ECU MERCEDES-BENZ GLS SUV 2016 Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: GLS SUV, Model: MERCEDES-BENZ GLS SUV 2016Pages: 397, PDF Size: 14.21 MB

Page 358 of 397

Do not use a rapid charging device to start the vehicle. If your vehicle's battery is discharged, the

engine can be jump-started from another vehicle or from a second battery using jump leads.

Observe the following points:

R The battery is not accessible in all vehicles. If the other vehicle's battery is not accessible, jump-

start the vehicle using a second battery or a jump-starting device.

R Vehicles with a petrol engine: jump-start the vehicle only when the engine and exhaust system

are cold.

R Do not start the engine if the battery is frozen. Let the battery thaw first.

R Jump-starting may be performed only using batteries with a nominal voltage of 12 V.

R Use only jump leads that have a sufficient cross-section and insulated terminal clamps.

R If the battery is fully discharged, leave the battery that is being used to jump-start connected for

a few minutes before attempting to start. This charges the empty battery a little.

R Make sure that the two vehicles do not touch.

Make sure that:

R The jump leads are not damaged.

R Non-insulated parts of the terminal clamps do not come into contact with other metal parts while

the jump leads are connected to the battery.

R The jump leads cannot come into contact with parts that can move when the engine is running,

such as the V-belt pulley or the fan.

X Secure the vehicle by applying the electric parking brake.

X Shift the transmission to position P.

X Make sure that the ignition is switched off . All indicator lamps on the instrument cluster must be

off. When using the key, turn the key to position 0in the ignition lock and remove it (Y page 148).

X Switch off all electrical consumers, e.g. rear window heating, lighting etc.

