wheel MERCEDES-BENZ METRIS 2019 MY19 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2019Pages: 318, PDF Size: 5.07 MB

Page 301 of 318

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XShift the transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel

change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe the legal requirements on the cor-

rect use of the warning triangle or warning

lamp for the country in which you are cur-

rently driving

XSecure the vehicle to prevent it from rolling

away.

Observe the safety notes on parking under

"Driving and parking" (

Ypage 135)

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitable objects under the wheels on the front and rear axles opposite the wheel to be

changed.

XIf included in the vehicle equipment, take the

tire-changing tool kit out of the vehicle tool kit

(

Ypage 272).

Apart from some country-specific variants,

vehicles are not equipped with tire-changing

tools. Some tools for changing a wheel are

specific to the vehicle. Consult a qualified

specialist workshop for more information on

which tools are required to perform a wheel

change on your vehicle.

XIf included in the vehicle equipment, remove

the spare wheel from the spare wheel bracket (

Ypage 303). Observe the safety notes listed

under "Spare wheel" (Ypage 303).

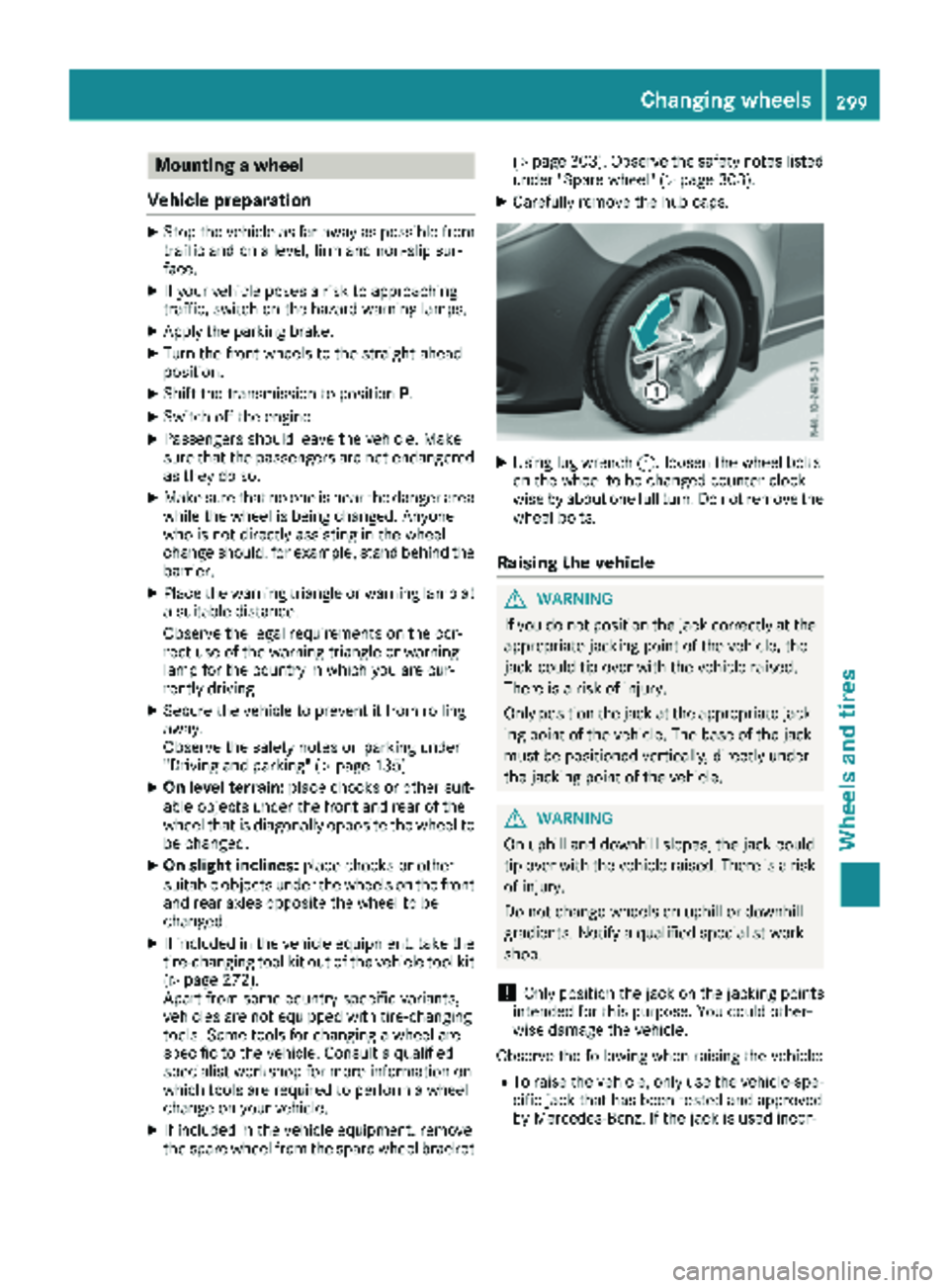

XCarefully remove the hub caps.

