MERCEDES-BENZ GLE SUV 2019 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: GLE SUV, Model: MERCEDES-BENZ GLE SUV 2019Pages: 398, PDF Size: 12.25 MB

Page 371 of 398

requirements of the U.S. Department of Trans-

portation.

Manufacturer identification code: manufac-

turer identification code 0044provides details on

the tire manufacturer. New tires have a code

with two symbols. Retreaded tires have a code

with four symbols.

For further information about retreaded tires,

see (Y page 376).

Tire size: identifier0087describes the tire size.

Tire type code: tire type code0085can be used by

the manufacturer as a code to describe specific

characteristics of the tire.

Date of manufacture: date of manufacture0083

provides information about the age of a tire. The

first and second positions represent the week of manufacture, starting with "01" for the first cal-

endar week. Positions three and four represent

the year of manufacture. For example, a tire that

is marked "3214" was manufactured in week 32 in 2014.

i Tire data is vehicle-specific and may deviate

from the data in the example.

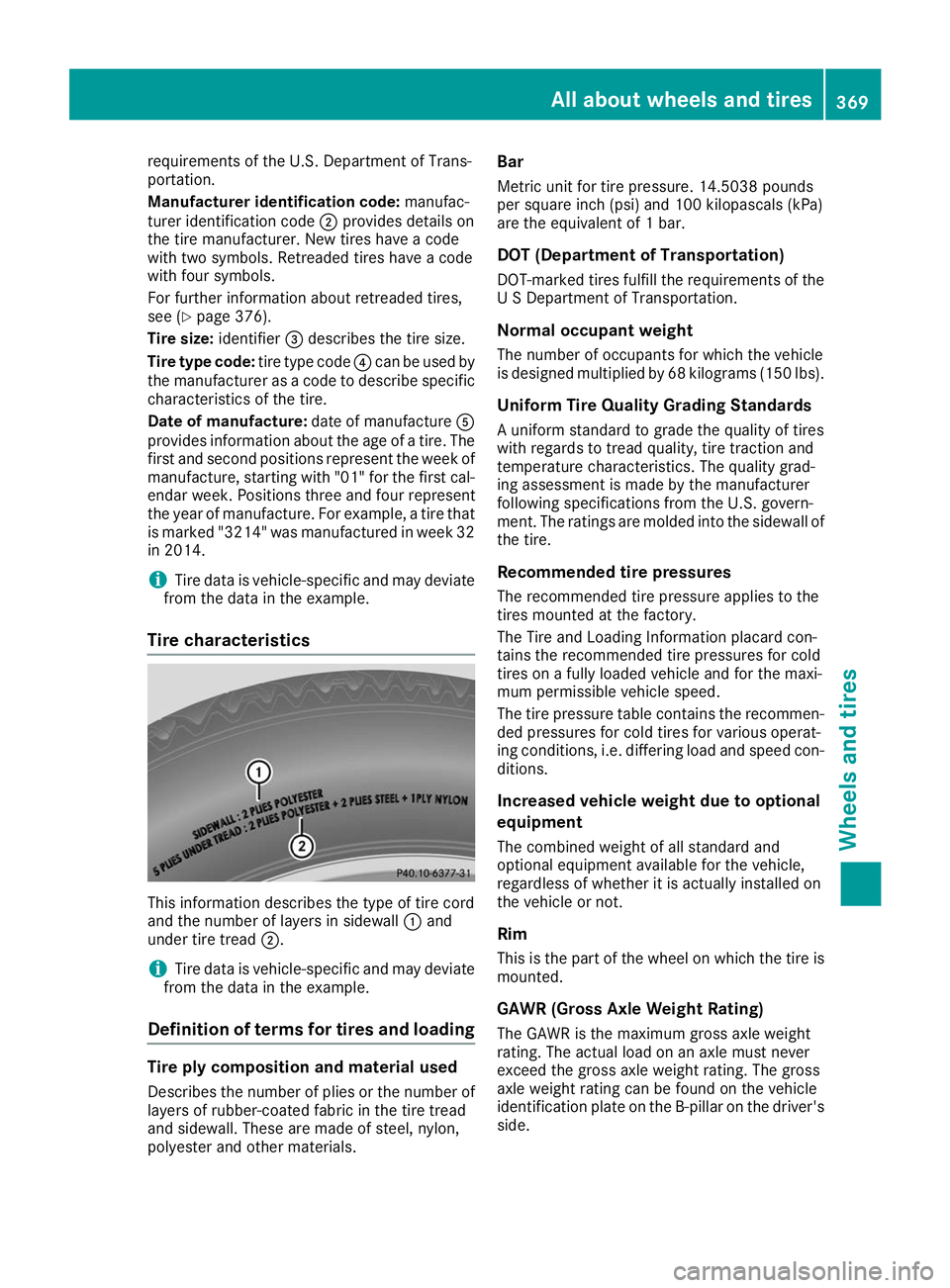

Tire characteristics This information describes the type of tire cord

and the number of layers in sidewall 0043and

under tire tread 0044.

i Tire data is vehicle-specific and may deviate

from the data in the example.

Definition of terms for tires and loading Tire ply composition and material used

Describes the number of plies or the number of

layers of rubber-coated fabric in the tire tread

and sidewall. These are made of steel, nylon,

polyester and other materials. Bar

Metric unit for tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascals (kPa)

are the equivalent of 1 bar.

DOT (Department of Transportation)

DOT-marked tires fulfill the requirements of the U S Department of Transportation.

Normal occupant weight

The number of occupants for which the vehicle

is designed multiplied by 68 kilograms (150 lbs).

Uniform Tire Quality Grading Standards

A uniform standard to grade the quality of tires

with regards to tread quality, tire traction and

temperature characteristics. The quality grad-

ing assessment is made by the manufacturer

following specifications from the U.S. govern-

ment. The ratings are molded into the sidewall of the tire.

Recommended tire pressures The recommended tire pressure applies to the

tires mounted at the factory.

The Tire and Loading Information placard con-

tains the recommended tire pressures for cold

tires on a fully loaded vehicle and for the maxi-

mum permissible vehicle speed.

The tire pressure table contains the recommen-

ded pressures for cold tires for various operat-

ing conditions, i.e. differing load and speed con-

ditions.

Increased vehicle weight due to optional

equipment The combined weight of all standard and

optional equipment available for the vehicle,

regardless of whether it is actually installed on

the vehicle or not.

Rim

This is the part of the wheel on which the tire is

mounted.

