oil change MERCEDES-BENZ ML320 1997 Complete Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3191 of 4133

Valve seal not okay :

#

3

Remove/install/replace valve seal.

AR05.30-P-3500B

Cause 6:

Remedy 6:

00 001 70

1.5 mm hole missing on individual right

cylinder head covers at connection to

crankcase ventilation.

1

Check cylinder head cover

Up to production 06/1999.

Crankcase ventilation out of order, engine can

sludge up and consume oil as a result

Cylinder head cover not okay:

#

2

Remove/install/replace cylinder head

cover.

ENGINE

112

Air cleaner positioned on engine

side.

ENGINE

113

Air cleaner positioned on engine

side.

AR01.20-P-5014BV

ENGINE

112

Air cleaner positioned on engine side

ENGINE

113

Air cleaner positioned on engine side

AR01.20-P-5014B

Cause 7:

Remedy 7:

00 001 70

Engine oil sludging due to excessively long

engine oil change intervals

Service information: Oil sludge

SI18.00-P-0010A

If the service interval according to

ASSYST is exceeded, the engine oil sludges

up sooner or later depending on the oil

quality, type of operation and operating time.

Engine consumes oil.

See Service Information.

1

Print out ASSYST printout.

2

Check oil change intervals

3

Inform vehicle owner.

4

Remove/install/replace piston rings.

AR03.10-P-7311BV

Disassemble and clean sludged engines

completely because dirty oil usually gets into

clean-oil side due to clogged oil filter.

Cause 8:

Remedy 8:

00 001 70

Piston rings sticky or have coke deposits from

engine oils (e.g. API-S in USA) in connection

with regionally poor fuel quality.

Always use engine oils according to

Specifications for Operating Fluids 229.3, do

not add special additives to engine oil and fuel

BB00.40-P-0229-03A

1

Remove/install/replace piston rings.

AR03.10-P-7311BV

Cause 9:

Remedy 9:

00 001 70

Piston ring wear due to excessive

contamination/dust (model 163) through air

intake system.

1

Remove/install/replace gaskets on air

intake line and distribution element of

partial load ventilation.

e.g. due to incorrect assembly after

workshop visit or embrittlement of gaskets

The distribution element with optimized

material will be available as of 11/ 2000 as a

standard feature.

2

Remove/install/replace intake module.

Exterior oil loss, e.g. due to cast iron

porosity on left side of crankcase in area of

engine support is not considered to be oil

consumption

In the event of a customer complaint

regarding the engine oil consumption, always

determine the oil consumption definitely

because the oil indicator lamp can come on

due to other causes (e.g. defective oil sensor).

Commercially available tools

(see Workshop Equipment Manual)

Number

Designation

Make (e. g.)

Order number

WH58.30-Z-1009-05A

Flexible inspection light

Scope of supply 1 (complete unit):

-glass fiber optical fiber

-light projector

-230 V, storage case

-operating instructions

-graphics protocol

Richard Wolf GmbH

Pforzheimerstr. 32

D-75438 Knittlingen

Karl Storz GmbH

Mittelstr. 8

D-78532 Tuttlingen

1.00565.00

80902

WH58.30-Z-1010-05A

Flexible inspection light

Scope of delivery 2 (for workshops which already have an approved

Wolf or Storz inspection light):