XUsing lug wrench :, loosen the wheel bolts

on the wheel to be changed counter-clock-

wise by about one full turn. Do not remove the

wheel bolts.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

Observe the following when raising the vehicle:

RTo raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If the jack is used incor-

Changing wheels299

Wheels and tires

Z

Page 302 of 318

rectly, it could tip over while the vehicle is

raised.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

raised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door or the tailgate/

door when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

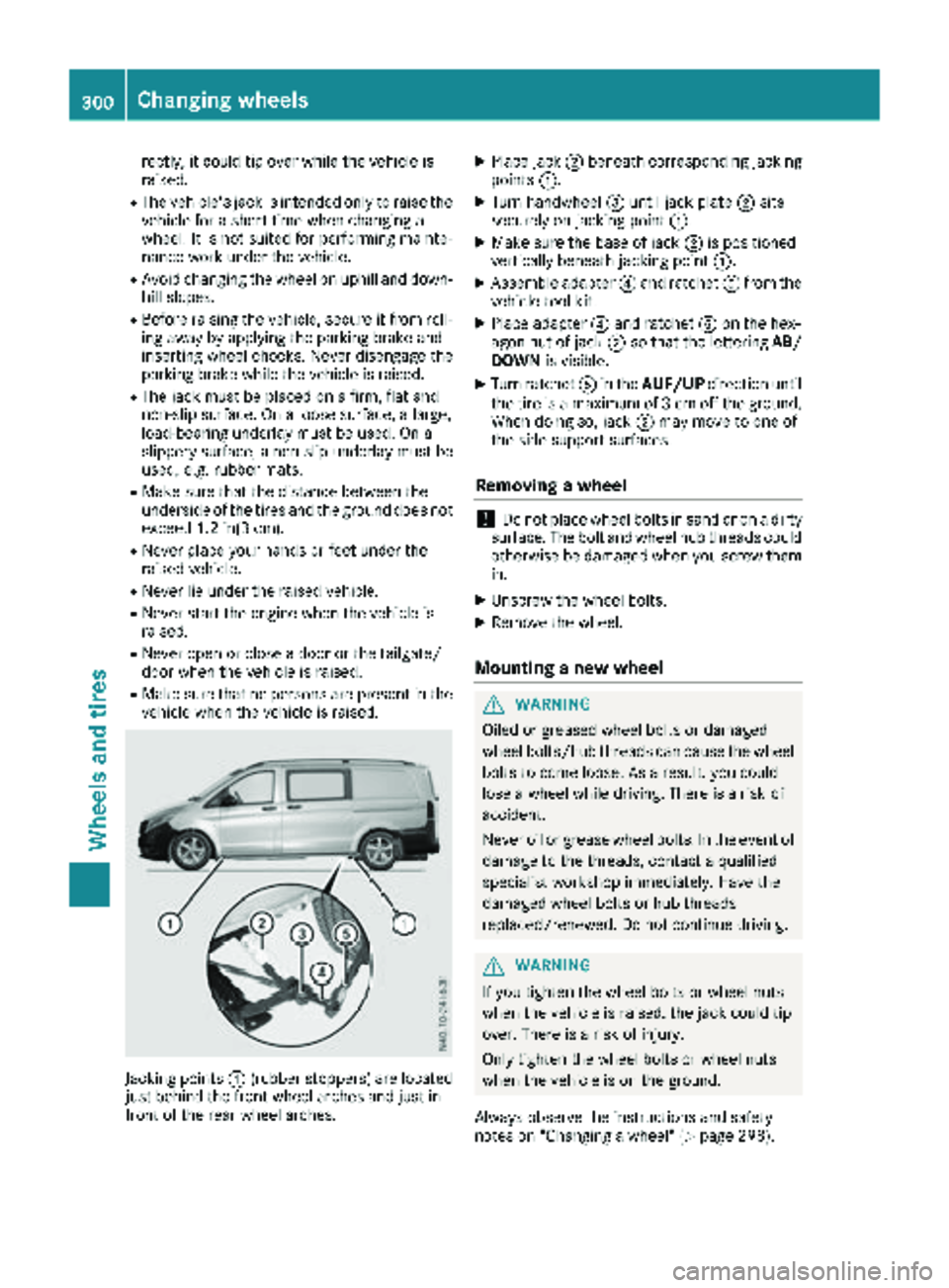

Jacking points :(rubber stoppers) are located

just behind the front wheel arches and just in

front of the rear wheel arches.

XPlace jack ;beneath corresponding jacking

points :.

XTurn handwheel =until jack plate ;sits

securely on jacking point :.

XMake sure the base of jack ;is positioned

vertically beneath jacking point :.

XAssemble adapter?and ratchet Afrom the

vehicle tool kit.

XPlace adapter ?and ratchet Aon the hex-

agon nut of jack ;so that the lettering AB/

DOWN is visible.

XTurn ratchet Ain the AUF/UP direction until

the tire is a maximum of 3 cm off the ground.

When doing so, jack ;may move to one of

the side support surfaces.

Removing a wheel

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

XUnscrew the wheel bolts.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 298).

300Changing wheels

Wheels and tires

Page 303 of 318

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

XClean the wheel and wheel hub contact sur-

faces.

XSlide the new wheel onto the wheel hub and

push it on.