GAWR (Gross Axle Weight Rating)The GAWR is the maximum gross axle weight

rating. The actual load on an axle must never

exceed the gross axle weight rating. The gross

axle weight rating can be found on the vehicle

identification plate on the B-pillar on the driver's

side. All about wheels and tires

369Wheels and tires Z

Page 372 of 398

Speed rating

The speed rating is part of the tire identification. It specifies the speed range for which the tire is

approved.

GTW (Gross Trailer Weight)

The GTW is the weight of a trailer including the

weight of the load, luggage, accessories etc. on

the trailer.

GVW (Gross Vehicle Weight) The gross vehicle weight includes the weight of

the vehicle including fuel, tools, the spare wheel, accessories installed, occupants, luggage and

the drawbar noseweight, if applicable. The gross

vehicle weight must not exceed the gross vehi-

cle weight rating GVWR as specified on the vehi- cle identification plate on the B-pillar on the

driver's side.

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permissible gross

weight of a fully loaded vehicle (the weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight, if

applicable). The gross vehicle weight rating is

specified on the vehicle identification plate on

the B-pillar on the driver's side.

Maximum loaded vehicle weightThe maximum weight is the sum of:

R the curb weight of the vehicle

R the weight of the accessories

R the load limit

R the weight of the factory installed optional

equipment

Kilopascal (kPa) Metric unit for tire pressure. 6.9 kPa corre-

sponds to 1 psi. Another unit for tire pressure is

bar. 100 kilopascals (kPa) are the equivalent of

1 bar.

Load index

In addition to the load-bearing index, the load

index may also be imprinted on the sidewall of

the tire. This specifies the load-bearing capacity

more precisely.

Curb weight The weight of a vehicle with standard equipment

including the maximum capacity of fuel, oil and

coolant. It also includes the air-conditioning sys- tem and optional equipment if these are instal-

led in the vehicle, but does not include passen-

gers or luggage.

Maximum load rating The maximum tire load is the maximum permis-

sible weight in kilograms or lbs for which a tire is approved.

Maximum permissible tire pressure Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (pounds per square inch) A standard unit of measure for tire pressure.

Aspect ratio Relationship between tire height and tire width

in percent.

Tire pressure

This is pressure inside the tire applying an out-

ward force to each square inch of the tire's sur-

face. The tire pressure is specified in pounds per

square inch (psi), in kilopascal (kPa) or in bar.

The tire pressure should only be corrected when the tires are cold.

Cold tire pressure

The tires are cold:

R if the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and

R if the vehicle has not been driven further than

1 mile (1.6 km)

Tread The part of the tire that comes into contact with

the road.

BeadThe tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim. 370

All about wheels and tiresWheels and tires

Page 373 of 398

Sidewall

The part of the tire between the tread and the

bead.

Weight of optional extras The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-per-

formance battery, are not included in the curb

weight and the weight of the accessories.

TIN (Tire Identification Number) This is a unique identifier which can be used by

a tire manufacturer to identify tires, for example for a product recall, and thus identify the pur-

chasers. The TIN is made up of the manufactur-

er's identity code, tire size, tire type code and

the manufacturing date.

Load bearing index

The load bearing index (also load index) is a code that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires and the road surface.

TWR (Tongue Weight Rating)

The TWR specifies the maximum permissible

weight that the ball coupling of the trailer tow

hitch can support.

Treadwear indicators Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of 00CDin (1.6 mm)

has been reached.

Occupant distribution

The distribution of occupants in a vehicle at their designated seating positions.

Total load limit Nominal load and luggage load plus 68 kg

(150 lbs) multiplied by the number of seats in

the vehicle. Changing a wheel

Flat tire

The "Breakdown assistance" section

(Y page 335) contains information and notes on

how to deal with a flat tire. Information on driv-

ing with MOExtended tires in the event of a flat

tire can be found under "MOExtended tires (tires with run-flat characteristics" (Y page 336).

Vehicles with an emergency spare wheel: in

the event of a flat tire, mount the emergency

spare wheel according to the description under "Mounting a wheel" (Y page 372). Rotating the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y page 372).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in

the center.

On vehicles that have the same size front and

rear wheels, you can rotate the wheels accord-

ing to the intervals in the tire manufacturer's

warranty book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000 to

10,000 km). Depending on tire wear, this may Changing a wheel

371Wheels and tires Z

Page 374 of 398

be required earlier. Do not change the direction

of wheel rotation.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is rota- ted. Check the tire pressure and, if necessary,

restart the tire pressure loss warning system or

the tire pressure monitor (Y page 358).Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. These advantages can only be gained if the tires are installed corresponding to the

direction of rotation.

An arrow on the sidewall of the tire indicates itscorrect direction of rotation. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from oil, grease, gasoline and diesel. Mounting a wheel

Preparing the vehicle X

Vehicle with emergency spare wheel:

when mounting the emergency spare wheel in

the event of a flat tire, follow the additional

notes on vehicle preparation under "Flat tire"

(Y page 335).

X Stop the vehicle on solid, non-slippery and

level ground.

X Apply the electric parking brake manually.

X Bring the front wheels into the straight-ahead

position.

X Vehicles with automatic transmission:

shift the transmission to position

005D.

X Vehicles with the AIRMATIC package:

make sure that the normal vehicle level is

selected (Y page 185).

X Vehicles with the Off-Road Engineering

package:

make sure that the normal vehicle

level is selected (Y page 179).

X Switch off the engine.

X Vehicles without KEYLESS-GO: remove the

SmartKey from the ignition lock. X

Vehicles with KEYLESS-GO: open the driv-

er's door.

The vehicle electronics are now in position

0092. This means no SmartKey is in the ignition

lock.

X Vehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

(Y page 135).

X Make sure that the engine cannot be started

via your smartphone (Y page 137).

X If included in the vehicle equipment, remove

the tire-change tool kit from the vehicle.

X Safeguard the vehicle against rolling away.

i Apart from certain country-specific varia-

tions, vehicles are not equipped with a tire-

change tool kit. For more information on

which tools are required to perform a wheel

change on your vehicle, consult a qualified

specialist workshop.

