MERCEDES-BENZ GLA SUV 2018 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: GLA SUV, Model: MERCEDES-BENZ GLA SUV 2018Pages: 338, PDF Size: 5.59 MB

Page 321 of 338

PSI (pounds per square inch)

A standard unit of measure for tire pressure.

Aspect ratio

Relationship between tire height and tire width

in percent.

Tire pressure

This is pressure inside the tire applying an out-

ward force to each square inch of the tire's sur-

face. The tire pressure is specified in pounds per

square inch (psi), in kilopascal (kPa) or in bar.

The tire pressure should only be corrected when

the tires are cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tread

The part of the tire that comes into contact with

the road.

Bead

The tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose fromthe wheel rim.

Sidewall

The part of the tire between the tread and the

bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-per-

formance battery, are not included in the curb

weight and the weight of the accessories.

TIN (Tire Identification Number)

This is a unique identifier which can be used by

a tire manufacturer to identify tires, for example

for a product recall, and thus identify the pur-

chasers. The TIN is made up of the manufactur-

er's identity code, tire size, tire type code and

the manufacturing date.

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

Treadwear indicators

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of áin (1.6 mm)

has been reached.

Occupant distribution

The distribution of occupants in a vehicle at their

designated seating positions.

Total load limit

Nominal load and luggage load plus 68 kg

(150 lbs) multiplied by the number of seats in

the vehicle.

Changing a wheel

Flat tire

The "Breakdown assistance" section

(Ypage 284) contains information and notes on

how to deal with a flat tire. Information on driv-

ing with MOExtended tires in the event of a flat

tire can be found under "MOExtended tires (tires

with run-flat characteristics" (

Ypage 284).

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Changing a wheel319

Wheels and tires

Z

Page 322 of 338

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Observe the instructions and safety notes in the

"Changing a wheel" section (

Ypage 319).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in

the center.

On vehicles that have the same size front and

rear wheels, you can rotate the wheels accord-

ing to the intervals in the tire manufacturer's

warranty book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000 to

10,000 km). Depending on tire wear, this may

be required earlier. Do not change the direction

of wheel rotation.

Clean the contact surfaces of the wheel and the brake disc thoroughly every time a wheel is rota-

ted. Check the tire pressure and, if necessary,

restart the tire pressure loss warning system

(Canada only) or the tire pressure monitor (USA

only).

Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. These advantages can only be gained if

the tires are installed corresponding to the

direction of rotation.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from oil, grease, gasoline and diesel.

Mounting a wheel

Preparing the vehicle

XStop the vehicle on solid, non-slippery and

level ground.

XApply the electric parking brake manually.

XBring the front wheels into the straight-ahead position.

XShift the transmission to position j.

XSwitch off the engine.

XVehicles without KEYLESS-GO:remove the

SmartKey from the ignition lock.

XVehicles with KEYLESS-GO start-function

or KEYLESS-GO: open the driver's door.

The vehicle electronics are now in position

u. This is the same as “key removed”.

XVehicles with KEYLESS-GO start-function

or KEYLESS-GO: remove the Start/Stop but-

ton from the ignition lock (

Ypage 124).

XMake sure that the engine cannot be started

via your smartphone (Ypage 84).

XIf included in the vehicle equipment, remove

the tire-change tool kit from the vehicle.

XSafeguard the vehicle against rolling away

(Ypage 143).

iApart from certain country-specific varia-

tions, the vehicles are not equipped with a

tire-change tool kit. Some tools for changing a

wheel are specific to the vehicle. For more

information on which tools are required to

perform a wheel change on your vehicle, con-

sult a qualified specialist workshop.

Necessary tire-changing tools can include, for

example:

RJack

RWheel chock

RLug wrench

320Changing a wheel

Wheels and tires

Page 323 of 338

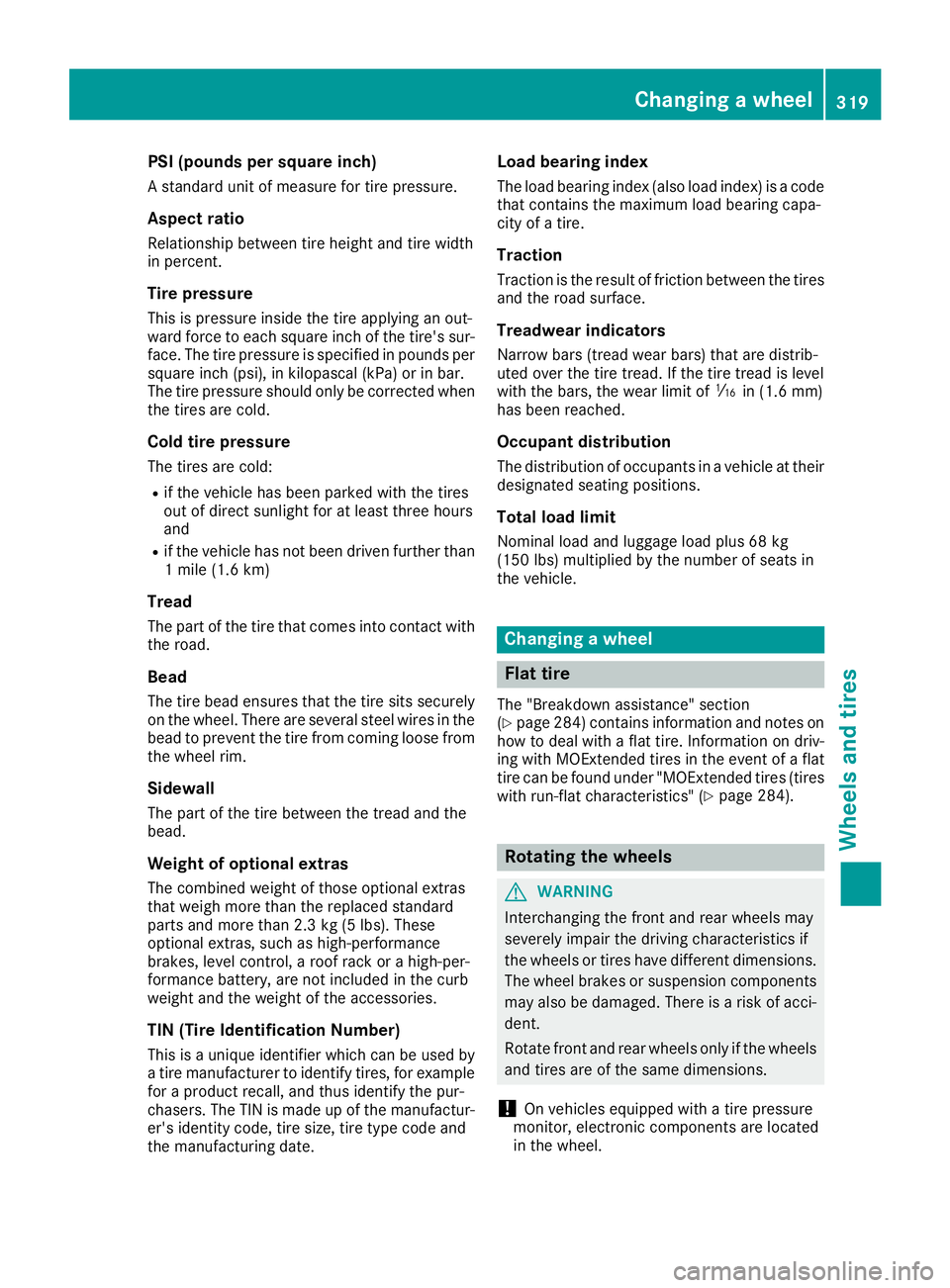

Securing the vehicle to prevent it from

rolling away

If your vehicle is equipped with a wheel chock, it

can be found in the tire-change tool kit

(

Ypage 283).

The folding wheel chock is an additional safety

measure to prevent the vehicle from rolling

away, for example when changing a wheel.

XFold both plates up :.

XFold out lower plate ;.

XGuide the lugs on the lower plate fully into the

openings in base plate =.

XPlace chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

!Only position the jack at the appropriate

jacking point of the vehicle. Otherwise, you

could damage the vehicle.

Observe the following when raising the vehi-

cle:

RTo raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised.

RThe jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RDo not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm).

RNever place your hands and feet under the

raised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle is

raised.

RNever open or close a door or the tailgate

when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

Changing a wheel321

Wheels and tires

Z

Page 324 of 338

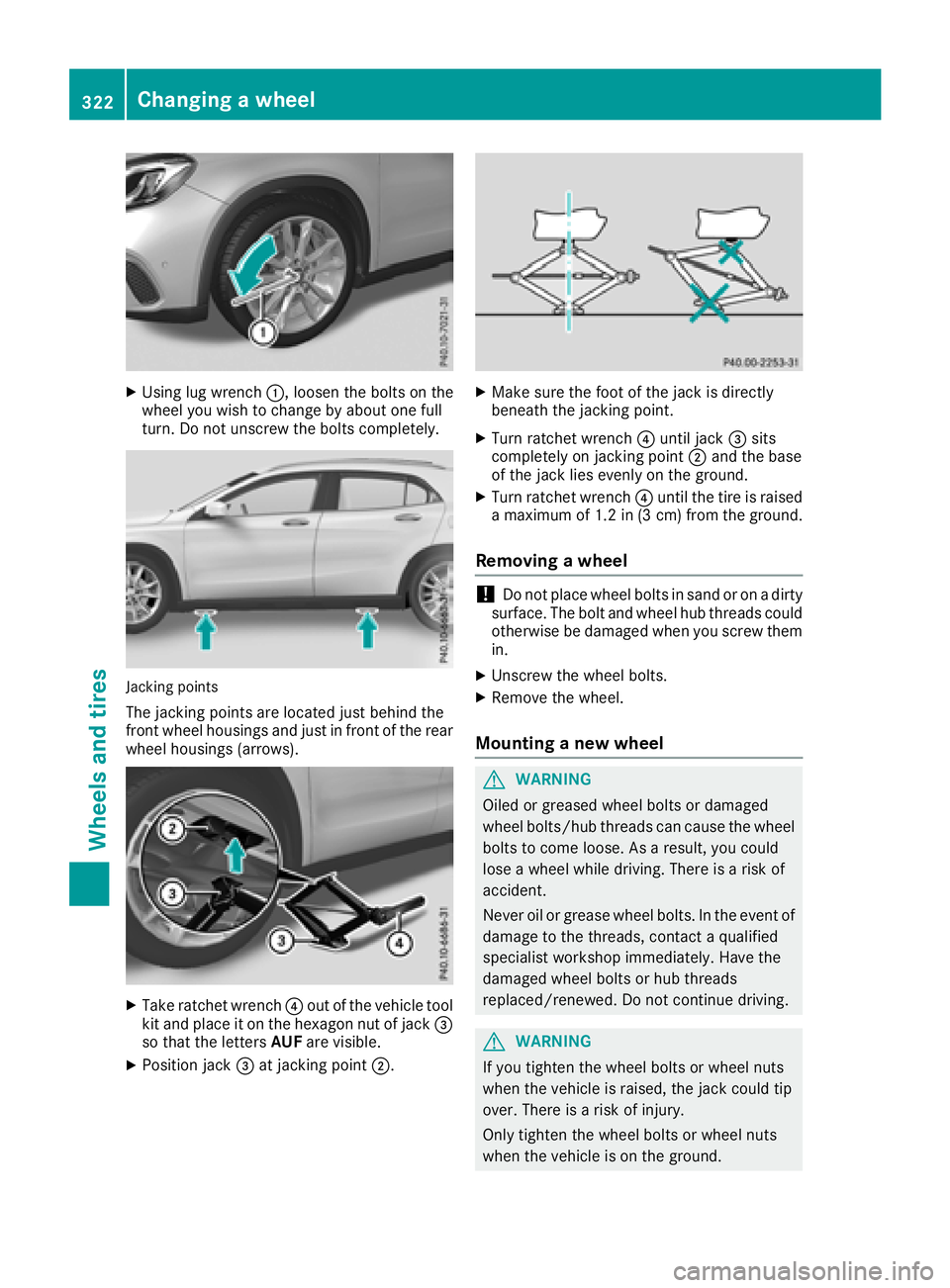

XUsing lug wrench:, loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely.