-storage case

-operating instructions

-pictures protocol

Richard Wolf GmbH

Pforzheimerstr. 32

D-75438 Knittlingen

Karl Storz GmbH

Mittelstr. 8

D-78532 Tuttlingen

7.05065.00

K03506AJ

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3369 of 4133

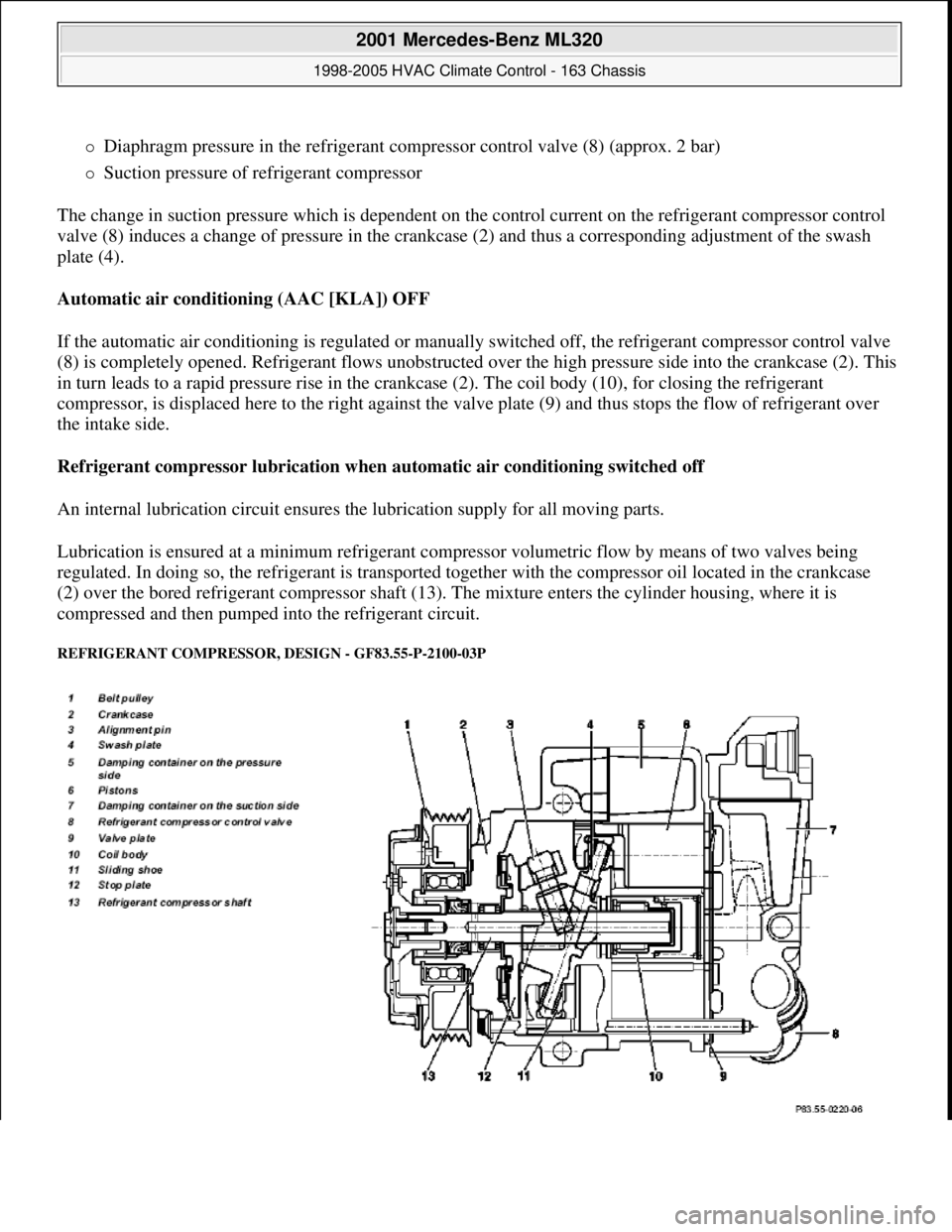

Diaphragm pressure in the refrigerant compressor control valve (8) (approx. 2 bar)

Suction pressure of refrigerant compressor

The change in suction pressure which is dependent on the control current on the refrigerant compressor control

valve (8) induces a change of pressure in the crankcase (2) and thus a corresponding adjustment of the swash

plate (4).

Automatic air conditioning (AAC [KLA]) OFF

If the automatic air conditioning is regulated or manually switched off, the refrigerant compressor control valve

(8) is completely opened. Refrigerant flows unobstructed over the high pressure side into the crankcase (2). This

in turn leads to a rapid pressure rise in the crankcase (2). The coil body (10), for closing the refrigerant

compressor, is displaced here to the right against the valve plate (9) and thus stops the flow of refrigerant over

the intake side.

Refrigerant compressor lubrication when automatic air conditioning switched off

An internal lubrication circuit ensures the lubrication supply for all moving parts.

