brake sensor MERCEDES-BENZ ML320 1997 Complete Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2523 of 4133

Fig. 3: Identifying Front Axle Components

Position in major assemblies compartment (left and right)

Fig. 4: Identifying RPM Sensor Connector

Modification notes

7.11.00Figure modified from 170 Nm to

200 NmValue in BA33.10-P-1001-01C changed

for Model 163*BA33.10-P-1001-

01C

Remove/install

Notes on self-locking nuts

and boltsAll modelsAH00.00-N-0001-01A

1Remove front wheels

Remove/install wheels,

rotate if necessaryAP40.10-P-4050GH

2Remove shock absorber AR32.25-P-0105GH

3Unplug speed sensor

connector (L6/1x1,

L6/2x1)

Risk of poisoning caused

by swallowing brake

fluid. Risk of injury

caused by brake fluid

coming into contact with

skin and eyes.Pour brake fluid only into

suitable and appropriately

marked containers. Wear

protective clothing and eye

protection when handling

brake fluid.AS42.50-Z-0001-01A

4Unscrew brake pipe from

brake hoseSeal off line connections

with plugs to prevent brake

fluid from running out.

Installation: The brake

hose must not be twisted

after tightening.

Brake fluid notesAll modelsAH42.50-P-0001-01A

Notes on installation of Model Series 163AH42.10-P-9406-01GH

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:21 PMPage 4 © 2006 Mitchell Repair Information Company, LLC.

Page 2532 of 4133

Fig. 14: Identifying RPM Sensor Connector

Remove/Install

Notes on self-locking nuts

and boltsAll modelsAH00.00-N-0001-01A

1 Remove front wheels

Remove/install wheels,

rotate if necessaryAP40.10-P-4050GH

2Detach hexagon collared

nut (65a) from front axle

shaft Installation: Install

new hexagon nut with

collar (65a).

*BA33.30-P-1001-02B

3Remove left or right front

springs AR32.20-P-0200GH

4Remove fender liner. AR88.10-P-1300GH

5Remove shock absorber AR32.25-P-0105GH

6Unplug rpm sensor

connector (L6/1x1,

L6/2x1)

Risk of poisoning from

swallowing brake fluid.

Risk of injury from skin

and eye contact with brake

fluid.Pour brake fluid only into

suitable and appropriately

marked containers. Wear

protective clothing and

eye protection when

handling brake fluid.AS42.50-Z-0001-01A

7Unscrew brake line from

brake hose Plug line connections

with plugs to prevent

brake fluid running out.

Installation: The

brake hose must not be

twisted after tightening.

Notes on brake fluidAll modelsAH42.50-P-0001-01A

Notes on installing brake

hosesModel 163AH42.10-P-9406-01GH

*BA42.10-P-1001-04A

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 13 © 2006 Mitchell Repair Information Company, LLC.

