wheel bolts MERCEDES-BENZ GLC 2017 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: GLC, Model: MERCEDES-BENZ GLC 2017Pages: 374, PDF Size: 8.42 MB

Page 316 of 374

If water no longer forms "beads" on the paint

surface, use the paint care products recommen-

ded and approved by Mercedes-Benz. This is the

case approximately every three to five months,

depending on the climate conditions and the

care product used.

The cleaning product Paint Cleaner, which has

been recommended and approved by

Mercedes-Benz, should be used when dirt has

penetrated the paint surface.

Also use Paint Cleaner on paint that has become

dull.

Do not use these care products in the sun or on

the hood while the hood is hot. X

Use a suitable touch-up stick, e.g. MB Touch-

Up Stick, to repair slight damage to the paint-

work quickly and provisionally.

Matte finish care

! Never polish the vehicle or the light alloy

wheels. Polishing causes the finish to shine.

! The following may cause the paint to

become shiny and thus reduce the matte

effect: R

strong rubbing of the paintwork with

unsuitable materials R

frequent use of automatic car washes R

washing the vehicle in direct sunlight

! Never use paint cleaner, buffing or polishing

products, or gloss preserver, e.g. wax, for the

purpose of paintwork care. These products

are only suitable for high-gloss surfaces. Their

use on vehicles with matte paintwork leads to

considerable surface damage or, more spe-

cifically, to shiny, spotted areas.

Always have paintwork repairs carried out at a

qualified specialist workshop.

! Do not use wash programs with a hot wax

treatment under any circumstances.

Observe these notes if your vehicle has a clear

matte finish. This will help you to avoid damage

to the paintwork due to incorrect treatment.

These notes also apply to light alloy wheels with

a clear matte finish.

The vehicle should preferably be washed by

hand using a soft sponge, car shampoo and

plenty of water. Use only insect remover and car shampoo from

the range of approved Mercedes-Benz care

products.

Cleaning the vehicle parts

Cleaning the wheels

G WARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior damage

to the tires or chassis components. Compo-

nents damaged in this way may fail unexpect-

edly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced imme-

diately.

! Do not use acidic wheel cleaning products

to remove brake dust. This could damage

wheel bolts and brake components.

! Do not park your vehicle for a long period of

time directly after cleaning, particularly after

cleaning the wheel rim with wheel cleaner.

Wheel cleaner can lead to the increased cor-

rosion of the brake discs and pads. Therefore,

drive for a few minutes after cleaning. By

heating up the brakes, the brake discs and

pads dry. The vehicle can then be parked for a

long period of time.

Cleaning the windows

G WARNING

You could become trapped by the windshield

wipers if they start moving while cleaning the

windshield or wiper blades. There is a risk of

injury.

Always switch off the windshield wipers and

the ignition before cleaning the windshield or

wiper blades.