Lubrication is ensured at a minimum refrigerant compressor volumetric flow by means of two valves being

regulated. In doing so, the refrigerant is transported together with the compressor oil located in the crankcase

(2) over the bored refrigerant compressor shaft (13). The mixture enters the cylinder housing, where it is

compressed and then pumped into the refrigerant circuit.

REFRIGERANT COMPRESSOR, DESIGN - GF83.55-P-2100-03P

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:16 PMPage 125 © 2006 Mitchell Repair Information Company, LLC.

Page 3441 of 4133

poisoning from swallowing

coolant.Wear protective gloves, protective

clothing and eye protection.

1Drain coolantEngine 111 in MODEL 163.AR20.00-P-

1142HG

Engines 112 /113 in MODEL 163.AR20.00-

P-1142HA

Engine 628.963 in MODEL 163.128.AR20.00-P-

1142HB

Engine 612.963 in MODEL 163.113.AR20.00-P-

1142M

2.1 Detach

brake line

from the

front end of

the radiator

Only required for right-hand steering.

3.1 Detach

ignition

cable from

the front end

of the

radiator

Only required on right-hand drive vehicles

with ENGINES 111 /112/113.

4Release coolant overflow from

battery shield

5Disconnect upper coolant hose

from the electric coolant pump Detach hose clamp from the upper

coolant hose.

6Unscrew nuts from expansion

reservoir at firewall

7Remove expansion reservoir from

the firewall and lay aside

8Disconnect coolant delivery/return

hoses for heat exchanger (17) Detach hose clamps from coolant

delivery/ return hoses for heat exchanger.

9Discharge air conditioning system

Installation: Evacuate air

conditioning, refill and check for proper

operation and leaktightness.AR83.30-

P-1760GH

10Unscrew self-locking nut (16) at

the expansion valve (15) Replace self-locking nut.

*BA83.30-

P-1003-01B

11

Detach low-pressure refrigerant

line (13) and high-pressure

refrigerant line (14) from expansion

valve (15)

Installation: Install new sealing rings

and moisten with compressor oil.

12Remove instrument panel carrier

(4) AR68.10-

P-1111GH

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 197 © 2006 Mitchell Repair Information Company, LLC.

Page 3464 of 4133

Remove/install

Risk of injury to skin and eyes

suffering scalding from contact with

hot coolant spray. Risk of poisoning

from swallowing coolant.

Do not open cooling system unless coolant

temperature is below 90°C. Open cap slowly

and release the pressure. Do not pour

coolant into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-

0001-01A

Risk of explosion from welding or

soldering work on closed air

conditioning system. Risk of

poisoning. Inhaling overheated

refrigerant vapors may be toxic. Risk

of injury from skin and eye contact

with liquid refrigerant.Do not carry out any welding work on the

closed air conditioning system or in the

surrounding area. No smoking or open

flames. Wear eye protection and protective

gloves. Work only in well ventilated areas.

Carry out repair work on the air

conditioning system circuit only after the

system has been discharged.

AS83.00-Z-

0001-01A

Procedures if air conditioning system

is damaged or leakingAll models

AH83.30-

N-0004-

01A

Protect air conditioning circuit and

components from moisture when

carrying out repair work

All models fitted with air conditioning

AH83.30-

N-0005-

01A

Notes on handling refrigerant R134aAll models fitted with air conditioning

AH83.30-

N-0003-

01A

1Drain coolant J Engine 112, 113.AR20.00-P-

1142HA

Engine 111.AR20.00-P-

1142HG

Engine 612.963.AR20.00-P-

1142M

2Unscrew coolant compensating

reservoir (1) on firewall Lay compensating reservoir to one side.

3Disconnect coolant delivery/return

hoses for heat exchanger (2) Remove hose clamps from coolant hoses.

4Discharge air conditioning system

Installation: Evacuate air conditioning,

refill and check for proper operation and

leaktightness.AR83.30-P-

1760GH

5Remove cover on expansion valve

(4)

6Remove nut (3) on expansion valve

(4) Replace self-locking nut.

