wheel bolts MERCEDES-BENZ GLK SUV 2008 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2008, Model line: GLK SUV, Model: MERCEDES-BENZ GLK SUV 2008Pages: 261, PDF Size: 8.67 MB

Page 19 of 261

Washer fluid reservoir...............

149, 249

Filling capacity. ............................... 249

Wearing seat belts............................... 70

Wheel bolts Tightening torque............................ 231

Wheel chock

Use. ................................................ 176

Wheels

General notes. ................................ 150

Interchanging.................................. 154

Technical data. ............................... 252

Windowbag........................................... 39

Windowbags Display message (luxury multi-

function steering wheel) .................198

Display message (multi-function

steering wheel). .............................. 182

Windows

Cleaning. ........................................ 169

Cleaning the windscreen ...............169

see Side windows

Windscreen washer fluid................... 249

Topping up. ..................................... 149

Windscreen washer system...... 149, 249

Windscreen wipers.............................. 79

Cleaning. ........................................ 169

Malfunction..................................... 210

Replacing the wiper blades .............220

Winter diesel...................................... 146

Winter driving............................. 155, 156

Winter tyres ........................................ 155

Limit speed (on-board computer,

luxury multi-function steering

wheel). ............................................ 113

Wooden trim

Cleaning. ........................................ 17116 Index

X204_AKB; 1; 5, en-GB

wobuchh,

Version: 2.11.4 2008-10-15T13:20:56+02:00 - Seite 16Dateiname: 6515_0671_02_buchblock.pdf; preflight

Page 157 of 261

Yes+ Cancel-

To confirm the restart of the tyre pressure

loss warning system:

X Press the +button.

The following appears in the multi-function

display: Run Flat Indicator restar-

ted.

After a teach-in period, the tyre pressure

loss warning system will monitor the set

tyre pressures of all four tyres.

or

To cancel the restart of the tyre pressure

loss warning system:

X Press the -button.

The previous settings will not be changed.

Configuring with the luxury multi-func-

tion steering wheel*

X Make sure that the key is in position 2in

the ignition lock.

X Press the (or& button to select the

Service menu.

X Press the $or% button to select

Tyre pressure.

X Press #.

The following appears in the multi-function

display: Run Flat Indicator active

Restart with OK

X Press #.

The following appears in the multi-function

display: Tyre press. now OK?

To confirm the restart of the tyre pressure

loss warning system:

X Press $or% to select Yes.

X Press #.

The following appears in the multi-function

display: Run Flat Indicator restarted

After a teach-in period, the tyre pressure

loss warning system will monitor the set

tyre pressures of all four tyres.

or

To cancel the restart of the tyre pressure

loss warning system: X

Press $or% to select Cancel.

X Press #.

The previous settings will not be changed. Interchanging the wheels

G

Risk of accident

Interchange the front and rear wheels only if

they have the same dimensions: for example

size, offset, etc.

After every wheel interchange/change, have

the tightening torque checked at a qualified

specialist workshop that has the necessary

specialist knowledge and tools to carry out

the work required. Mercedes-Benz recom-

mends that you use a Mercedes-Benz Service

Centre for this purpose. In particular, work

relevant to safety or on safety-related sys-

tems must be carried out at a qualified spe-

cialist workshop.

The wheels could work loose if they are not

tightened to a torque of 150 Nm.

For safety reasons, Mercedes-Benz recom-

mends that you only use wheel bolts of the

correct size which have been approved for

Mercedes-Benz vehicles.

The wear patterns on the front and rear tyres

differ, depending on the operating conditions.

Interchange the wheels before a clear wear

pattern has formed on the tyres. Front tyres

typically wear more on the shoulders and the

rear tyres in the centre.

Interchange the wheels every 5,000 km to

10,000 km depending on the degree of tyre

wear, provided that the vehicle has the same

size front and rear tyres. Do not reverse the

direction of tyre rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is interchanged. Check the tyre pressure and,

if necessary, restart the tyre pressure loss

warning system. 154 Tyres and wheelsOperation

* optional

X204_AKB; 1; 5, en-GB

wobuchh,

Version: 2.11.4 2008-10-15T13:20:56+02:00 - Seite 154Dateiname: 6515_0671_02_buchblock.pdf; preflight

Page 230 of 261

To reduce the tyre pressure:

press yellow

pressure release button Enext to pres-

sure gauge F.

