ECU MERCEDES-BENZ G-CLASS 2018 Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: G-CLASS, Model: MERCEDES-BENZ G-CLASS 2018Pages: 294, PDF Size: 4.86 MB

Page 267 of 294

displayed after driving a few minutesmessage appears.

After a teach-in process, the tire pressure mon-

itor automatically detects new wheels or new

sensors. As long as a clear allocation of the tire

pressure value to the individual wheels is not

possible, theTire

PressureMonitorActivedisplay message is shown instead of the tire

pressure display. The tire pressures are already

being monitored.

If a spare wheel is installed, the system may

continue to show the tire pressure of the wheel

that has been removed for a few minutes. Please

note that in this case, the value displayed for the

replaced wheel does not indicate the current

tire pressure of the spare wheel.

Tire pressure monitor warning mes-

sages

If the tire pressure monitor detects a pressure

loss in one or more tires, a warning message is

shown in the multifunction display. The yellow

htire pressure warning lamp then lights up.

RIf the Correct Tire Pressuremessage

appears in the multifunction display, the tire

pressure in at least one tire is too low. The tire

pressure must be corrected when the oppor-

tunity arises.

RIf the Check Tiresmessage appears in the

multifunction display, the tire pressure in at

least one tire has dropped significantly. The

tires must be checked.

RIf the Caution - Tire Malfunc.message

appears in the multifunction display, the tire

pressure in at least one tire has dropped sud-

denly. The tires must be checked.

Be sure to observe the instructions and safety

notes in the display messages in the "Tires" sec-

tion (

Ypage 187).

If the position of the wheels on the vehicle is

changed, the tire pressure may be displayed in

the wrong positions for a short time. This is rec- tified after a few minutes of driving, and the tire

pressures are displayed for the correct posi-

tions.

Restarting the tire pressure monitor

When you restart the tire pressure monitor, all

existing warning messages are deleted and the

h warning lamp goes out. The monitor uses

the currently set tire pressures as the reference

values for monitoring. In most cases, the tire pressure monitor will automatically detect the

new reference values after you have changed

the tire pressure. However, you can also set ref-

erence values manually as described here. The

tire pressure monitor then monitors the new tire

pressure values.

XSet the tire pressure to the value recommen-ded for the corresponding driving situation on

the Tire and Loading Information placard on

the B-pillar on the driver's side.

You can find more tire pressures for various

operating conditions in the tire pressure table

inside the filler flap.

Observe the information on tire pressure

when doing so (

Ypage 260).

XMake sure that the tire pressure is correct on

all four wheels.

XEnsure that the SmartKey is in position 2in

the ignition lock.

XPress the =or; button on the steering

wheel to select the Serv.menu.

XPress the9or: button to select

Tire Pressure.

XPress the abutton.

The multifunction display shows the current

tire pressure for each tire or the Tire pres‐

surewillbedisplayedafterdrivinga few minutesmessage appears.

XPress the:button.

The UseCurrentPressuresasNewRef‐erenceValuesmessage appears in the mul-

tifunction display.

If you wish to confirm the restart:

XPress the abutton.

The TirePress.MonitorRestartedmes-

sage appears in the multifunction display.

After driving for a few minutes, the system

checks whether the current tire pressures are within the specified range. The new tire pres-

sures are then accepted as reference values

and monitored.

If you wish to cancel the restart:

XPress the %button.

The tire pressure values stored at the last

restart will continue to be monitored.

Tire pressure265

Wheels and tires

Z

Page 277 of 294

PSI (pounds per square inch)

A standard unit of measure for tire pressure.

Aspect ratio

Relationship between tire height and tire width

in percent.

Tire pressure

This is pressure inside the tire applying an out-

ward force to each square inch of the tire's sur-

face. The tire pressure is specified in pounds per

square inch (psi), in kilopascals (kPa) or in bar.

The tire pressure should only be corrected when

the tires are cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tread

The part of the tire that comes into contact with

the road.