*BA83.30-

P-1003-01B

7Disconnect refrigerant lines from

expansion valve Installation: Install new sealing rings

and moisten with compressor oil.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:19 PMPage 220 © 2006 Mitchell Repair Information Company, LLC.

Page 3479 of 4133

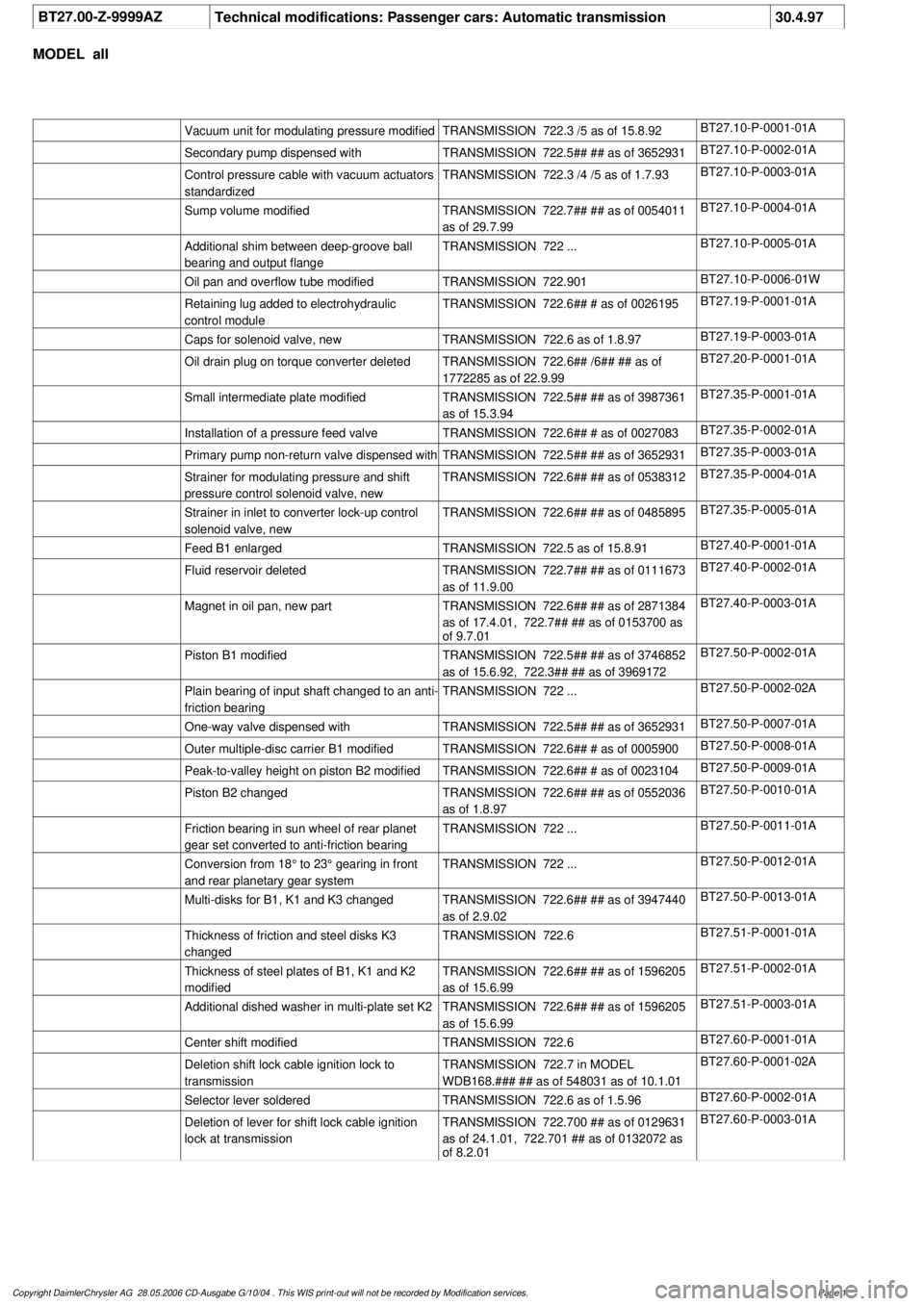

BT27.00-Z-9999AZ

Technical modifications: Passenger cars: Automatic transmission

30.4.97

MODEL all

Vacuum unit for modulating pressure modified

TRANSMISSION 722.3 /5 as of 15.8.92

BT27.10-P-0001-01A

Secondary pump dispensed with

TRANSMISSION 722.5## ## as of 3652931

BT27.10-P-0002-01A

Control pressure cable with vacuum actuators

standardized

TRANSMISSION 722.3 /4 /5 as of 1.7.93

BT27.10-P-0003-01A

Sump volume modified

TRANSMISSION 722.7## ## as of 0054011

as of 29.7.99

BT27.10-P-0004-01A

Additional shim between deep-groove ball

bearing and output flange

TRANSMISSION 722 ...

BT27.10-P-0005-01A

Oil pan and overflow tube modified

TRANSMISSION 722.901

BT27.10-P-0006-01W

Retaining lug added to electrohydraulic

control module

TRANSMISSION 722.6## # as of 0026195

BT27.19-P-0001-01A

Caps for solenoid valve, new

TRANSMISSION 722.6 as of 1.8.97

BT27.19-P-0003-01A

Oil drain plug on torque converter deleted

TRANSMISSION 722.6## /6## ## as of

1772285 as of 22.9.99

BT27.20-P-0001-01A

Small intermediate plate modified

TRANSMISSION 722.5## ## as of 3987361

as of 15.3.94

BT27.35-P-0001-01A

Installation of a pressure feed valve

TRANSMISSION 722.6## # as of 0027083

BT27.35-P-0002-01A

Primary pump non-return valve dispensed with

TRANSMISSION 722.5## ## as of 3652931

BT27.35-P-0003-01A

Strainer for modulating pressure and shift