X Drive to the nearest workshop and have the

tyre changed there.

X Have the TIREFIT kit replaced as soon as

possible at a qualified specialist workshop,

e.g. at a Mercedes-Benz Service Centre. G

Risk of accident

Do not exceed the maximum speed of

80 km/h.

The "max. 80 km/h" label must be affixed in

the driver's field of vision.

The vehicle's handling characteristics may be

affected. H

Environmental note

Have the used TIREFIT kit disposed of profes-

sionally, e.g. at a Mercedes-Benz Service

Centre.

X Have the TIREFIT kit replaced every four

years at a qualified specialist workshop,

e.g. a Mercedes-Benz Service Centre. Changing a wheel/fitting the emer-

gency spare wheel* G

Risk of accident

The wheel dimensions and tyre size of the

emergency spare wheel* may differ from

those of the standard wheels.

The handling characteristics of your vehicle

will change if you fit an emergency spare

wheel*. Adapt your style of driving accord-

ingly.

You may only use the emergency spare

wheel* for a short while. Do not exceed the

maximum speed of 80 km/h and do not deac-

tivate ESP ®

.

Never drive the vehicle with more than one

emergency spare wheel* fitted. G

Risk of accident

Have the emergency spare wheel* replaced

as soon as possible at a qualified specialist

workshop which has the necessary specialist

knowledge and tools to carry out the work

required. Mercedes-Benz recommends that

you use a Mercedes-Benz Service Centre for

this purpose. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist workshop.

Preparing the vehicle X

Prepare the vehicle as described

(Y page 222).

X If a trailer is coupled, uncouple it.

X Place the wheels in the straight-ahead posi-

tion.

X Take the following from the stowage well

beneath the luggage compartment floor:

R

the collapsible emergency spare wheel*

R the wheel bolts of the collapsible emer-

gency spare wheel*

R the vehicle tool kit

R the jack

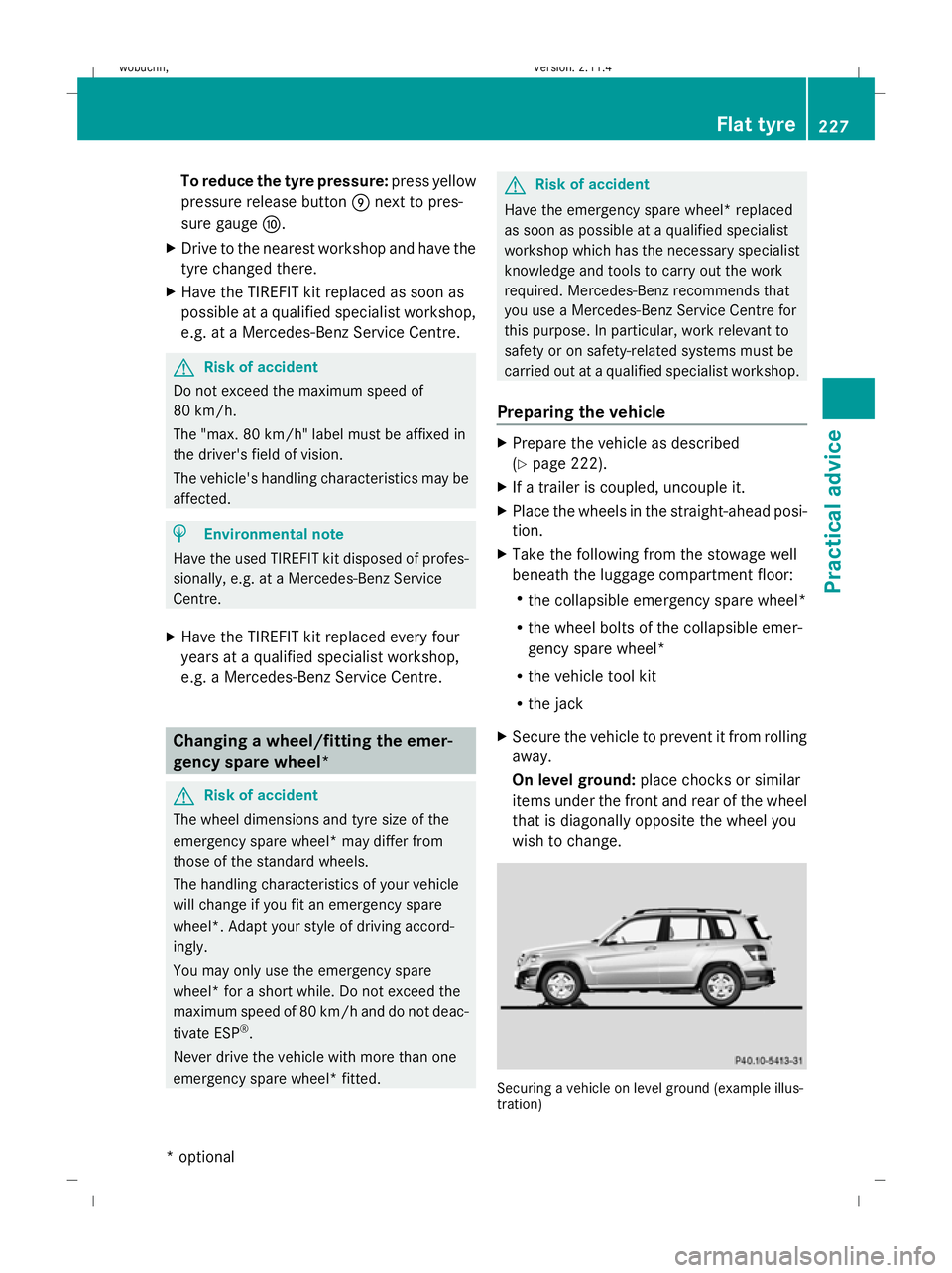

X Secure the vehicle to prevent it from rolling

away.

On level ground: place chocks or similar

items under the front and rear of the wheel

that is diagonally opposite the wheel you

wish to change. Securing a vehicle on level ground (example illus-

tration) Flat tyre

227Practical advice

* optional

X204_AKB; 1; 5, en-GB

wobuchh

,V ersion: 2.11.4

2008-10-15T13:20:56+02:00 - Seite 227 ZDateiname: 6515_0671_02_buchblock.pdf; preflight