Bead

The tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose fromthe wheel rim.

Sidewall

The part of the tire between the tread and the

bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-per-

formance battery, are not included in the curb

weight and the weight of the accessories.

TIN (Tire Identification Number)

This is a unique identifier which can be used by

a tire manufacturer to identify tires, for example

for a product recall, and thus identify the pur-

chasers. The TIN is made up of the manufactur-

er's identity code, tire size, tire type code and

the manufacturing date.

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

TWR (Tongue Weight Rating)

The TWR specifies the maximum permissible

weight that the ball coupling of the trailer tow

hitch can support.

Treadwear indicators

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of áin (1.6 mm)

has been reached.

Occupant distribution

The distribution of occupants in a vehicle at their

designated seating positions.

Total load limit

Nominal load and luggage load plus 68 kg

(150 lbs) multiplied by the number of seats in

the vehicle.

Changing a wheel

Flat tire

You can find information on what to do in the

event of a flat tire in the "Breakdown assistance"

section (

Ypage 246).

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

Changing a wheel275

Wheels and tires

Z

Page 278 of 294

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes under "Installing a wheel" (

Ypage 276).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in the center.

On vehicles that have the same size front and

rear wheels, you can rotate the wheels accord-

ing to the intervals in the tire manufacturer's

warranty book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000 to

10,000 km). Depending on tire wear, this may

be required earlier. Do not change the direction

of wheel rotation.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is rota-

ted. Check the tire pressure and reactivate the

tire pressure monitor if necessary (

Ypage 265).

Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. You will only gain these benefits if the

correct direction of rotation is observed.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

You may mount the spare wheel against the

direction of rotation. Adhere to the time restric-

tion on use as well as the speed limitation speci-

fied on the spare wheel.

Storing wheels

Store tires that are not being used in a cool, dry

and preferably dark place. Protect the tires from

oil, grease, gasoline and diesel.

Mounting a wheel

Preparing the vehicle

GWARNING

When you remove the spare wheel from the

spare wheel bracket, the vehicle’s weight dis-

tribution changes. If the vehicle is already

raised, the jack could tip over. There is a risk

of injury.

Remove the spare wheel from the spare wheel

bracket before lifting the vehicle.

XStop the vehicle on solid, non-slippery and

level ground.

XApply the parking brake.

XBring the front wheels into the straight-ahead

position.

XShift the automatic transmission to position

j.

XSwitch off the engine.

XRemove the vehicle tools and jack from the

vehicle (Ypage 244).

XRemove the spare wheel from the spare wheel bracket (Ypage 245).

XSafeguard the vehicle against rolling away.

Securing the vehicle to prevent it from

rolling away

XPlace chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

!Only position the jack at the appropriate

jacking point of the vehicle. Otherwise, you

could damage the vehicle.

276Changing a wheel

Wheels and tires

Page 279 of 294

Observe the following when raising the vehi-

cle:

RTo raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised.

RThe jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RDo not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm).

RDo not place your hands or feet under the

raised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle is

raised.

RDo not open or close a door when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