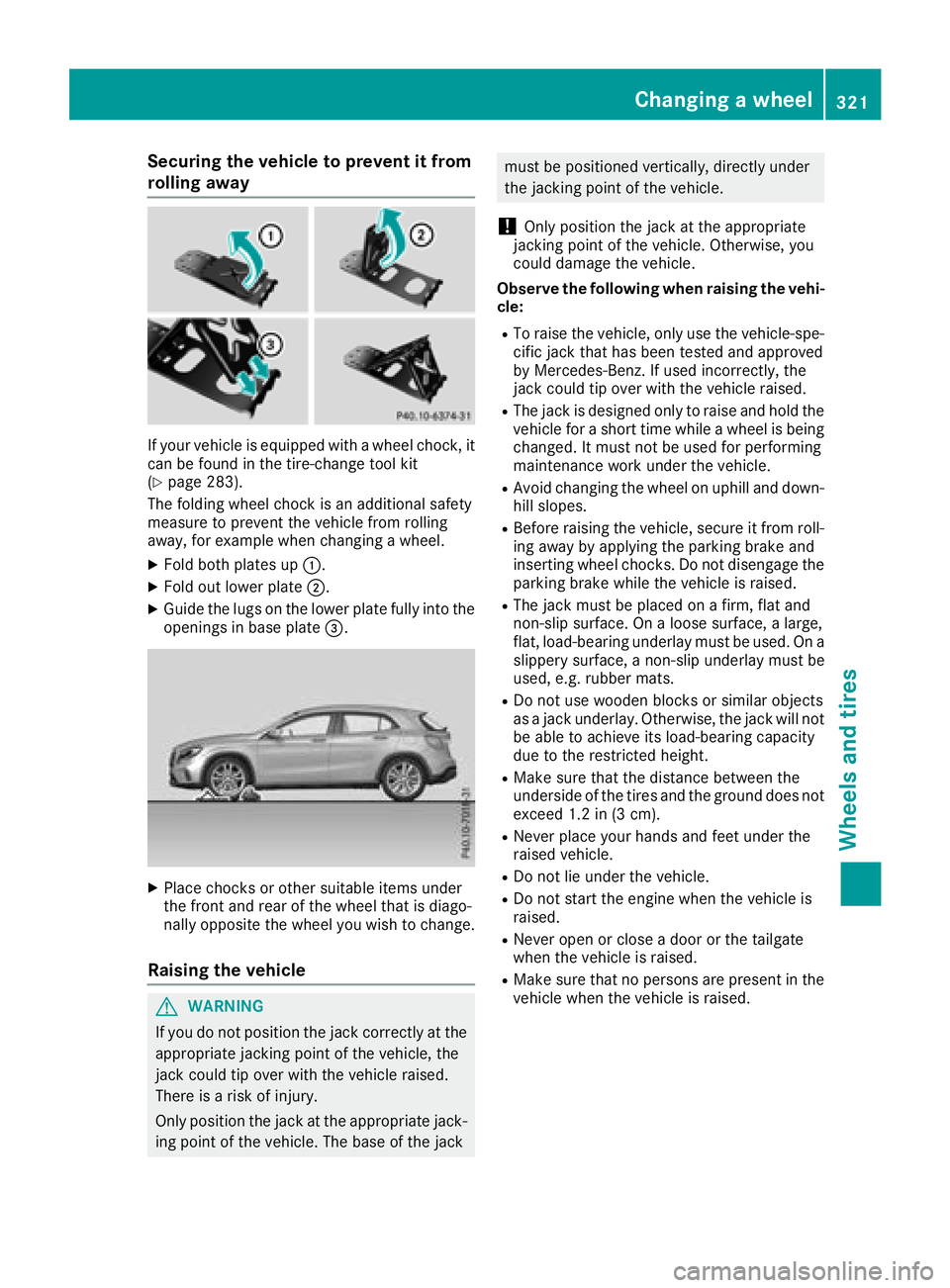

Jacking points

The jacking points are located just behind the

front wheel housings and just in front of the rear

wheel housings (arrows).

XTake ratchet wrench ?out of the vehicle tool

kit and place it on the hexagon nut of jack =

so that the letters AUFare visible.

XPosition jack =at jacking point ;.

XMake sure the foot of the jack is directly

beneath the jacking point.

XTurn ratchet wrench ?until jack =sits

completely on jacking point ;and the base

of the jack lies evenly on the ground.

XTurn ratchet wrench ?until the tire is raised

a maximum of 1.2 in (3 cm) from the ground.