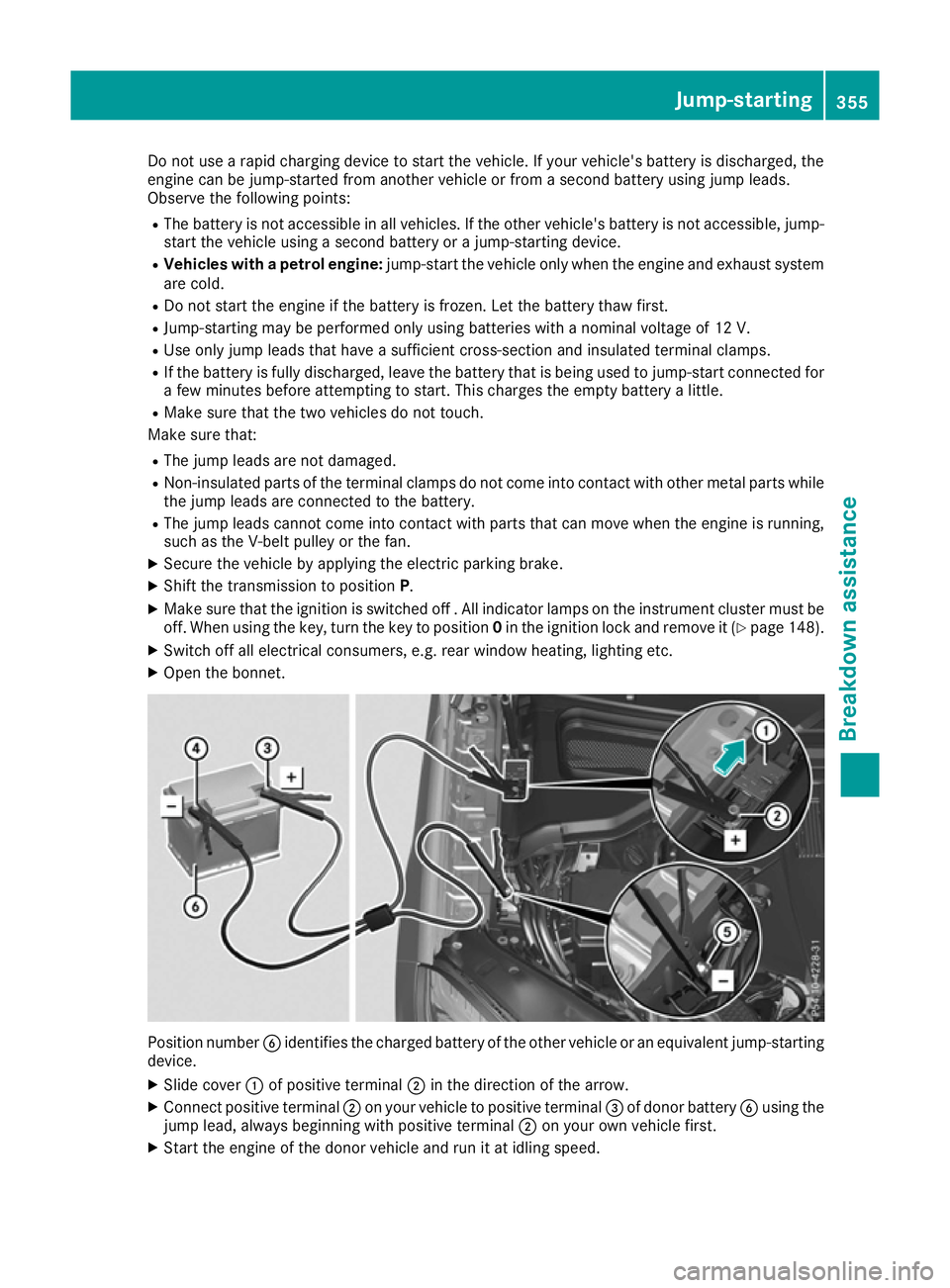

X Open the bonnet. Position number

Bidentifies the charged battery of the other vehicle or an equivalent jump-starting

device.

X Slide cover :of positive terminal ;in the direction of the arrow.

X Connect positive terminal ;on your vehicle to positive terminal =of donor battery Busing the

jump lead, always beginning with positive terminal ;on your own vehicle first.

X Start the engine of the donor vehicle and run it at idling speed. Jump-starting

355Breakdown assistance Z

Page 359 of 397

X

Connect negative terminal ?of donor battery Bto earth point Aof your vehicle using the jump

lead, connecting the jump lead to donor battery Bfirst.

X Start the engine.

X Before disconnecting the jump leads, let the engines run for several minutes.

X First, remove the jump leads from earth point Aand negative terminal ?, then from positive

clamp ;and positive terminal =. Each time, begin at the contacts on your own vehicle first.

X After removing the jump leads, close cover :of positive terminal clamp ;.

X Have the battery checked at a qualified specialist workshop.

Jump-starting is not considered to be a normal operating condition.

i Jump-starting cables and further information regarding jump-starting can be obtained at any

qualified specialist workshop. Towing away and tow-starting

Important safety notes

G

WARNING

Safety-relevant functions are restricted or not

available if:

R the engine is not running.

R the brake system or the power steering is

malfunctioning

R the voltage supply or the vehicle's electrical

system is malfunctioning.

If your vehicle is towed, significantly greater

force may be required to steer the vehicle or

to brake. There is a risk of an accident.

In such circumstances, use a towing bar.

Make sure that the steering is moving freely

before towing. G

WARNING

When towing or tow-starting another vehicle

and its weight is greater than the permissible gross weight of your vehicle, the:

R towing eye may be torn off

R car/trailer combination may swerve or

even overturn

There is a risk of an accident.

When towing or tow-starting another vehicle,

its weight should not be greater than the per- missible gross weight of your vehicle. Details on the permissible gross vehicle weight

of your vehicle can be found on the vehicle iden-

tification plate (Y page 380).

! When Active Brake Assist, Distance Pilot

DISTRONIC or the HOLD function is activated, the vehicle brakes automatically in certain

situations.

To avoid damage to the vehicle, deactivate

these systems in the following or similar sit-

uations:

R when towing away

R in a car wash

! Make sure that the electric parking brake is

released. If the electric parking brake is faulty, visit a qualified specialist workshop.

! Only secure the tow cable or tow bar to the

towing eyes or, if available, to the trailer tow

hitch. You could otherwise damage the vehi-

cle.

! Observe the following points when towing

with a tow rope:

R Secure the tow rope on the same side on

both vehicles.

R Make sure that the tow rope is not longer

than legally permitted. Mark the tow rope in

the middle, e.g. with a white cloth

(30 x 30 cm). This will make other road

users aware that a vehicle is being towed.

R Only secure the tow cable to the towing

eyes or, if available, to the trailer tow hitch.

R Observe the brake lamps of the towing

vehicle while driving. Always maintain a dis- 356

Towing away and tow-startingBreakdown assistance

Page 361 of 397

Towing the vehicle with both axles on

the ground

The automatic transmission automatically shifts to position Pwhen you open the driver's or front-

passenger door or when you remove the key

from the ignition lock.

In order to ensure that the automatic transmis-

sion stays in position Nwhen towing away the

vehicle, you must observe the following points:

X Make sure that the vehicle is stationary.

