oil change MERCEDES-BENZ ML320 1997 Complete Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2088 of 4133

16

Remove poly V-belt (8)

Installation:

Lock tensioning device with

a drift or pin (diameter 5 mm).

Model 163.154 /157 /172.

AR13.22-P-1202B

Model 163.174 /175.

AR13.22-P-1202BA

17

Detach the coolant line (16) at the cylinder

head on the left

6 mm socket hexagon

*WH58.30-Z-1001-06A

7 mm socket hexagon

*WH58.30-Z-1002-06A

18.1

Remove fender liner (9)

Only with engine 113.113.942 /965 / 981.

AR88.10-P-1300GH

19.1

Remove shield (10)

Only with engine 113.942 /965 /981.

20.1

Remove exhaust bracket (11)

Only with engine 113.942 /965 /981.

Support exhaust system.

21

Detach exhaust system at exhaust manifold

Installation:

On vehicles with engine

damage, the exhaust system must be

examined for swarfs before assembling and

any swarfs present must be removed, in order

to avoid consequential damage.

*BA14.10-P-1002-01B

22

Position crankshaft to 40° after ignition TDC

on cylinder 1

The engine must not be turned back;

otherwise the timing chain can get jammed.

AR05.10-P-6858V

Rotate engine at the crankshaft in running

direction until scribe mark 40° on pulley/

vibration damper corresponds with scribe

mark on timing case.

The grooves on the camshafts must be

pointing toward the inner V.

23

Lock camshafts with locating plates

Locating plate

*112589003200

Locating plate

*112589013200

24

Remove chain tensioner (17)

Model 163.154 /157 with engine 112.942/

970, model 163.172 with engine 113.942.

AR05.10-P-7800C

Model 163.174 /175 with engine 113.981/ 965.

AR05.10-P-7800CA

25.1

Remove oil filter housing (18) together with oil-

water heat exchanger

Engine 113.942.

AR18.20-P-3471B

Engine 112.942/970.

AR18.20-P-3471BA

26

Unscrew camshaft sprockets (19)

If camshaft sprockets are removed,

engine must no longer be cranked, otherwise

timing chain might jam.

Engine 113.942 /965 /981:

#

Tie timing chain tight on both camshaft

sprockets with tie straps.

Engine 112.942 /970:

#

Right-hand camshaft sprocket:

Tie timing chain tight on camshaft sprocket

with tie strap.

Left-hand camshaft sprocket:

Mark camshaft sprocket to timing chain and

remove camshaft sprocket.

It is not possible for the timing chain to

jump across at the crankshaft and balancing

shaft.

After installation:

#

Inspect basic position of camshafts.

AR05.10-P-6858V

If necessary after checking:

#

Set the basic position of camshafts

AR05.20-P-6020AU

Open-end wrench

*112589000100

Insertion tool

*112589010300

Torque wrench

*001589722100

*BA05.20-P-1001-01B

27

Remove camshaft bearing bridges (28)

Pay attention to slackening and tightening

pattern!

AR05.20-P-7103AU

28

Unscrew bolts, cylinder head

!

timing case

cover (20)

*BA01.40-P-1002-01C

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 4

Page 2096 of 4133

16

Remove poly V-belt (8)

Installation:

Lock tensioning device with

a drift or pin (diameter 5 mm).

Model 163.154 /157 /172.

AR13.22-P-1202B

Model 163.174 /175.

AR13.22-P-1202BA

17

Detach the coolant line (16) at the cylinder

head on the left

6 mm socket hexagon

*WH58.30-Z-1001-06A

7 mm socket hexagon

*WH58.30-Z-1002-06A

18.1

Remove fender liner (9)

Only with engine 113.113.942 /965 / 981.

AR88.10-P-1300GH

19.1

Remove shield (10)

Only with engine 113.942 /965 /981.

20.1

Remove exhaust bracket (11)

Only with engine 113.942 /965 /981.

Support exhaust system.

21

Detach exhaust system at exhaust manifold

Installation:

On vehicles with engine

damage, the exhaust system must be

examined for swarfs before assembling and

any swarfs present must be removed, in order

to avoid consequential damage.

*BA14.10-P-1002-01B

22

Position crankshaft to 40° after ignition TDC

on cylinder 1

The engine must not be turned back;

otherwise the timing chain can get jammed.

AR05.10-P-6858V

Rotate engine at the crankshaft in running

direction until scribe mark 40° on pulley/

vibration damper corresponds with scribe

mark on timing case.

The grooves on the camshafts must be

pointing toward the inner V.

23

Lock camshafts with locating plates

Locating plate

*112589003200

Locating plate

*112589013200

24

Remove chain tensioner (17)

Model 163.154 /157 with engine 112.942/

970, model 163.172 with engine 113.942.

AR05.10-P-7800C

Model 163.174 /175 with engine 113.981/ 965.

AR05.10-P-7800CA

25.1

Remove oil filter housing (18) together with oil-

water heat exchanger

Engine 113.942.

AR18.20-P-3471B

Engine 112.942/970.

AR18.20-P-3471BA

26

Unscrew camshaft sprockets (19)

If camshaft sprockets are removed,

engine must no longer be cranked, otherwise

timing chain might jam.

Engine 113.942 /965 /981:

#

Tie timing chain tight on both camshaft

sprockets with tie straps.

Engine 112.942 /970:

#

Right-hand camshaft sprocket:

Tie timing chain tight on camshaft sprocket

with tie strap.

Left-hand camshaft sprocket:

Mark camshaft sprocket to timing chain and

remove camshaft sprocket.

It is not possible for the timing chain to

jump across at the crankshaft and balancing

shaft.