XScrew in the wheel bolts and tighten them

lightly.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

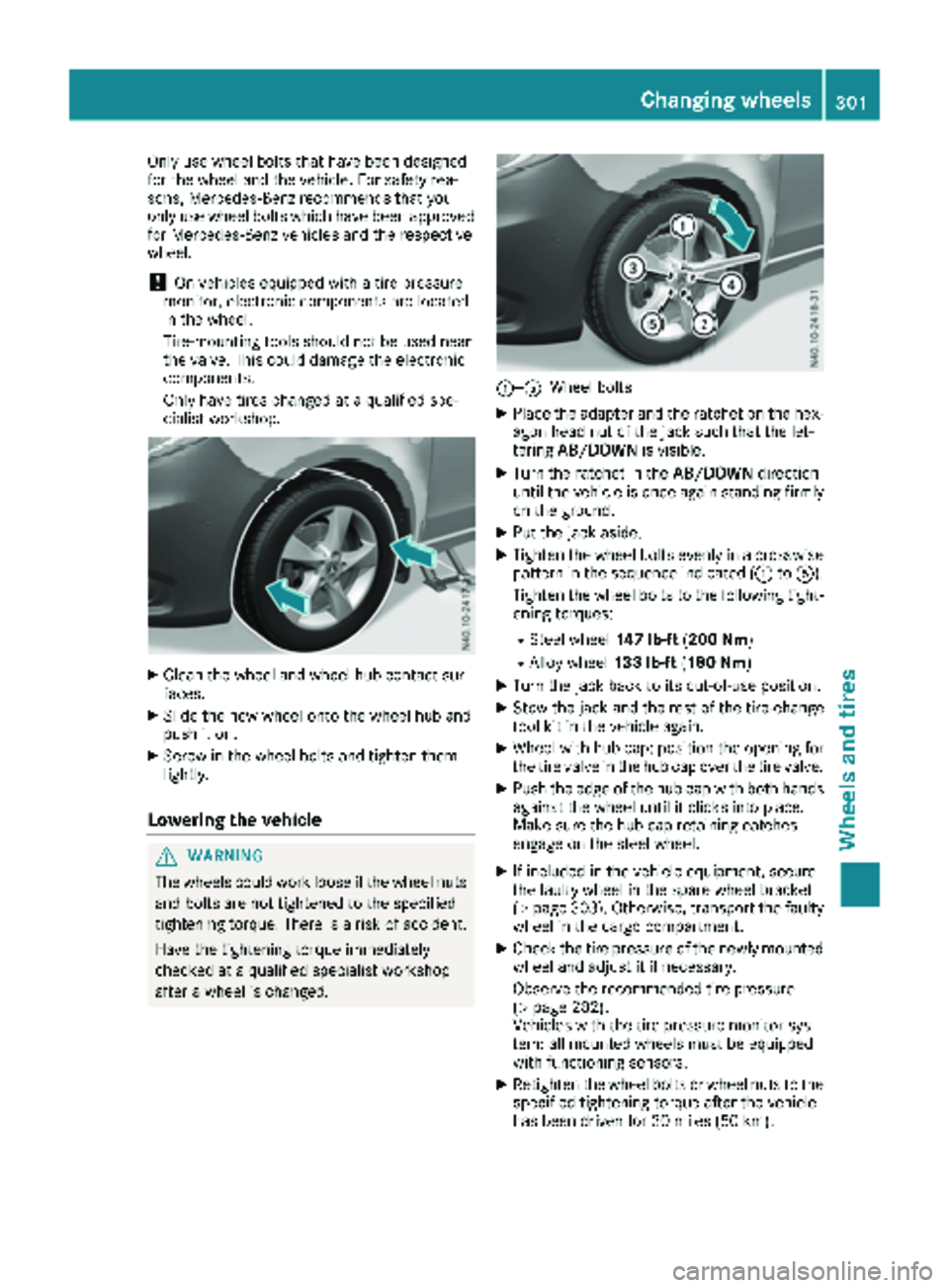

:—AWheel bolts

XPlace the adapter and the ratchet on the hex-

agon head nut of the jack such that the let-

tering AB/DOWN is visible.

XTurn the ratchet in the AB/DOWNdirection

until the vehicle is once again standing firmly

on the ground.

XPut the jack aside.

XTighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (: toA).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 147 lb-ft(200 Nm)

RAlloy wheel 133 lb-ft(180 Nm)

XTurn the jack back to its out-of-use position.

XStow the jack and the rest of the tire-change

tool kit in the vehicle again.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands

against the wheel until it clicks into place.

Make sure the hub cap retaining catches

engage on the steel wheel.

XIf included in the vehicle equipment, secure

the faulty wheel in the spare wheel bracket

(

Ypage 303). Otherwise, transport the faulty

wheel in the cargo compartment.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 282).

Vehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functioning sensors.

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

Changing wheels301

Wheels and tires

Z

Page 304 of 318

When using a wheel/spare wheel with a new or

newly painted wheel rim, have the wheel bolts/

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

Wheel and tire combination

General notes

!

Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tires. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires if you have no information about their previous

usage.