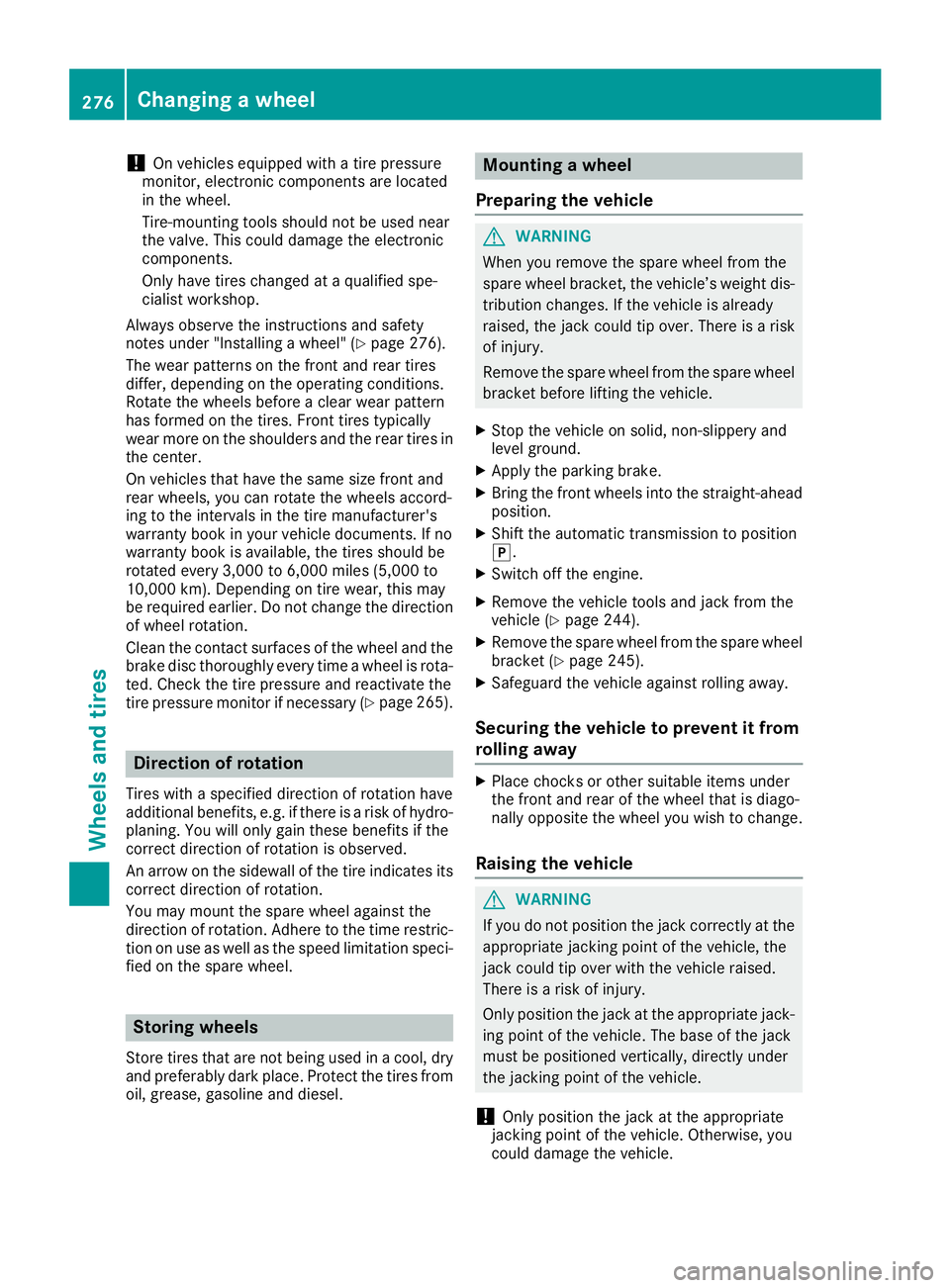

XUsing lug wrench :, loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely.

XAssemble the pump lever for the jack from the vehicle tool kit.

XTurn lowering screw =on the jack clockwise

as far as it will go using notch ;on the pump

lever.

Pressure release screw =is closed.

iDo not turn pressure release screw =by

more than one to two revolutions. Otherwise,

hydraulic fluid could escape.