After installation:

#

Inspect basic position of camshafts.

AR05.10-P-6858V

If necessary after checking:

#

Set the basic position of camshafts

AR05.20-P-6020AU

Open-end wrench

*112589000100

Insertion tool

*112589010300

Torque wrench

*001589722100

*BA05.20-P-1001-01B

27

Remove camshaft bearing bridges (28)

Pay attention to slackening and tightening

pattern!

AR05.20-P-7103AU

28

Unscrew bolts, cylinder head

!

timing case

cover (20)

*BA01.40-P-1002-01C

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 4

Page 2232 of 4133

AP18.00-P-0101AR

Engine - oil and filter change

20.1.99

ENGINE

612

Modification notes

12.9.02

Engine oil level modified

Step 9:

Only Model 203:

Up to engine end number: 134 163 oil level

MAX. 135

mm,

MIN 110

mm.

As of engine end number: 134 164 oil level

MAX. 124,5

mm,

MIN 99,5

mm.

Remove

Danger!

Risk of death

cased by vehicle slipping or

toppling off of the lifting platform.

Align vehicle between the columns of the

hydraulic hoist and position the four support

plates below the hoist support points specified

by the vehicle manufacturer.

AS00.00-Z-0010-01A

Danger!

Risk of accident

caused by vehicle starting

off by itself when engine is running.

Risk of

injury

caused by contusions and burns when

working in engine during starting procedure

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

Change the engine oil only when the engine

is at operating temperature

1

Remove trim panel of cylinder head cover

AR01.20-P-5014-02B

2

Replace oil filter element, drain oil filter

Model 203: Remove clamp attaching fuel

line in order to insert wrench socket.

AP18.00-P-0101-06EG

*BA18.20-P-1002-01G

Socket wrench bit

*103589020900

3.1

Suction off engine oil

AP18.00-P-0101-02Z

4.1

Remove rear left frame cross brace

Only necessary when draining engine oil

at oil drain plug.

MODEL 163

f

Model 203 except 203.018/218/718, 209

AR94.30-P-5300P

Model 210

AR94.30-P-5300AB

4.2

Detach lower engine compartment paneling

Only necessary when draining engine oil

at oil drain plug.

f

Only Model 203.018/218/718

AR61.20-P-1105P

5.1

Unscrew oil drain plug, drain engine oil

Install

6.1

Screw in oil drain plug

Replace sealing ring, in order to avoid

leakage.

*BA01.45-P-1003-01A

7

Pour in engine oil

Note specified and approved quality

grades and viscosity classes conforming to

SAE at enduring ambient temperatures.

*BE18.00-P-1001-02B

*BF18.00-P-1001-01A

g

Viscosity classes of engine oils (car engines)

Sheet 224.1

BB00.40-P-0224-01A

8

Run engine and inspect for leaks

9

Switch off engine

10.1

Fit on bottom part of noise encapsulation

Only necessary when draining engine oil

at oil drain plug.

f

Model 210

AR94.30-P-5300AB

MODEL 203, 209

AR94.30-P-5300P

MODEL 163

10.2

Install lower engine compartment paneling.

Only necessary when draining engine oil

at oil drain plug.