Necessary tire-changing tools can include, for

example:

R Jack

R Wheel chock

R Lug wrench

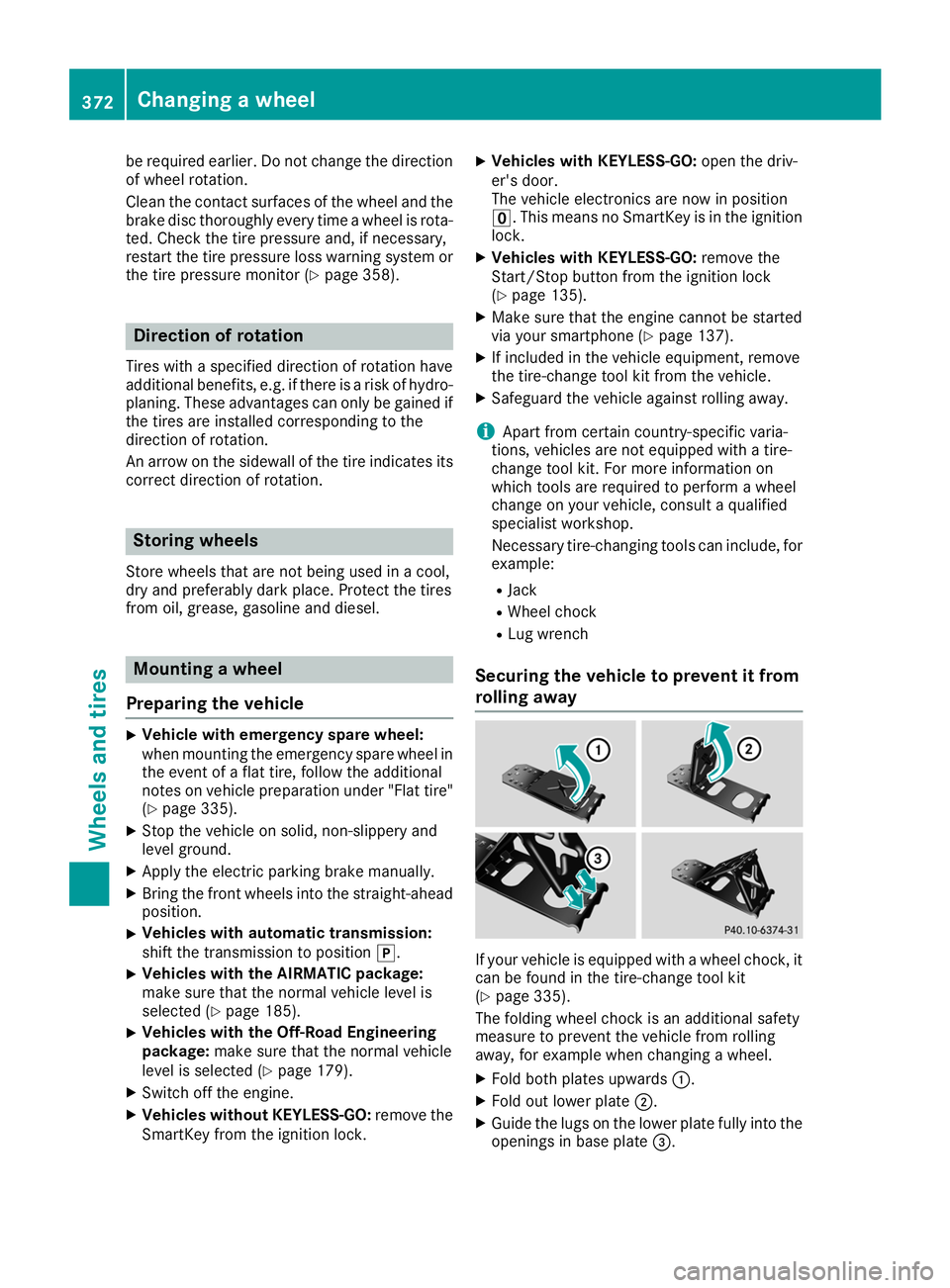

Securing the vehicle to prevent it from

rolling away If your vehicle is equipped with a wheel chock, it

can be found in the tire-change tool kit

(Y page 335).

The folding wheel chock is an additional safety

measure to prevent the vehicle from rolling

away, for example when changing a wheel.

X Fold both plates upwards 0043.

X Fold out lower plate 0044.