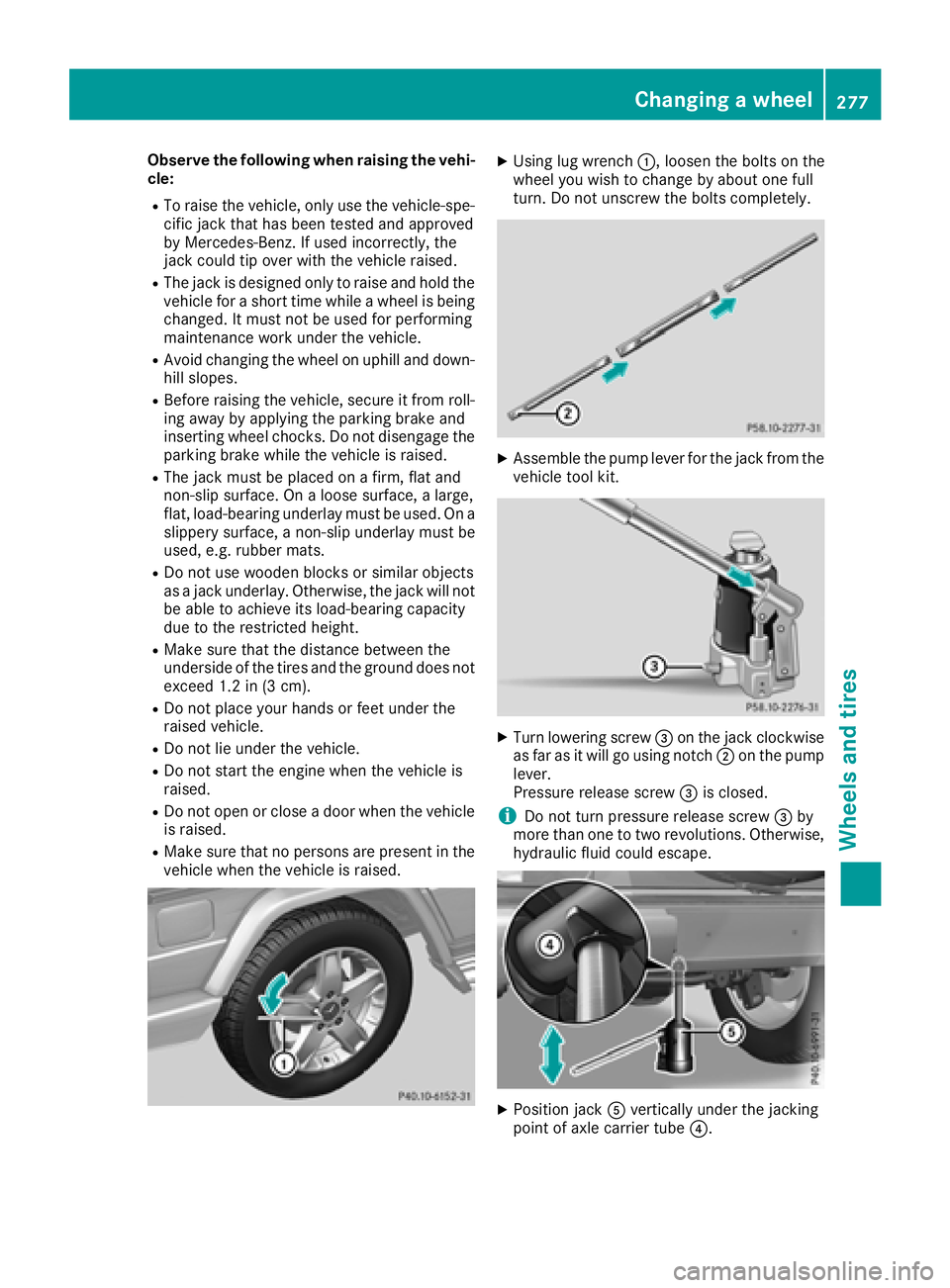

XPosition jack Avertically under the jacking

point of axle carrier tube ?.

Changing a wheel277

Wheels and tires

Z

Page 280 of 294

Make sure that jackAis at the correct posi-

tion under axle carrier tube ?. The front or

rear axle must sit securely in the recess of

jack A.

XKeep pumping until axle carrier tube ?sits

securely in the recess of jack Aand the base

of the jack lies evenly on the ground.