! Do not use dry cloths, abrasive products,

solvents or cleaning agents containing sol-

vents to clean the inside of the windows. Do

not touch the insides of the windows with

hard objects, e.g. an ice scraper or ring. There

is otherwise a risk of damaging the windows.314

Care

Maintenance and care

Page 360 of 374

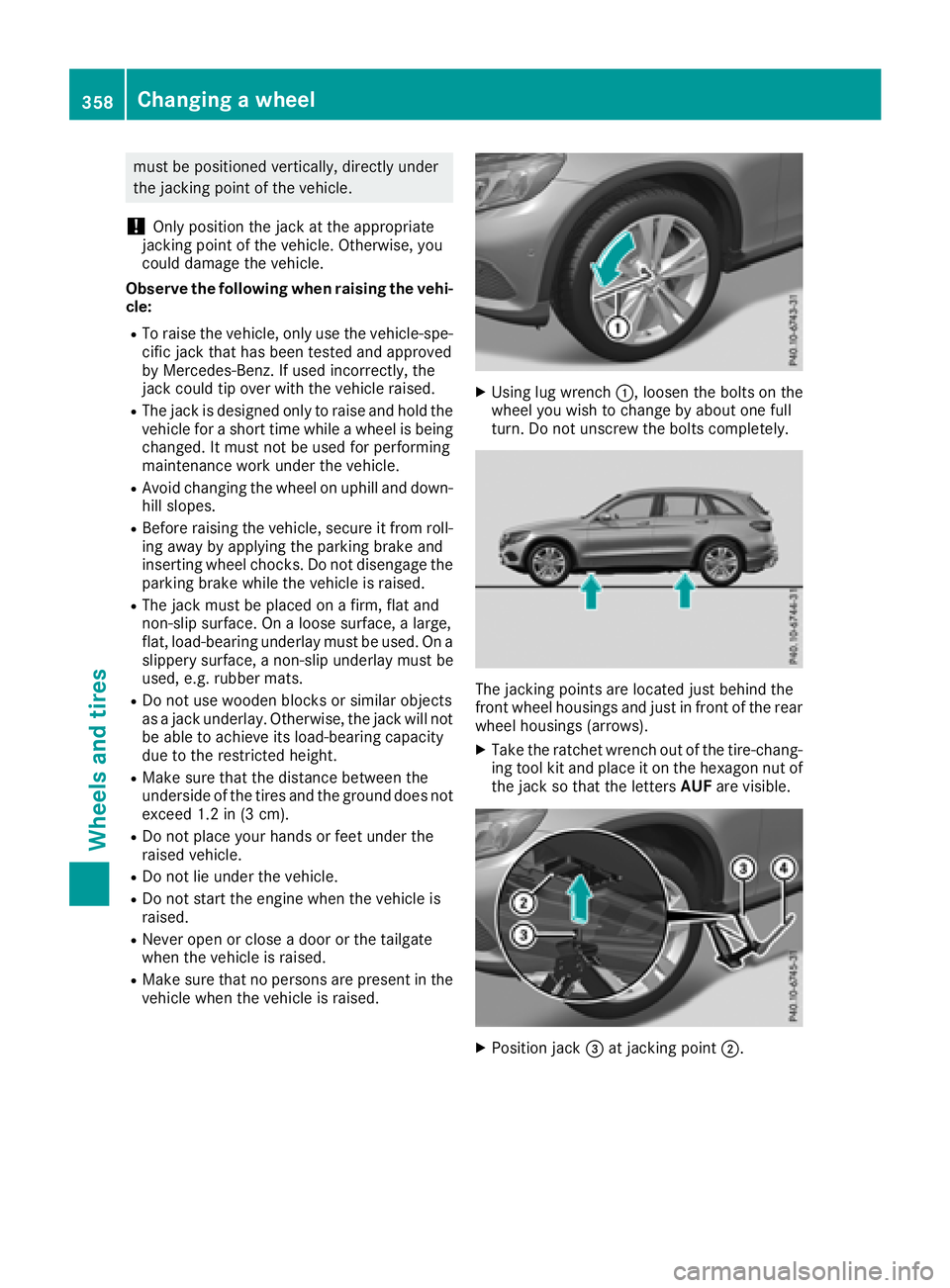

must be positioned vertically, directly under

the jacking point of the vehicle.

! Only position the jack at the appropriate

jacking point of the vehicle. Otherwise, you

could damage the vehicle.

Observe the following when raising the vehi-

cle: R

To raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised. R

The jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle. R

Avoid changing the wheel on uphill and down-

hill slopes. R

Before raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised. R

The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats. R

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height. R

Make sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm). R

Do not place your hands or feet under the

raised vehicle. R

Do not lie under the vehicle. R

Do not start the engine when the vehicle is

raised. R

Never open or close a door or the tailgate

when the vehicle is raised. R

Make sure that no persons are present in the

vehicle when the vehicle is raised. X

Using lug wrench �C , loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely.

The jacking points are located just behind the

front wheel housings and just in front of the rear

wheel housings (arrows). X

Take the ratchet wrench out of the tire-chang-

ing tool kit and place it on the hexagon nut of

the jack so that the letters AUF are visible.

