MERCEDES-BENZ GLA SUV 2013 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: GLA SUV, Model: MERCEDES-BENZ GLA SUV 2013Pages: 401, PDF Size: 11.9 MB

Page 361 of 401

Restarting the tyre pressure loss warn-

ing system Restart the tyre pressure loss warning system

if you have:

R changed the tyre pressure

R changed the wheels or tyres

R fitted new wheels or tyres

X Before restarting, make sure that the tyre

pressures are set properly on all four tyres

for the respective operating conditions.

The recommended tyre pressures can be

found in the tyre pressure table on the fuel

filler flap.

The tyre pressure loss warning system can only give reliable warnings if you have set

the correct tyre pressure. If an incorrect

tyre pressure is set, these incorrect values

will be monitored.

X Observe the notes in the section on tyre

pressures (Y page 356).

X Make sure that the key is in position 2in the

ignition lock (Y page 159).

X Press the =or; button on the steer-

ing wheel to select the Serv.

Serv. menu.

X Press the 9or: button to select

Tyre pressure

Tyre pressure .

X Press the abutton.

The Run Flat Indicator active Run Flat Indicator active

Restart

Restart with

withOK

OKmessage appears in the

multifunction display.

If you wish to confirm the restart: X Press the abutton.

The Tyre press. now OK?

Tyre press. now OK? message

appears in the multifunction display.

X Press the 9or: button to select

Yes

Yes.

X Press the abutton.

The Run Flat Indicator restarted

Run Flat Indicator restarted

message appears in the multifunction dis-

play.

After a teach-in period, the tyre pressure

loss warning system will monitor the set

tyre pressures of all four tyres. If you wish to cancel the restart:

X Press the %button.

or X When the Tyre Tyrepress. press. now

nowOK?

OK?message

appears, press the 9or: button to

select Cancel

Cancel.

X Press the abutton.

The tyre pressure values stored at the last

restart will continue to be monitored. Tyre pressure monitor

General notes If a tyre pressure monitor system is fitted, the

vehicle's wheels have sensors fitted that

monitor the tyre pressures in all four tyres.

The tyre pressure monitor warns you if the

pressure drops in one or more of the tyres.

The tyre pressure monitor only functions if

the corresponding sensors are fitted to all

wheels.

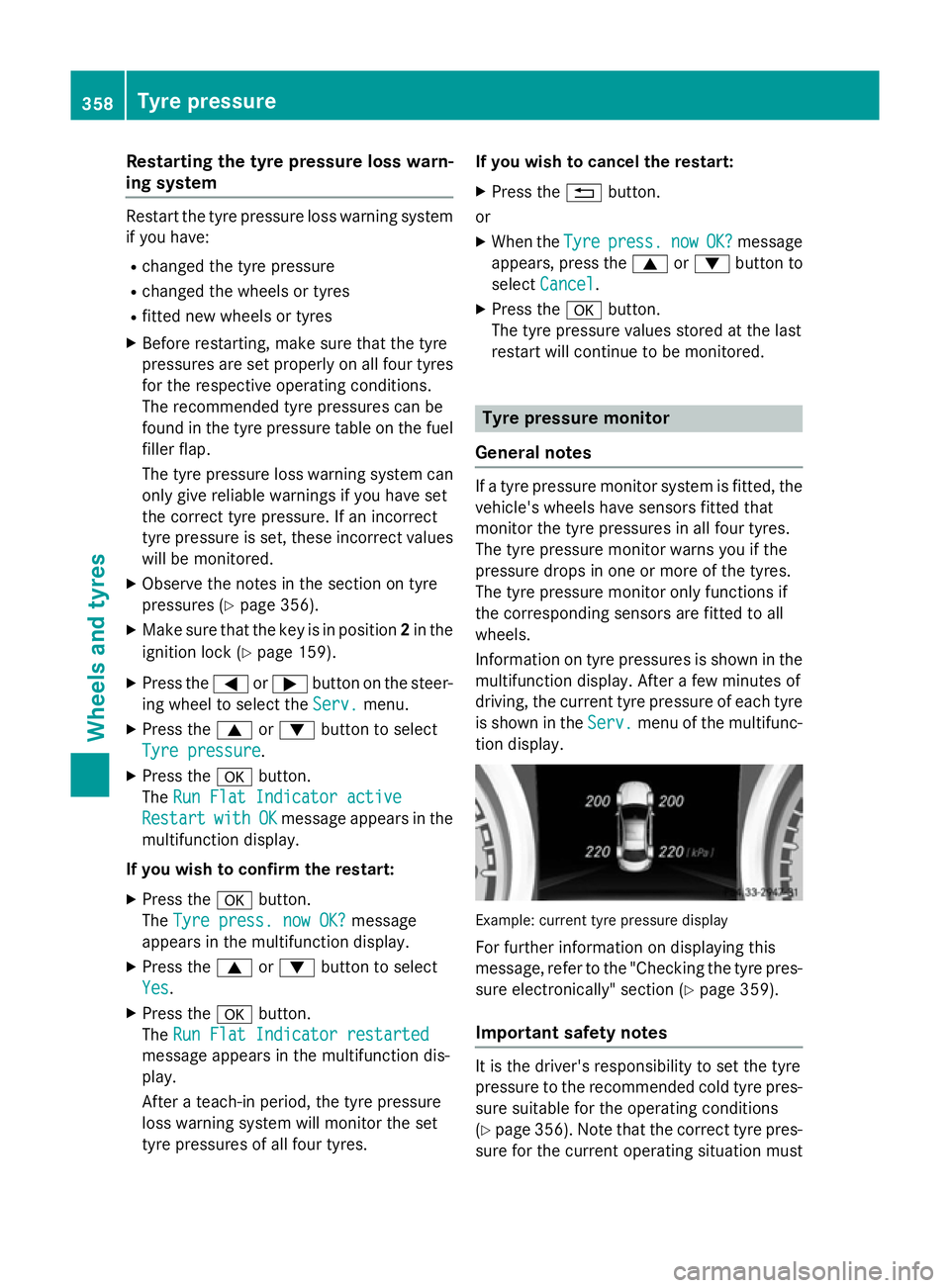

Information on tyre pressures is shown in the multifunction display. After a few minutes of