f

Only Model 203.018/218/718

AR61.20-P-1105P

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2234 of 4133

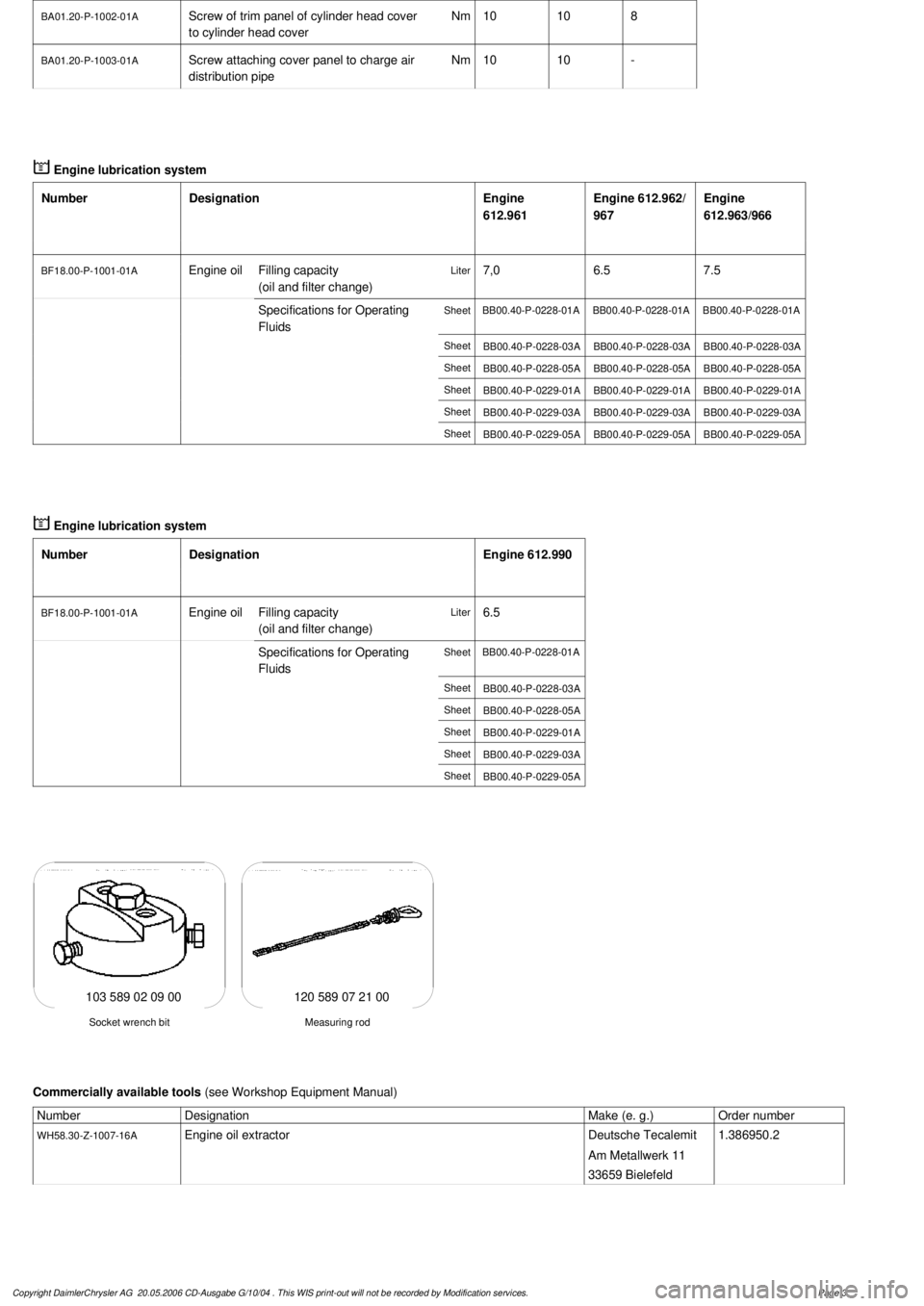

BA01.20-P-1002-01A

Screw of trim panel of cylinder head cover

to cylinder head cover

Nm

1010

8

BA01.20-P-1003-01A

Screw attaching cover panel to charge air

distribution pipe

Nm

1010

-

Designation

Engine

612.961

Engine 612.962/

967

Engine

612.963/966

BF18.00-P-1001-01A

Engine oil

Filling capacity

(oil and filter change)

Liter

7,06.57.5

Specifications for Operating

Fluids

SheetBB00.40-P-0228-01ABB00.40-P-0228-01ABB00.40-P-0228-01A

SheetBB00.40-P-0228-03ABB00.40-P-0228-03ABB00.40-P-0228-03A

SheetBB00.40-P-0228-05ABB00.40-P-0228-05ABB00.40-P-0228-05A

SheetBB00.40-P-0229-01ABB00.40-P-0229-01ABB00.40-P-0229-01A

SheetBB00.40-P-0229-03ABB00.40-P-0229-03ABB00.40-P-0229-03A

SheetBB00.40-P-0229-05ABB00.40-P-0229-05ABB00.40-P-0229-05A

Engine lubrication system

Number

Designation

Engine 612.990

BF18.00-P-1001-01A

Engine oil

Filling capacity

(oil and filter change)

Liter

6.5

Specifications for Operating

Fluids

SheetBB00.40-P-0228-01A

SheetBB00.40-P-0228-03A

SheetBB00.40-P-0228-05A

SheetBB00.40-P-0229-01A

SheetBB00.40-P-0229-03A

SheetBB00.40-P-0229-05A

120 589 07 21 00

Measuring rod

Socket wrench bit

103 589 02 09 00

Commercially available tools

(see Workshop Equipment Manual)

Number

Designation

Make (e. g.)

Order number

WH58.30-Z-1007-16A

Engine oil extractor

Deutsche Tecalemit

Am Metallwerk 11

33659 Bielefeld

1.386950.2

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 2236 of 4133

GF00.20-P-2009A

Engine oil monitor function

24.10.96

MODEL

129 with ENGINE 112, 113

MODEL

163 with ENGINE 112, 113, 612

MODEL

168 with ENGINE 166, 668

MODEL

202 with ENGINE 112, 611

MODEL

208 up to 31.7.99 with ENGINE 112, 113

MODEL

210 up to 30.6.99 with ENGINE 112, 113, 611

General

The oil level is constantly monitored by the oil sensor, and the

appropriate data transmitted to the processor by the ASSYST.

Oil replenishments are detected automatically and result in a bonus,

which extends the service interval accordingly.

An excess oil level or insufficient oil level appears in the display

together with the oil can symbol.

Display of low oil level at maximum:

D

at driver request

Display of warnings: D

automatically, at the earliest 60 s after engine start and oil

temperature greater than 60°C:

D

if oil level too high: the oil can symbol appears together

with the readout "OIL LEVEL ABOVE MAX". In addition, a

brief warning signal sounds. (On models not fitted with

multifunction displaly, "HI" appears flashing.)

D

if oil level too low: the oil can symbol appears together with

the readout "OIL LEVEL BELOW MIN". In addition, a brief

warning signal sounds. (On models not fitted with multifunction

display, the oil level warning lamp (A1e12) comes on and the

readout "-2L" appears flashing.)

-----------------------------------------------------------------------------------------

D

if oil at minimum: the oil can symbol appears together with

the readout "OIL LEVEL MINIMUM". In addition, a brief

warning signal sounds. (On models not fitted with multifunction

display, the oil level warning lamp (A1e12) comes on.)

D

automatically 13 s after ignition ON:

D

if

no oil

is in engine: the oil can symbol appears together

with the readout "OIL LEVEL BELOW MIN". In addition, a

warning signal sounds. (On models not fitted with multifunction

display, the oil level warning lamp (A1e12) comes on and the

readout "-2L"appears flashing. In addition a brief warning

signal sounds.)

The missing oil quantity displayed no longer changes during the

display. In other words, any change in oil level cannot be observed

directly at the display. The new oil level is only displayed once the

conditions described below exist.

