ABS MERCEDES-BENZ METRIS 2018 MY18 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2018Pages: 318, PDF Size: 5.07 MB

Page 248 of 318

XAlways transport loads in the cargo compart-

ment and with the seat backrests folded up

and properly locked in position.

XAlways place the load against the backrests ofthe front or rear seats.

XMove large and heavy loads as far towards thefront of the vehicle as possible against the

front or rear seats. Stow the load flush with

the rear or front seats.

XAlways additionally secure the load with suit-

able load-securing aids or tie downs.

Observe the following notes:

RDo not stack loads higher than the upper edge

of the backrests.

RTransport loads behind seats that are not

occupied.

RIf the rear bench seat is not occupied, insert

the seat belts crosswise into the buckle of the

opposite seat belt.

Cargo compartment variations

You can vary the cargo compartment according

to your transportation requirements as follows:

Rby folding the seat backrests forward to the

table position.

Rby removing the rear bench seat.

You will find information about rear bench seats in the "Rear bench seats" section (

Ypage 87).

Securing loads

Important safety notes

GWARNING

If you attach the tie-down incorrectly when

securing the load, the following may occur in

the event of abrupt changes in direction, brak- ing maneuvers or an accident:

Rthe cargo tie-down rings may become

detached or the tie-down may tear if the

permissible load is exceeded

Rthe load may not be restrained.

This may cause the load to slip, tip over or be

tossed about, striking vehicle occupants.

There is a risk of an accident and injury.

Always tension the tie-downs in the proper

manner and only between the described

cargo tie-down rings. Always use tie-downs

designed specifically for the loads.

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act- ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force

absorption. Load the anchorages evenly.

Spread the load evenly across the cargo tie-

down points/cargo tie-down rings. You will find information on the maximum loading capacity of

the cargo tie-down points under "Cargo tie-

down points and carrier systems" (

Ypage 314).

Do not attempt to modify or repair the cargo tie-

down points/cargo tie-down rings or tie downs.

Read the information on qualified specialist

workshops: (

Ypage 31).

As the driver, you are responsible for ensuring

that:

RThe load is secured against slipping, tipping,

rolling or falling off in normal traffic condi-

tions, should the vehicle swerve to avoid an

obstacle, in the event of full brake application

and on poor road surfaces.

RThe applicable requirements and guidelines

relating to load-securing practices must be

met.

If this is not the case, this may constitute a

punishable offense, depending on local legis-

lation and any ensuing consequences.

Always observe the legal requirements for the country you are currently in.

Make sure that the load is secure before every

journey and at regular intervals during a long

journey. Correct an incorrectly or inadequately

secured load if necessary.

Always observe the operating instructions or the

notes of the lashing strap manufacturer for the

operation of the lashing strap.

You can obtain information about securing the

load correctly from the manufacturer of the load

securing aids or tie down for securing the load.

246Securing loads

Transporting loads

Page 249 of 318

Also observe the safety information in the load-

ing directions (Ypage 244).

XFill spaces between the load and the cargo

compartment walls or wheel housings (form-

locking). Use rigid load securing aids, such as

wedges, wooden fixings or padding.

XAttach secured and stabilized loads in all

directions to the cargo tie-down rings and the

guide rails in the rear.

Only use tie downs, such as lashing nets and

lashing straps, that have been tested in

accordance with current standards.

When securing a load, always use the closest cargo tie-down rings and pad sharp edges for

protection.

