horn MERCEDES-BENZ ML320 1997 Complete Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3898 of 4133

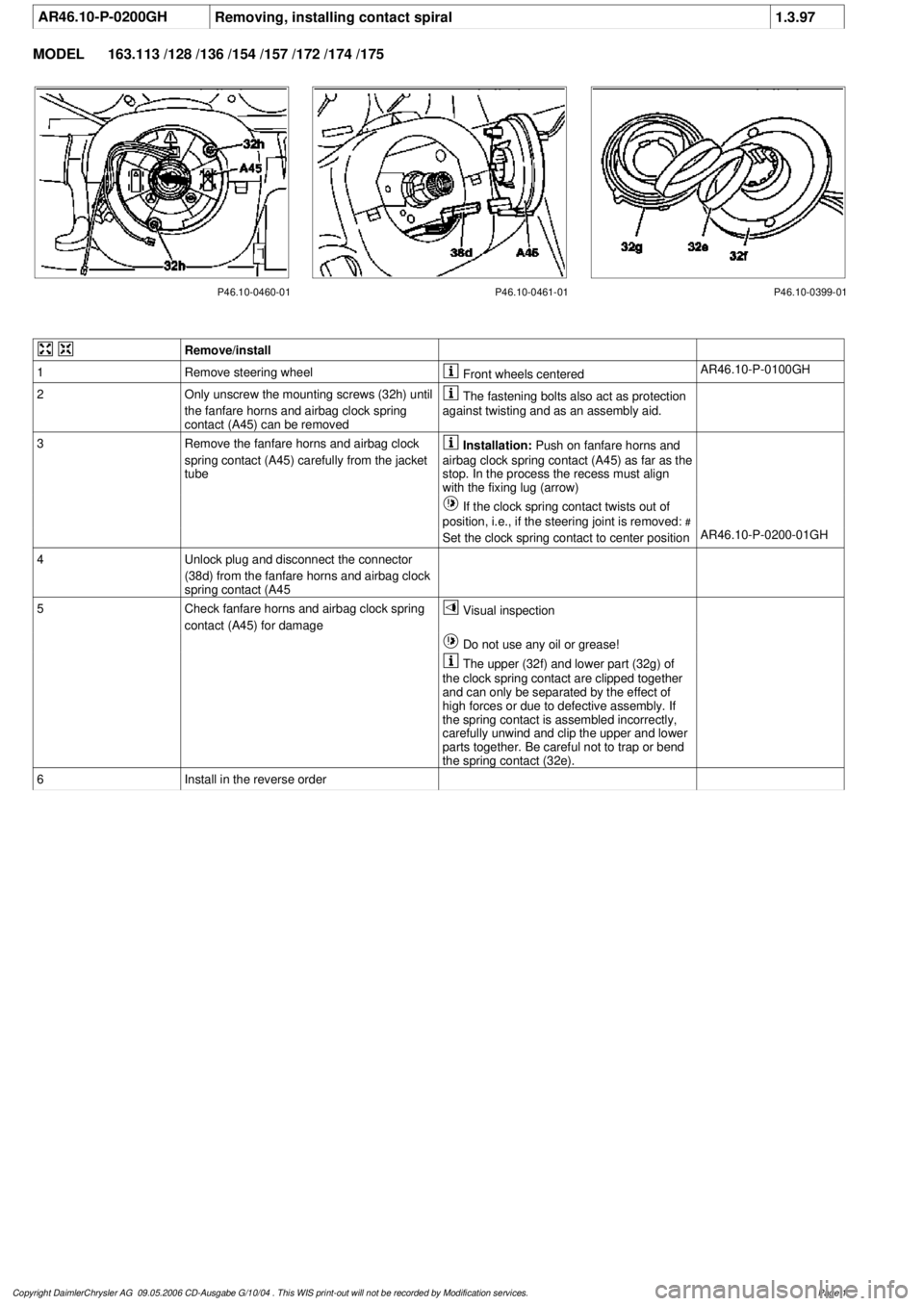

AR46.10-P-0200GH

Removing, installing contact spiral

1.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.10-0460-01 P46.10-0461-01 P46.10-0399-01

Remove/install

1

Remove steering wheel

Front wheels centered

AR46.10-P-0100GH

2

Only unscrew the mounting screws (32h) until

the fanfare horns and airbag clock spring

contact (A45) can be removed

The fastening bolts also act as protection

against twisting and as an assembly aid.