Display of oil quantity at driver request

The text "DISPLAY OIL LEVEL?" appears 10 s after the start switch

has been turned into position "2" (on models not fitted with

multifunction display, the oil can and the clock symbol are displayed).

If the reset button of the trip counter is pressed twice within one sec.

during this readout, for example, "add 1.0L oil" (or "-1.0L")

-----------------------------------------------------------------------------------------

appears in the display if oil level too low. The readout appears only

after the elapse of a waiting time after engine OFF. The waiting time

depends on the engine oil temperature.

It is

D

up to 20°C

30 minutes

D

from 60°C

1 minute

D

The waiting time is between these two limits at other engine oil

temperatures.

Possible readouts are (text in parenthesis relates to models not fitted

with multifunction display.):

D

"OIL LEVEL OKAY" ("o.k."),

D

1.0L, 1.5L, 2L,

D

"Overfilling" ("HI"),

D

"OBSERVE WAITING TIME" (clock symbol flashing and oil can

symbol),

D

"DISPLAY OIL LEVEL" (clock and oil can symbols.)

If there is a fault at the oil sensor (oil level/temperature/quality, B40)

the oil can symbol and the text "OIL LEVEL SENSOR FAULTY"

appears only 30 s after the fault has occurred.

(On models not fitted with multifunction display, the oil level warning

lamp (A1e12) comes on accordingly.)

For diagnosis, read also the injection system control module (N3)

with the HHT. (The instrument cluster (A1) receives the sensor data

through the CAN from the injection system control module (N3)).

-----------------------------------------------------------------------------------------

Oil change

The ASSYST has to be reset each time the oil is changed. Resetting

ASSYST also resets the remaining time and the remaining distance.

Resetting can be performed at the instrument cluster or using the

HHT.

The following data are stored when the system is reset:

D

current kilometer reading rounded off to 100,

D

total oil replenishments in the last interval,

D

remaining distance,

D

remaining time,

D

product of the quality factors,

D

the data of the last 5 resettings in 5 data sets

These data can only be read with the HHT!

If the specified quantity of oil is not replenished when the oil is

changed, the (internal) start distance is reduced.

Detecting oil replenishments

D

With the

HHT

it is possible to retrieve the last 10 oil

replenishments and the corresponding kilometer readings of

the current interval.

D

In the normal case, detection of an oil replenishment is

displayed by the remaining distance in the instrument cluster

being extended

-----------------------------------------------------------------------------------------

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2237 of 4133

Oil replenishments are always only detected once the following

conditions are met:

D

the replenished quantity is

at least 1 l

D

after replenishing the oil, the car must be driven a distance of

at

least 5 km

under

normal driving conditions

at an

oil

temperature of at least 60 °C

.

There are instances, however, in which the readout of the remaining

distance nevertheless appears implausible after replenishing oil;

according to the display, no bonus or only a small bonus has been

issued. This is caused by the fact that the remaining distance is

always only displayed within a range from 15 000 km up to 30 000

km (or 20 000 km up to 40 000 km in the case of engine 668), but

internally the system calculates with the actual values which may also

be beyond this range. These internal values can only be displayed

with the HHT.