Page 2555 of 4133

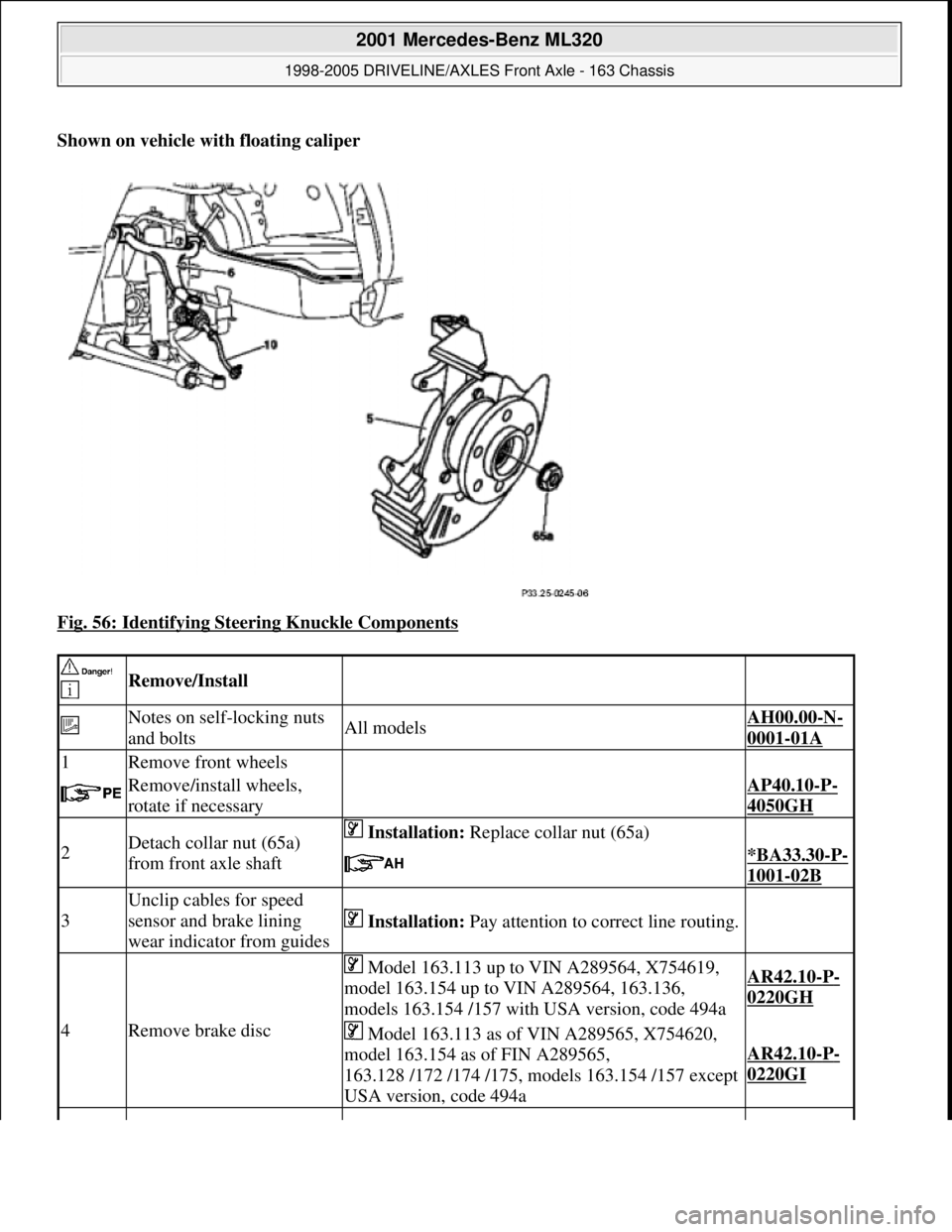

Shown on vehicle with floating caliper

Fig. 56: Identifying Steering Knuckle Components

Remove/Install

Notes on self-locking nuts

and boltsAll modelsAH00.00-N-

0001-01A

1Remove front wheels

Remove/install wheels,

rotate if necessaryAP40.10-P-

4050GH

2Detach collar nut (65a)

from front axle shaft Installation: Replace collar nut (65a)

*BA33.30-P-

1001-02B

3

Unclip cables for speed

sensor and brake lining

wear indicator from guides

Installation: Pay attention to correct line routing.

4Remove brake disc

Model 163.113 up to VIN A289564, X754619,

model 163.154 up to VIN A289564, 163.136,

models 163.154 /157 with USA version, code 494aAR42.10-P-

0220GH

Model 163.113 as of VIN A289565, X754620,

model 163.154 as of FIN A289565,

163.128 /172 /174 /175, models 163.154 /157 except

USA version, code 494a

AR42.10-P-

0220GI

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 36 © 2006 Mitchell Repair Information Company, LLC.

Page 3220 of 4133

FUNCTIONAL TEST PREPARATION

1. Check condition of fuses F16, F41, F43 and F44. See WIRING DIAGRAMS . Repair and/or replace

fuses and necessary.