3

Remove the fanfare horns and airbag clock

spring contact (A45) carefully from the jacket

tube

Installation:

Push on fanfare horns and

airbag clock spring contact (A45) as far as the

stop. In the process the recess must align

with the fixing lug (arrow)

If the clock spring contact twists out of

position, i.e., if the steering joint is removed:

#

Set the clock spring contact to center position

AR46.10-P-0200-01GH

4

Unlock plug and disconnect the connector

(38d) from the fanfare horns and airbag clock

spring contact (A45

5

Check fanfare horns and airbag clock spring

contact (A45) for damage

Visual inspection

Do not use any oil or grease!

The upper (32f) and lower part (32g) of

the clock spring contact are clipped together

and can only be separated by the effect of

high forces or due to defective assembly. If

the spring contact is assembled incorrectly,

carefully unwind and clip the upper and lower

parts together. Be careful not to trap or bend

the spring contact (32e).

6

Install in the reverse order

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3899 of 4133

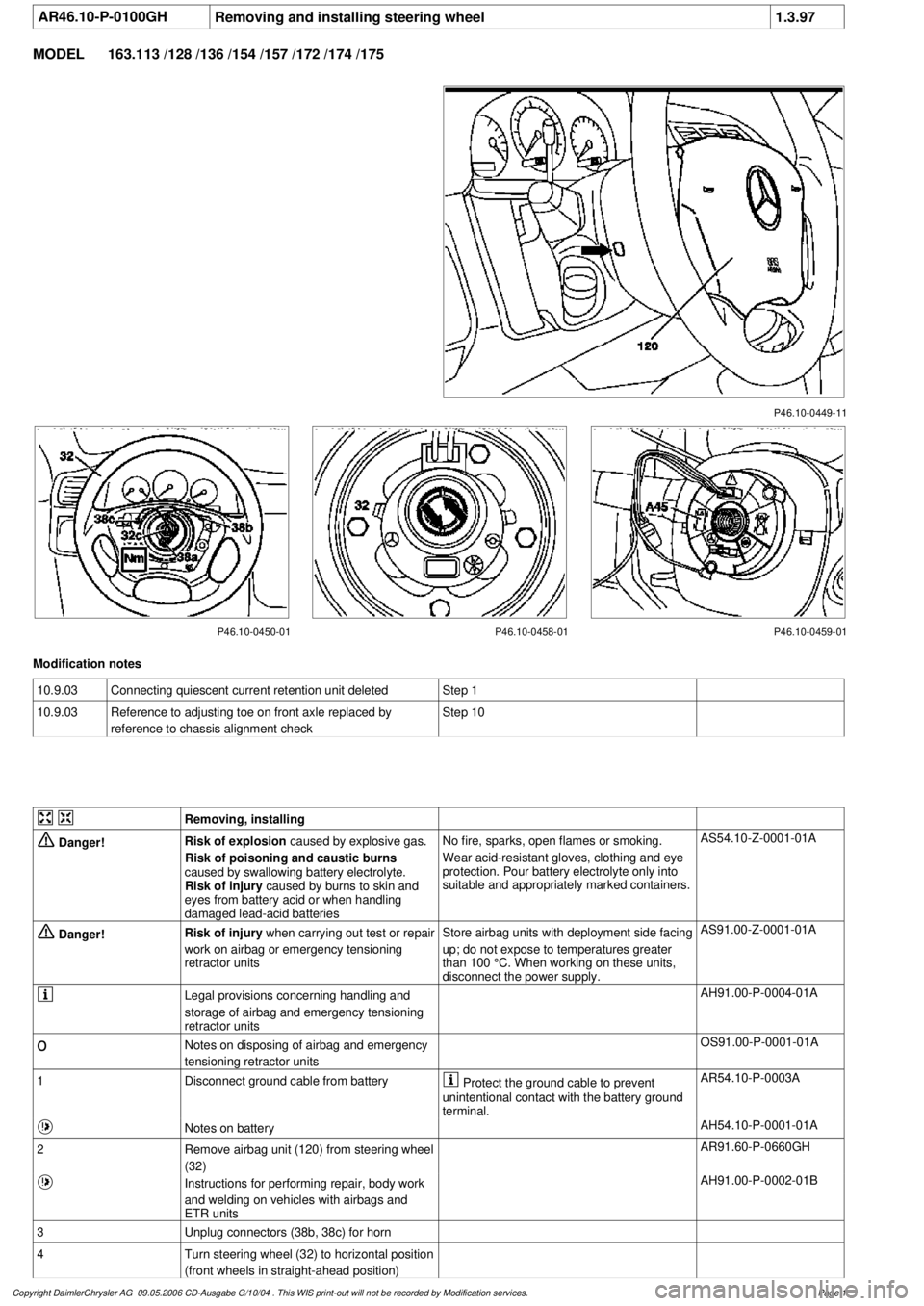

AR46.10-P-0100GHRemoving and installing steering wheel

1.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.10-0449-11

P46.10-0450-01 P46.10-0458-01 P46.10-0459-01

Modification notes

10.9.03

Connecting quiescent current retention unit deleted

Step 1

10.9.03

Reference to adjusting toe on front axle replaced by

reference to chassis alignment check

Step 10

Removing, installing

Danger!

Risk of explosion

caused by explosive gas.

Risk of poisoning and caustic burns

caused by swallowing battery electrolyte.

Risk of injury

caused by burns to skin and

eyes from battery acid or when handling

damaged lead-acid batteries

No fire, sparks, open flames or smoking.

Wear acid-resistant gloves, clothing and eye

protection. Pour battery electrolyte only into

suitable and appropriately marked containers.

AS54.10-Z-0001-01A

Danger!

Risk of injury

when carrying out test or repair

work on airbag or emergency tensioning

retractor units

Store airbag units with deployment side facing

up; do not expose to temperatures greater

than 100 °C. When working on these units,

disconnect the power supply.

AS91.00-Z-0001-01A

Legal provisions concerning handling and

storage of airbag and emergency tensioning

retractor units

AH91.00-P-0004-01A

o

Notes on disposing of airbag and emergency

tensioning retractor units