driving, the current tyre pressure of each tyre

is shown in the Serv. Serv.menu of the multifunc-

tion display. Example: current tyre pressure display

For further information on displaying this

message, refer to the "Checking the tyre pres-

sure electronically" section (Y page 359).

Important safety notes It is the driver's responsibility to set the tyre

pressure to the recommended cold tyre pres-

sure suitable for the operating conditions

(Y page 356). Note that the correct tyre pres-

sure for the current operating situation must 358

Tyre pressureWheels and tyres

Page 362 of 401

first be taught-in to the tyre pressure monitor.

If there is a substantial loss of pressure, the

warning threshold for the warning message is aligned to the reference values taught-in.

Restart the tyre pressure monitor after

adjusting to the cold tyre pressure

(Y page 360). The current pressures are

saved as new reference values. This will

ensure that a warning message will only

appear if the tyre pressure drops significantly.

The tyre pressure monitor does not warn you

of an incorrectly set tyre pressure. Observe

the notes on the recommended tyre pressure

(Y page 356).

The tyre pressure monitor is not able to warn

you of a sudden loss of pressure, e.g. if the

tyre is penetrated by a foreign object. In the

event of a sudden loss of pressure, bring the

vehicle to a halt by braking carefully. Avoid

abrupt steering manoeuvres.

The tyre pressure monitor has a yellow warn-

ing lamp in the instrument cluster for indicat- ing a pressure loss or malfunction. Depending

on how the warning lamp flashes or lights up, a tyre pressure that is too low or a malfunc-

tion in the tyre pressure monitor is indicated:

R if the warning lamp is lit continuously, the

tyre pressure on one or more tyres is sig-

nificantly too low. The tyre pressure moni-

tor is not malfunctioning.

R if the warning lamp flashes for around a

minute and then remains lit constantly, the tyre pressure monitor is malfunctioning.

i In addition to the warning lamp, a mes-

sage appears in the multifunction display.

Further information can be found on

(Y page 280).

If the tyre pressure monitor is malfunctioning,

it may take more than ten minutes for the tyre pressure warning lamp to inform you of the

malfunction by flashing for approximately one

minute and then remaining lit. When the fault

has been rectified, the tyre pressure warning lamp goes out after you have driven for a few

minutes. The tyre pressure values indicated by the on-

board computer may differ from those meas-

ured at a filling station using a pressure

gauge. The tyre pressures shown by the on-

board computer refer to those measured at

sea level. At high altitudes, the tyre pressure

values indicated by a pressure gauge are

higher than those shown by the on-board

computer. In this case, do not reduce the tyre

pressures.

The operation of the tyre pressure monitor

can be affected by interference from radio

transmitting equipment (e.g. radio head-

phones, two-way radios) that may be being

operated in or near the vehicle.

Checking the tyre pressure electroni-

cally X

Make sure that the key is in position 2in the

ignition lock (Y page 159).

X Press the =or; button on the steer-

ing wheel to select the Serv. Serv.menu.

X Press the 9or: button to select

Tyre pressure

Tyre pressure.

X Press the abutton.

The current tyre pressure for each wheel

will be displayed in the multifunction dis-

play.

If the vehicle was parked for longer than

20 minutes, the Tyre Tyrepressures

pressures will

willbe

be

displayed after a few minutes of

displayed after a few minutes of

driving driving message is shown.

After a teach-in period, the tyre pressure

monitor automatically detects new wheels or new sensors. As long as a clear allocation of

the tyre pressure values to the individual

wheels is not possible, the Tyre pressure Tyre pressure

monitor active

monitor active message is shown instead

of the tyre pressure display. The tyre pres-

sures are already being monitored.

i If an emergency spare wheel is fitted, for

a few minutes the system may continue to

show the tyre pressure of the wheel that

has been removed. If this occurs, note that

the value displayed for the position where Tyre pressure

359Wheels and tyres Z

Page 363 of 401

the spare wheel is fitted is not the same as

the current tyre pressure of the emergencyspare wheel.

Warning messages of the tyre pressure monitor If the tyre pressure monitor detects a pres-

sure loss in one or more tyres, a warning mes-

sage is shown in the multifunction display and the yellow tyre pressure monitor warning light

comes on.

R If the Please correct tyre pressure

Please correct tyre pressure

message appears in the multifunction dis-

play, the tyre pressure in at least one tyre is too low and must be corrected at the next

opportunity.

R If the Tyre pressure Check tyres

Tyre pressure Check tyres mes-

sage appears in the multifunction display,

the tyre pressure in one or more tyres has

dropped significantly and the tyres must be checked.

R If the Tyre pressure Caution Tyre

Tyre pressure Caution Tyre

malfunction

malfunction message appears in the mul-

tifunction display, the tyre pressure in one

or more tyres has dropped suddenly and

the tyres must be checked.