X Turn the key to position 2in the ignition lock.

X Depress the brake pedal and keep it

depressed.

X Shift the automatic transmission to position

N.

X Leave the key in position 2in the ignition lock.

X Release the brake pedal.

X Release the electric parking brake.

X Switch on the hazard warning lamps

(Y page 122).

In order to signal a change of direction when

towing the vehicle with the hazard warning

lamps switched on, use the combination switch

as usual. In this case, only the turn signals for

the desired direction flash. When you reset the

combination switch, the hazard warning lamps

start flashing again. Transporting the vehicle

4MATIC vehicles/vehicles with auto-

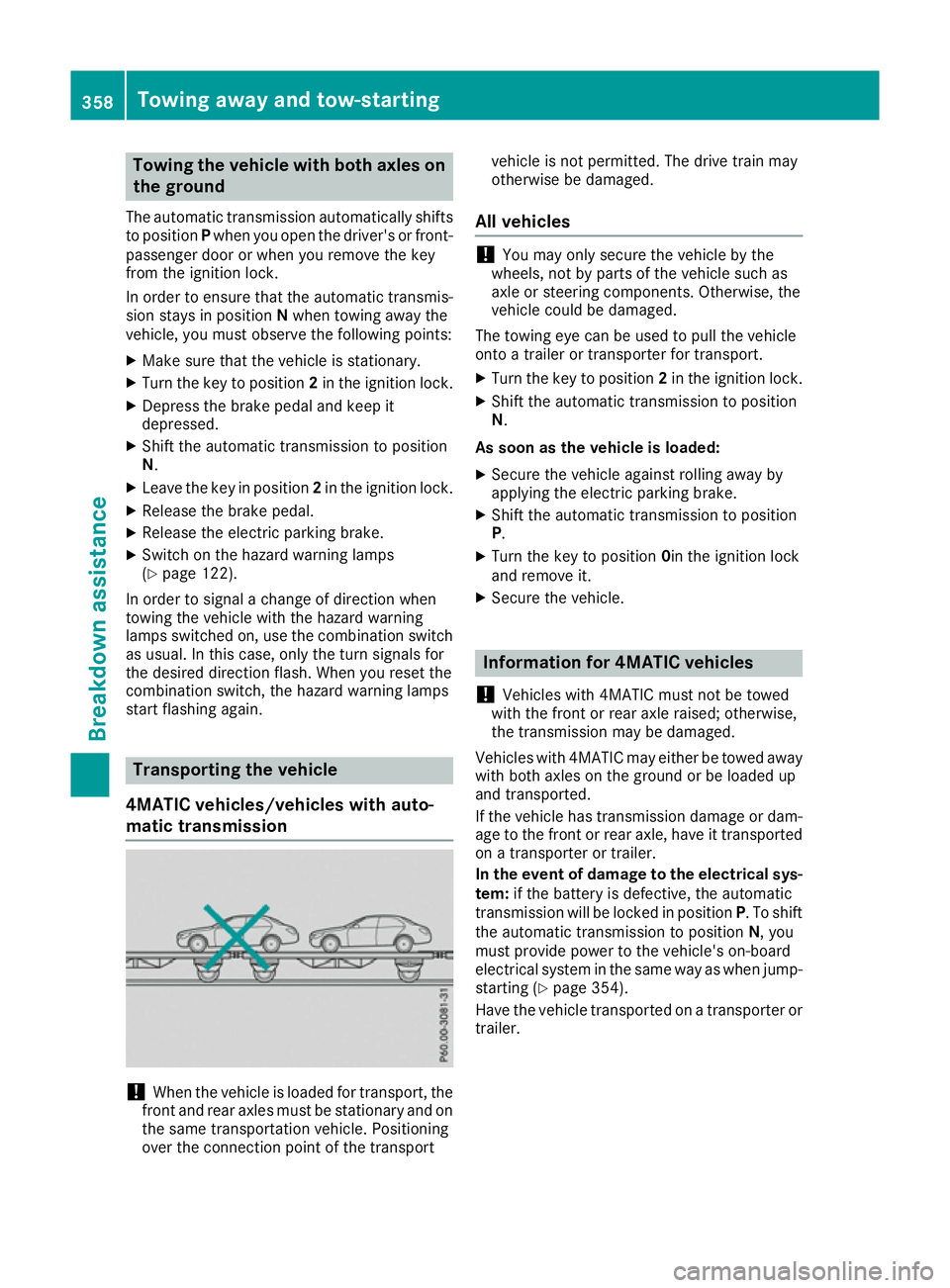

matic transmission !