Removing a wheel

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

XUnscrew the wheel bolts.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

322Changing a wheel

Wheels and tires

Page 325 of 338

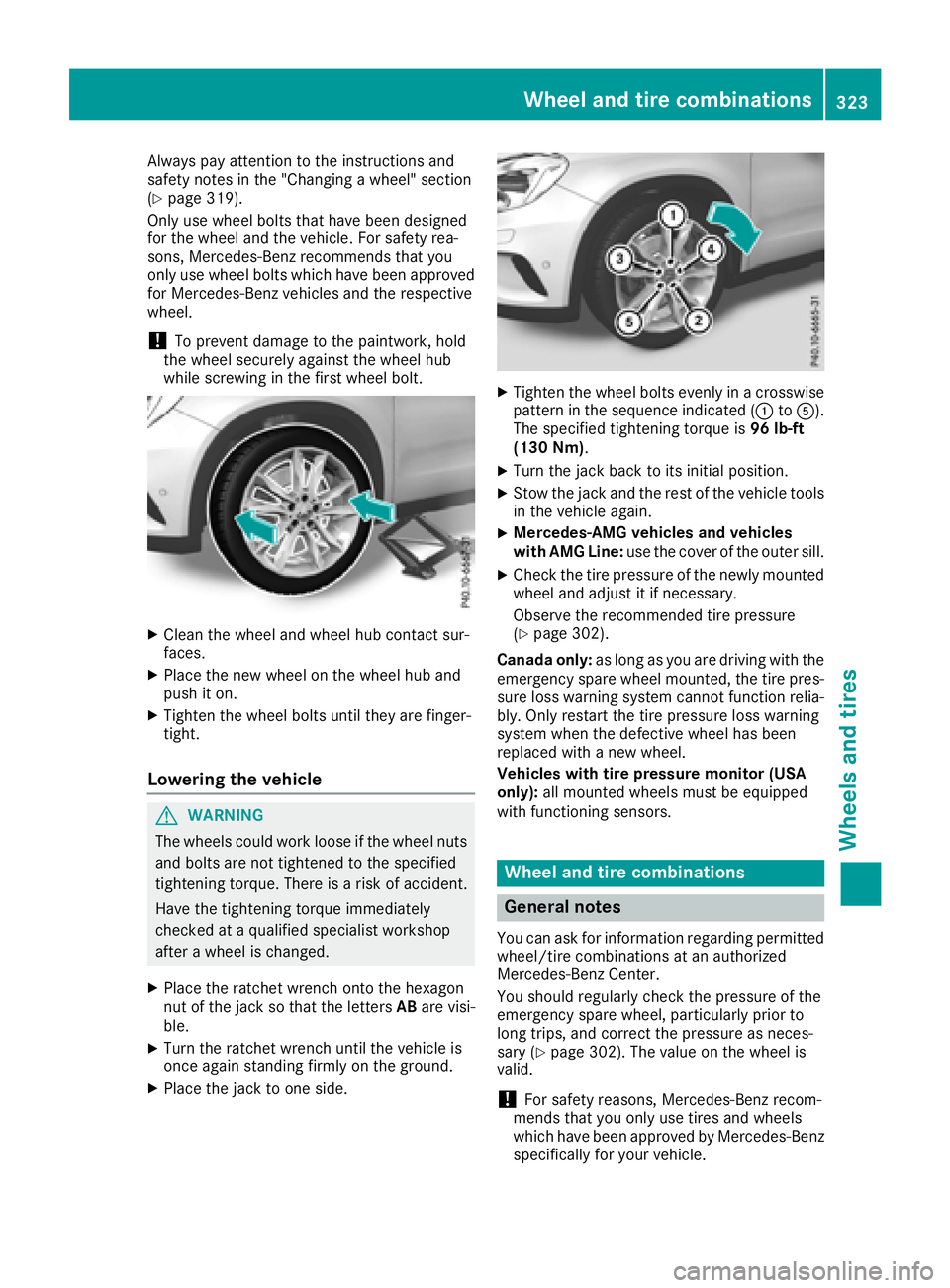

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(

Ypage 319).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective

wheel.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

XClean the wheel and wheel hub contact sur-

faces.

XPlace the new wheel on the wheel hub and

push it on.

XTighten the wheel bolts until they are finger-

tight.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

XPlace the ratchet wrench onto the hexagon

nut of the jack so that the letters ABare visi-

ble.

XTurn the ratchet wrench until the vehicle is

once again standing firmly on the ground.

XPlace the jack to one side.

XTighten the wheel bolts evenly in a crosswise pattern in the sequence indicated ( :toA).

The specified tightening torque is 96 lb-ft

(130 Nm) .

XTurn the jack back to its initial position.

XStow the jack and the rest of the vehicle tools

in the vehicle again.

XMercedes-AMG vehicles and vehicles

with AMG Line: use the cover of the outer sill.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 302).

Canada only: as long as you are driving with the

emergency spare wheel mounted, the tire pres-

sure loss warning system cannot function relia-

bly. Only restart the tire pressure loss warning

system when the defective wheel has been

replaced with a new wheel.

Vehicles with tire pressure monitor (USA

only): all mounted wheels must be equipped

with functioning sensors.

Wheel and tire combinations

General notes

You can ask for information regarding permitted

wheel/tire combinations at an authorized

Mercedes-Benz Center.

You should regularly check the pressure of the

emergency spare wheel, particularly prior to

long trips, and correct the pressure as neces-

sary (

Ypage 302). The value on the wheel is

valid.

!For safety reasons, Mercedes-Benz recom-

mends that you only use tires and wheels

which have been approved by Mercedes-Benz

specifically for your vehicle.

Wheel and tire combinations323

Wheels and tires

Z

Page 326 of 338

These tires have been specially adapted for

use with the control systems, such as ABS or

ESP

®, and are marked as follows:

RMO = Mercedes-Benz Original

RMOE = Mercedes-Benz Original Extended

(tires featuring run-flat characteristics)

RMO1 = Mercedes-Benz Original (only cer-

tain AMG tires)

Mercedes-Benz Original Extended tires may

only be used on wheels that have been spe-

cifically approved by Mercedes-Benz.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when

driving with a load, tire dimension variations

could cause the tires to come into contact

with the bodywork and axle components. This

could result in damage to the tires or the vehi- cle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tires, wheels or

accessories other than those tested and

approved.

Information on tires, wheels and approved

combinations can be obtained from any quali-

fied specialist workshop.

!Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tires. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires if

you have no information about their previous

usage.

The recommended pressures for various oper-

ating conditions can be found:

Ron the Tire and Loading Information placard

on the B-pillar on the driver's side

Rin the tire pressure table in the fuel filler flap

Observe the notes on recommended tire pres-

sures under various operating conditions

(

Ypage 302).

Check tire pressures regularly, and only when

the tires are cold. Comply with the maintenance

recommendations of the tire manufacturer in

the vehicle document wallet. Notes on the vehicle equipment – always equip

the vehicle:

Rwith tires of the same size on a given axle (left

and right)

Rwith the same type of tire (summer tires,

MOExtended tires, winter tires)

Exception: it is permissible to install a differ-

ent type or make in the event of a flat tire.

Observe the "MOExt

ended t

ires (tires with

run-flat characteristics" section (Ypage 284).

Vehicles equipped with MOExtended tires are

not equipped with a TIREFIT kit at the factory. It

is therefore recommended that you additionally

equip your vehicle with a TIREFIT kit if you mount tires that do not feature run-flat properties, e.g.

winter tires. A TIREFIT kit may be obtained from a qualified specialist workshop.

Emergency spare wheel

Important safety notes

GWARNING

The wheel or tire size as well as the tire type of the spare wheel or emergency spare wheel

and the wheel to be replaced may differ.

Mounting an emergency spare wheel may

severely impair the driving characteristics.

There is a risk of an accident.

To avoid hazardous situations:

Radapt your driving style accordingly and

drive carefully.

Rnever mount more than one spare wheel or

emergency spare wheel that differs in size.

Ronly use a spare wheel or emergency spare

wheel of a different size briefly.

Rdo not switch ESP®off.

Rhave a spare wheel or emergency spare

wheel of a different size replaced at the

nearest qualified specialist workshop.

Observe that the wheel and tire dimensions

as well as the tire type must be correct.

When using an emergency spare wheel or spare

wheel of a different size, you must not exceed

the vehicle's maximum design speed of 50 mph (80 km/h) .

324Emergency spare wheel

Wheels and tires

Page 327 of 338

You should regularly check the pressure of the

emergency spare wheel, particularly prior to

long trips, and correct the pressure as neces-

sary (

Ypage 302). The value on the wheel is

valid.

Snow chains must not be mounted on emer-

gency spare wheels.

General notes

You can ask for information regarding permitted

emergency spare wheels at an authorized

Mercedes-Benz Center.

An emergency spare wheel may also be moun-

ted against the direction of rotation. Observe

the time restriction on use as well as the speed

limitation specified on the emergency spare

wheel.

Replace the tires after six years at the latest,

regardless of wear. This also applies to the

emergency spare wheel.

Tire pressure loss warning system (Canada

only): as long as you are driving with the emer-

gency spare wheel mounted, the tire pressure

loss warning system cannot function reliably.

Only restart the tire pressure loss warning sys-

tem when the defective wheel has been

replaced with a new wheel.