Ensure that the jack is located vertically under

the jacking point.

XRaise the vehicle by pumping until the tire is

no more than 1.2 in (3 cm) off the ground.

Removing a wheel

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

When mounting/removing wheels, and for as

long as the wheels are removed, avoid applying

any external force on the brake disks. This could impair the level of comfort when braking.

XUnscrew the wheel bolts.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts/wheel nuts and

damaged wheel bolt/wheel nut/wheel hub

threads can cause wheel bolts/wheel nuts to

come loose. As a result, you could lose a

wheel while driving. There is a risk of an acci-

dent.

Never oil or grease wheel bolts/wheel nuts. In

the event of damage to the threads, contact a

qualified specialist workshop immediately.

Have the damaged wheel bolts/wheel nuts or

hub threads replaced/renewed. Do not con-

tinue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(

Ypage 275).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

XClean the wheel and wheel hub contact sur-

faces.

XPlace the new wheel on the wheel hub and

push it on.

XTighten the wheel bolts until they are finger-

tight.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

XSlowly open the pressure release screw on

the jack using the pump lever by approx-

imately one full turn and carefully lower the

vehicle (

Ypage 276).

XYou can put the jack aside.

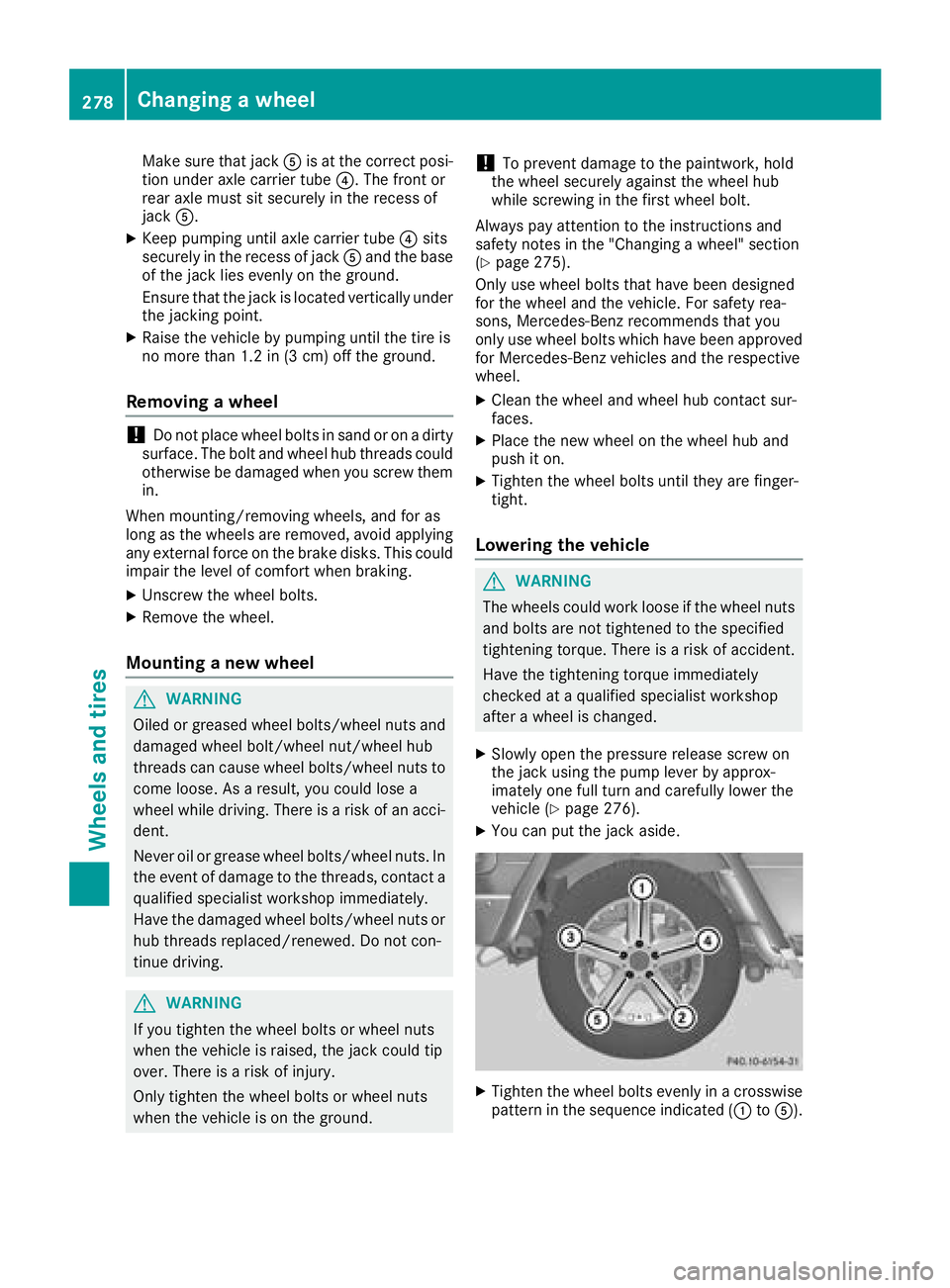

XTighten the wheel bolts evenly in a crosswisepattern in the sequence indicated (: toA).

278Changing a wheel

Wheels and tires

Page 281 of 294

The tightening torque must be96 lb-ft

(130 Nm).

XDismantle the pump lever.

XPush the jack piston back in and close the

drain plug.

XUse the nuts to secure the faulty wheel to the

spare wheel bracket (Ypage 245).

XStow the jack and the vehicle tools in the

vehicle again.

XCheck the tire pressure of the newly installed

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 260).

If you are driving with the emergency spare

wheel installed, the tire pressure monitor can-

not function reliably. Only restart the tire pres-

sure monitor when the defective wheel has been replaced with a new wheel.

All mounted wheels must be equipped with func-