X Guide the lugs on the lower plate fully into the

openings in base plate 0087.372

Changing a wheelWheels and tires

Page 375 of 398

X

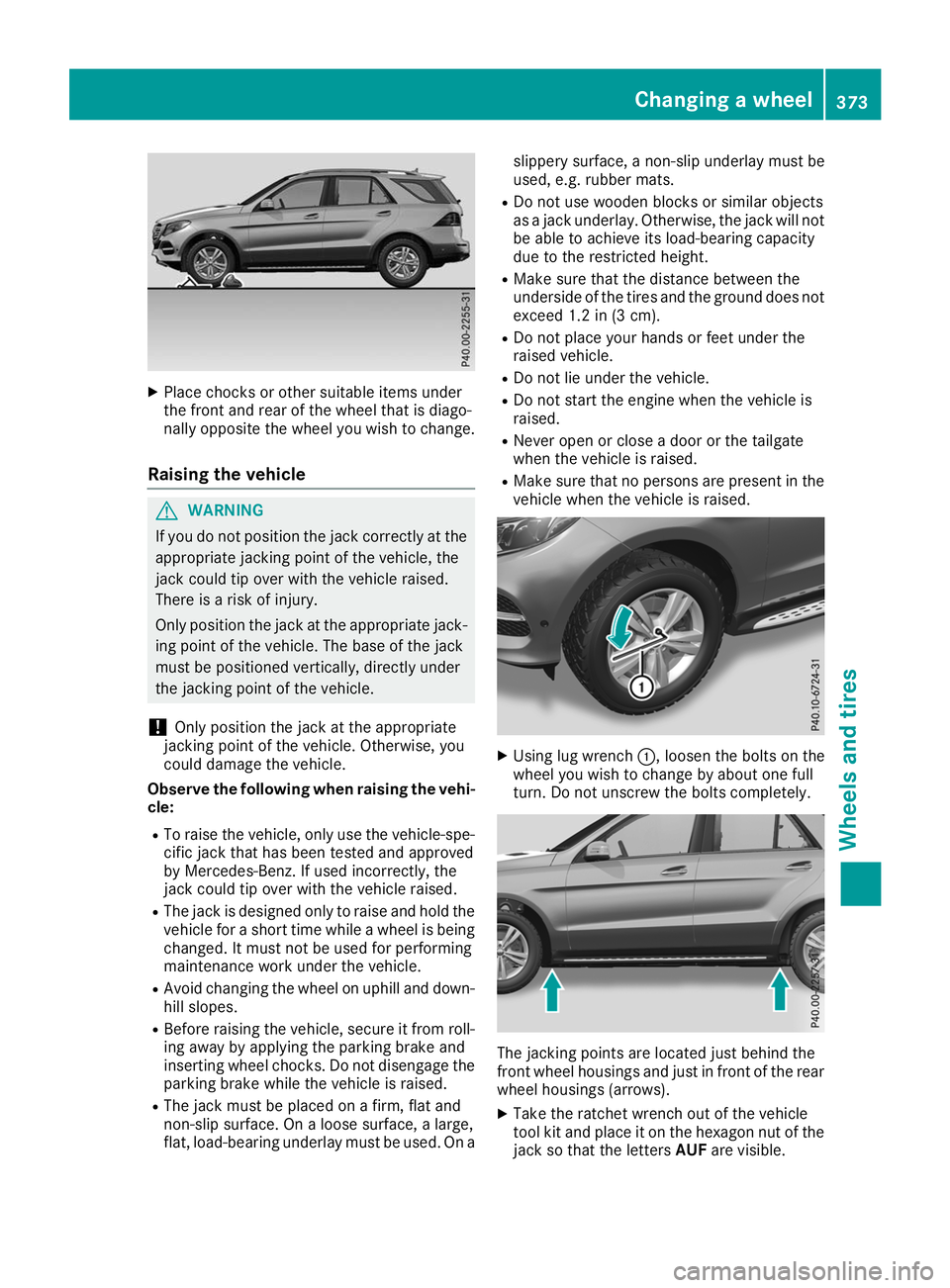

Place chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

! Only position the jack at the appropriate

jacking point of the vehicle. Otherwise, you

could damage the vehicle.

Observe the following when raising the vehi- cle:

R To raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised.

R The jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle.

R Avoid changing the wheel on uphill and down-

hill slopes.

R Before raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the parking brake while the vehicle is raised.

R The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

R Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

R Make sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm).

R Do not place your hands or feet under the

raised vehicle.

R Do not lie under the vehicle.

R Do not start the engine when the vehicle is

raised.

R Never open or close a door or the tailgate

when the vehicle is raised.

R Make sure that no persons are present in the

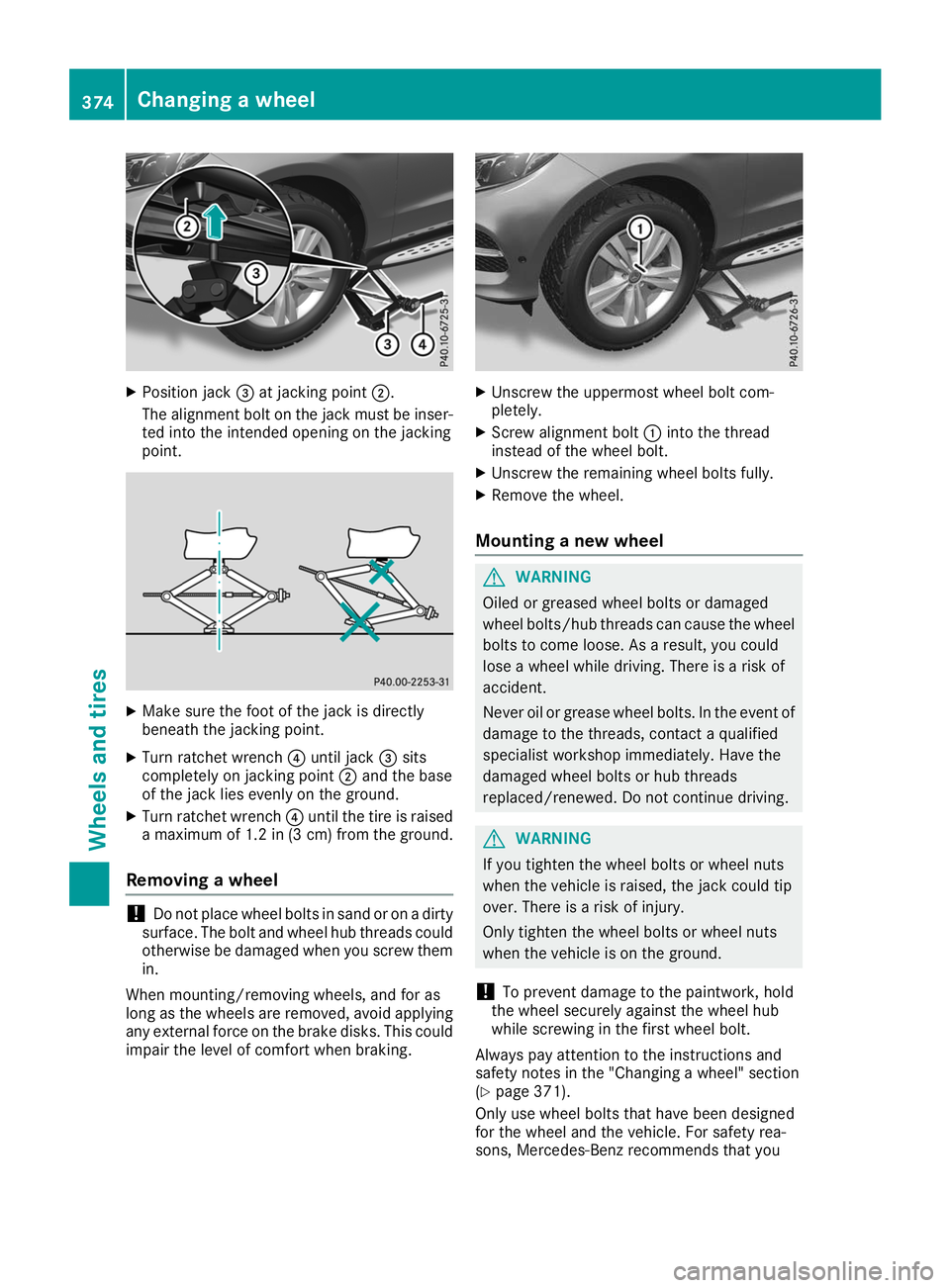

vehicle when the vehicle is raised. X

Using lug wrench 0043, loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely. The jacking points are located just behind the

front wheel housings and just in front of the rear

wheel housings (arrows).