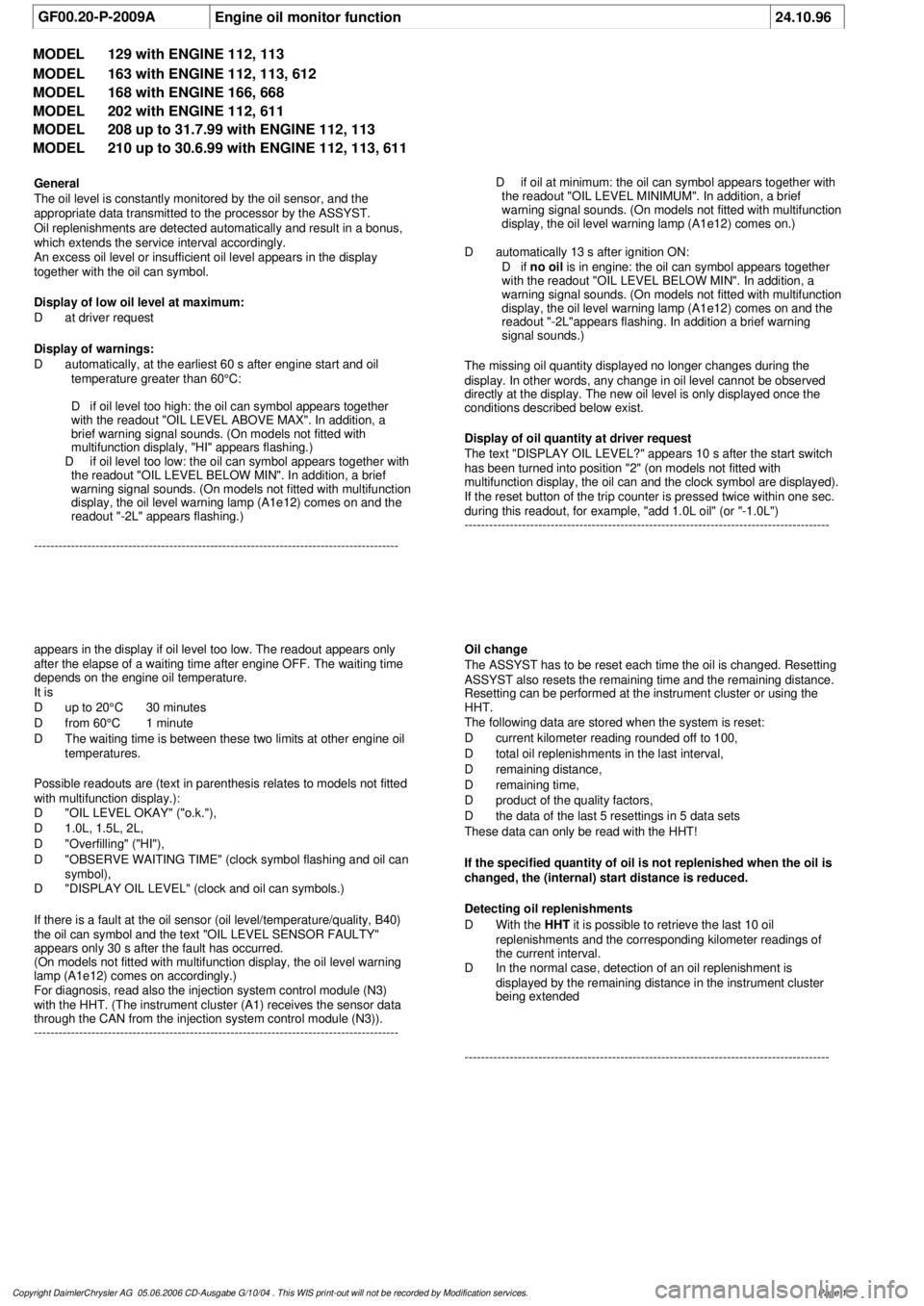

In the charts overleaf, a number of examples of this are presented.

The horizontal (x) axis represents the service interval and the vertical

(y) axis is the remaining distance in each case in km.

The readout of ASSYST in the instrument cluster always moves

within the light range.

The remaining distance calculated internally may also, however, be

within the two dark ranges. These internal values can only be

displayed with the HHT.

All examples relate to gasoline engines fitted with an oil sensor.

P00.20-0201-06

Example 1 :

Sufficient oil was added during the oil change.

This means that the starting distance is 15

000 km.

After 10 000 km oil is topped up under normal

driving conditions (a). The bonus (B1) is

issued and displayed. What this means is that

when the remaining distance is retrieved, a

greater remaining distance is displayed.

(Provided the aforementioned conditions for

detecting the oil replenishment are met.)

Oil is topped up again after a further

5 000 km (b). In this case also a bonus (B2) is

issued and displayed.

If, after this, no further oil is topped up and

the car continues to be driven in the same

manner, a service interval of about

24 000 km is thus achieved.

In this example, the curve moves at all points

within the light range of the chart;

consequently, all the oil replenishments are

displayed by increasing the remaining

distance.

P00.20-0204-06

Example 2:

The specified quantity of oil was added when

the oil was changed.

The car is driven under very favorable

conditions and oil is topped up after

10 000 km (a). Internally, the bonus B1 is

issued, the service interval is extended

accordingly by enlarging the remaining

distance. However, as the curve is sometimes

within the shaded area, only the part of B1

which is within the light area, is at first

displayed as an extension of the remaining

distance. (Provided the aforementioned

conditions for detecting oil replenishment are

met.)

Oil is topped up once again at 18 000 km (b).

In view of the fact that the maximum service

interval of 30 000 km was exceeded, the

bonus B2 is not initially displayed as an

extension. The entire service interval in this

case is 30 000 km.

If, from point b, the car continues to be driven

under less favorable conditions, it may still

also be possible now to achieve the maximum

service interval of 30 000 km because of the

internal bonus B2.