!For safety reasons, Mercedes-Benz recom-

mends that you only use tires, wheels and

accessories which have been specially

approved by Mercedes-Benz for your vehicle.

These tires have been specially adapted for

use with the driving safety systems, such as

ABS or ESP

®.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when

driving with a load, tire dimension variations

could cause the tires to come into contact

with the bodywork and axle components. This could result in damage to the tires or the vehi-

cle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tires, wheels or

accessories other than those tested and

approved.

Further information on wheels, tires and

approved combinations can be obtained from

any qualified specialist workshop.

!Large wheels: the lower the section width

for a certain wheel size, the lower the ride

comfort is on poor road surfaces. Roll comfort and suspension comfort are reduced and the

risk of damage to the wheels and tires as a

result of driving over obstacles increases.

You will find a table with the recommended tire

pressures for various vehicle loads on the inside

of your vehicle's fuel filler flap or under "Tire

pressure tables" (

Ypage 290). You can find fur-

ther information under "Tire pressure"

(

Ypage 282).

Check tire pressures regularly and only when

the tires are cold.

Notes on the vehicle equipment – always equip

the vehicle:

Rwith tires of the same size across an axle

(left/right)

Rwith the same type of tires on all wheels at a

given time (summer tires, winter tires)

iNot all wheel/tire combinations can be

installed at the factory in all countries.

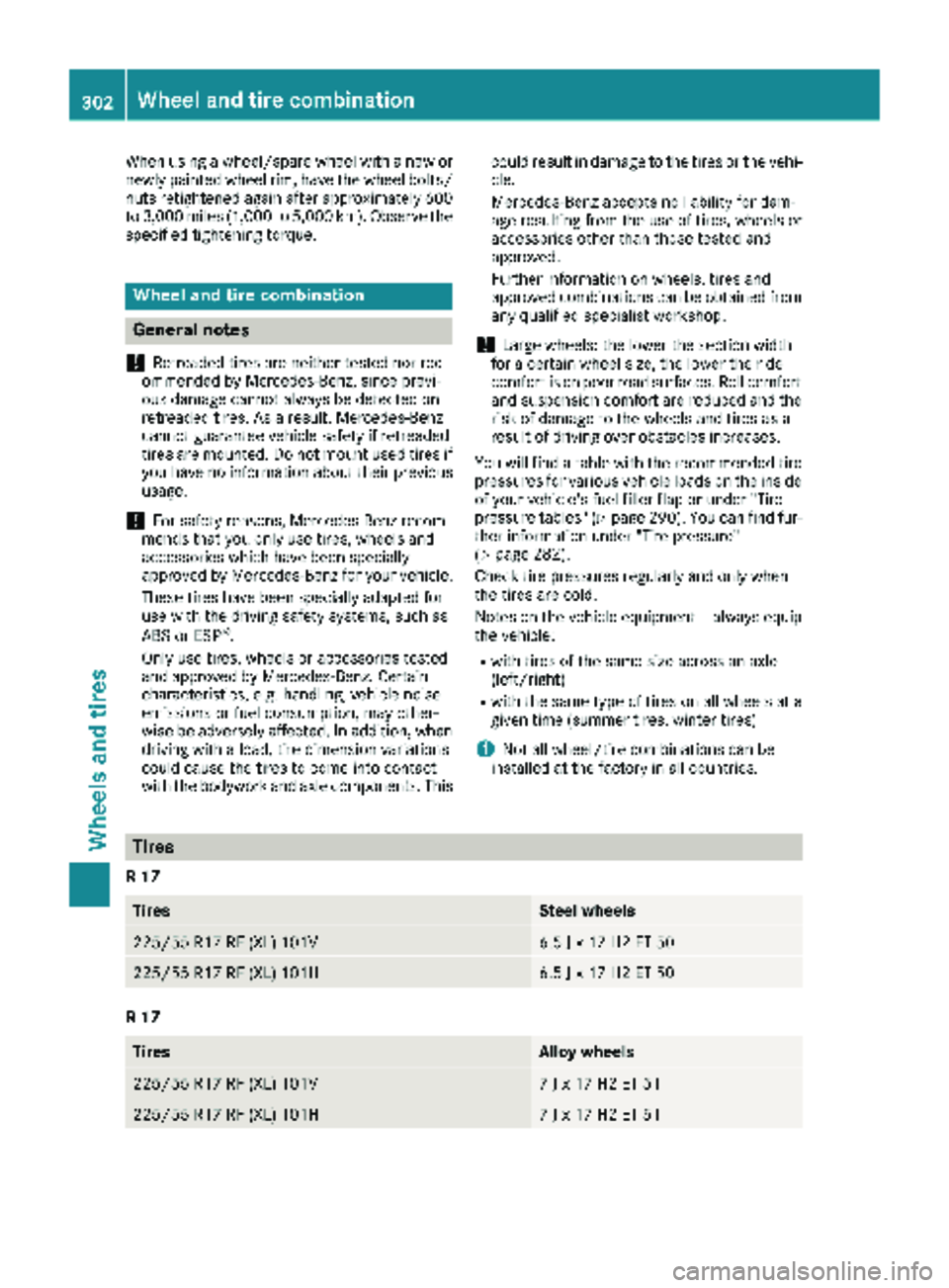

Tires

R 17

TiresSteel wheels

225/55 R17 RF (XL) 101V6.5 J x 17 H2 ET 50

225/55 R17 RF (XL) 101H6.5 J x 17 H2 ET 50

R 17

TiresAlloy wheels

225/55 R17 RF (XL) 101V7 J x 17 H2 ET 51

225/55 R17 RF (XL) 101H7 J x 17 H2 ET 51

302Wheel and tire combination

Wheels and tires

Page 305 of 318

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size, do

not exceed the maximum permissible speed of

50 mph (80 km/h).