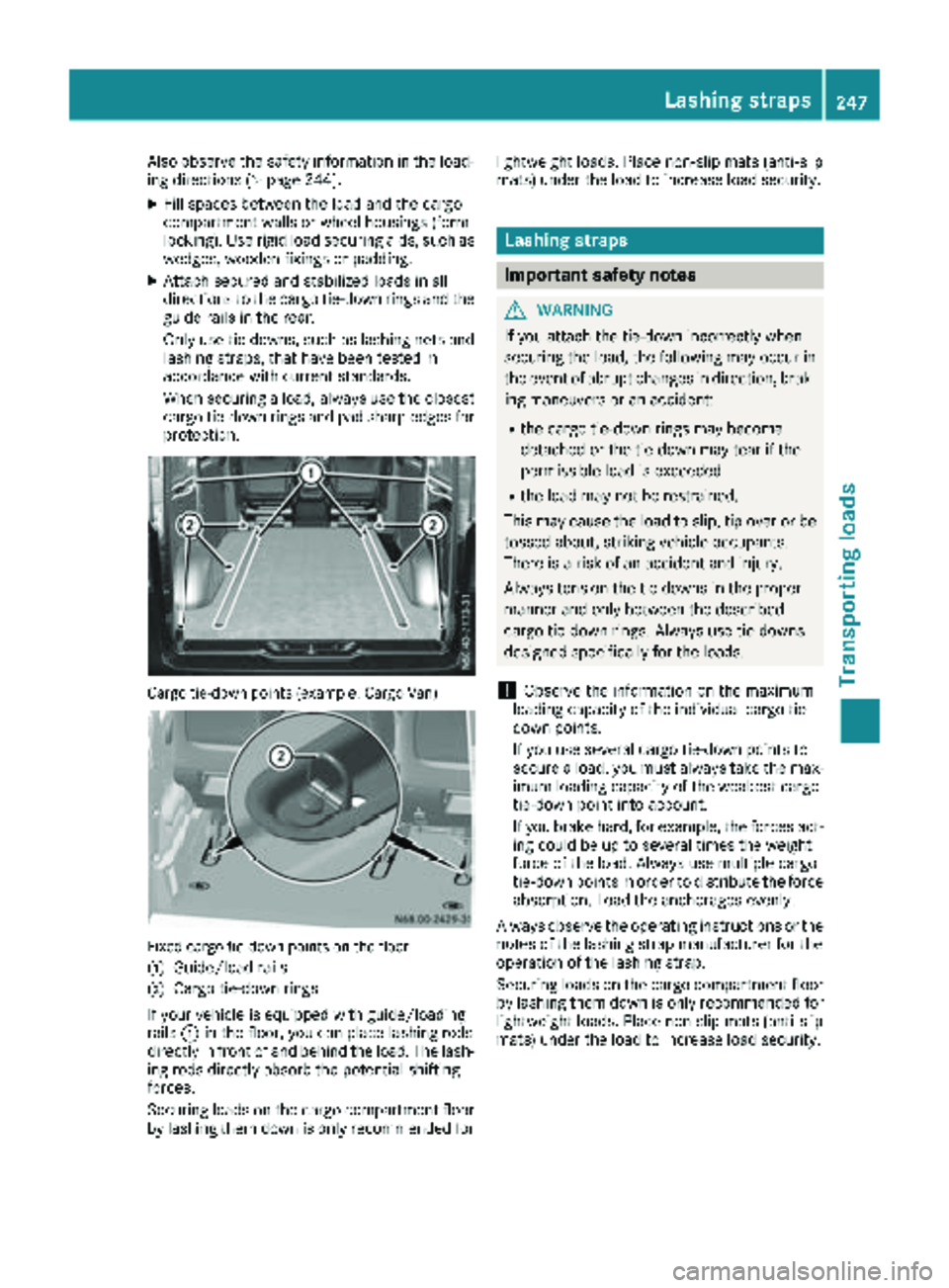

Cargo tie-down points (example: Cargo Van)

Fixed cargo tie-down points on the floor

:

Guide/load rails

;Cargo tie-down rings

If your vehicle is equipped with guide/loading

rails :in the floor, you can place lashing rods

directly in front of and behind the load. The lash-

ing rods directly absorb the potential shifting

forces.

Securing loads on the cargo compartment floor

by lashing them down is only recommended for lightweight loads. Place non-slip mats (anti-slip

mats) under the load to increase load security.

Lashing straps

Important safety notes

GWARNING

If you attach the tie-down incorrectly when

securing the load, the following may occur in

the event of abrupt changes in direction, brak- ing maneuvers or an accident:

Rthe cargo tie-down rings may become

detached or the tie-down may tear if the

permissible load is exceeded

Rthe load may not be restrained.

This may cause the load to slip, tip over or be

tossed about, striking vehicle occupants.

There is a risk of an accident and injury.

Always tension the tie-downs in the proper

manner and only between the described

cargo tie-down rings. Always use tie-downs

designed specifically for the loads.

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act-

ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force absorption. Load the anchorages evenly.

Always observe the operating instructions or the

notes of the la shing strap ma

nufacturer for the

operation of the lashing strap.