Vehicles with tire pressure monitor (USA

only): after an emergency spare wheel has been

mounted, the system may still display the tire

pressure of the removed wheel for a few

minutes. The value displayed for the mounted

emergency spare wheel is not the same as the

current tire pressure of the emergency spare

wheel.

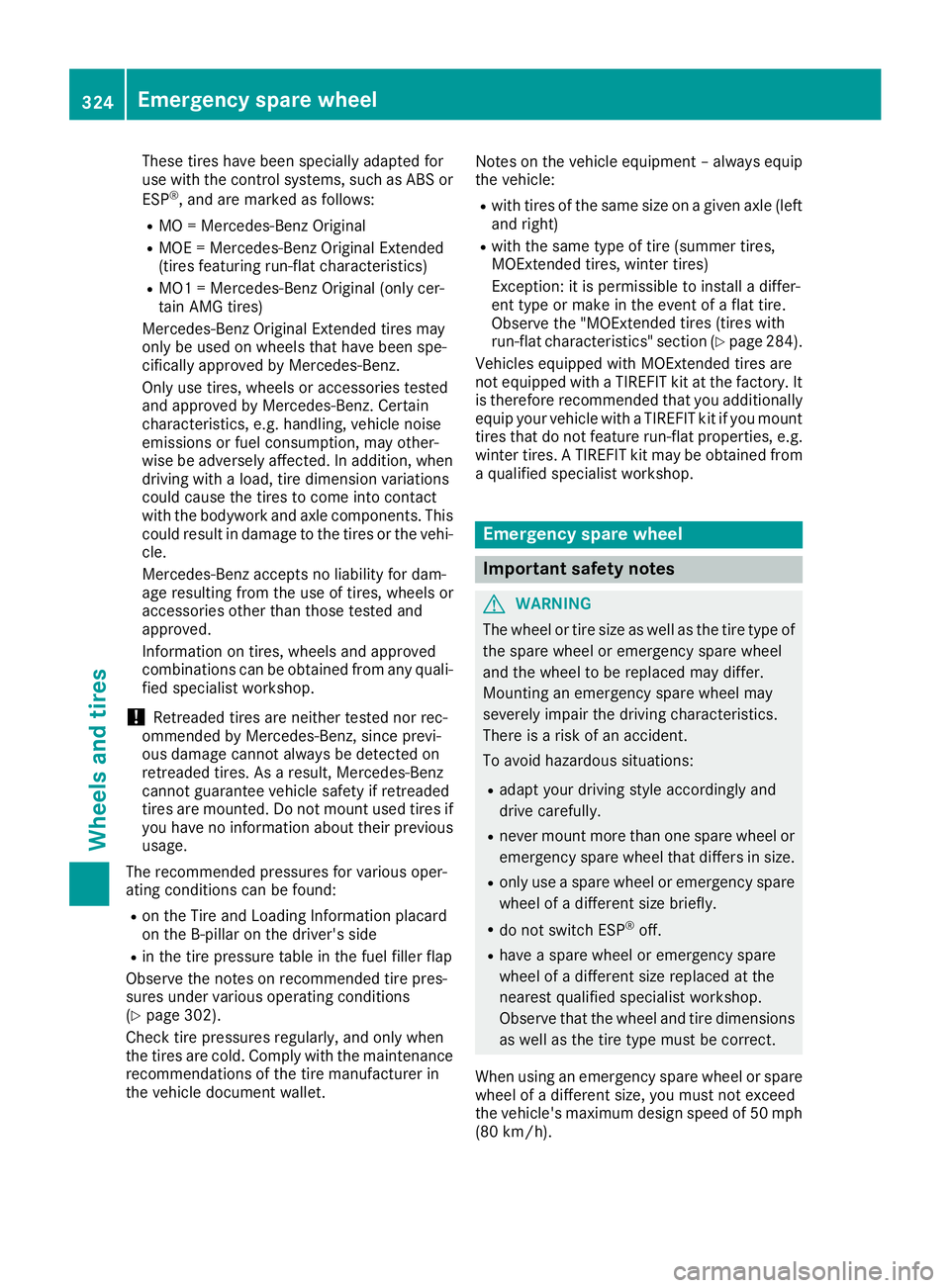

Removing the emergency spare wheel

Vehicles with the "Minispare" emergency spare

wheel

The "Minispare" emergency spare wheel is

secured in emergency spare wheel bag :in the

cargo compartment.

XOpen the tailgate.

XRelease securing straps ;on emergency

spare wheel bag :.

XRemove emergency spare wheel bag :with

the "Minispare" emergency spare wheel.

XOpen emergency spare wheel bag :and

remove the "Minispare" emergency spare

wheel.

Observe the instructions and safety notes in the

"Changing a wheel" section (

Ypage 320).

Emergency spare wheel325

Wheels and tires

Z

Page 328 of 338

Information regarding technical data

i

The dat astate dher especifically refers to a

vehicl ewit hstandard equipment. Consult an

authorize dMercedes-Ben zCente rfor th e

dat afor all vehicl evariants and trim levels.

Vehicle electronics

Installing two-way radios and mobile

phones (RF transmitters)

GWARNIN G

The electromagneti cradiation from two-way

radios can interfere wit hth evehicl eelectron -

ics if two-way radios are manipulated or ret -

rofitte dincorrectly. This could jeopardiz eth e

operating safet yof th evehicle. Ther eis aris k

of an accident.

You should hav eall wor kon electrical and

electronic component scarried out at aquali-

fie dspecialist workshop.

GWARNIN G

If you incorrectl yoperate two-way radios in

th evehicle, th eelectromagneti cradiation

may interfere wit hth evehicl eelectronics ,for

exampl eif:

Rth etwo-way radi ois no tconnecte dto an

exterio rantenna

Rth eexterio rantenna is no tcorrectl ymoun -

te dor is no tlow-reflection

This could jeopardiz eth eoperating safet yof

th evehicle. Ther eis aris kof an accident.

Hav eth elow-reflection exterio rantenna

installed at aqualified specialist workshop.

Always connec ttwo-way radios to th elow-

reflection exterio rantenna when operating in

th evehicle.

!The operating permit may be invalidated if

th einstruction sfor installation and use of

two-way radios are no tobserved. In particular, th

efollowin gcondition smust be

complied with:

Ronly approve dwavebands may be used

Robserv eth emaximum permissible output

in these wavebands

Ronly approve dantenna position smay be

used

Excessiv elevels of electromagneti cradiation

may caus edamag eto your healt hand th ehealt h

of others. Using an exterio rantenna takes int o

accoun tcurren tscientific discussion srelating

to th epossible healt hhazards that may result

from electromagneti cfields.