General notes

The procedure for mounting the spare wheel is

described in "Mounting a wheel" (Ypage 299).

The following should be checked regularly, par-

ticularly prior to long journeys:

Rthe tire pressure of the spare wheel, which

should then be corrected if necessary

(

Ypage 282)

Rthe fastenings of the spare wheel bracket

The spare wheel is located either in the left rear

compartment or in a spare wheel bracket under

the vehicle.

Replace the tires after six years at the latest,

regardless of wear. This also applies to the spare

wheel.

Vehicles with tire pressure monitor: the

spare wheel is not equipped with a sensor for

monitoring tire pressure. If you have installed a spare wheel, the tire pressure monitor will not

function for this wheel. The system may con-

tinue to show the tire pressure of the wheel that

has been removed for a few minutes. The value

displayed for the position where the spare wheel

is installed is not the same as the current tire

pressure of the spare wheel.

When you are driving with the spare wheel

mounted, the tire pressure monitor cannot func-

tion reliably. Only restart the tire pressure mon- itor when the defective wheel has been replaced

with a new wheel and sensor.

More Information can be found under "Tire pres-

sure monitor" (

Ypage 286).

Removing and installing the spare

wheel

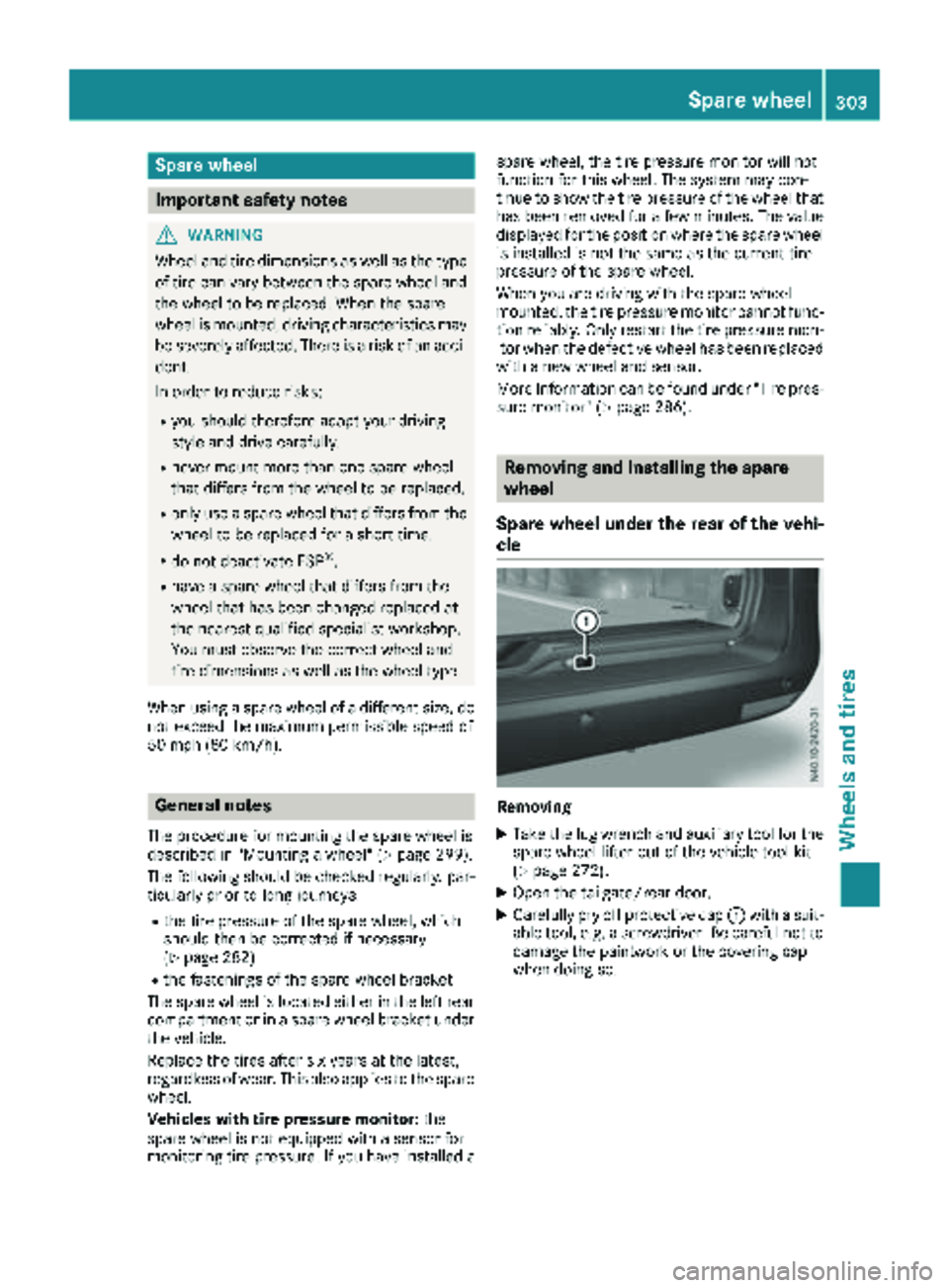

Spare wheel under the rear of the vehi-

cle

Removing

XTake the lug wrench and auxiliary tool for the

spare wheel lifter out of the vehicle tool kit

(

Ypage 272).

XOpen the tailgate/rear door.

XCarefully pry off protective cap :with a suit-

able tool, e.g. a screwdriver. Be careful not to

damage the paintwork or the covering cap

when doing so.

Spare wheel303

Wheels and tires

Z

Page 306 of 318

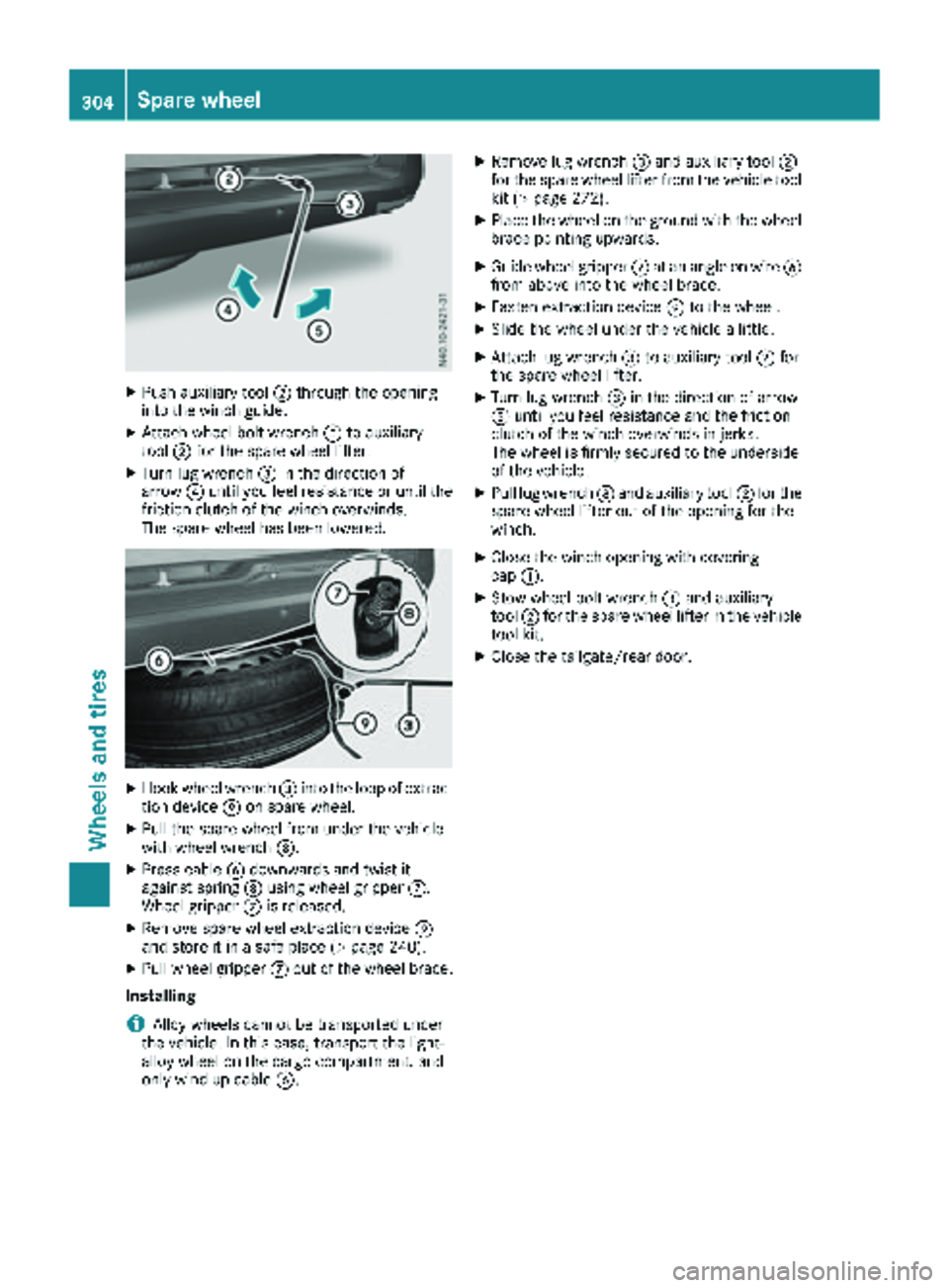

XPush auxiliary tool;through the opening

into the winch guide.