2. Turn ignition on. Locate in-vehicle temperature sensor aspirator blower vent grille above anti-theft

indicator light. Place a half-inch square of tissue paper over aspirator blower vent grille. If paper stays on

vent grille, go to next step. If paper does not stay on vent grille, correct insufficient aspirator blower

ventilation.

3. Put shift lever in "P" and engage parking brake. Run engine at idle until it reaches normal operating

temperature, about 176°F (80°C). Ensure ambient (outside) temperature is greater than 58°F (15°C).

4. Manually open center and side air outlets. Ensure recirculation button is not depressed. Set blower speed

knob to position No. 1.

FUNCTION TEST

Defrost Mode

To check operation in defrost mode, set temperature selector knob to White range (vertical). Set mode control

knob to 12-o'clock position (vertical). Ensure A/C button indicator is illuminated. Air will vent from defrost and

center outlets and A/C compressor will engage. If operation is not as specified, perform the following in order:

Check voltage supply circuit Z50/2 between No. 16 fuse (15-amp) and connected components. See

VOLTAGE SUPPLY CIRCUIT Z50/2

under ELECTRICAL TESTS.

Check ground circuit. See GROUND CIRCUIT Z50/4 under ELECTRICAL TESTS.

Check in-vehicle temperature sensor signal voltage. See IN-VEHICLE TEMPERATURE SENSOR

under ELECTRICAL TESTS.

Check in-vehicle temperature sensor signal resistance. See IN-VEHICLE TEMPERATURE SENSOR

under ELECTRICAL TESTS.

Check icing protection temperature sensor signal voltage. See ICING PROTECTION

TEMPERATURE SENSOR under ELECTRICAL TESTS.

Check icing protection temperature sensor resistance. See ICING PROTECTION TEMPERATURE

SENSOR under ELECTRICAL TESTS.

Check activation voltage during temperature reduction. See ACTIVATION VOLTAGE

TEMPERATURE under ELECTRICAL TESTS.

Check activation voltage during temperature increase. See ACTIVATION VOLTAGE

TEMPERATURE under ELECTRICAL TESTS.

Check blend air flap actuator motor operation voltage. See BLEND AIR FLAP ACTUATOR MOTOR

under ELECTRICAL TESTS.

Check blend air flap actuator motor resistance. See BLEND AIR FLAP ACTUATOR MOTOR under

ELECTRICAL TESTS.

Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

Check A/C pressure switch. See A/C REFRIGERANT PRESSURE SWITCH under ELECTRICAL NOTE: Function test steps must be performed in order given.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 9 © 2006 Mitchell Repair Information Company, LLC.