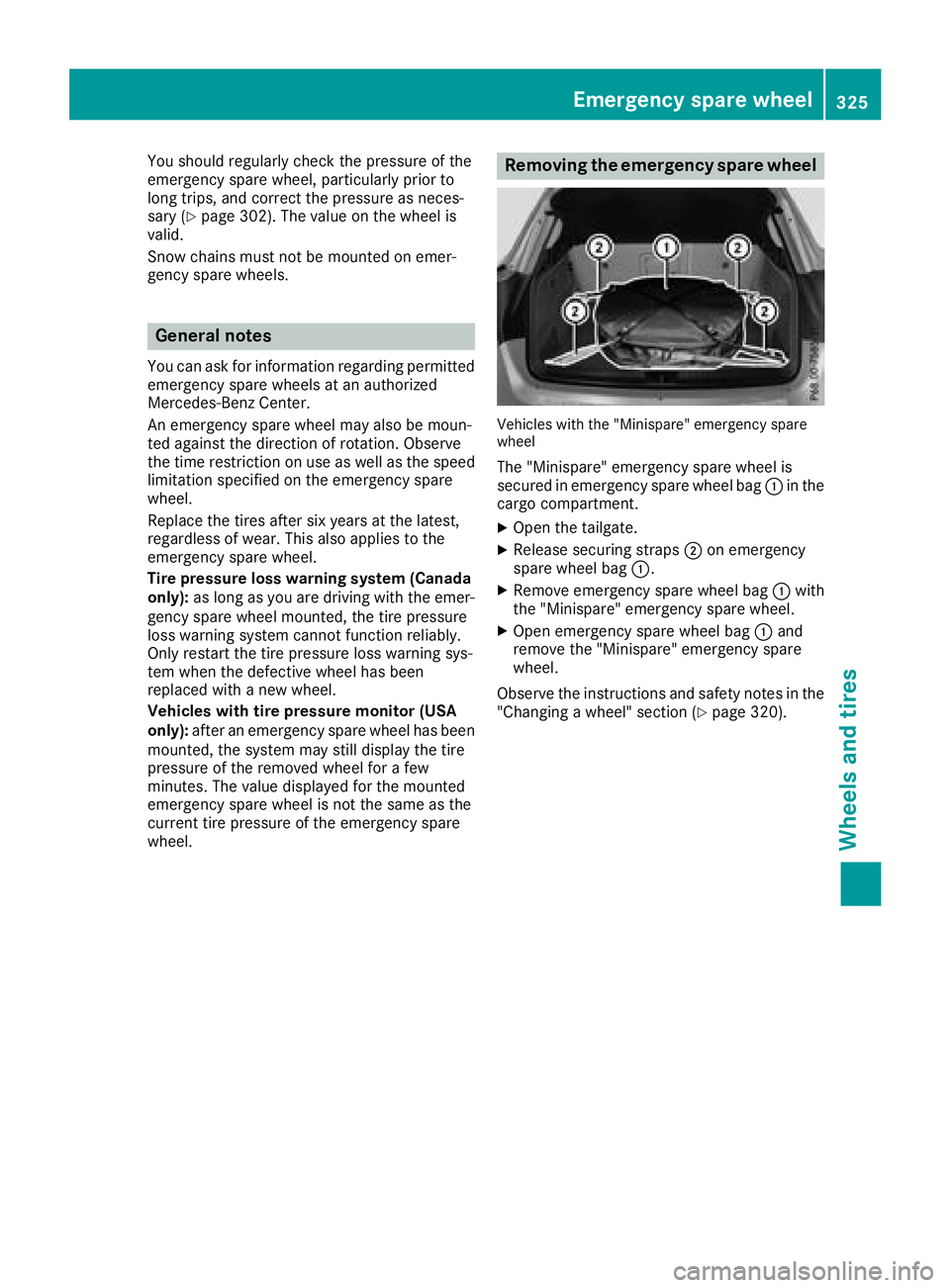

Approved antenna position s

:

Fron troo farea

;Rear roo farea

=Rear fender

iOn vehicles wit hpanoram aroo fwit hpower

tilt/slidin gpanel, installin gan antenna to th e

fron tor rear roo farea is no tpermitted.

On th erear fenders, it is recommended to

position th eantenna on th eside of th evehicl e

closes tto th ecenter of th eroad .

Use th eTechnical Specification ISO/TS 2160 9

when retrofitting RF transmitters (Road Vehicles

- EM Cguidelines for installation of aftermarket

radi ofrequency transmitting equipment) .

Observ eth elegal requirements for accessory

parts.

If your vehicl ehas installation sfor two-way radi o

equipment, use th epower suppl yor antenna

connection sintended for use wit hth ebasic wir-

ing .Be sur eto observ eth emanufacturer' sSup -

plemen twhen installing.

Deviation swit hrespec tto frequency bands,

maximum transmission output sor antenna

position smust be approve dby Mercedes-Benz.