OS91.00-P-0001-01A

1

Disconnect ground cable from battery

Protect the ground cable to prevent

unintentional contact with the battery ground

terminal.

AR54.10-P-0003A

Notes on battery

AH54.10-P-0001-01A

2

Remove airbag unit (120) from steering wheel

(32)

AR91.60-P-0660GH

Instructions for performing repair, body work

and welding on vehicles with airbags and

ETR units

AH91.00-P-0002-01B

3

Unplug connectors (38b, 38c) for horn

4

Turn steering wheel (32) to horizontal position

(front wheels in straight-ahead position)

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3900 of 4133

5

Remove key and engage steering lock

6

Unscrew bolt (32c)

Hold the steering wheel (32).

Installation:

Replace bolt (32c).

*BA46.10-P-1001-02A

7

Pull off steering wheel (32)

Pass cables carefully through the openings.

Installation:

Align recesses of the splines

in the steering wheel with the markings on the

steering shaft (arrows).

8

Check fanfare horns and airbag clock spring

contact (A45) for damage

The clock spring contact must not be

turned while the steering wheel is removed

otherwise it will be damaged.

Visual inspection, replace clock spring

contact if necessary:

#

Removing and installing clock spring contact

AR46.10-P-0200GH

9

Install in the reverse order

10

Carry out road test

Tests during the road test:

Turn signal canceling:

When the steering wheel is offset by

more than 1 tooth, satisfactory resetting of the

turn signal is no longer guaranteed.

Airbag indicator lamp:

The SRS indicator lamp must not light up

on full steering lock in both directions.

Steering wheel position:

If the steering wheel is crooked, adjust it

by max. 1 tooth. If the difference is greater:

#

Check toe on front axle and adjust if

necessary, see:

#

Performing chassis alignment check

AR40.20-P-0200A

Steering wheel

Number

Designation

Model 163

BA46.10-P-1001-02A

Bolt, steering wheel to steering shaft

Nm

80

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 4057 of 4133

Fig. 29: Headlights Circuit, W/O Xenon Lamps (2 of 2)

HORN

2001 Mercedes-Benz ML320

2001 SYSTEM WIRING DIAGRAMS Mercedes-Benz - ML320

me

Saturday, October 02, 2010 3:27:59 PMPage 59 © 2006 Mitchell Repair Information Company, LLC.

Page 4059 of 4133

Fig. 30: Horn Circuit

INSTRUMENT CLUSTER

2001 Mercedes-Benz ML320

2001 SYSTEM WIRING DIAGRAMS Mercedes-Benz - ML320

me

Saturday, October 02, 2010 3:27:59 PMPage 61 © 2006 Mitchell Repair Information Company, LLC.