Observe the instructions and safety notes in

the display messages in the "Tyres" section

(Y page 280).

i If the wheel positions on the vehicle are

interchanged, the tyre pressures may be

displayed for the wrong positions for a

short time. After a few minutes of driving,

this is rectified and the tyre pressures are

displayed for the correct positions.

Restarting the tyre pressure monitor When you restart the tyre pressure monitor,

all existing warning messages are deleted and

the warning lamps go out. The monitor uses

the currently set tyre pressures as the refer-

ence values for monitoring. In most cases, the tyre pressure monitor will automatically

detect the new reference values after you

have changed the tyre pressure. However, you can also define reference values man-

ually as described here. The tyre pressure

monitor then monitors the new tyre pressure

values.

X Use the table on the inside of the fuel filler

flap to ensure that the tyre pressure is set

correctly in all four tyres for the current

operating conditions.

Also observe the notes in the section on

tyre pressures (Y page 356).

X Make sure that the key is in position 2in the

ignition lock.

X Press the =or; button on the steer-

ing wheel to select the Serv. Serv.menu.

X Press the 9or: button to select

Tyre pressure

Tyre pressure.

X Press the abutton.

The multifunction display shows the cur-

rent tyre pressure for each tyre or the

Tyre pressures will be displayed Tyre pressures will be displayed

after after a

afew

few minutes

minutes of

ofdriving

driving mes-

sage.

X Press the :button.

The multifunction display shows the Use

Use

current

current pressures

pressures as

asnew

new reference

reference

values

values message.

If you wish to confirm the restart: X Press the abutton.

The Tyre press. monitor restarted

Tyre press. monitor restarted

message appears in the multifunction dis-

play.

After you have driven for a few minutes, the

system checks whether the current tyre

pressures are within the specified range.

The new tyre pressures are then accepted

as reference values and monitored.

If you wish to cancel the restart:

X Press the %button.

The tyre pressure values stored at the last

restart will continue to be monitored. 360

Tyre pressureWheels and tyres

Page 364 of 401

Radio type approval for the tyre pres-

sure monitor Country Radio type approval number

Brazil 2770-12-8001

Model: MW2433A

0381-13-8001

Model: GG4

Dubai TRA, Registered NO

ER0092100/12

TRA, Registered NO

ER0099792/12

TRA, Registered NO

ER0076990/11

Dealer-NO: DA0047074/10

Jordan Model: Gen Alpha Wal 2 TPMS

transmitter

Type Approval Number:

TRC/LPD/2012/114

Model: Gen Gamma Gen 4

433.92 Mhz.

Type Approval Number:

TRC/LPD/2012/190

Model: Corax 3 MRXMC34MA4

Type Approval Number:

TRC/LPD/2011/158

Type Number: LPD Morocco MR7319 ANRT 2012/

11/07/2012

MR7672 ANRT 2012/

23/11/2012

MR6706 ANRT 2011

Moldova 1024

Philip-

pines No: ESD-1206394C

No: ESD-1306995C

Serbia И 011 12 Country Radio type approval number

Singa-

pore Compliance with IDA Standard

DA- 103365

South

Africa TA-2012/719

TA-2012/1540

TA-2011/1370

Changing a wheel

Flat tyre

You can find information on what to do in the event of flat tyre in the "Flat tyre" section

(Y page 334). Information on driving with

MOExtended tyres in the event of a flat tyre

can be found under "Breakdown assistance"

(Y page 334).

Vehicles with an emergency spare wheel: in the event of a flat tyre, the emergency

spare wheel is fitted according to the descrip-

tion under "Fitting a wheel" (Y page 362). Interchanging the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tyres have different dimensions. The wheel brakes or suspension components may also be damaged. There is a risk of acci-

dent.

Interchange front and rear wheels only if the

wheels and tyres are of the same dimensions.

! On vehicles fitted with a tyre pressure

monitor, electronic components are loca-

ted in the wheel.

Tyre-fitting tools should not be applied in

the area of the valve, as this could damage

the electronic components.

Only have tyres changed at a qualified spe- cialist workshop. Changing a wheel

361Wheels and tyres Z

Page 365 of 401

Interchanging the front and rear wheels of

differing dimensions can render the general

operating permit invalid.

Always pay attention to the instructions and

safety notes when changing a wheel

(Y page 361).

The wear patterns on the front and rear tyres differ, depending on the operating conditions. Interchange the wheels before a clear wear

pattern has formed on the tyres. Front tyres

typically wear more on the shoulders and the

rear tyres in the centre.

On vehicles that have the same size front and rear wheels, you can interchange the wheels

every 5,000 to 10,000 km depending on the

degree of tyre wear. Ensure that the direction

of rotation is maintained.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is interchanged. Check the tyre pressure and, if necessary, restart the tyre pressure loss

warning system or the tyre pressure monitor. Direction of rotation

Tyres with a specified direction of rotation

have additional benefits, e.g. if there is a risk of aquaplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tyre indicates

its correct direction of rotation. Storing wheels

Store wheels that are not being used in a cool, dry and preferably dark place. Protect the

tyres against oil, grease, petrol and diesel. Cleaning the wheels

G

WARNING

The water jet of circular-jet nozzles (dirt grind- ers) can cause damage not visible from the

outside to tyres or chassis components. Com- ponents damaged in this way can unexpect-

edly fail. There is a risk of an accident.