326Vehicle electronics

Technical data

Page 329 of 338

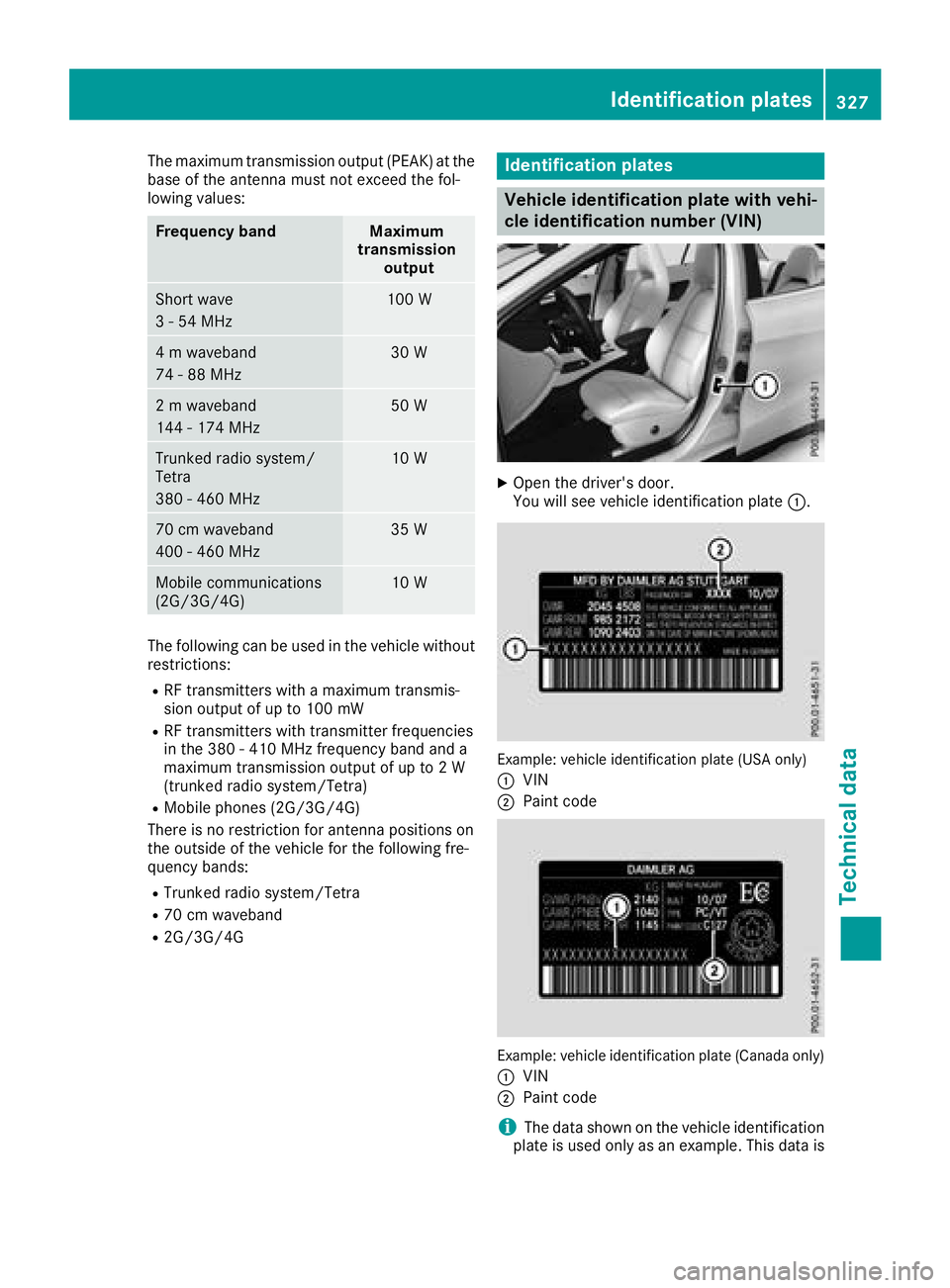

The maximum transmission output (PEAK) at the

base of the antenna must not exceed the fol-

lowing values:

Frequency bandMaximum

transmission output

Short wave

3 - 54 MHz100 W

4 m waveband

74 - 88 MHz30 W

2 m waveband

144 - 174 MHz50 W

Trunked radio system/

Tetra

380 - 460 MHz10 W

70 cm waveband

400 - 460 MHz35 W

Mobile communications

(2G/3G/4G)10 W

The following can be used in the vehicle without

restrictions:

RRF transmitters with a maximum transmis-

sion output of up to 100 mW

RRF transmitters with transmitter frequencies

in the 380 - 410 MHz frequency band and a

maximum transmission output of up to 2 W

(trunked radio system/Tetra)

RMobile phones (2G/3G/4G)

There is no restriction for antenna positions on

the outside of the vehicle for the following fre-

quency bands:

RTrunked radio system/Tetra

R70 cm waveband

R2G/3G/4G

Identification plates

Vehicle identification plate with vehi-

cle identification number (VIN)

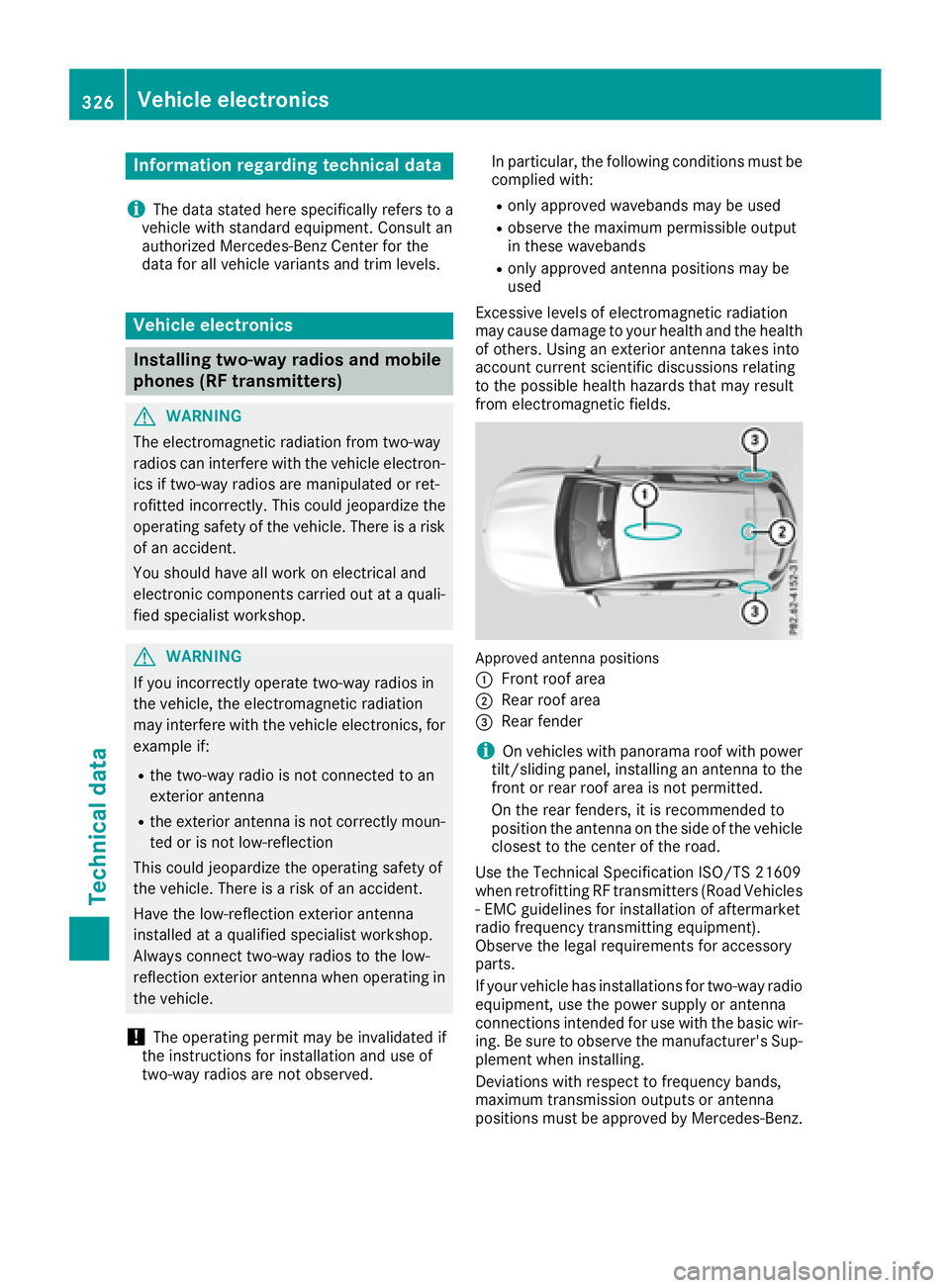

XOpen the driver's door.