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 2238 of 4133

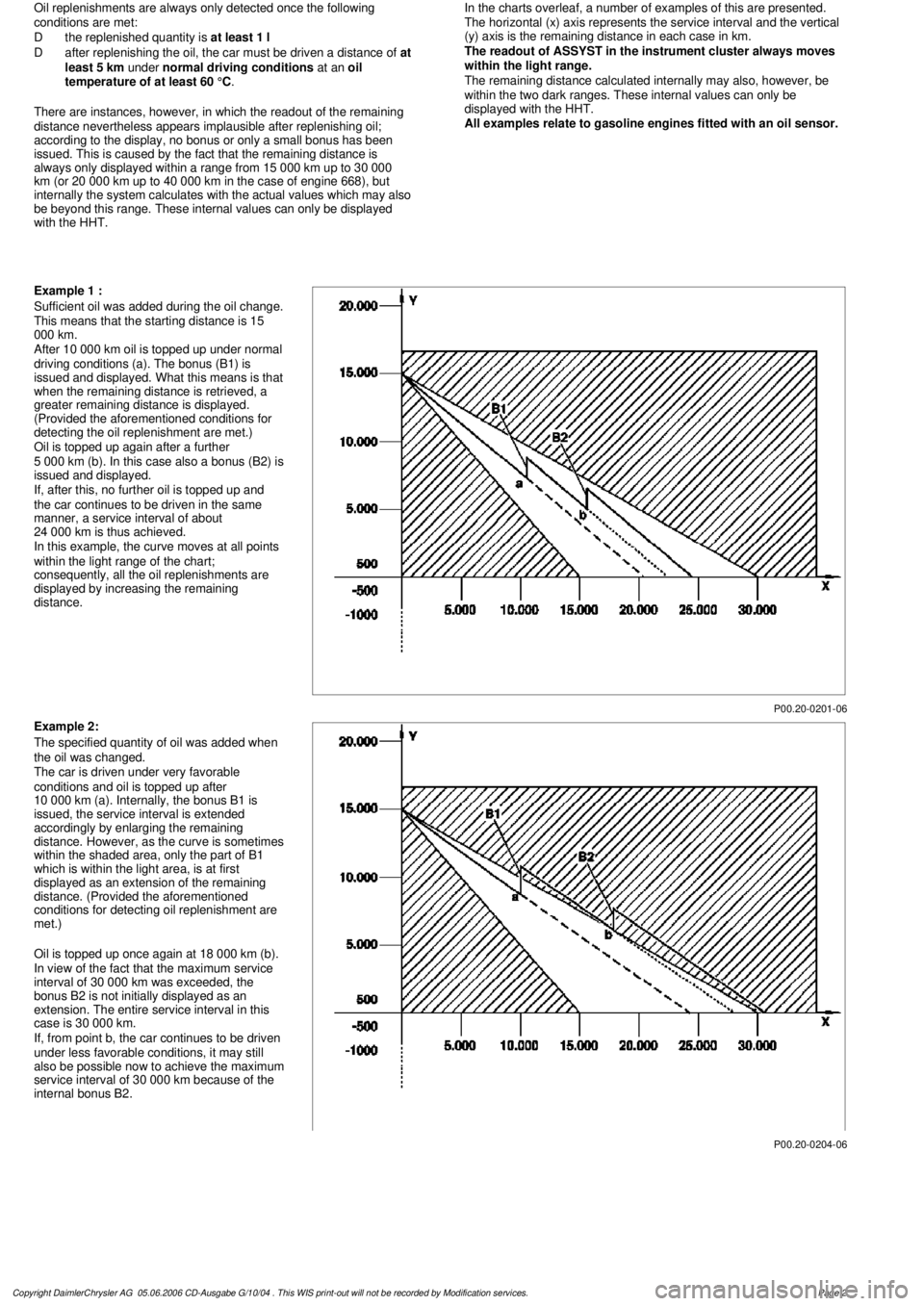

P00.20-0202-06

Example 3:

When the oil was changed, the quantity

added was less than the specified quantity.

Consequently, the start distance is less than

15 000 km.

If oil is now topped up after 5 000 km (a), the

remaining distance displayed is not extended

as the curve is within the shaded area. The

bonus B1 is nevertheless added internally

and results in an extension of the service

interval to slightly more than

15 000 km - provided the driving conditions

remain the same or are more favorable.

(The service interval of 15 000 km is always

reached, however, even if the internal value

were less.)

P00.20-0203-06

Example 4:

Oil has been topped up after 5 000 km under

unfavorable driving conditions (a) and the oil

replenishment (bonus B1) detected internally.

We now have two cases to consider:

D

If the car continues to be driven under

the same conditions (unbroken line), the

remaining distance displayed is not

extended as the curve is within the

shaded area.

The service interval in this case is

nevertheless 15 000 km although the

internal value is less. (The remaining

distance displayed can always only be

within the light area.)

D

If the car continues to be operated

under more favorable conditions

(broken line), the value of the internal

remaining distance slowly moves into

the light area. Consequently, the service

interval may be greater than

15 000 km.

Active service system survey of display

facilities

GF00.20-P-0003-04A

Active service system technology/ influencing

variables

GF00.20-P-0003-05A

Active service system survey

model/engine/sensor/instrument cluster

GF00.20-P-0003-06A

Active service system (ASSYST) operating

instructions, resetting

GF00.20-P-0003-01A

Oil sensor position/task/function

Oil sensor position, task, function

GF18.40-P-4111A

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 2296 of 4133

i040*WH58.30-Z-

1003-28A

3Place camshaft bearing

bridge on board (4) Fig. 56

4

Remove the rocker arm

spindle (3) by tapping

gently with a hammer If it is tapped very hard, th ere is a danger of distorting the

camshaft bearing bridge and da maging the hollow rocker arm

spindle (3).

Fig. 53

Check

5

Inspect bearing

surfaces of rocker arms

for damage Pay attention to any long score marks caused by the

removal of the rocker arm spindl es (3). Replace the rocker arm

if damaged.

Installing

6

Insert the guide shafts

into the camshaft

bearing bridge. At the same time, preassemble the rocker arm on guide

shaft.

Fig. 54

Fig. 55

Risk of injury to skin

and eyes caused by

handling hot or glowing

objects.

Wear safety gloves, protective cl othing and safety glasses, if

necessary.AS00.00-Z-

0002-01A

7

Heat camshaft bearing

bridge to approx. 150°

C

Heat the camshaft bearing bridge uniformly, but do not

heat it over 160°C; there is a danger of structural changes.

WH58.30-Z-

1001-28A

*WH58.30-Z-

1003-28A

8Cool the rocker arm

spindle (3)

9

Place heated camshaft

bearing bridge on board

(4) Fig. 56

10Install rocker arm

spindle (3)

Insert the rocker arm spindle (3) in the camshaft bearing

bridge by tapping gently with a hammer and simultaneously

remove the guide shaft. Ensure that the rocker arms do not get

jammed.

11Align the rocker arm

spindle (3)

In order to align and secure the rocker arm spindle (3), fit

two screws through the mount ing bores in the camshaft

bearing bridge. The oil supply bores of the rocker arm spindle

(3) point towards the cylinder head.

Engines 112, 113 except engines 113.967 /990 in models 219,

engines 113.964 /971 /989 /993AR05.20-P-

7103AU

Engine 113.993 in model 463AR05.20-P-

7103GX

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:38 PMPage 55 © 2006 Mitchell Repair Information Company, LLC.