X Take the ratchet wrench out of the vehicle

tool kit and place it on the hexagon nut of the

jack so that the letters AUFare visible. Changing a wheel

373Wheels and tires Z

Page 376 of 398

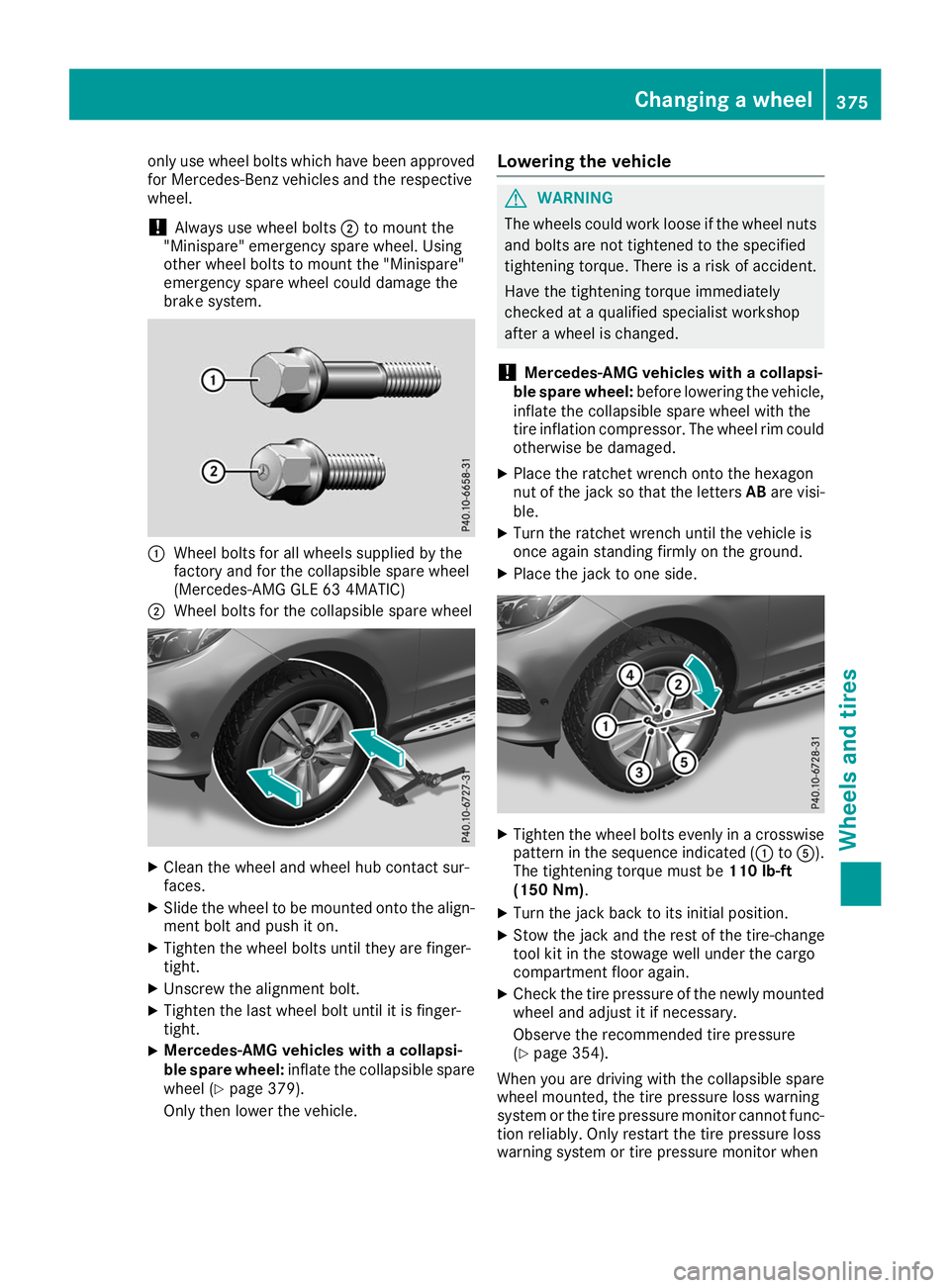

X

Position jack 0087at jacking point 0044.

The alignment bolt on the jack must be inser- ted into the intended opening on the jacking

point. X

Make sure the foot of the jack is directly

beneath the jacking point.

X Turn ratchet wrench 0085until jack 0087sits

completely on jacking point 0044and the base

of the jack lies evenly on the ground.

X Turn ratchet wrench 0085until the tire is raised

a maximum of 1.2 in (3 cm) from the ground.

Removing a wheel !

Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

When mounting/removing wheels, and for as

long as the wheels are removed, avoid applying any external force on the brake disks. This could impair the level of comfort when braking. X

Unscrew the uppermost wheel bolt com-

pletely.

X Screw alignment bolt 0043into the thread

instead of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event ofdamage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(Y page 371).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you 374

Changing a wheelWheels and tires

Page 377 of 398

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

! Always use wheel bolts

0044to mount the

"Minispare" emergency spare wheel. Using

other wheel bolts to mount the "Minispare"

emergency spare wheel could damage the

brake system. 0043

Wheel bolts for all wheels supplied by the

factory and for the collapsible spare wheel

(Mercedes-AMG GLE 63 4MATIC)

0044 Wheel bolts for the collapsible spare wheel X

Clean the wheel and wheel hub contact sur-

faces.

X Slide the wheel to be mounted onto the align-

ment bolt and push it on.

X Tighten the wheel bolts until they are finger-

tight.

X Unscrew the alignment bolt.

X Tighten the last wheel bolt until it is finger-

tight.

X Mercedes-AMG vehicles with a collapsi-

ble spare wheel:

inflate the collapsible spare

wheel (Y page 379).

Only then lower the vehicle. Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Mercedes-AMG vehicles with a collapsi-

ble spare wheel: before lowering the vehicle,

inflate the collapsible spare wheel with the

tire inflation compressor. The wheel rim could

otherwise be damaged.

X Place the ratchet wrench onto the hexagon

nut of the jack so that the letters ABare visi-

ble.

X Turn the ratchet wrench until the vehicle is

once again standing firmly on the ground.