Page 231 of 261

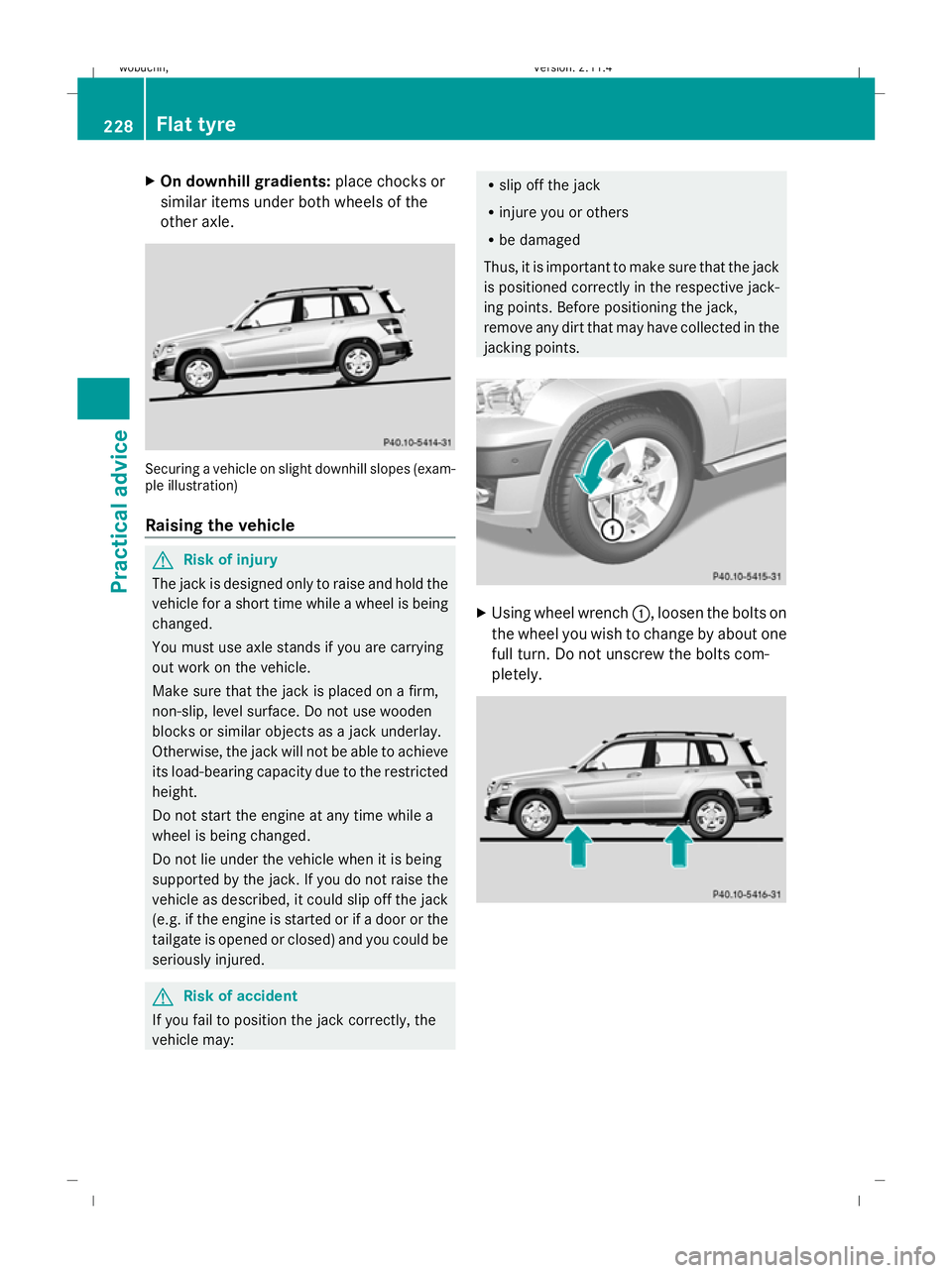

X

On downhill gradients: place chocks or

similar items under both wheels of the

other axle. Securing a vehicle on slight downhill slopes (exam-

ple illustration)

Raising the vehicle G

Risk of injury

The jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed.

You must use axle stands if you are carrying

out work on the vehicle.

Make sure that the jack is placed on a firm,

non-slip, level surface. Do not use wooden

blocks or similar objects as a jack underlay.

Otherwise, the jack will not be able to achieve

its load-bearing capacity due to the restricted

height.

Do not start the engine at any time while a

wheel is being changed.

Do not lie under the vehicle when it is being

supported by the jack. If you do not raise the

vehicle as described, it could slip off the jack

(e.g. if the engine is started or if a door or the

tailgate is opened or closed) and you could be

seriously injured. G

Risk of accident

If you fail to position the jack correctly, the

vehicle may: R

slip off the jack

R injure you or others

R be damaged

Thus, it is important to make sure that the jack

is positioned correctly in the respective jack-

ing points. Before positioning the jack,

remove any dirt that may have collected in the

jacking points. X

Using wheel wrench 1, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts com-

pletely. 228 Flat tyrePractical advice

X204_AKB; 1; 5, en-GB

wobuchh,

Version: 2.11.4 2008-10-15T13:20:56+02:00 - Seite 228Dateiname: 6515_0671_02_buchblock.pdf; preflight