X

Position jack �

Page 362 of 374

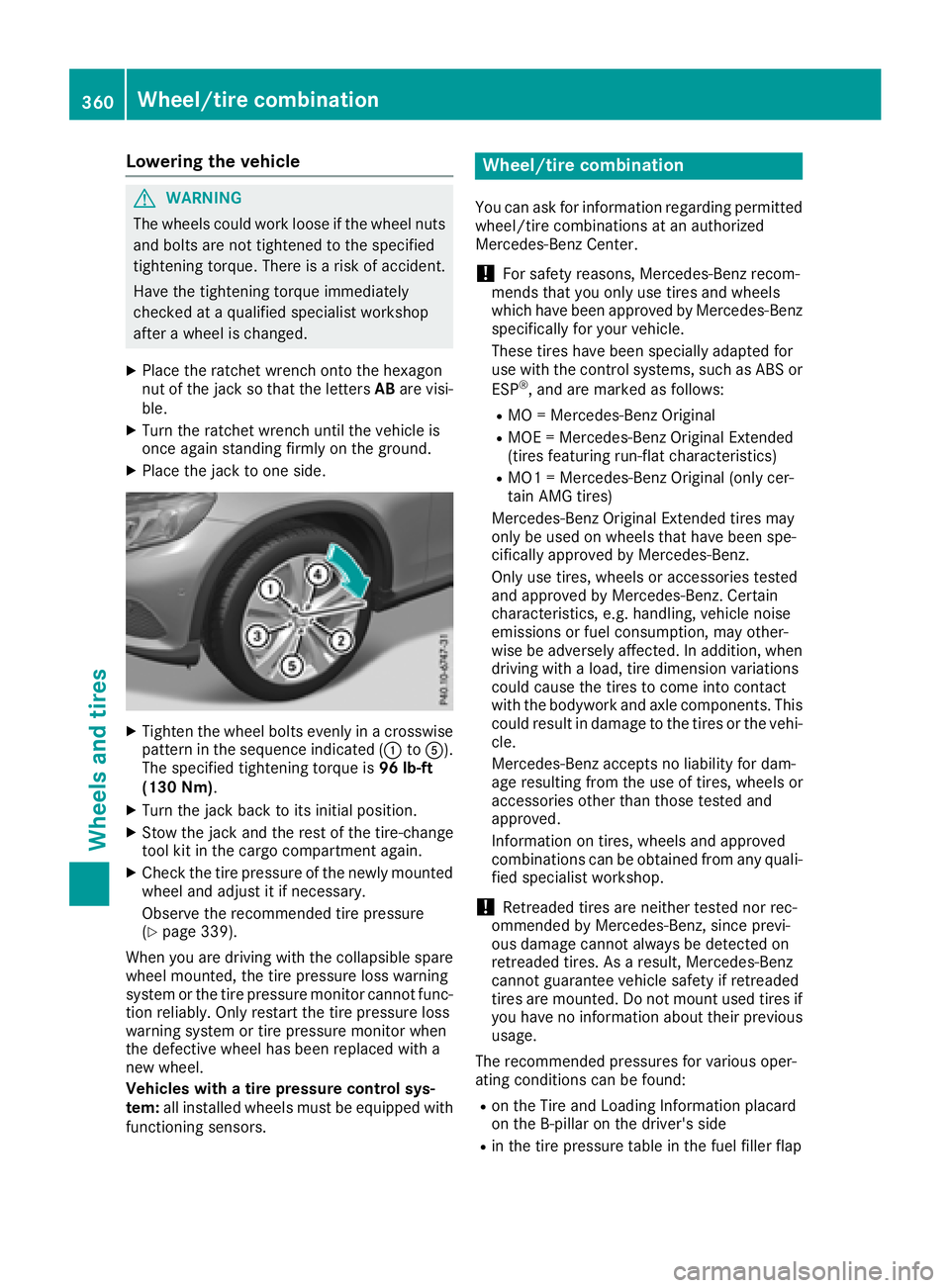

Lowering the vehicle

G WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed. X

Place the ratchet wrench onto the hexagon

nut of the jack so that the letters AB are visi-

ble. X

Turn the ratchet wrench until the vehicle is

once again standing firmly on the ground. X

Place the jack to one side.

X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated ( �C to �