Do not use high-pressure cleaners with circu- lar-jet nozzles to clean the vehicle. Have dam-aged tyres or chassis components replaced

immediately. Fitting a wheel

Preparing the vehicle X

Stop the vehicle on solid, non-slippery and

level ground.

X Apply the electric parking brake manually

(Y page 180).

X Move the front wheels to the straight-

ahead position.

X Vehicles with manual transmission:

depress the clutch pedal fully and engage

first or reverse gear.

X Vehicles with automatic transmission:

move the DIRECT SELECT lever to P.

X Switch off the engine.

X Remove the key from the ignition lock.

X If a trailer is coupled to the vehicle, uncou-

ple it.

X If included in the vehicle equipment,

remove the tyre-change tool kit from the

vehicle.

X Secure the vehicle to prevent it from rolling

away.

i Apart from certain country-specific varia-

tions, vehicles are not equipped with a tyre-

change tool kit. For information on which

tools are required to perform a wheel

change on your vehicle, consult a

Mercedes-Benz Service Centre.

Necessary wheel-changing tools may

include, for example:

R jack

R wheel chock

R wheel wrench 362

Changing a wheelWheels and tyres

Page 366 of 401

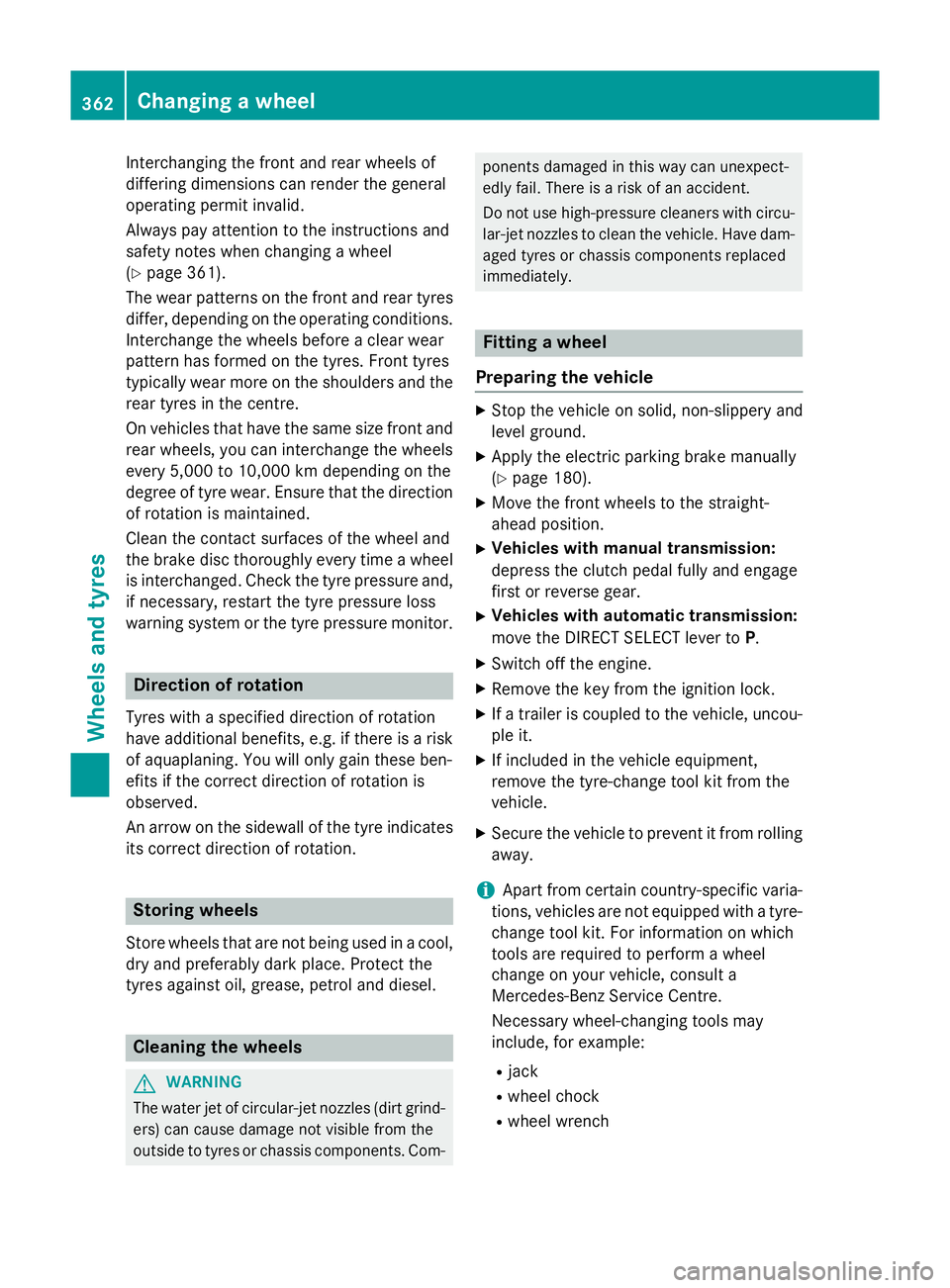

Securing the vehicle against rolling

away

If your vehicle is equipped with a wheel chock,

it can be found in the tyre-change tool kit

(Y page 333).

The folding wheel chock is an additional

securing measure to prevent the vehicle from

rolling away, for example when changing a

wheel.

X Fold both plates upwards :.

X Fold out lower plate ;.