Page 232 of 261

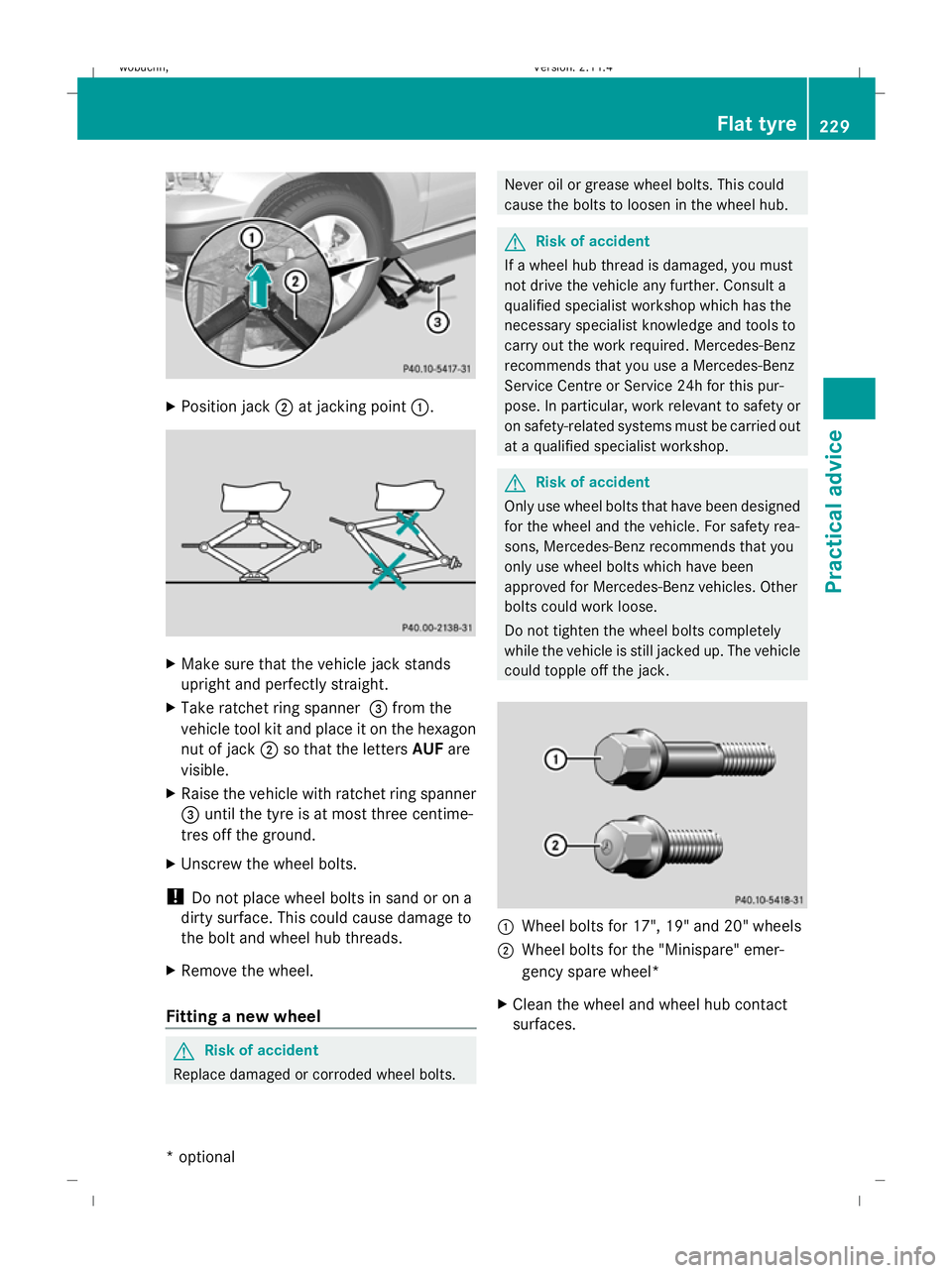

X

Position jack 2at jacking point 1. X

Make sure that the vehicle jack stands

upright and perfectly straight.

X Take ratchet ring spanner 3from the

vehicle tool kit and place it on the hexagon

nut of jack 2so that the letters AUFare

visible.

X Raise the vehicle with ratchet ring spanner

3 until the tyre is at most three centime-

tres off the ground.

X Unscrew the wheel bolts.

! Do not place wheel bolts in sand or on a

dirty surface. This could cause damage to

the bolt and wheel hub threads.

X Remove the wheel.

Fitting a new wheel G

Risk of accident

Replace damaged or corroded wheel bolts. Never oil or grease wheel bolts. This could

cause the bolts to loosen in the wheel hub.