When the vehicle is loaded for transport, the

front and rear axles must be stationary and on

the same transportation vehicle. Positioning

over the connection point of the transport vehicle is not permitted. The drive train may

otherwise be damaged.

All vehicles !

You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise, the

vehicle could be damaged.

The towing eye can be used to pull the vehicle

onto a trailer or transporter for transport. X Turn the key to position 2in the ignition lock.

X Shift the automatic transmission to position

N.

As soon as the vehicle is loaded: X Secure the vehicle against rolling away by

applying the electric parking brake.

X Shift the automatic transmission to position

P.

X Turn the key to position 0in the ignition lock

and remove it.

X Secure the vehicle. Information for 4MATIC vehicles

! Vehicles with 4MATIC must not be towed

with the front or rear axle raised; otherwise,

the transmission may be damaged.

Vehicles with 4MATIC may either be towed away

with both axles on the ground or be loaded up

and transported.

If the vehicle has transmission damage or dam- age to the front or rear axle, have it transportedon a transporter or trailer.

In the event of damage to the electrical sys-

tem: if the battery is defective, the automatic

transmission will be locked in position P. To shift

the automatic transmission to position N, you

must provide power to the vehicle's on-board

electrical system in the same way as when jump- starting (Y page 354).

Have the vehicle transported on a transporter or trailer. 358

Towing away and tow-startingBreakdown assistance

Page 373 of 397

The wear patterns on the front and rear tyres

differ depending on the operating conditions.

Interchange the wheels before a clear wear pat-

tern has formed on the tyres. Front tyres typi-

cally wear more on the shoulders, while rear

tyres wear more in the centre.

On vehicles that have the same size front and

rear wheels, you can interchange the wheels

every 5,000 to 10,000 km depending on the

degree of tyre wear. Ensure that the direction of

rotation is maintained.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is

interchanged. Check the tyre pressure and, if

necessary, restart the tyre pressure loss warn-

ing system or the tyre pressure monitor

(Y page 366). Direction of rotation

Tyres with a specified direction of rotation have additional benefits, e.g. if there is a risk of aqua- planing. These advantages can only be gained if

the tyres are fitted corresponding to the direc-

tion of rotation.

An arrow on the sidewall of the tyre indicates its correct direction of rotation. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tyres

against oil, grease, petrol and diesel. Fitting a wheel

Preparing the vehicle X

Vehicles with an emergency spare wheel:

when fitting the emergency spare wheel in the

event of a flat tyre, observe the additional

notes on vehicle preparation under "Flat tyre"

(Y page 346).

X Stop the vehicle on solid, non-slippery and

level ground.

X Apply the electric parking brake manually.

X Move the front wheels to the straight-ahead

position.

X Vehicles with automatic transmission:

shift the transmission to position

P.X

Vehicles with the AIRMATIC package:

make sure that the normal vehicle level is

selected (Y page 198).

X Vehicles with the Off-Road Engineering

package:

make sure that the normal level is

selected (Y page 192).

X Switch off the engine.

X Vehicles without KEYLESS-GO: remove the

key from the ignition lock.

X Vehicles with KEYLESS-GO: open the driv-

er's door.

The on-board electronics now have status 0.

This is the same as the key having been

removed.

X Vehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

(Y page 148).

X If included in the vehicle equipment, remove

the tyre-change tool kit from the vehicle.

X Safeguard the vehicle against rolling away.

i Apart from certain country-specific varia-

tions, vehicles are not equipped with a tyre-

change tool kit. For information on which

tools are required to perform a wheel change

on your vehicle, consult a Mercedes-Benz

Service Centre.

Necessary tyre-changing tools may include,

for example:

R jack

R wheel chock

R wheel wrench

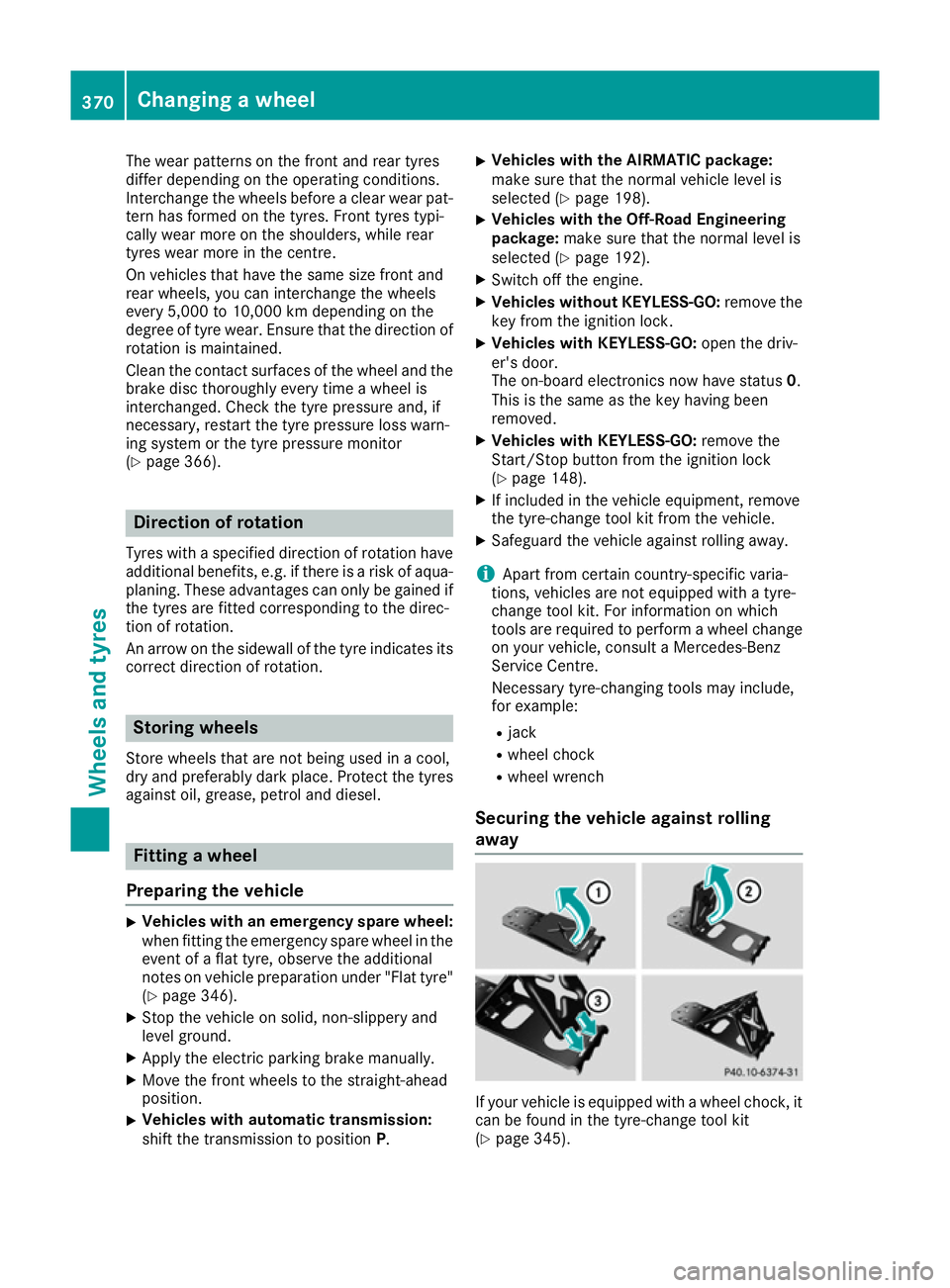

Securing the vehicle against rolling

away If your vehicle is equipped with a wheel chock, it

can be found in the tyre-change tool kit

(Y page 345). 370

Changing a wheelWheels and tyres

Page 374 of 397

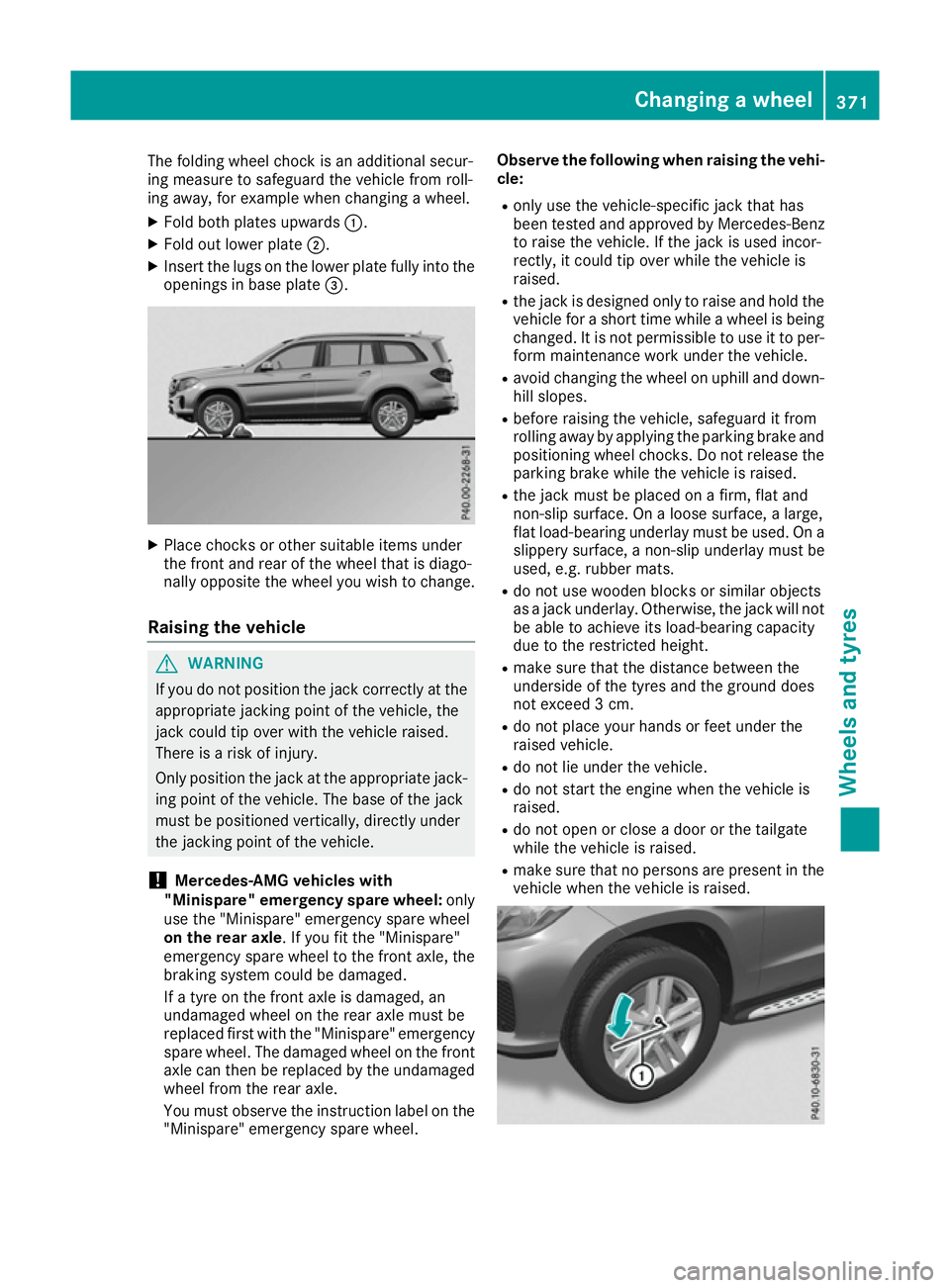

The folding wheel chock is an additional secur-

ing measure to safeguard the vehicle from roll-

ing away, for example when changing a wheel.

X Fold both plates upwards :.

X Fold out lower plate ;.

X Insert the lugs on the lower plate fully into the

openings in base plate =.X

Place chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

! Mercedes-AMG vehicles with

"Minispare" emergency spare wheel: only

use the "Minispare" emergency spare wheel

on the rear axle. If you fit the "Minispare"

emergency spare wheel to the front axle, the

braking system could be damaged.

If a tyre on the front axle is damaged, an

undamaged wheel on the rear axle must be

replaced first with the "Minispare" emergency spare wheel. The damaged wheel on the front

axle can then be replaced by the undamaged

wheel from the rear axle.

You must observe the instruction label on the "Minispare" emergency spare wheel. Observe the following when raising the vehi-

cle:

R only use the vehicle-specific jack that has

been tested and approved by Mercedes-Benz

to raise the vehicle. If the jack is used incor-

rectly, it could tip over while the vehicle is

raised.

R the jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It is not permissible to use it to per- form maintenance work under the vehicle.

R avoid changing the wheel on uphill and down-

hill slopes.

R before raising the vehicle, safeguard it from

rolling away by applying the parking brake and

positioning wheel chocks. Do not release theparking brake while the vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

R do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

R make sure that the distance between the

underside of the tyres and the ground does

not exceed 3 cm.

R do not place your hands or feet under the

raised vehicle.

R do not lie under the vehicle.

R do not start the engine when the vehicle is

raised.