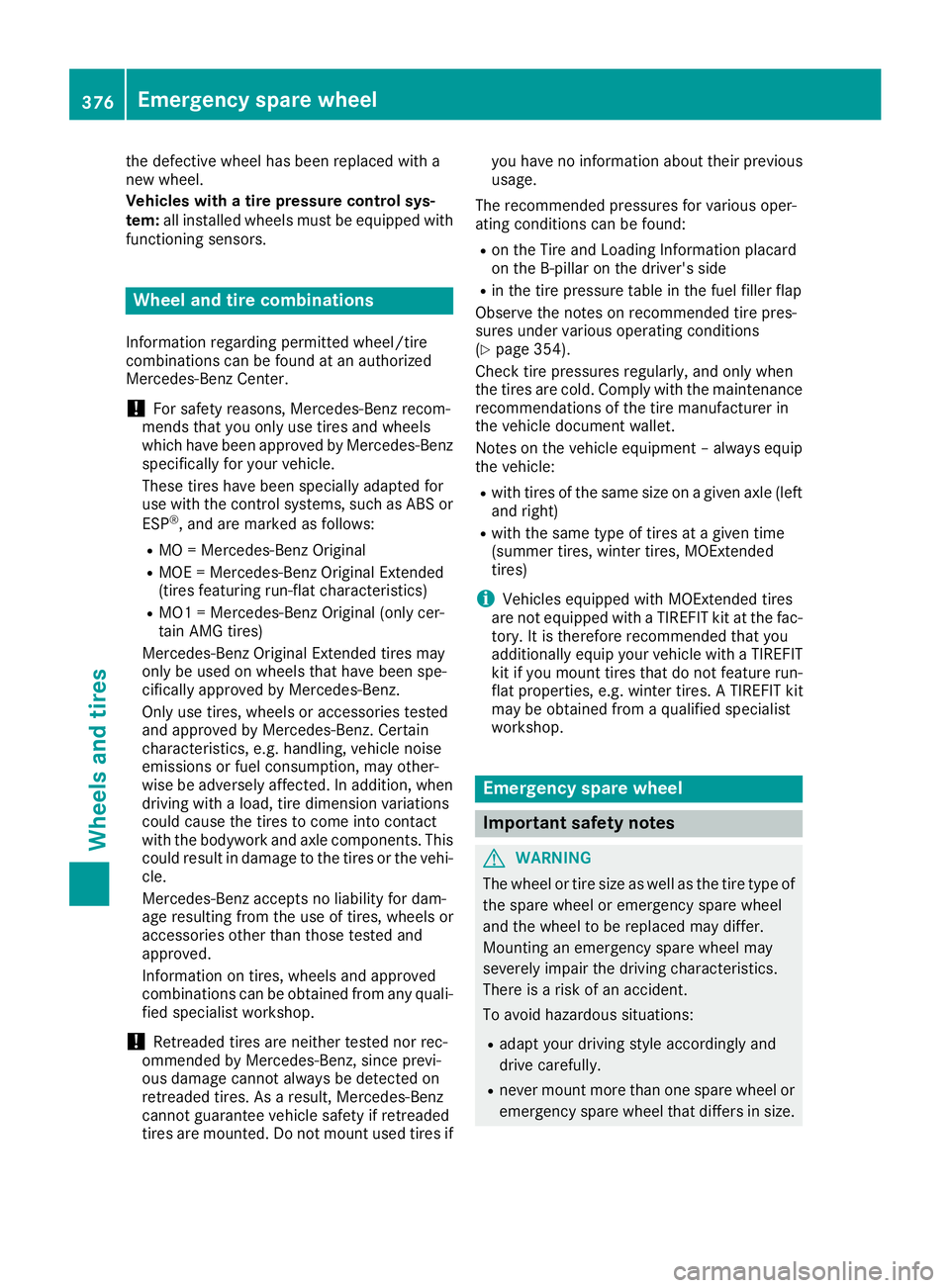

X Place the jack to one side. X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (0043 to0083).

The tightening torque must be 110 lb-ft

(150 Nm).

X Turn the jack back to its initial position.

X Stow the jack and the rest of the tire-change

tool kit in the stowage well under the cargo

compartment floor again.

X Check the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 354).

When you are driving with the collapsible spare

wheel mounted, the tire pressure loss warning

system or the tire pressure monitor cannot func- tion reliably. Only restart the tire pressure loss

warning system or tire pressure monitor when Changing a wheel

375Wheels and tires Z

Page 378 of 398

the defective wheel has been replaced with a

new wheel.

Vehicles with a tire pressure control sys-

tem: all installed wheels must be equipped with

functioning sensors. Wheel and tire combinations

Information regarding permitted wheel/tire

combinations can be found at an authorized

Mercedes-Benz Center.

! For safety reasons, Mercedes-Benz recom-

mends that you only use tires and wheels

which have been approved by Mercedes-Benz specifically for your vehicle.

These tires have been specially adapted for

use with the control systems, such as ABS or

ESP ®

, and are marked as follows:

R MO = Mercedes-Benz Original

R MOE = Mercedes-Benz Original Extended

(tires featuring run-flat characteristics)

R MO1 = Mercedes-Benz Original (only cer-

tain AMG tires)

Mercedes-Benz Original Extended tires may

only be used on wheels that have been spe-

cifically approved by Mercedes-Benz.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when

driving with a load, tire dimension variations

could cause the tires to come into contact

with the bodywork and axle components. This

could result in damage to the tires or the vehi- cle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tires, wheels or

accessories other than those tested and

approved.

Information on tires, wheels and approved

combinations can be obtained from any quali- fied specialist workshop.

! Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tires. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires if you have no information about their previous

usage.

The recommended pressures for various oper-

ating conditions can be found:

R on the Tire and Loading Information placard

on the B-pillar on the driver's side

R in the tire pressure table in the fuel filler flap

Observe the notes on recommended tire pres-

sures under various operating conditions

(Y page 354).

Check tire pressures regularly, and only when

the tires are cold. Comply with the maintenance recommendations of the tire manufacturer in

the vehicle document wallet.

Notes on the vehicle equipment – always equip

the vehicle:

R with tires of the same size on a given axle (left

and right)

R with the same type of tires at a given time

(summer tires, winter tires, MOExtended

tires)

i Vehicles equipped with MOExtended tires

are not equipped with a TIREFIT kit at the fac- tory. It is therefore recommended that you

additionally equip your vehicle with a TIREFIT

kit if you mount tires that do not feature run- flat properties, e.g. winter tires. A TIREFIT kit

may be obtained from a qualified specialist

workshop. Emergency spare wheel

Important safety notes

G

WARNING

The wheel or tire size as well as the tire type of the spare wheel or emergency spare wheel

and the wheel to be replaced may differ.

Mounting an emergency spare wheel may

severely impair the driving characteristics.