XAttach wheel bolt wrench =to auxiliary

tool ;for the spare wheel lifter.

XTurn lug wrench =in the direction of

arrow ?until you feel resistance or until the

friction clutch of the winch overwinds.

The spare wheel has been lowered.

XHook wheel wrench =into the loop of extrac-

tion device Eon spare wheel.

XPull the spare wheel from under the vehicle

with wheel wrench =.

XPress cableBdownwards and twist it

against spring Dusing wheel gripper C.

Wheel gripper Cis released.

XRemove spare wheel extraction device E

and store it in a safe place (Ypage 240).

XPull wheel gripper Cout of the wheel brace.

Installing

iAlloy wheels cannot be transported under

the vehicle. In this case, transport the light-

alloy wheel on the cargo compartment, and

only wind up cable B.

XRemove lug wrench =and auxiliary tool ;

for the spare wheel lifter from the vehicle tool

kit (

Ypage 272).

XPlace the wheel on the ground with the wheel brace pointing upwards.

XGuide wheel gripper Cat an angle on wire B

from above into the wheel brace.

XFasten extraction device Eto the wheel.

XSlide the wheel under the vehicle a little.

XAttach lug wrench =to auxiliary tool ;for

the spare wheel lifter.

XTurn lug wrench =in the direction of arrow

A until you feel resistance and the friction

clutch of the winch overwinds in jerks.

The wheel is firmly secured to the underside

of the vehicle.

XPull lug wrench =and auxiliary tool ;for the

spare wheel lifter out of the opening for the

winch.

XClose the winch opening with covering

cap :.

XStow wheel bolt wrench =and auxiliary

tool ;for the spare wheel lifter in the vehicle

tool kit.

XClose the tailgate/rear door.

304Spare wheel

Wheels and tires

Page 311 of 318

The following components of the different vehi-

cle versions influence fuel consumption:

Rtire sizes, tire tread, tire pressure, tire condi-

tion

Rtransmission ratios for the drive assemblies

Radditional equipment (e.g. air-conditioning

system, auxiliary heating system)

For these reasons, the actual consumption fig-

ures for your vehicle may deviate from the con-

sumption figures determined according to EU

Directive 80/1268/EE C.

Details on fuel consumption can be called up in

the on-board computer:

Ron vehicles without steering wheel buttons

(Ypage 174)

Ron vehicles with steering wheel buttons

(Ypage 181)

Engine oil

General notes

When handling engine oil, observe the important

safety notes on operating fluids (Ypage 306).

The quality of the engine oil used is of decisive

importance for the engine's functionality and

operating life. Mercedes-Benz continually

approves engine oils based on complex experi-

ments according to the current state of the art. Therefore, only Mercedes-Benz approved

engine oils may be used in Mercedes-Benz

engines. Mercedes-Benz recommends having

the oil changed at a qualified specialist work-

shop. Information about engine oils approved by

Mercedes-Benz can be obtained:

Rfrom any Mercedes-Benz Commercial Van

Center

Ron the Internet at

http://bevo.mercedes-benz.co

mbyenterin g

th edesignation ,e.g. 229.5.

Mercedes-Ben zapprova lis indicate don th eoil

container by th einscription „MB-Freigabe “or

„MB Approval“ and th ecorrespondin gdesigna-

tion ,e.g. MB-Freigabe or MB Approval 229.5.

Designation sof th eapprove dengin eoils for

your vehicl e

MB-Freigabe or MB

Approval229.5

Mercedes-Ben zrecommends that you only use

approve dmultigrade engin eoils of th eSA E

classe sSA E0W-30 and SA E0W-40 or

SA E5W-30 and SA E5W-40. These engin eoils

ensur eoptimum lubrication eve nat ver ylow

outside temperatures (

Ypage 310).

Whe ntoppin gup, we recommen dthat you only

use engin eoil of th esam egrade (MB-Freigabe

or MB Approval designation )and SA Eclass as

th eoil filled at th elast oil change.

iIf th eengin eoils listed in th etable are no t

available, you may add th efollowin gengin e

oils until th enext oil change:

RMB-Freigabe or MB Approval 229.1, or

ACE AA3

This mus tonly be added once and th eamount

mus tno tbe greate rthan 1qt (1. 0l).

Subsequentl yhav eth eengin eoil changed at

th eearliest possibl eopportunity.

!Using engin eoils of another grade qualit yis

no tpermitted.

Capacities

!Do no tadd to omuc hoil. addin gto omuc h

engin eoil can result in damage to th eengin e

or to th ecatalytic converter. Hav eexcess

engin eoil siphoned off .