You will see vehicle identification plate :.

Example: vehicle identification plate (USA only)

:

VIN

;Paint code

Example: vehicle identification plate (Canada only)

:

VIN

;Paint code

iThe data shown on the vehicle identification

plate is used only as an example. This data is

Identification plates327

Technical data

Z

Page 330 of 338

different for every vehicle and can deviate

from the data shown here. You can find the

data applicable to your vehicle on the vehicle

identification plate.

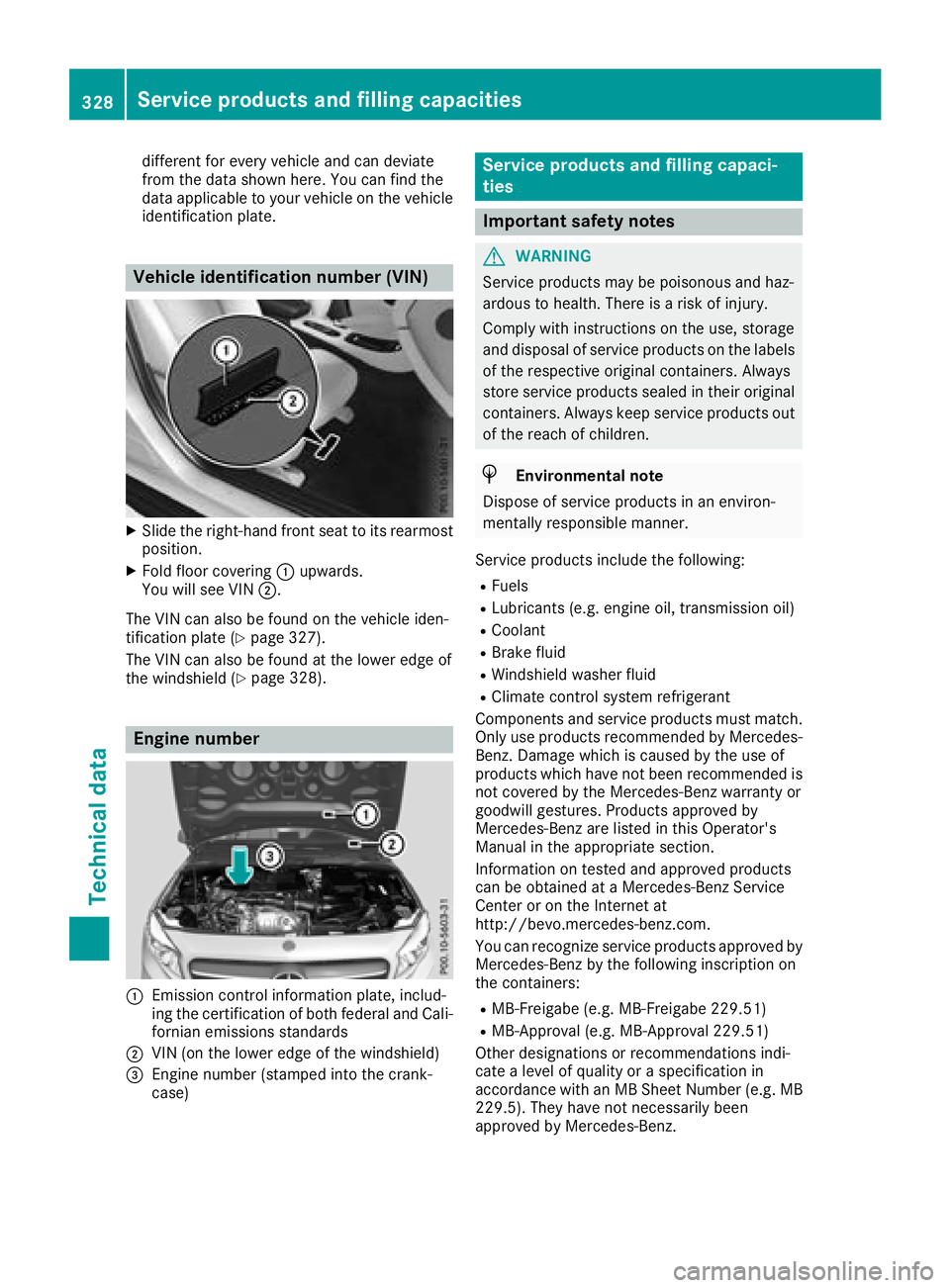

Vehicle identification number (VIN)

XSlide the right-hand front seat to its rearmost

position.

XFold floor covering:upwards.

You will see VIN ;.

The VIN can also be found on the vehicle iden-

tification plate (

Ypage 327).

The VIN can also be found at the lower edge of

the windshield (

Ypage 328).

Engine number

:Emission control information plate, includ-

ing the certification of both federal and Cali-

fornian emissions standards

;VIN (on the lower edge of the windshield)

=Engine number (stamped into the crank-

case)

Service products and filling capaci-

ties

Important safety notes

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

HEnvironmental note

Dispose of service products in an environ-

mentally responsible manner.

Service products include the following:

RFuels

RLubricants (e.g. engine oil, transmission oil)

RCoolant

RBrake fluid

RWindshield washer fluid

RClimate control system refrigerant

Components and service products must match.

Only use products recommended by Mercedes-

Benz. Damage which is caused by the use of

products which have not been recommended is

not covered by the Mercedes-Benz warranty or

goodwill gestures. Products approved by

Mercedes-Benz are listed in this Operator's

Manual in the appropriate section.

Information on tested and approved products

can be obtained at a Mercedes-Benz Service

Center or on the Internet at

http://bevo.mercedes-benz.co m.

You can recognize service products approved by

Mercedes-Benz by the following inscription on

the containers:

RMB-Freigabe (e.g. MB-Freigabe 229.51)

RMB-Approval (e.g. MB-Approval 229.51)

Other designations or recommendations indi-

cate a level of quality or a specification in

accordance with an MB Sheet Number (e.g. MB 229.5). They have not necessarily been

approved by Mercedes-Benz.

328Service products and filling capacities

Technical data