Page 3232 of 4133

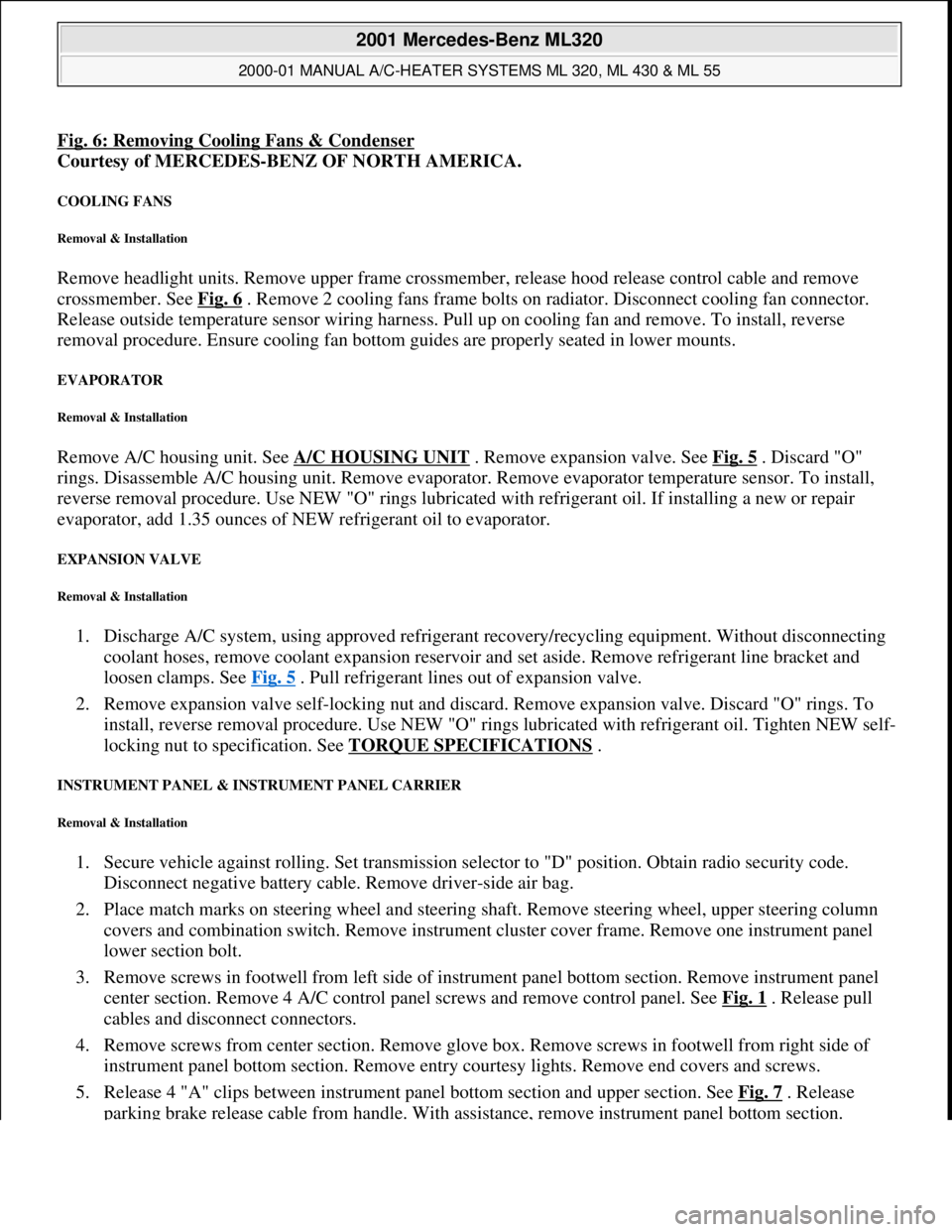

Fig. 6: Removing Cooling Fans & Condenser

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

COOLING FANS

Removal & Installation

Remove headlight units. Remove upper frame crossmember, release hood release control cable and remove

crossmember. See Fig. 6

. Remove 2 cooling fans frame bolts on radiator. Disconnect cooling fan connector.

Release outside temperature sensor wiring harness. Pull up on cooling fan and remove. To install, reverse

removal procedure. Ensure cooling fan bottom guides are properly seated in lower mounts.

EVAPORATOR

Removal & Installation

Remove A/C housing unit. See A/C HOUSING UNIT . Remove expansion valve. See Fig. 5 . Discard "O"

rings. Disassemble A/C housing unit. Remove evaporator. Remove evaporator temperature sensor. To install,

reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. If installing a new or repair

evaporator, add 1.35 ounces of NEW refrigerant oil to evaporator.

EXPANSION VALVE

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Without disconnecting

coolant hoses, remove coolant expansion reservoir and set aside. Remove refrigerant line bracket and

loosen clamps. See Fig. 5

. Pull refrigerant lines out of expansion valve.

2. Remove expansion valve self-locking nut and discard. Remove expansion valve. Discard "O" rings. To

install, reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. Tighten NEW self-

locking nut to specification. See TORQUE SPECIFICATIONS

.

INSTRUMENT PANEL & INSTRUMENT PANEL CARRIER

Removal & Installation

1. Secure vehicle against rolling. Set transmission selector to "D" position. Obtain radio security code.

Disconnect negative battery cable. Remove driver-side air bag.

2. Place match marks on steering wheel and steering shaft. Remove steering wheel, upper steering column

covers and combination switch. Remove instrument cluster cover frame. Remove one instrument panel

lower section bolt.