Securing loads on the cargo compartment floor

by lashing them down is only recommended for

lightweight loads. Place non-slip mats (anti-slip

mats) under the load to increase load security.

Lashing straps247

Transporting loads

Z

Page 259 of 318

Adding coolant

XIfthe coolant drops under marker bar=in

the filler neck, add coolant.

Observe the information on the correct cool-

ant mixture rat ioand the required water qual-

ity under "Service products and capacities"

(

Ypage 311). To prevent damage to the

engine co oling system, use only appr oved

corrosion inh ibitor/antifreeze that co mplies

wit h the Mercedes-Benz Specifications for

Service Products.

XReplac e cap:and tighten ina clock wise

dire ction.

XStart the engine.

XSet the temperature inthe veh icleinterior to

the maximum output on the air-conditioning

system control panel.

XAfter approximate lyfive minutes, switch off

the engine again and allow itto cool down.

XCheck the coolant level again and add coolant

ifnecessary.

XClose the hood.

Brake fluid

GWAR NING

Service products may be poisonous and haz-

ardous to health. There isa risk of injury.

Comp ly with instructions on the use, storage

and dispo sal of service products on the labels

of the respective original containers. Always

store service products sealed intheir original

containers. Always keep service products out

of the reach of ch ildren.

GWAR NING

Opening the hood when the engine isover-

heated or when there isa fire inthe engine

compartment could expose you to hot gases

or other service products. There isa risk of

injury.

Let an overheated engine cool downbefore

opening the hood. Ifthere isa fire inthe

engine compartment, keep the hood closed

and contact the fire department.

GWARNING

Certain components in the engine compart-

ment, such as the engine, radiator and parts

of the exhaust system, can become very hot.

Working in the engine compartment poses a

risk of injury.

Where possible, let the engine cool downand

touch only the components describe d in the

foll owin g.

Brake fluid is hazardous to health. Also observe the safety notes under "Service products and

capacities" (

Ypage 306).

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. Ifthe boilin g point of the brake

fluid is too low,vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!If the brake fluid level in the brake fluid res-

ervoir has fallen to the MIN mark or below,

check the brake system immediately for

leaks. Also check the thickness of the brake

linings. Visit a qualified specialist workshop

immediately.

Do not add brake fluid. This does not correct

the malfunction.

!Brake fluid corrodes paint, plastic and rub-

ber. Ifpaint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

Have the brake fluid renewed every two years at a qualified specialist workshop. Observe the

information regarding brake fluid in the "Service

products and capacities" section (

Ypage 311).

Engine compartment257

Maintenance and care

Z

Page 262 of 318

Rfrequent operation in mountainous terrain or

on poor road surfaces

Rleaving the engine idling for long periods on a

frequent basis

In these or similar operating conditions, have

the air filter, engine oil and oil filter, for example,

replaced more frequently. Under more arduous

operating conditions, the tires must be checked more often. Further information can be obtained

at a qualified specialist workshop, e.g. an

authorized Mercedes-Benz Commercial Van

Center.

Hiding service messages

Vehicles without steering wheel buttons

XPress the 3button on the instrument clus-

ter.

Vehicles with steering wheel buttons

XPress the aor% button on the steering

wheel.

Calling up the service due date

Vehicles without steering wheel buttons

The vehicle must be stationary. Use the buttons

in the instrument cluster.

XTurn the SmartKey to position 2in the ignition

lock.

XPress Èto select the service display.

The display shows a possible service mes-

sage.

Vehicles with steering wheel buttons

Using the steering wheel buttons

XTurn the SmartKey to position 2in the ignition

lock.

XPress =or; to select the Servicemenu.

XPress9or: to select the ASSYSTPLUSsubmenu and press ato confirm.

The display shows the service due date.

Battery

Important safety notes

Work on the battery, e.g. removing or installing,

requires specialist knowledge and the use of

special tools. Therefore, always have work on the battery carried out at a qualified specialist

workshop.

GWARNING

Work carried out incorrectly on the battery

can lead, for example, to a short circuit and

thus damage the vehicle electronics. This can

lead to function restrictions applying to

safety-relevant systems, e.g. the lighting sys-

tem, the ABS (anti-lock braking system) or the

ESP

®(Electronic Stability Program). The oper-

ating safety of your vehicle may be restricted.