G

Risk of accident

If a wheel hub thread is damaged, you must

not drive the vehicle any further. Consult a

qualified specialist workshop which has the

necessary specialist knowledge and tools to

carry out the work required. Mercedes-Benz

recommends that you use a Mercedes-Benz

Service Centre or Service 24h for this pur-

pose. In particular, work relevant to safety or

on safety-related systems must be carried out

at a qualified specialist workshop. G

Risk of accident

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been

approved for Mercedes-Benz vehicles. Other

bolts could work loose.

Do not tighten the wheel bolts completely

while the vehicle is still jacked up. The vehicle

could topple off the jack. 1

Wheel bolts for 17", 19" and 20" wheels

2 Wheel bolts for the "Minispare" emer-

gency spare wheel*

X Clean the wheel and wheel hub contact

surfaces. Flat tyre

229Practical advice

* optional

X204_AKB; 1; 5, en-GB

wobuchh,

Version: 2.11.4 2008-10-15T13:20:56+02:00 - Seite 229 ZDateiname: 6515_0671_02_buchblock.pdf; preflight

Page 233 of 261

X

Place the collapsible emergency spare

wheel*o nto the wheel hub and push it on. X

Tighten the wheel bolts until they are fin-

ger-tight.

Inflating the "Minispare" emergency

spare wheel* G

Risk of accident

Pump up the collapsible emergency spare

wheel before lowering the vehicle. Otherwise,

you could damage the wheel rim.