X Guide the lugs on the lower plate fully into

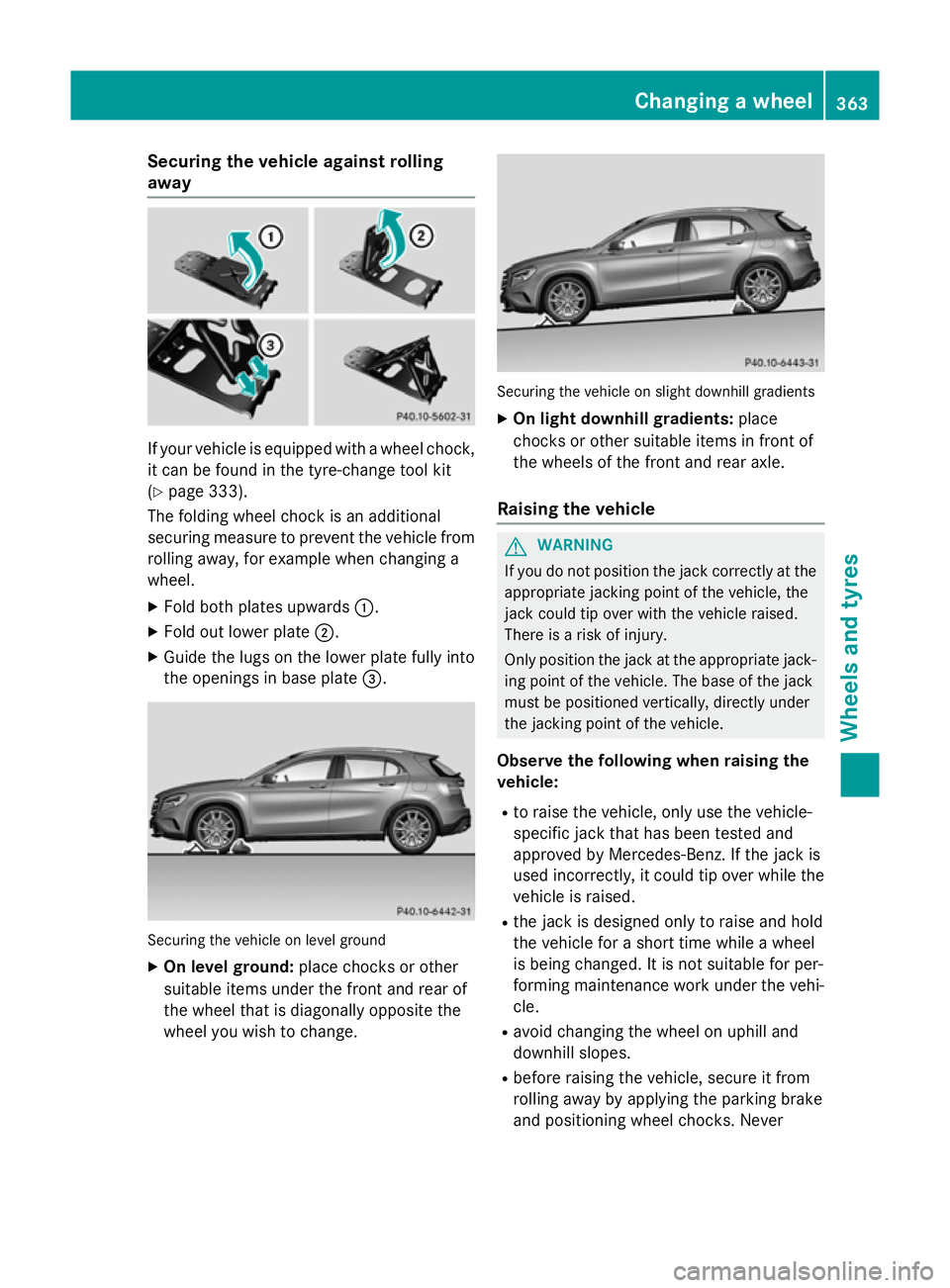

the openings in base plate =.Securing the vehicle on level ground

X On level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change. Securing the vehicle on slight downhill gradients

X On light downhill gradients: place

chocks or other suitable items in front of

the wheels of the front and rear axle.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

Observe the following when raising the

vehicle: R to raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If the jack is

used incorrectly, it could tip over while the vehicle is raised.

R the jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suitable for per-

forming maintenance work under the vehi- cle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and positioning wheel chocks. Never Changing a wheel

363Wheels and tyres Z

Page 367 of 401

release the parking brake while the vehicle

is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, flat load-bearing underlay must be

used. On a slippery surface, a non-slip

underlay must be used, e.g. rubber mats.

R do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure that the distance between the

underside of the tyres and the ground does

not exceed 3 cm.

R never place your hands or feet under the

raised vehicle.

R do not lie under the vehicle.

R do not start the engine when the vehicle is

raised.

R do not open or close a door or the tailgate

while the vehicle is raised.