R do not open or close a door or the tailgate

while the vehicle is raised.

R make sure that no persons are present in the

vehicle when the vehicle is raised. Changing a wheel

371Wheels and tyres Z

Page 379 of 397

Removing the emergency spare wheel

X Lift the luggage compartment floor upwards

(Y page 319).

X Vehicles with a lockable luggage compart-

ment floor: remove the stowage tray.

X Release the Velcro fastener (Y page 345).

X Remove the warning triangle and jack.

X Turn emergency spare wheel retainer :anti-

clockwise and remove it.

X Remove stowage well ;.

X Remove "Minispare" emergency spare wheel

=.

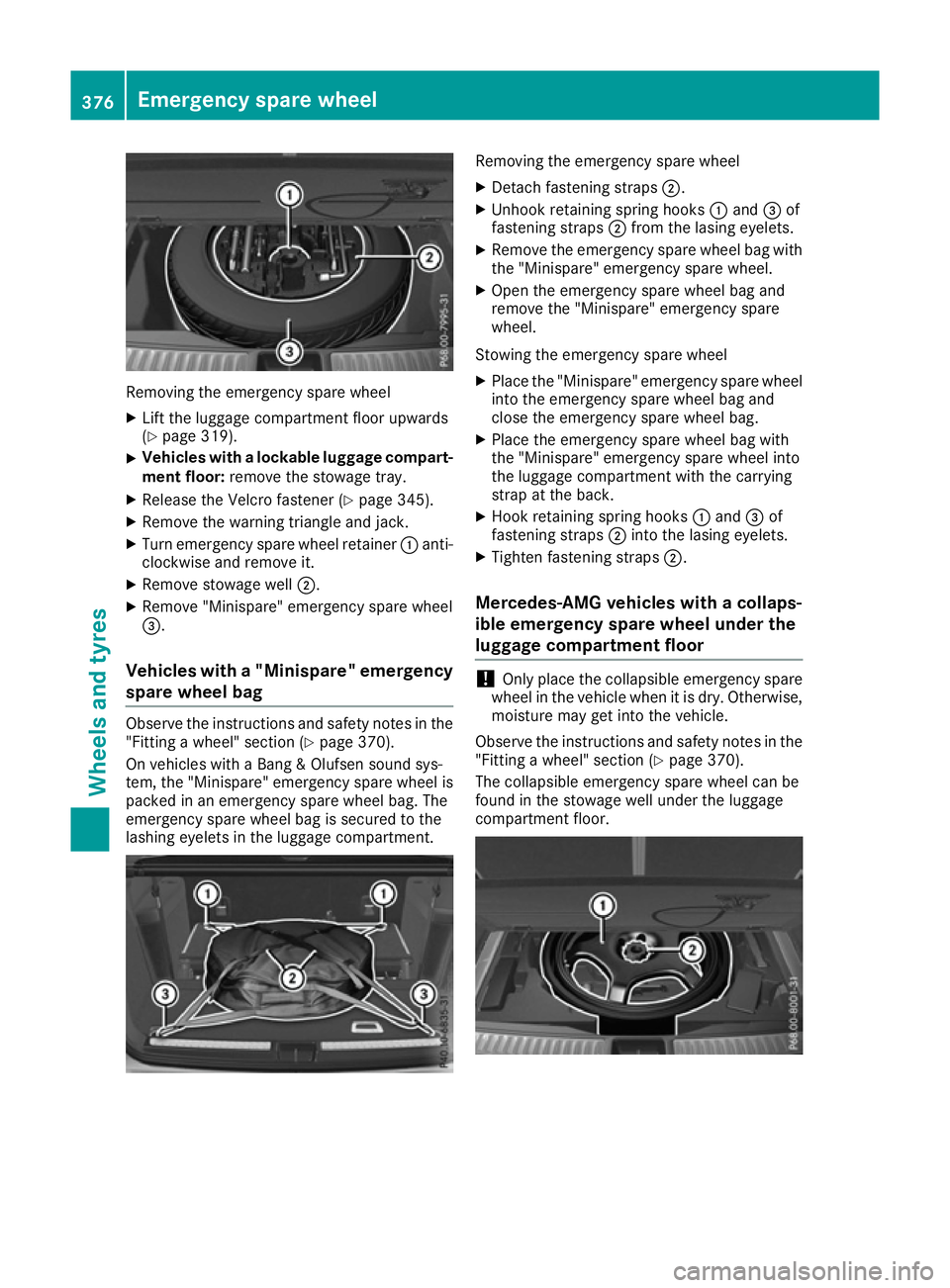

Vehicles with a "Minispare" emergency spare wheel bag Observe the instructions and safety notes in the

"Fitting a wheel" section (Y page 370).