3. Remove screws in footwell from left side of instrument panel bottom section. Remove instrument panel

center section. Remove 4 A/C control panel screws and remove control panel. See Fig. 1

. Release pull

cables and disconnect connectors.

4. Remove screws from center section. Remove glove box. Remove screws in footwell from right side of

instrument panel bottom section. Remove entry courtesy lights. Remove end covers and screws.

5. Release 4 "A" clips between instrument panel bottom section and upper section. See Fig. 7

. Release

parkin

g brake release cable from handle. With assistance, remove instrument panel bottom section.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

Page 3482 of 4133

GF54.30-P-3003A

Indicator/warning messages triggered via CAN data buses, function

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

Indicator and warning displays triggered via CAN

Low brake fluid level/parking brake indicator lamp (A1e7)

The parking brake signal comes from the traction system

control module.

The brake fluid signal comes directly from the switch (S11)

(except model 163).

Brake pad wear indicator lamp (A1e6)

The parking brake signal comes from the traction system

control module (N47)

Low engine oil level indicator lamp (A1e12)

The oil level signal comes from the injection system control

module (N3).

For vehicles with ASSYST, also refer to document: ASSYST

engine oil monitoring.

Preglow indicator lamp (A1e16)

The signal comes directly from the injection system control

module (N3).

Coolant level and temperature warning lamp (A1e11) model 168

only as of 9.99

The coolant temperature signal comes from the injection

system control module (N3)

-----------------------------------------------------------------------------------------

ABS MIL (A1e17)

The parking brake signal comes from the traction system

control module (N47).

"CHECK ENGINE" MIL (A1e26),

I

only

The signal comes from the injection system control module (N3)

ETS (A1e35) or ASR (A1e22) or ESP (A1e42) MIL

Lamp illuminated if there is a fault in the respective system.

The signal comes from the traction system control module

(N47).

ETS (A1e36) or ASR (A1e21) or ESP (A1e41) warning lamp

The lamp indicates that the respective system is active.

The signal comes from the traction system control module

(N47).

-----------------------------------------------------------------------------------------

Severe leak warning (

I

as of 97 only)

The fuel reserve indicator lamp (A1e4) flashes. The signal

comes from the injection system control module (N3).

The warning takes place at the earliest 30 minutes after cold

start with the engine idling and the vehicle stationary.

Also refer to document: Purge system with leak test, function

Fog lamps indicator lamp (A1e57), model 163 only except

I

)

The signal comes from the All-activity module (AAM, N10)

"LOW RANGE" indicator lamp (A1e53), model 163 only

The signal comes from the transfer case control module (N78)

Active service system (ASSYST)

Engines 112, 113, 611 (engines with oil

sensor)

GF00.20-P-2009A

Engine oil monitoring, function

Model 210 as of 01.03.97 with engine M111,

OM602, OM604, OM605 and OM606

As of 06.97 models 129, 140, 170, 202 except

engines 112, 113, 611

(Valid for engines with low oil level switch).

GF00.20-P-2009B

Displaying coolant temperature, function

Model 168 as of 9.99

GF54.30-P-3020GC

Purge system with leak test, function

GF47.30-P-3016L

Bus systems, overall function

GF54.00-P-0004A

Copyright DaimlerChrysler AG 04.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3737 of 4133