R make sure that no persons are present in

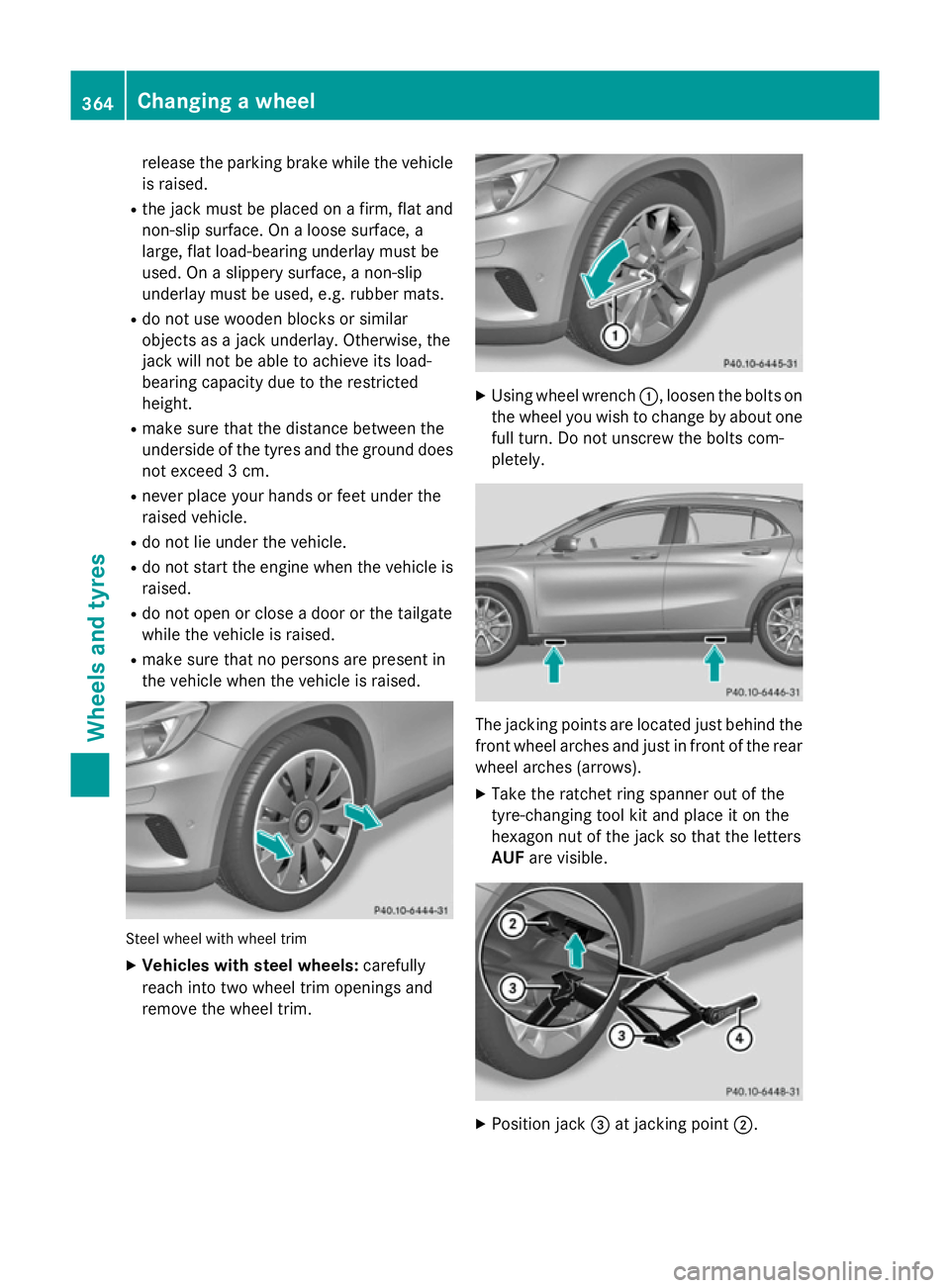

the vehicle when the vehicle is raised. Steel wheel with wheel trim

X

Vehicles with steel wheels: carefully

reach into two wheel trim openings and

remove the wheel trim. X

Using wheel wrench :, loosen the bolts on

the wheel you wish to change by about one full turn. Do not unscrew the bolts com-

pletely. The jacking points are located just behind the

front wheel arches and just in front of the rear wheel arches (arrows).