On vehicles with a Bang & Olufsen sound sys-

tem, the "Minispare" emergency spare wheel is

packed in an emergency spare wheel bag. The

emergency spare wheel bag is secured to the

lashing eyelets in the luggage compartment. Removing the emergency spare wheel

X Detach fastening straps ;.

X Unhook retaining spring hooks :and =of

fastening straps ;from the lasing eyelets.

X Remove the emergency spare wheel bag with

the "Minispare" emergency spare wheel.

X Open the emergency spare wheel bag and

remove the "Minispare" emergency spare

wheel.

Stowing the emergency spare wheel

X Place the "Minispare" emergency spare wheel

into the emergency spare wheel bag and

close the emergency spare wheel bag.

X Place the emergency spare wheel bag with

the "Minispare" emergency spare wheel into

the luggage compartment with the carrying

strap at the back.

X Hook retaining spring hooks :and =of

fastening straps ;into the lasing eyelets.

X Tighten fastening straps ;.

Mercedes-AMG vehicles with a collaps-

ible emergency spare wheel under the

luggage compartment floor !

Only place the collapsible emergency spare

wheel in the vehicle when it is dry. Otherwise,

moisture may get into the vehicle.

Observe the instructions and safety notes in the

"Fitting a wheel" section (Y page 370).

The collapsible emergency spare wheel can be

found in the stowage well under the luggage

compartment floor. 376

Emergency spare wheelWheels and ty

res

Page 380 of 397

Removing the emergency spare wheel

X Lift the luggage compartment floor upwards

(Y page 319).

X Unscrew retaining screw ;anti-clockwise.

X Remove collapsible emergency spare

wheel :from the spare wheel well.

Inflating the collapsible emergency spare wheel (Y page 377).

Take the following steps to stow a used collaps-

ible emergency spare wheel. Otherwise, it will

not fit in the spare wheel well. Mercedes-Benz

recommends that you have this work performed

at a qualified specialist workshop, e.g. at a

Mercedes-Benz Service Centre.

Stowing the emergency spare wheel

X Unscrew the valve cap from the valve.

X If possible, unscrew the valve insert from the

valve and release the air.

i Fully deflating the tyre may take a few

minutes.

X Screw the valve insert back into the valve.

X Screw the valve cap back on.

X Lay collapsible emergency spare wheel :in

the emergency spare wheel well.

X Screw in retaining screw ;clockwise in the

collapsible emergency wheel to the stop.

X Swing the luggage compartment floor down

(Y page 319).

Mercedes-AMG vehicles with a collaps-

ible emergency spare wheel in the

emergency spare wheel bag Observe the instructions and safety notes in the

"Fitting a wheel" section (Y page 370).

On Mercedes-AMG vehicles with a Bang & Oluf-

sen sound system, the collapsible emergency

spare wheel is packed in an emergency spare

wheel bag. The emergency spare wheel bag is

secured to the lashing eyelets in the luggage

compartment. Removing the emergency spare wheel

X Unhook retaining spring hooks :of fasten-

ing strap ;from the lashing eyelets.

X Remove the emergency spare wheel bag with

the collapsible emergency spare wheel.

X Open the emergency spare wheel bag and

remove the collapsible emergency spare

wheel.

Inflating the collapsible emergency spare wheel (Y page 377).

Stowing the emergency spare wheel

X Place the collapsible emergency spare wheel

into the emergency spare wheel bag and

close the emergency spare wheel bag.

X Place the emergency spare wheel bag with

the collapsible emergency spare wheel into

the luggage compartment with the carrying

strap at the back.

X Hook retaining spring hooks :of fastening

strap ;into the lashing eyelets.

X Tighten fastening strap ;. Inflating the collapsible emergency

spare wheel (Mercedes-AMG GLS 63)

! Inflate the collapsible emergency spare

wheel using the tyre inflation compressor

before lowering the vehicle. The wheel rim

could otherwise be damaged.

! Do not operate the tyre inflation compres-

sor for longer than eight minutes at a time

without a break. It may otherwise overheat.

The tyre inflation compressor can be oper-

ated again once it has cooled down.

Comply with the manufacturer's safety instruc-

tions on the tyre inflation compressor label and

on the tyre sealant bottle. Emergency spare wheel

377Wheels and tyres Z