Page 2444 of 4133

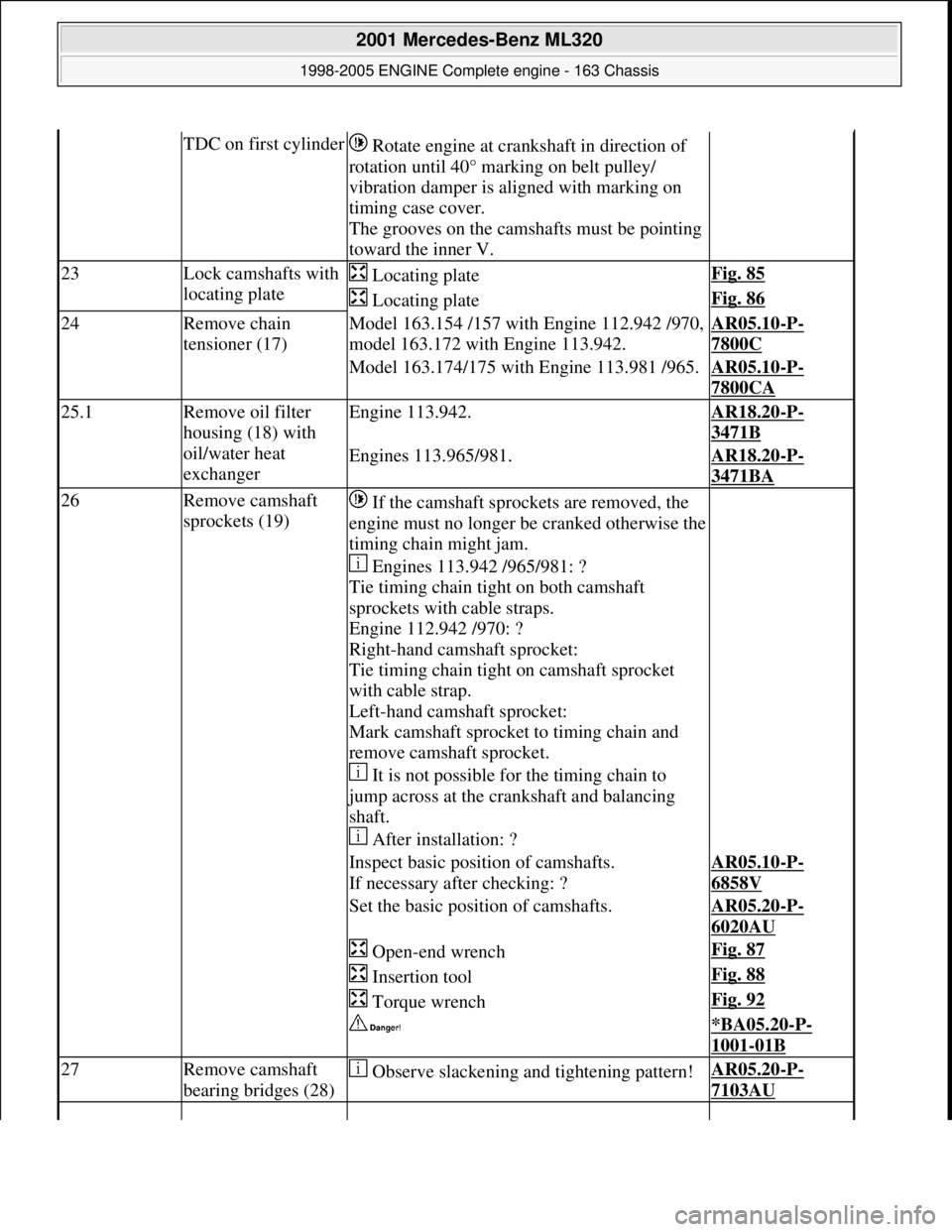

TDC on first cylinder Rotate engine at cra nkshaft in direction of

rotation until 40° marking on belt pulley/

vibration damper is al igned with marking on

timing case cover.

The grooves on the camshafts must be pointing

toward the inner V.

23Lock camshafts with

locating plate Locating plateFig. 85

Locating plateFig. 86

24Remove chain

tensioner (17)Model 163.154 /157 with Engine 112.942 /970,

model 163.172 with Engine 113.942.AR05.10-P-

7800C

Model 163.174/175 with Engine 113.981 /965.AR05.10-P-

7800CA

25.1Remove oil filter

housing (18) with

oil/water heat

exchangerEngine 113.942.AR18.20-P-

3471B

Engines 113.965/981.AR18.20-P-

3471BA

26Remove camshaft

sprockets (19) If the camshaft sprockets are removed, the

engine must no longer be cranked otherwise the

timing chain might jam.

Engines 113.942 /965/981: ?

Tie timing chain tight on both camshaft

sprockets with cable straps.

Engine 112.942 /970: ?

Right-hand camshaft sprocket:

Tie timing chain tight on camshaft sprocket

with cable strap.

Left-hand camshaft sprocket:

Mark camshaft sprocket to timing chain and

remove camshaft sprocket.

It is not possible for the timing chain to

jump across at the crankshaft and balancing

shaft.

After installation: ?

Inspect basic positi on of camshafts.

If necessary after checking: ?AR05.10-P-

6858V

Set the basic position of camshafts.AR05.20-P-

6020AU

Open-end wrenchFig. 87

Insertion toolFig. 88

Torque wrenchFig. 92

*BA05.20-P-

1001-01B

27Remove camshaft

bearing bridges (28) Observe slackening and tightening pattern!AR05.20-P-

7103AU

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 88 © 2006 Mitchell Repair Information Company, LLC.