You could lose control of the vehicle, for

example:

Rwhen braking

Rin the event of abrupt steering maneuvers

and/or when the vehicle's speed is not

adapted to the road conditions

There is a risk of an accident.

In the event of a short circuit or a similar inci-

dent, contact a qualified specialist workshop

immediately. Do not drive any further. You

should have all work involving the battery car- ried out at a qualified specialist workshop.

Further information can be found under "ABS"

(

Ypage 64) and under "ESP®" (Ypage 65).

GWARNING

Electrostatic build-up can lead to the creation of sparks, which could ignite the highly explo-

sive gases of a battery. There is a risk of an

explosion.

Before handling the battery, touch the vehicle

body to remove any existing electrostatic

build-up.

The flammable gas mix is produced when the

battery is charged or when the vehicle is jump-

started.

Always make sure that neither you nor the bat-

tery are electro statically charged. Electrostatic

charging results, for example, from:

Rwearing synthetic clothing

Rfriction between clothing and the seat

Rdragging or pushing the battery across carpet

flooring or any other synthetic materials

Rrubbing the battery with cloths or towels.

260Battery

Maintenance and care

Page 283 of 318

RDo not drive with tires which have too little

tread depth, as this significantly reduces the

traction on wet roads (hydroplaning).

RReplace the tires after six years at the latest,

regardless of wear. This also applies to the

spare wheel.

Operation in winter

General notes

Have your vehicle winterproofed at a qualified

specialist workshop at the onset of winter.

Only use wheels with tire sizes approved by

Mercedes-Benz.

Prior to the onset of winter, ensure that snow

chains are stowed in the vehicle (

Ypage 282).

Snow chains cannot be mounted on all wheel/

tire combinations. Observe the restrictions on

the use of snow chains under "Wheel/tire com-

binations" (

Ypage 302).

Also observe the notes in the "Changing a

wheel" section (

Ypage 298).

Driving with summer tires

At temperatures below 45 ‡ (+7 †), summer

tires lose elasticity and therefore traction and

braking power. Change the tires on your vehicle

to M+S tire s. Usingsu mmer tires at very cold

temperatures could cause tears to form,

thereby damaging the tires permanently.

Mercedes-Benz cannot accept responsibility for

this type of damage.

M+S tires

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

GWARNING

M+S tires with a tire tread depth of less than

ã in (4 mm) are not suitable for use in winter

and do not provide sufficient traction. There is

a risk of an accident.

M+S tires with a tread depth of less than ãin

(4 mm) must be replaced immediately.

Use winter tires or all-season tires at tempera-

tures below 45 ‡ (+7 †). Both types of tire are

identified by the M+S marking.

Only winter tires bearing the isnowflake

symbol in addition to the M+S marking provide

the best possible grip in wintry road conditions.

Only these tires will allow driving safety systems

such as ABS and ESP

®to function optimally in

winter. These tires have been developed specif-

ically for driving in snow.

For safe driving, use M+S tires of the same make

and tread pattern on all wheels.

Always observe the maximum permissible

speed specified for the M+S tires you have

mounted.

If you mount M+S tires that have a lower maxi-

mum permissible speed than the maximum

design speed of the vehicle, affix a correspond- ing warning label in the driver's field of vision.

You can obtain this at a qualified specialist work-

shop.

Once you have mounted the winter tires:

XCheck the tire pressure (Ypage 282).

XRestart the tire pressure monitor

(Ypage 289).

Operation in winter281

Wheels and tires

Z

Page 304 of 318

When using a wheel/spare wheel with a new or

newly painted wheel rim, have the wheel bolts/

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

Wheel and tire combination

General notes

!

Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tires. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires if you have no information about their previous

usage.

!For safety reasons, Mercedes-Benz recom-

mends that you only use tires, wheels and

accessories which have been specially

approved by Mercedes-Benz for your vehicle.

These tires have been specially adapted for

use with the driving safety systems, such as

ABS or ESP

®.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when

driving with a load, tire dimension variations

could cause the tires to come into contact

with the bodywork and axle components. This could result in damage to the tires or the vehi-

cle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tires, wheels or

accessories other than those tested and

approved.

Further information on wheels, tires and

approved combinations can be obtained from

any qualified specialist workshop.