Oil change includin goil filter

Engin eoilApprox. 2US gal

(7.75 l)

Service products and capacities309

Technical data

Z

Page 316 of 318

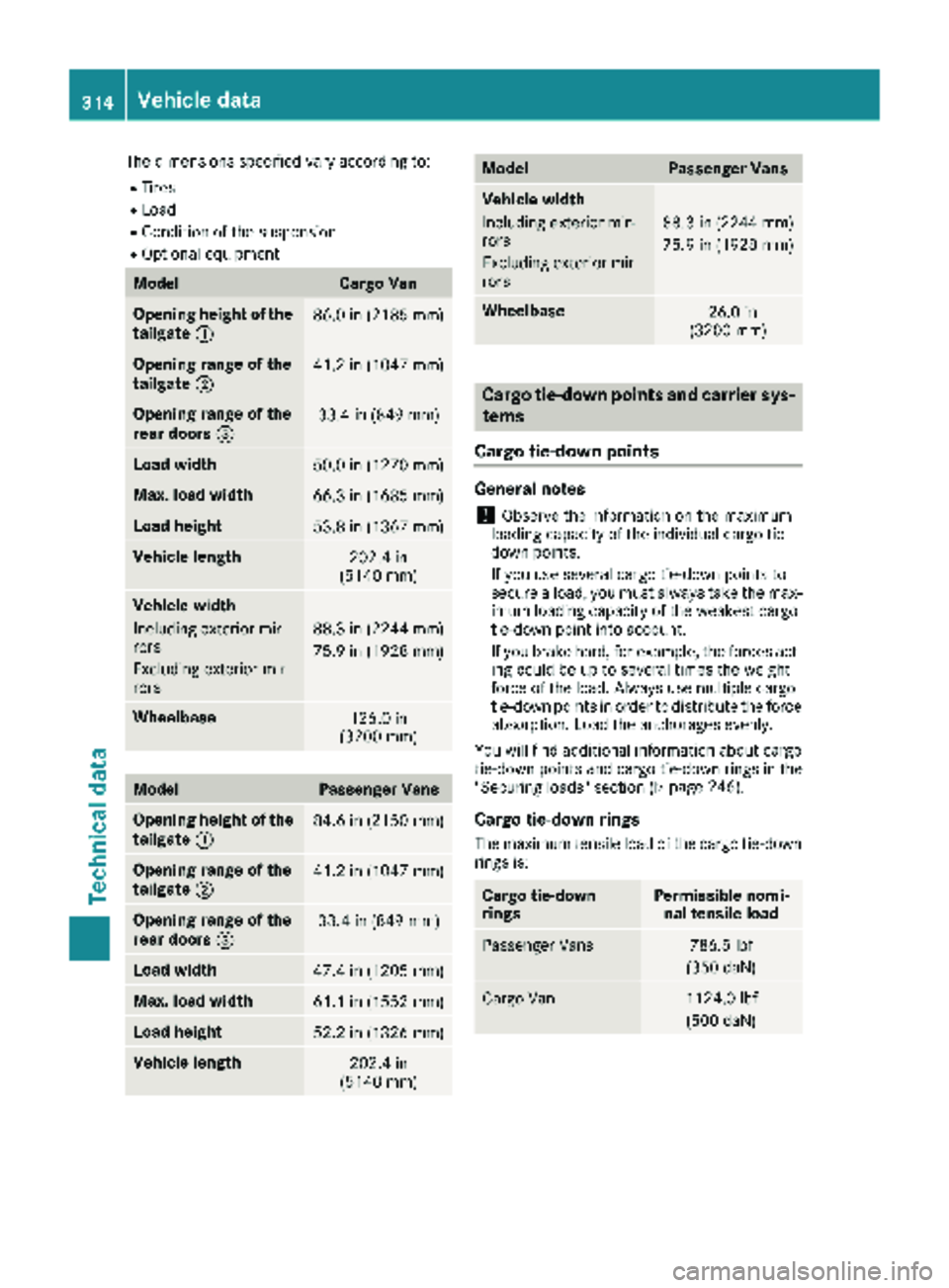

The dimensions specified vary according to:

RTires

RLoad

RCondition of the suspension

ROptional equipment

ModelCargo Van

Opening height of the

tailgate:86.0 in (2185 mm)

Opening range of the

tailgate;41.2 in (1047 mm)

Opening range of the

rear doors =33.4 in (849 mm)

Load width50.0 in (1270 mm)

Max. load width66.3 in (1685 mm)

Load height53.8 in (1367 mm)

Vehicle length202.4 in

(5140 mm)

Vehicle width

Including exterior mir-

rors

Excluding exterior mir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(3200 mm)

ModelPassenger Vans

Opening height of the

tailgate :84.6 in (2150 mm)

Opening range of the

tailgate;41.2 in (1047 mm)

Opening range of the

rear doors =33.4 in (849 mm)

Load width47.4 in (1205 mm)

Max. load width61.1 in (1552 mm)

Load height52.2 in (1326 mm)

Vehicle length202.4 in

(5140 mm)

ModelPassenger Vans

Vehicle width

Including exterior mir-

rors

Excluding exterior mir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(3200 mm)

Cargo tie-down points and carrier sys-

tems

Cargo tie-down points

General notes

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act-

ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force absorption. Load the anchorages evenly.

You will find additional information about cargo

tie-down points and cargo tie-down rings in the

"Securing loads" section (

Ypage 246).

Cargo tie-down rings

The maximum tensile load of the cargo tie-down

rings is:

Cargo tie-down

ringsPermissible nomi- nal tensile load

Passenger Vans786.5 lbf

(350 daN)

Cargo Van1124.0 lbf (500 daN)

314Vehicle data

Technical data