tioning sensors for the tire pressure monitor.

Wheel and tire combinations

You can ask for information regarding permittedwheel/tire combinations at an authorized

Mercedes-Benz Center.

!For safety reasons, Mercedes-Benz recom-

mends that you only use tires, wheels and

accessories which have been specifically

approved by Mercedes-Benz for your vehicle.

These are specially adapted to the various

driving safety systems, such as ABS or ESP

®.

Only use tires, wheels and accessories tested

and recommended by Mercedes-Benz. Cer-

tain characteristics, such as handling, vehicle

noise emissions, fuel consumption, etc. may

otherwise be adversely affected. In addition,

other wheel sizes may cause the tires to rub

against the vehicle body and axle compo-

nents, when under load. This may result in

damage to the tire or to the vehicle.

Mercedes-Benz is not responsible for any

damage caused by using tires, wheels or

accessories different from those recommen-

ded.

Information on tires, wheels and permissible

combinations can be obtained at a qualified

specialist workshop.

!Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since previ- ous damage cannot always be detected on

retreaded tires. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires if

you have no information about their previous

usage.

The recommended pressures for various oper-

ating conditions can be found:

Ron the Tire and Loading Information placard

on the B-pillar on the driver's side

Rin the tire pressure table in the fuel filler flap

Observe the notes on recommended tire pres-

sures under various operating conditions

(

Ypage 260).

Check tire pressures regularly, and only when

the tires are cold. Comply with the maintenance

recommendations of the tire manufacturer in

the vehicle document wallet.

Notes on equipping the vehicle:

Ralways install tires of the same size on one

axle (left/right)

Ralways install the same type of tires on your

vehicle (summer tires, winter tires, all-

weather tires, all-terrain tires)

Spare wheel

If the tire and wheel dimensions of the spare

wheel differ from the wheel to be replaced, the

spare wheel is an emergency spare wheel.

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Spare wheel279

Wheels and tires

Z