There is a risk of an accident.

To avoid hazardous situations:

R adapt your driving style accordingly and

drive carefully.

R never mount more than one spare wheel or

emergency spare wheel that differs in size. 376

Emergency spare

wheelWheels and tires

Page 379 of 398

R

only use a spare wheel or emergency spare

wheel of a different size briefly.

R do not switch ESP ®

off.

R have a spare wheel or emergency spare

wheel of a different size replaced at the

nearest qualified specialist workshop.

Observe that the wheel and tire dimensions

as well as the tire type must be correct.

! Mercedes-AMG vehicles with

"Minispare" emergency spare wheel: only

use the "Minispare" emergency spare wheel

on the rear axle. If you mount the

"Minispare" emergency spare wheel on the

front axle, this could result in damage to the

brake system.

If a tire on the front axle is defective, an intact

wheel from the rear axle must first be

replaced with the "Minispare" emergency

spare wheel. The damaged wheel on the front

axle can then be replaced by the undamaged wheel from the rear axle.

Make sure to note the placard on the

"Minispare" emergency spare wheel.

When using an emergency spare wheel or spare wheel of a different size, you must not exceed

the maximum speed of 50 mph (80 km/h).

You should regularly check the pressure of the

emergency spare wheel, particularly prior to

long trips, and correct the pressure as neces-

sary (Y page 354). The value on the wheel is

valid.

Snow chains must not be mounted on emer-

gency spare wheels. General notes

Information regarding permitted emergency

spare wheels can be found at an authorized

Mercedes-Benz Center.

Mounting the emergency spare wheel is descri- bed under "Mounting a wheel" (Y page 372).

An emergency spare wheel may also be moun-

ted against the direction of rotation. Observe

the time restriction on use as well as the speed

limitation specified on the emergency spare

wheel.

Replace the tires after six years at the latest,

regardless of wear. This also applies to the

emergency spare wheel. When you are driving with the collapsible spare

wheel mounted, the tire pressure loss warning

system or the tire pressure monitor cannot func-

tion reliably. Only restart the tire pressure loss

warning system or tire pressure monitor when

the defective wheel has been replaced with a

new wheel.

Vehicles with tire pressure monitor: after

mounting an emergency spare wheel, the sys-

tem may still display the tire pressure of the

removed wheel for a few minutes. The value dis- played for the mounted emergency spare wheelis not the same as the current tire pressure of

the emergency spare wheel. Removing/stowing the emergency

spare wheel

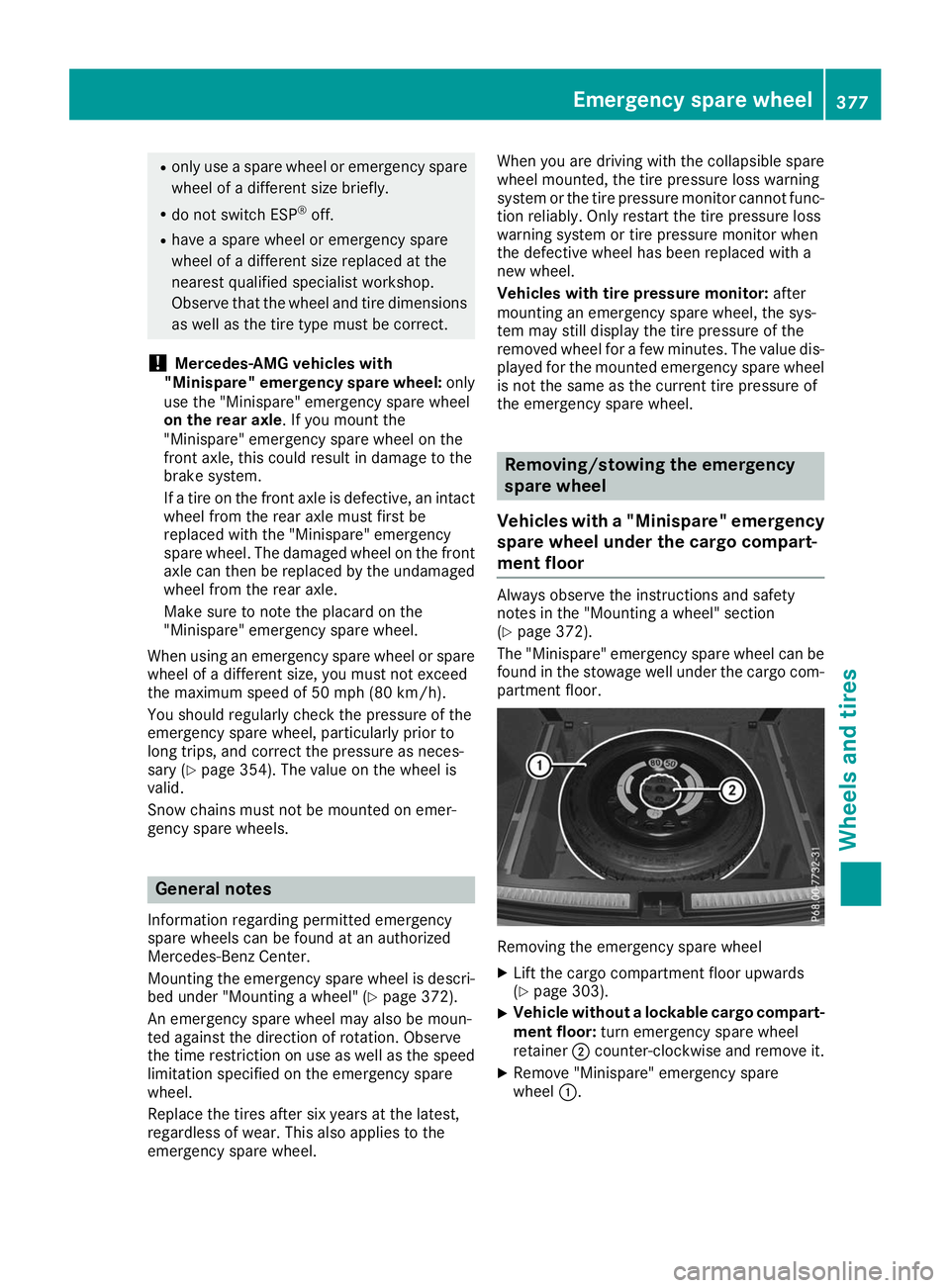

Vehicles with a "Minispare" emergency

spare wheel under the cargo compart-

ment floor Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y

page 372).