X Take the ratchet ring spanner out of the

tyre-changing tool kit and place it on the

hexagon nut of the jack so that the letters

AUF are visible. X

Position jack =at jacking point ;.364

Changing a wheelWheels and tyres

Page 368 of 401

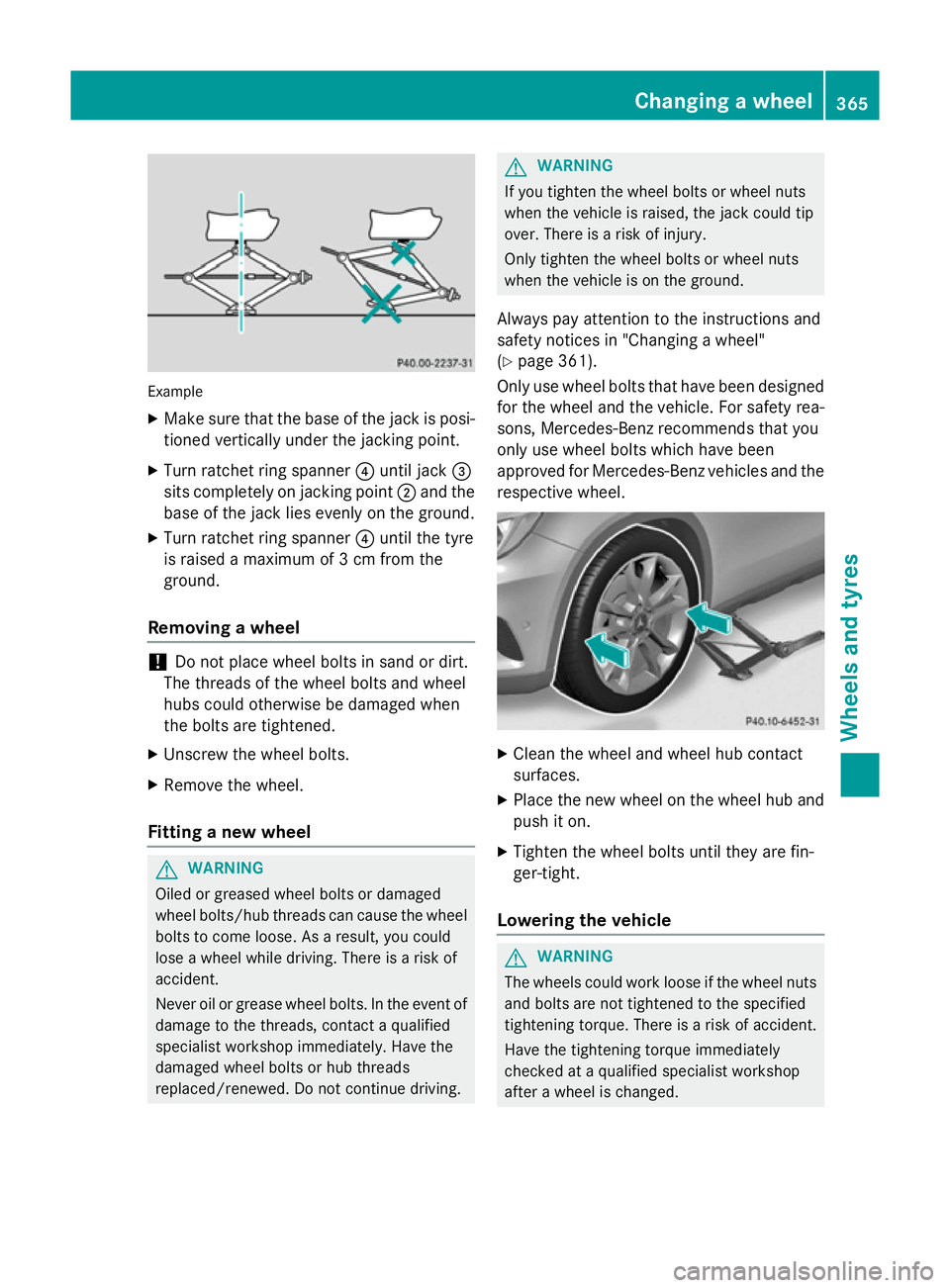

Example

X Make sure that the base of the jack is posi-

tioned vertically under the jacking point.

X Turn ratchet ring spanner ?until jack =

sits completely on jacking point ;and the

base of the jack lies evenly on the ground.

X Turn ratchet ring spanner ?until the tyre

is raised a maximum of 3 cm from the

ground.

Removing a wheel !

Do not place wheel bolts in sand or dirt.

The threads of the wheel bolts and wheel

hubs could otherwise be damaged when

the bolts are tightened.

X Unscrew the wheel bolts.

X Remove the wheel.

Fitting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event ofdamage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notices in "Changing a wheel"

(Y page 361).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel. X

Clean the wheel and wheel hub contact

surfaces.

X Place the new wheel on the wheel hub and

push it on.

X Tighten the wheel bolts until they are fin-

ger-tight.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed. Changing a wheel