X Take the electric air pump out of the stow-

age well under the luggage compartment

floor (Y page 175). G

Risk of injury

Comply with the manufacturer’s safety

instructions on the sticker on the electric air

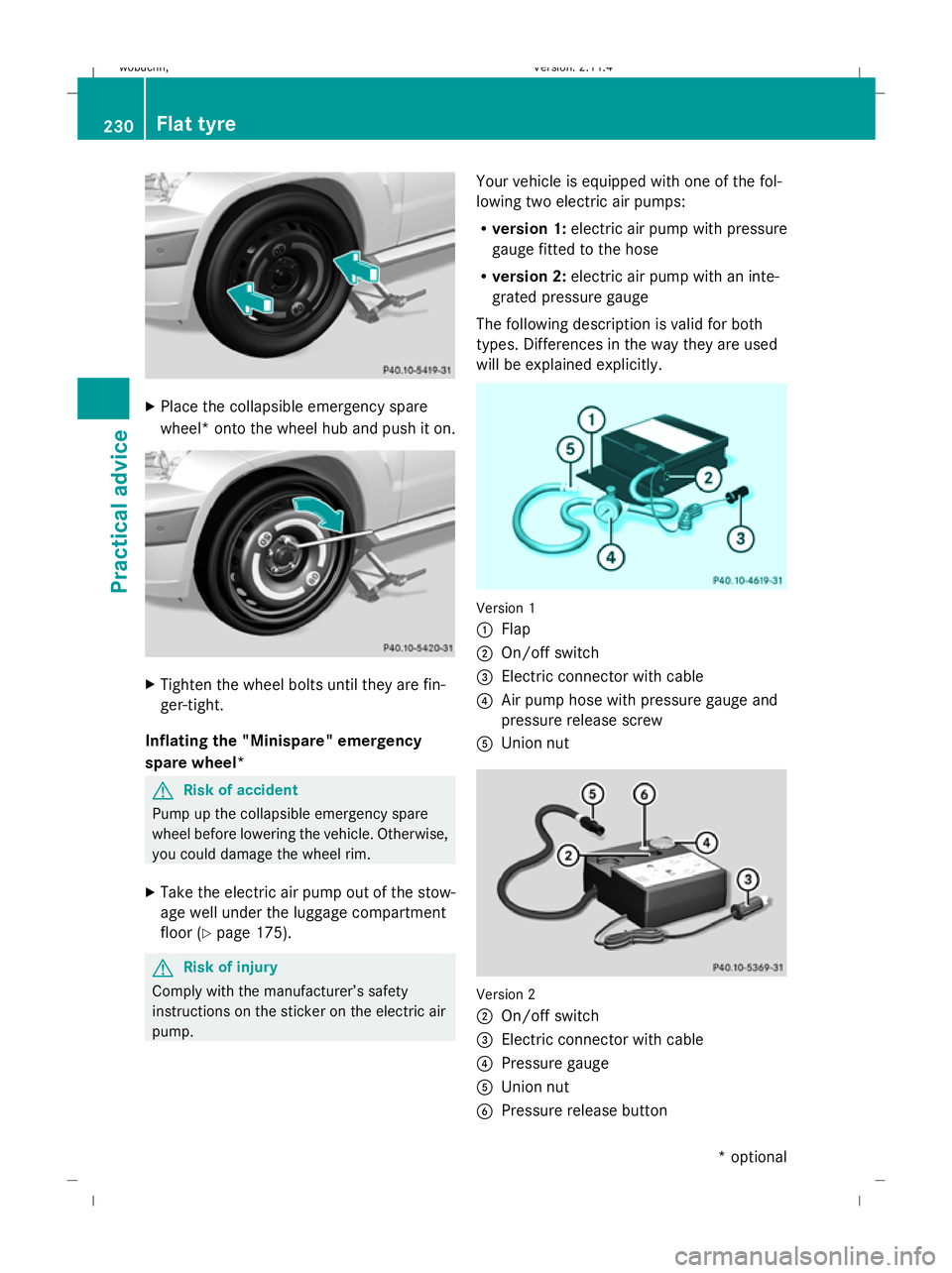

pump. Your vehicle is equipped with one of the fol-

lowing two electric air pumps:

R version 1: electric air pump with pressure

gauge fitted to the hose

R version 2: electric air pump with an inte-

grated pressure gauge

The following description is valid for both

types. Differences in the way they are used

will be explained explicitly. Version 1

1

Flap

2 On/off switch

3 Electric connector with cable

4 Air pump hose with pressure gauge and

pressure release screw

5 Union nut Version 2

2

On/off switch

3 Electric connector with cable

4 Pressure gauge

5 Union nut

6 Pressure release button 230 Flat tyrePractical advice

* optional

X204_AKB; 1; 5, en-GB

wobuchh

,V ersion: 2.11.4

2008-10-15T13:20:56+02:00 - Seite 230 Dateiname: 6515_0671_02_buchblock.pdf; preflight

Page 234 of 261

X

Version 1: open flap1.

X Version 1: pull connector 3and air hose

4 out of the housing.

X Version 2: pull connector 3and the air

hose out of the housing.

X Version 1: make sure that pressure

release screw 4on the pressure gauge is

fully closed.

X Remove the cap from the valve on the tyre.

X Screw union nut 5on the air hose onto the

valve.

X Make sure on/off switch 2of the electric

air pump is set to 0.

X Insert plug 3into the cigarette lighter

socket* (Y page 138) or into a 12 V socket

in your vehicle (Y page 139).

X Make sure that the key is in posi-

tion 2(Y page 61) in the ignition lock.

X Press on/off switch 2on the electric air

pump to I.

The electric air pump is switched on. The

tyre is inflated.

X When a tyre pressure of 2.8 bar is reached,

press on/off switch 2on the electric air

pump to 0.

The electric air pump is switched off.

! Do not operate the electric air pump for

longer than eight minutes at a time without

a break. Otherwise, it may overheat.

The air pump can be operated again once

it has cooled down.

If the tyre pressure is higher than 2.8 bar:

X Version 1: open pressure release

screw 4on the pressure gauge until the

tyre pressure is correct.

X Version 2: press pressure release button

6 until the tyre pressure is correct.

X Switch off the electric air pump at on/off

switch 2, disconnect from the tyre valve

and stow away. Lowering the vehicle X

Place the ratchet ring spanner onto the

hexagon nut of the jack so that the letters

AB are visible.

X Lower the vehicle by turning the ratchet

ring spanner until the vehicle is once again

standing firmly on the ground.