Page 2458 of 4133

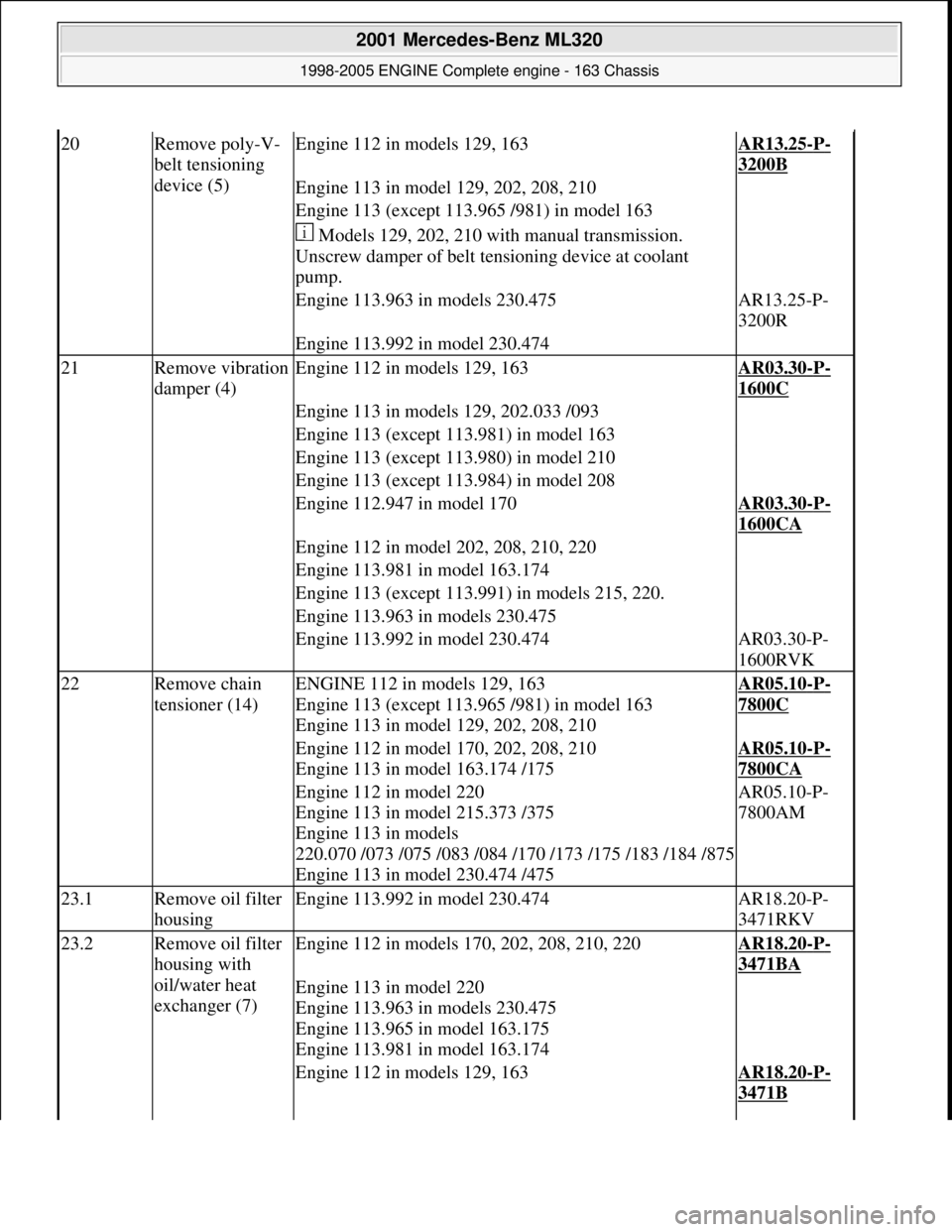

20Remove poly-V-

belt tensioning

device (5)Engine 112 in models 129, 163AR13.25-P-

3200B

Engine 113 in model 129, 202, 208, 210

Engine 113 (except 113.965 /981) in model 163

Models 129, 202, 210 with manual transmission.

Unscrew damper of belt te nsioning device at coolant

pump.

Engine 113.963 in models 230.475AR13.25-P-

3200R

Engine 113.992 in model 230.474

21Remove vibration

damper (4)Engine 112 in models 129, 163AR03.30-P-

1600C

Engine 113 in models 129, 202.033 /093

Engine 113 (except 113.981) in model 163

Engine 113 (except 113.980) in model 210

Engine 113 (except 113.984) in model 208

Engine 112.947 in model 170AR03.30-P-

1600CA

Engine 112 in model 202, 208, 210, 220

Engine 113.981 in model 163.174

Engine 113 (except 113.991) in models 215, 220.

Engine 113.963 in models 230.475

Engine 113.992 in model 230.474AR03.30-P-

1600RVK

22Remove chain

tensioner (14)ENGINE 112 in models 129, 163

Engine 113 (except 113.965 /981) in model 163

Engine 113 in model 129, 202, 208, 210AR05.10-P-

7800C

Engine 112 in model 170, 202, 208, 210

Engine 113 in model 163.174 /175AR05.10-P-

7800CA

Engine 112 in model 220

Engine 113 in model 215.373 /375

Engine 113 in models

220.070 /073 /075 /083 /084 /170 /173 /175 /183 /184 /875

Engine 113 in model 230.474 /475AR05.10-P-

7800AM

23.1Remove oil filter

housingEngine 113.992 in model 230.474AR18.20-P-

3471RKV

23.2Remove oil filter

housing with

oil/water heat

exchanger (7)Engine 112 in models 170, 202, 208, 210, 220AR18.20-P-

3471BA

Engine 113 in model 220

Engine 113.963 in models 230.475

Engine 113.965 in model 163.175

Engine 113.981 in model 163.174

Engine 112 in models 129, 163AR18.20-P-

3471B

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 102 © 2006 Mitchell Repair Information Company, LLC.