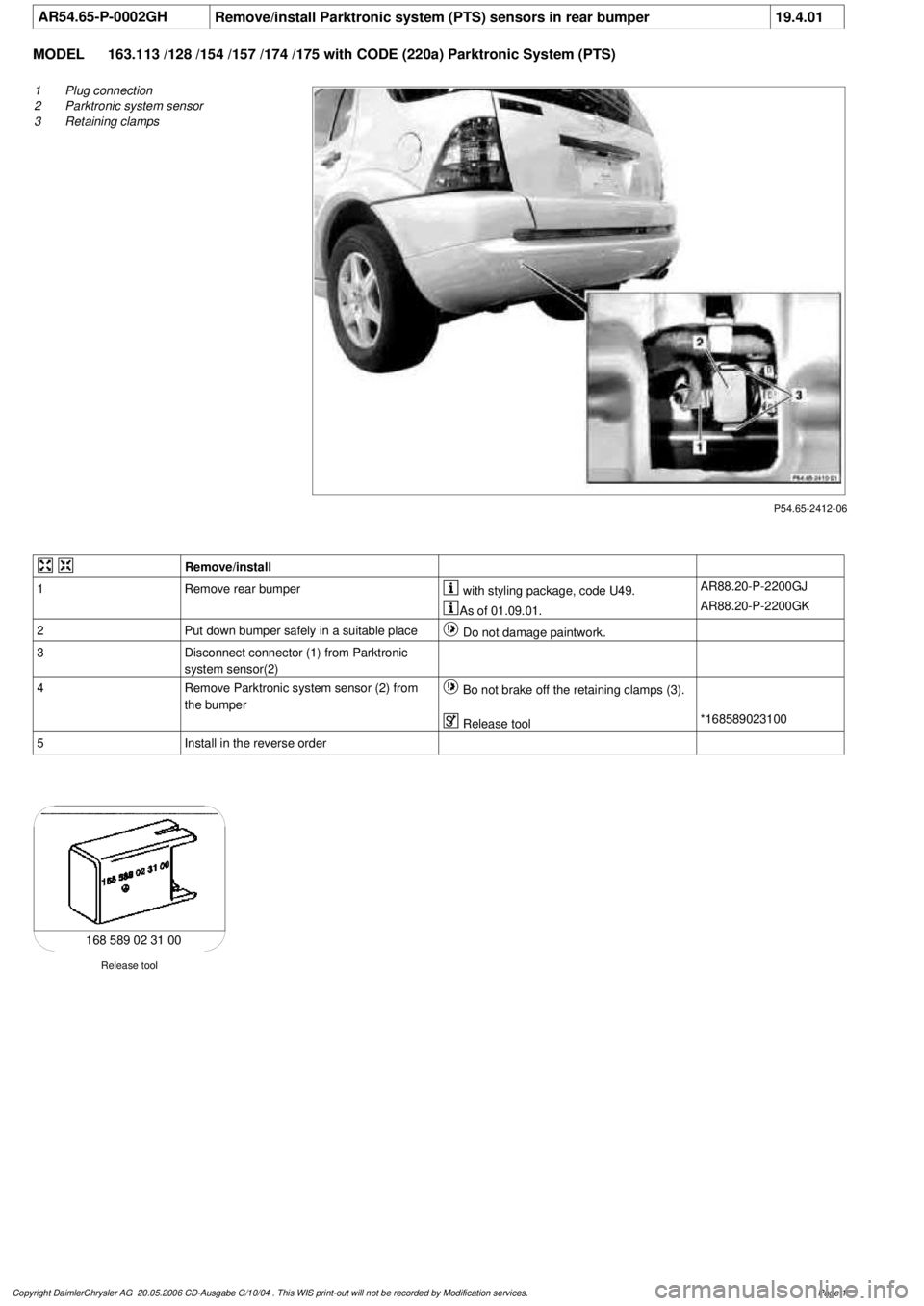

AR54.65-P-0002GH

Remove/install Parktronic system (PTS) sensors in rear bumper

19.4.01

MODEL

163.113 /128 /154 /157 /174 /175 with CODE (220a) Parktronic System (PTS)

P54.65-2412-06

1

Plug connection

2

Parktronic system sensor

3

Retaining clamps

Remove/install

1

Remove rear bumper

with styling package, code U49.

AR88.20-P-2200GJ

As of 01.09.01.

AR88.20-P-2200GK

2

Put down bumper safely in a suitable place

Do not damage paintwork.

3

Disconnect connector (1) from Parktronic

system sensor(2)

4

Remove Parktronic system sensor (2) from

the bumper

Bo not brake off the retaining clamps (3).

Release tool

*168589023100

5

Install in the reverse order

Release tool

168 589 02 31 00

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1