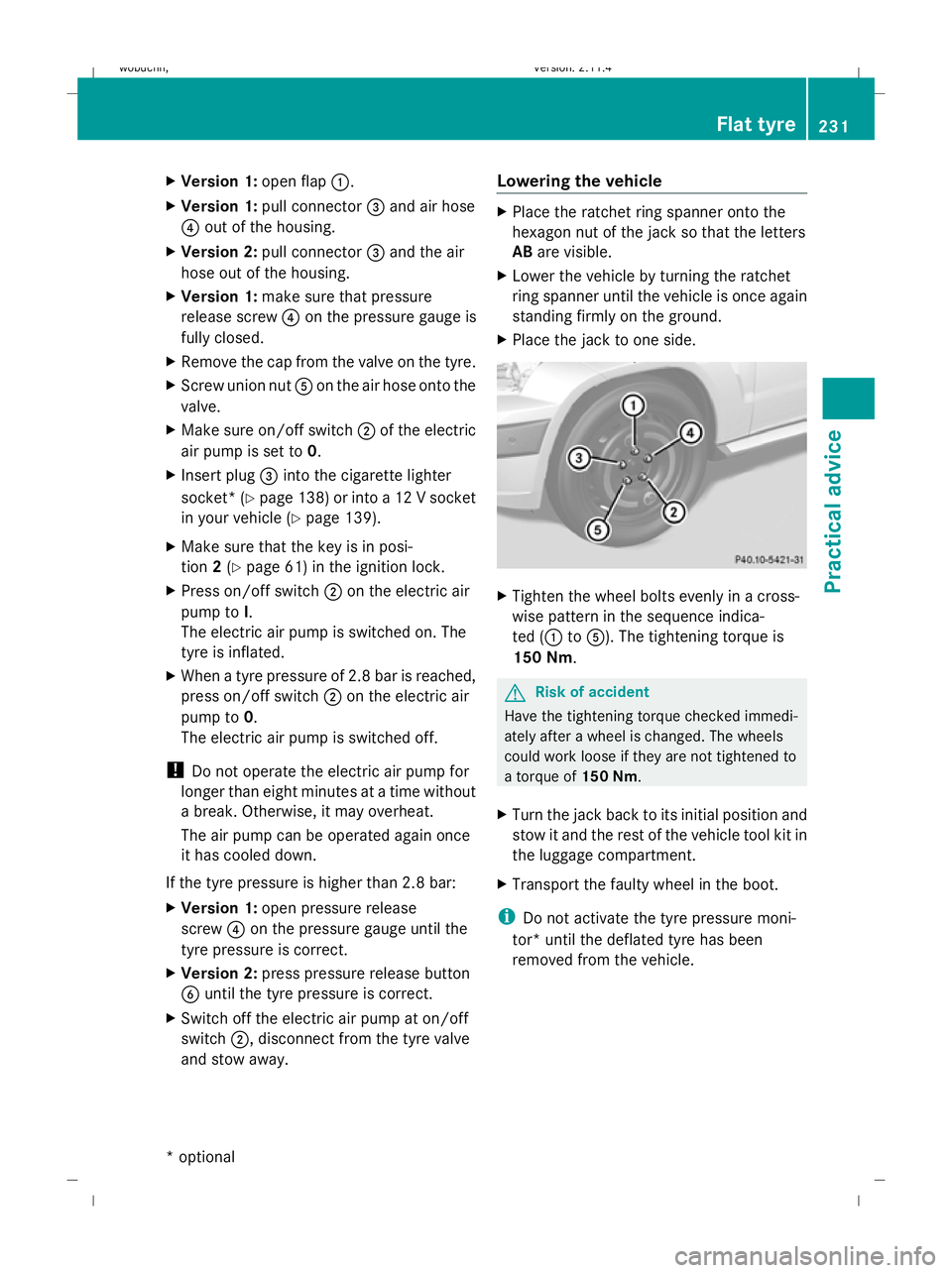

X Place the jack to one side. X

Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indica-

ted (1 to5). The tightening torque is

150 Nm. G

Risk of accident

Have the tightening torque checked immedi-

ately after a wheel is changed. The wheels

could work loose if they are not tightened to

a torque of 150 Nm.

X Turn the jack back to its initial position and

stow it and the rest of the vehicle tool kit in

the luggage compartment.

X Transport the faulty wheel in the boot.

i Do not activate the tyre pressure moni-

tor* until the deflated tyre has been

removed from the vehicle. Flat tyre

231Practical advice

* optional

X204_AKB; 1; 5, en-GB

wobuchh,

Version: 2.11.4 2008-10-15T13:20:56+02:00 - Seite 231 ZDateiname: 6515_0671_02_buchblock.pdf; preflight