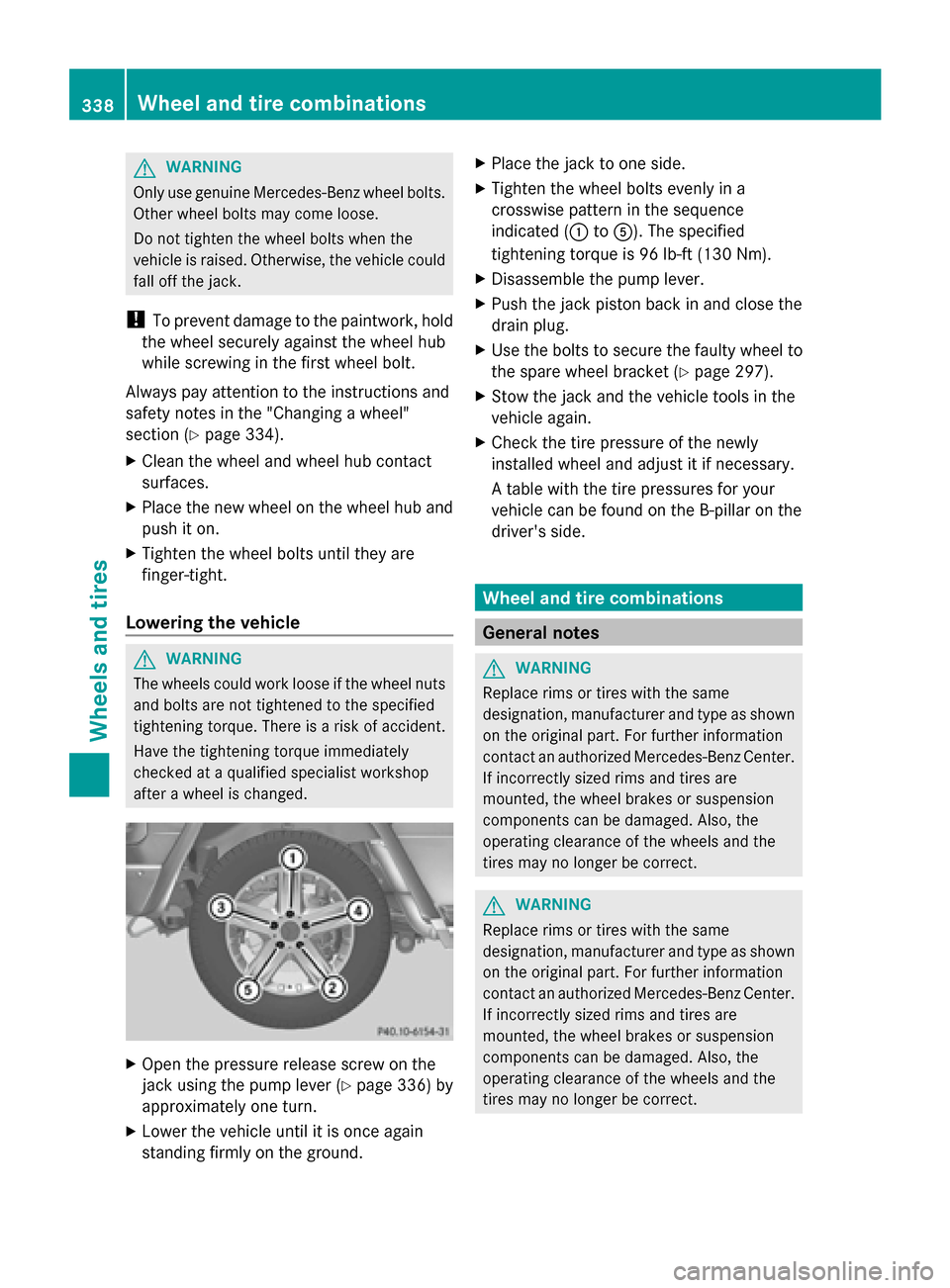

after a wheel is changed. X

Open the pressure release screw on the

jack using the pump lever (Y page 336) by

approximately one turn.

X Lower the vehicle until it is once again

standing firmly on the ground. X

Place the jack to one side.

X Tighten the wheel bolts evenly in a

crosswise pattern in the sequence

indicated (0043 to0083). The specified

tightening torque is 96 lb-ft (130 Nm).

X Disassemble the pump lever.

X Push the jack piston back in and close the

drain plug.

X Use the bolts to secure the faulty wheel to

the spare wheel bracket (Y page 297).

X Stow the jack and the vehicle tools in the

vehicle again.

X Check the tire pressure of the newly

installed wheel and adjust it if necessary.

A table with the tire pressures for your

vehicle can be found on the B-pillar on the

driver's side. Wheel and tire combinations

General notes

G

WARNING

Replace rims or tires with the same

designation, manufacturer and type as shown

on the original part. For further information

contact an authorized Mercedes-Benz Center.

If incorrectly sized rims and tires are

mounted, the wheel brakes or suspension

components can be damaged. Also, the

operating clearance of the wheels and the

tires may no longer be correct. G

WARNING

Replace rims or tires with the same

designation, manufacturer and type as shown

on the original part. For further information

contact an authorized Mercedes-Benz Center.

If incorrectly sized rims and tires are

mounted, the wheel brakes or suspension

components can be damaged. Also, the

operating clearance of the wheels and the

tires may no longer be correct. 338

Wheel and tire combinationsWheels and tires