The "Minispare" emergency spare wheel can be found in the stowage well under the cargo com-

partment floor. Removing the emergency spare wheel

X Lift the cargo compartment floor upwards

(Y page 303).

X Vehicle without a lockable cargo compart-

ment floor: turn emergency spare wheel

retainer 0044counter-clockwise and remove it.

X Remove "Minispare" emergency spare

wheel 0043. Emergency spare wheel

377Wheels and tires Z

Page 380 of 398

X

Vehicle with a lockable cargo compart-

ment floor:

remove the contents of stowage

tray 0087.

X Turn the central retaining screw in stowage

tray 0087and in "Minispare" emergency spare

wheel 0043counter-clockwise and remove it.

X Remove stowage well 0087.

X Remove "Minispare" emergency spare

wheel 0043.

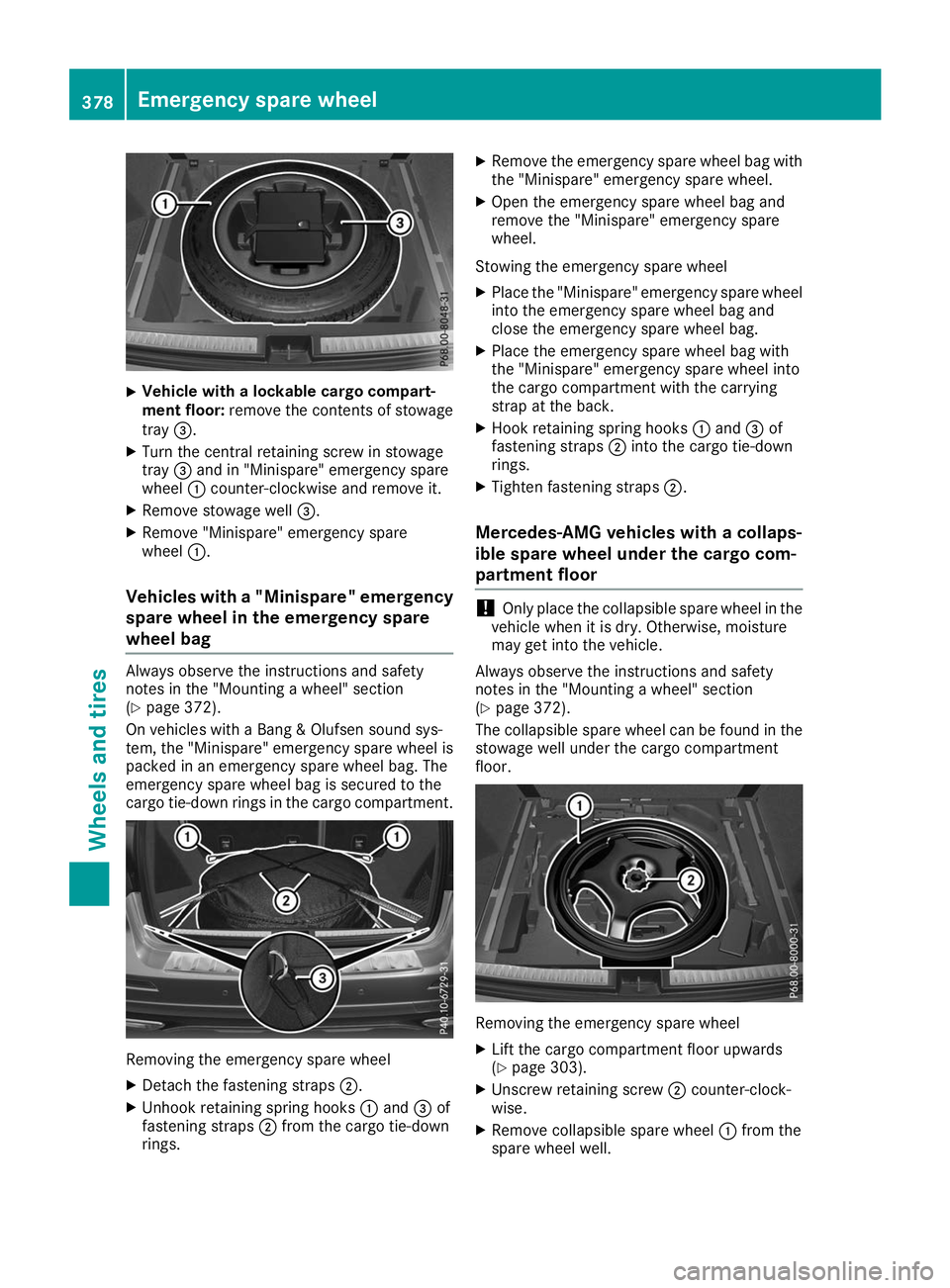

Vehicles with a "Minispare" emergency

spare wheel in the emergency spare

wheel bag Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y page 372).

On vehicles with a Bang & Olufsen sound sys-

tem, the "Minispare" emergency spare wheel is

packed in an emergency spare wheel bag. The

emergency spare wheel bag is secured to the

cargo tie-down rings in the cargo compartment. Removing the emergency spare wheel

X Detach the fastening straps 0044.

X Unhook retaining spring hooks 0043and 0087of

fastening straps 0044from the cargo tie-down

rings. X

Remove the emergency spare wheel bag with

the "Minispare" emergency spare wheel.

X Open the emergency spare wheel bag and

remove the "Minispare" emergency spare

wheel.

Stowing the emergency spare wheel

X Place the "Minispare" emergency spare wheel

into the emergency spare wheel bag and

close the emergency spare wheel bag.

X Place the emergency spare wheel bag with

the "Minispare" emergency spare wheel into

the cargo compartment with the carrying

strap at the back.

X Hook retaining spring hooks 0043and 0087of

fastening straps 0044into the cargo tie-down

rings.

X Tighten fastening straps 0044.

Mercedes-AMG vehicles with a collaps-

ible spare wheel under the cargo com-

partment floor !

Only place the collapsible spare wheel in the

vehicle when it is dry. Otherwise, moisture

may get into the vehicle.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y page 372).

The collapsible spare wheel can be found in the stowage well under the cargo compartment

floor. Removing the emergency spare wheel

X Lift the cargo compartment floor upwards

(Y page 303).

X Unscrew retaining screw 0044counter-clock-

wise.

X Remove collapsible spare wheel 0043from the

spare wheel well. 378

Emergency spare wheelWheels and tires