!Large wheels: the lower the section width

for a certain wheel size, the lower the ride

comfort is on poor road surfaces. Roll comfort and suspension comfort are reduced and the

risk of damage to the wheels and tires as a

result of driving over obstacles increases.

You will find a table with the recommended tire

pressures for various vehicle loads on the inside

of your vehicle's fuel filler flap or under "Tire

pressure tables" (

Ypage 290). You can find fur-

ther information under "Tire pressure"

(

Ypage 282).

Check tire pressures regularly and only when

the tires are cold.

Notes on the vehicle equipment – always equip

the vehicle:

Rwith tires of the same size across an axle

(left/right)

Rwith the same type of tires on all wheels at a

given time (summer tires, winter tires)

iNot all wheel/tire combinations can be

installed at the factory in all countries.

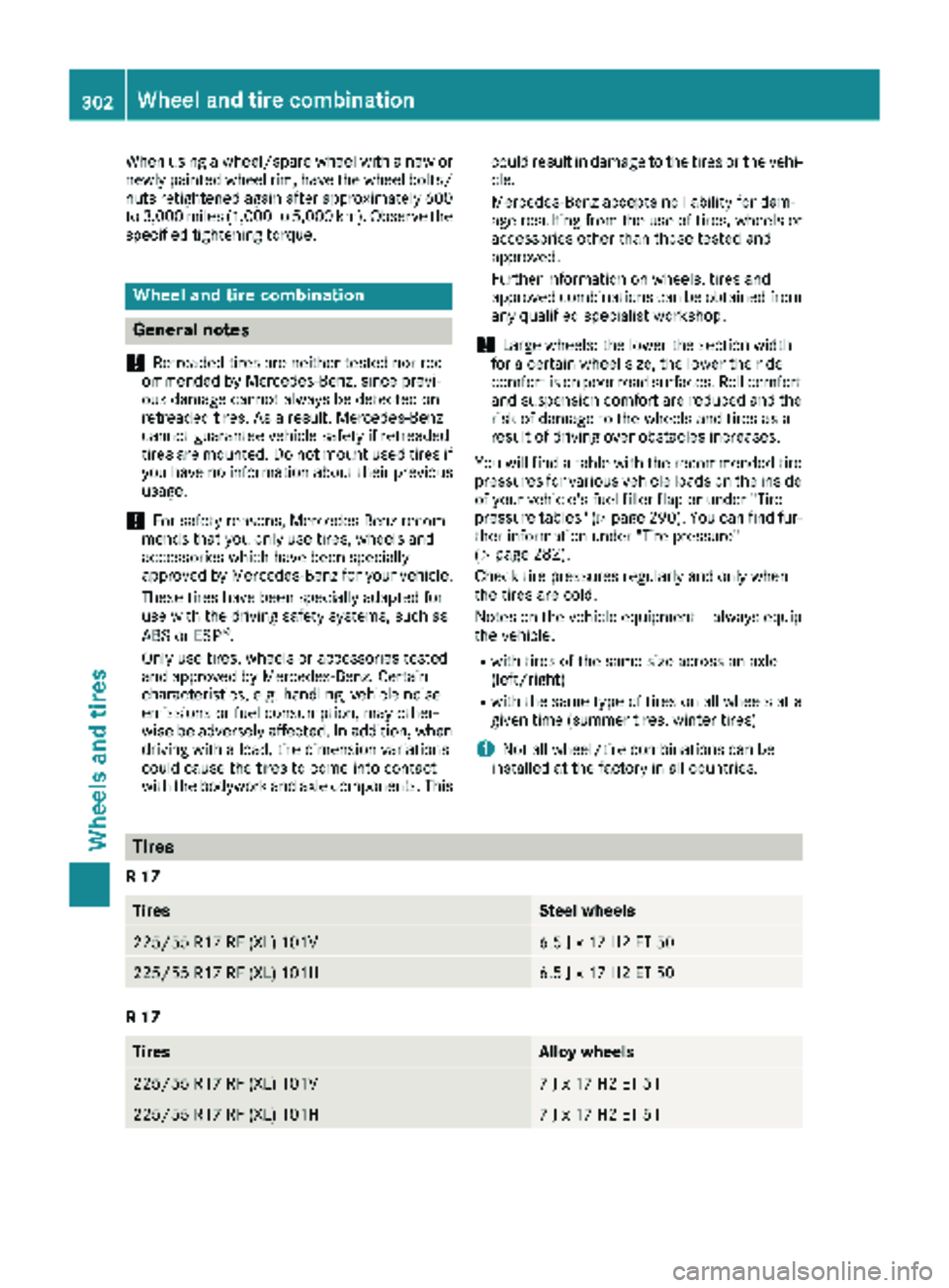

Tires

R 17

TiresSteel wheels

225/55 R17 RF (XL) 101V6.5 J x 17 H2 ET 50

225/55 R17 RF (XL) 101H6.5 J x 17 H2 ET 50

R 17

TiresAlloy wheels

225/55 R17 RF (XL) 101V7 J x 17 H2 ET 51

225/55 R17 RF (XL) 101H7 J x 17 H2 ET 51

302Wheel and tire combination

Wheels and tires

Page 313 of 318

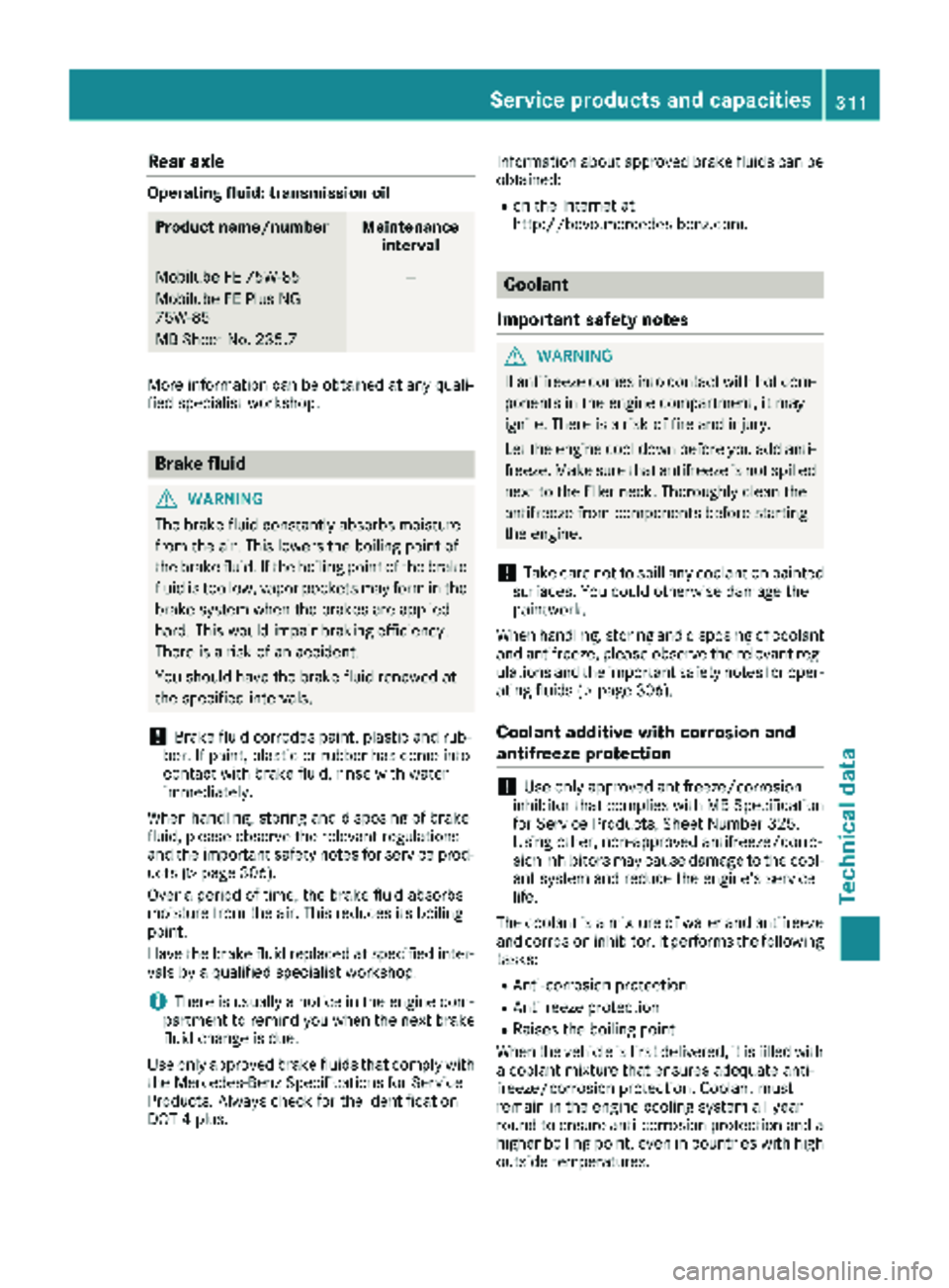

Rear axle