365Wheels and tyres Z

Page 369 of 401

X

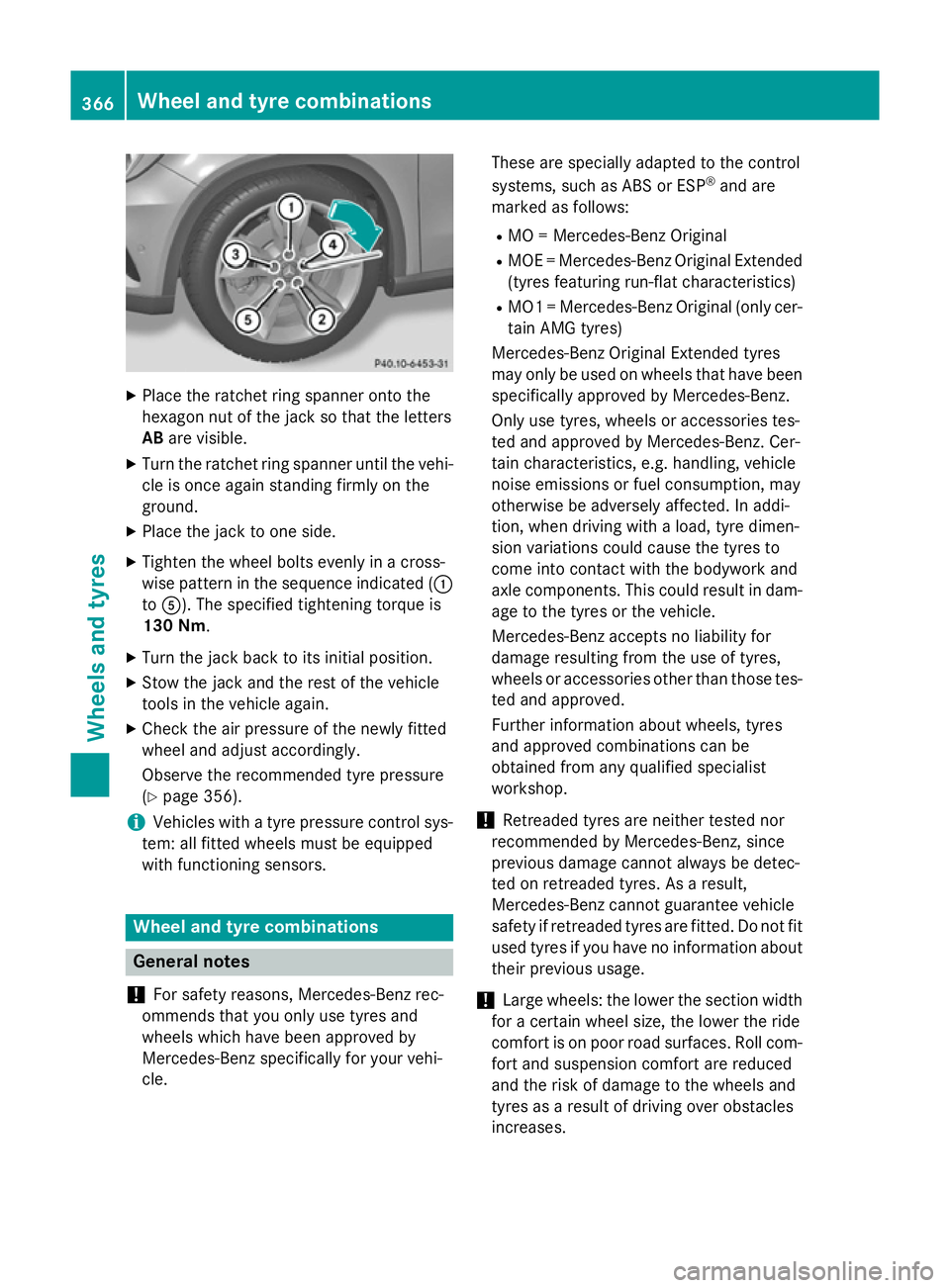

Place the ratchet ring spanner onto the

hexagon nut of the jack so that the letters

AB are visible.

X Turn the ratchet ring spanner until the vehi-

cle is once again standing firmly on the

ground.

X Place the jack to one side.

X Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indicated ( :

to A). The specified tightening torque is

130 Nm.

X Turn the jack back to its initial position.

X Stow the jack and the rest of the vehicle

tools in the vehicle again.

X Check the air pressure of the newly fitted

wheel and adjust accordingly.

Observe the recommended tyre pressure

(Y page 356).

i Vehicles with a tyre pressure control sys-

tem: all fitted wheels must be equipped

with functioning sensors. Wheel and tyre combinations

General notes

! For safety reasons, Mercedes-Benz rec-

ommends that you only use tyres and

wheels which have been approved by

Mercedes-Benz specifically for your vehi-

cle. These are specially adapted to the control

systems, such as ABS or ESP

®

and are

marked as follows:

R MO = Mercedes-Benz Original

R MOE = Mercedes-Benz Original Extended

(tyres featuring run-flat characteristics)

R MO1 = Mercedes-Benz Original (only cer-

tain AMG tyres)

Mercedes-Benz Original Extended tyres

may only be used on wheels that have been

specifically approved by Mercedes-Benz.

Only use tyres, wheels or accessories tes-

ted and approved by Mercedes-Benz. Cer-

tain characteristics, e.g. handling, vehicle

noise emissions or fuel consumption, may

otherwise be adversely affected. In addi-

tion, when driving with a load, tyre dimen-

sion variations could cause the tyres to

come into contact with the bodywork and

axle components. This could result in dam- age to the tyres or the vehicle.

Mercedes-Benz accepts no liability for

damage resulting from the use of tyres,

wheels or accessories other than those tes-

ted and approved.

Further information about wheels, tyres

and approved combinations can be

obtained from any qualified specialist

workshop.

! Retreaded tyres are neither tested nor

recommended by Mercedes-Benz, since

previous damage cannot always be detec-

ted on retreaded tyres. As a result,

Mercedes-Benz cannot guarantee vehicle

safety if retreaded tyres are fitted. Do not fit

used tyres if you have no information about their previous usage.

! Large wheels: the lower the section width

for a certain wheel size, the lower the ride

comfort is on poor road surfaces. Roll com-

fort and suspension comfort are reduced

and the risk of damage to the wheels and

tyres as a result of driving over obstacles

increases. 366

Wheel and tyre combinationsWheels and tyres

Page 370 of 401

Overview of abbreviations used in the follow-

ing tyre tables:

R BA: both axles

R FA: front axle

R RA: rear axle

You will find a table with recommended tyre

pressures for various operating conditions on

the inside of your vehicle's fuel filler flap. For

further information on tyre pressure, see

(Y page 356). Check tyre pressures regularly

and only when the tyres are cold.

Notes on the vehicle equipment – always fit

the vehicle:

R with tyres of the same size on a given axle

(left/right)

R with the same type of tyres at a given time

(summer tyres, winter tyres, MOExtended

tyres)

Exception: it is permissible to fit a different

type or make in the event of a flat tyre.

Observe the "MOExtended tyres (tyres with

run-flat characteristics)" section

(Y page 334).

i Vehicles with MOExtended tyres are not

equipped with a TIREFIT kit at the factory. It

is therefore recommended that you addi-

tionally equip your vehicle with a TIREFIT kit if you fit tyres that do not feature run-flat

characteristics, e.g. winter tyres. A TIREFIT

kit can be obtained from a qualified spe-

cialist workshop.

i Not all wheel/tyre combinations can be

fitted at the factory in all countries. Wheel and tyre combinations

367Wheels and tyres Z