Operating fluid: transmission oil

Product name/numberMaintenanceinterval

Mobilube FE 75W-85

Mobilube FE Plus NG

75W-85

MB Sheet No. 235.7—

More information can be obtained at any quali-

fied specialist workshop.

Brake fluid

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber. If paint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

When handling, storing and disposing of brake

fluid, please observe the relevant regulations

and the important safety notes for service prod-

ucts (

Ypage 306).

Over a period of time, the brake fluid absorbs

moisture from the air. This reduces its boiling

point.

Have the brake fluid replaced at specified inter-

vals by a qualified specialist workshop.

iThere is usually a notice in the engine com-

partment to remind you when the next brake

fluid change is due.

Use only approved brake fluids that comply with the Mercedes-Benz Specifications for Service

Products. Always check for the identification

DOT 4 plus. Information about approved brake fluids can be

obtained:

Ron the Internet at

http://bevo.mercedes-benz.co m.

Coolant

Important safety notes

GWARNING

If antifreeze comes into contact with hot com- ponents in the engine compartment, it may

ignite. There is a risk of fire and injury.

Let the engine cool down before you add anti-

freeze. Make sure that antifreeze is not spilled

next to the filler neck. Thoroughly clean the

antifreeze from components before starting

the engine.

!Take care not to spill any coolant on painted

surfaces. You could otherwise damage the

paintwork.

When handling, storing and disposing of coolant

and antifreeze, please observe the relevant reg-

ulations and the important safety notes for oper-

ating fluids (

Ypage 306).

Coolant additive with corrosion and

antifreeze protection

!Use only approved antifreeze/corrosion

inhibitor that complies with MB Specification for Service Products, Sheet Number 325.

Using other, non-approved antifreeze/corro-

sion inhibitors may cause damage to the cool-

ant system and reduce the engine's service

life.

The coolant is a mixture of water and antifreeze

and corrosion inhibitor. It performs the following

tasks:

RAnti-corrosion protection

RAntifreeze protection

RRaises the boiling point

When the vehicle is first delivered, it is filled with

a coolant mixture that ensures adequate anti-

freeze/corrosion protection. Coolant must

remain in the engine cooling system all year

round to ensure anti-corrosion protection and a

higher boiling point, even in countries with high

outside temperatures.

Service products and capacities311

Technical data

Z

Page 316 of 318

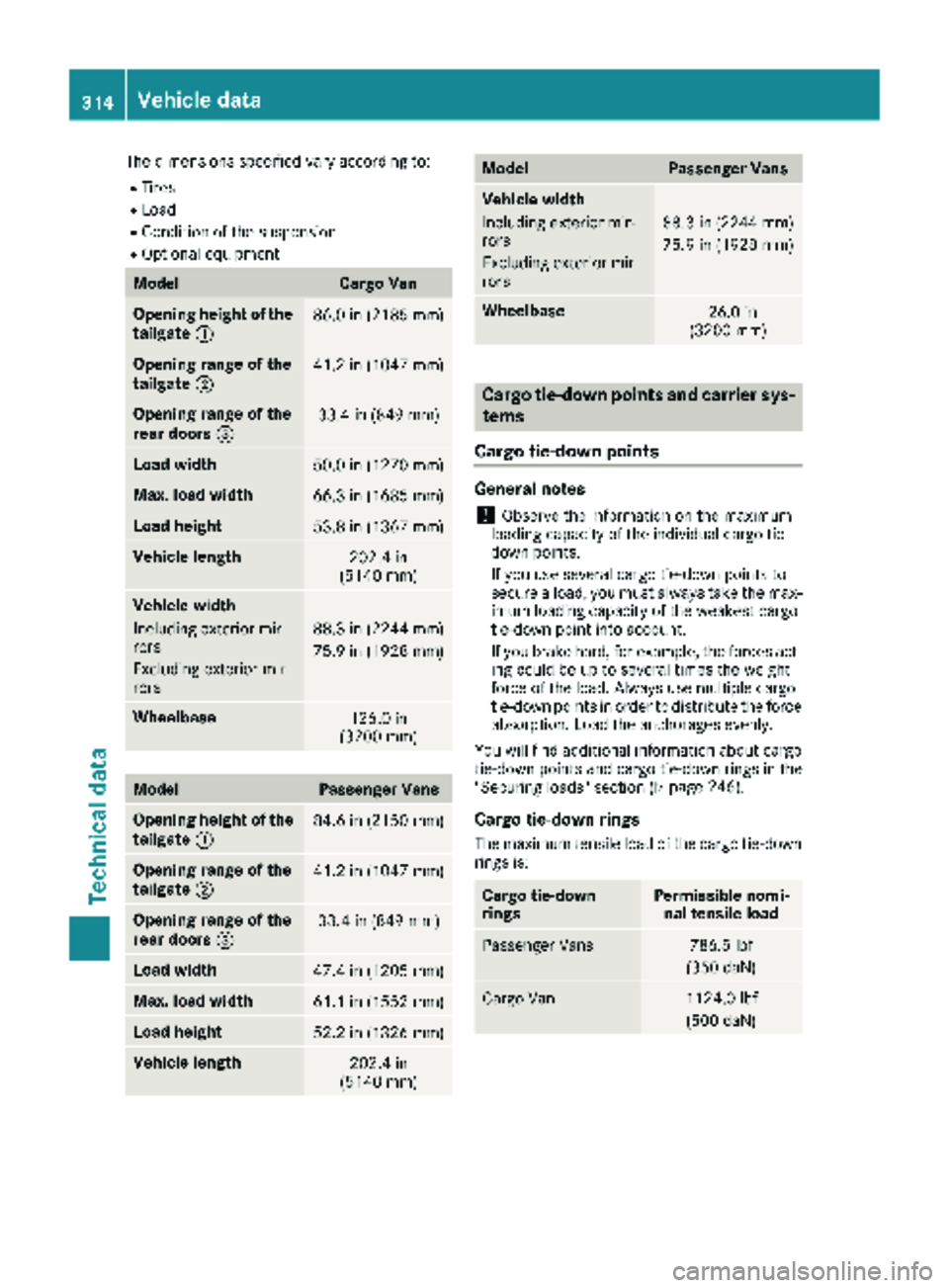

The dimensions specified vary according to:

RTires

RLoad

RCondition of the suspension

ROptional equipment

ModelCargo Van

Opening height of the

tailgate:86.0 in (2185 mm)

Opening range of the

tailgate;41.2 in (1047 mm)

Opening range of the

rear doors =33.4 in (849 mm)

Load width50.0 in (1270 mm)

Max. load width66.3 in (1685 mm)

Load height53.8 in (1367 mm)

Vehicle length202.4 in

(5140 mm)

Vehicle width

Including exterior mir-

rors

Excluding exterior mir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(3200 mm)

ModelPassenger Vans

Opening height of the

tailgate :84.6 in (2150 mm)

Opening range of the

tailgate;41.2 in (1047 mm)

Opening range of the

rear doors =33.4 in (849 mm)

Load width47.4 in (1205 mm)

Max. load width61.1 in (1552 mm)

Load height52.2 in (1326 mm)

Vehicle length202.4 in

(5140 mm)

ModelPassenger Vans

Vehicle width

Including exterior mir-

rors

Excluding exterior mir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(3200 mm)

Cargo tie-down points and carrier sys-

tems

Cargo tie-down points

General notes

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act-

ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force absorption. Load the anchorages evenly.

You will find additional information about cargo

tie-down points and cargo tie-down rings in the

"Securing loads" section (

Ypage 246).

Cargo tie-down rings

The maximum tensile load of the cargo tie-down

rings is:

Cargo tie-down

ringsPermissible nomi- nal tensile load

Passenger Vans786.5 lbf

(350 daN)

Cargo Van1124.0 lbf (500 daN)

314Vehicle data

Technical data