pressure control solenoid valve, new

TRANSMISSION 722.6## ## as of 0538312

BT27.35-P-0004-01A

Strainer in inlet to converter lock-up control

solenoid valve, newTRANSMISSION 722.6## ## as of 0485895

BT27.35-P-0005-01A

Feed B1 enlarged

TRANSMISSION 722.5 as of 15.8.91

BT27.40-P-0001-01A

Fluid reservoir deleted

TRANSMISSION 722.7## ## as of 0111673

as of 11.9.00

BT27.40-P-0002-01A

Magnet in oil pan, new part

TRANSMISSION 722.6## ## as of 2871384

as of 17.4.01, 722.7## ## as of 0153700 as

of 9.7.01

BT27.40-P-0003-01A

Piston B1 modified

TRANSMISSION 722.5## ## as of 3746852

as of 15.6.92, 722.3## ## as of 3969172

BT27.50-P-0002-01A

Plain bearing of input shaft changed to an anti-

friction bearing

TRANSMISSION 722 ...

BT27.50-P-0002-02A

One-way valve dispensed with

TRANSMISSION 722.5## ## as of 3652931

BT27.50-P-0007-01A

Outer multiple-disc carrier B1 modified

TRANSMISSION 722.6## # as of 0005900

BT27.50-P-0008-01A

Peak-to-valley height on piston B2 modified

TRANSMISSION 722.6## # as of 0023104

BT27.50-P-0009-01A

Piston B2 changed

TRANSMISSION 722.6## ## as of 0552036

as of 1.8.97

BT27.50-P-0010-01A

Friction bearing in sun wheel of rear planet

gear set converted to anti-friction bearing

TRANSMISSION 722 ...

BT27.50-P-0011-01A

Conversion from 18° to 23° gearing in front

and rear planetary gear system

TRANSMISSION 722 ...

BT27.50-P-0012-01A

Multi-disks for B1, K1 and K3 changed

TRANSMISSION 722.6## ## as of 3947440

as of 2.9.02

BT27.50-P-0013-01A

Thickness of friction and steel disks K3

changed

TRANSMISSION 722.6

BT27.51-P-0001-01A

Thickness of steel plates of B1, K1 and K2

modified

TRANSMISSION 722.6## ## as of 1596205

as of 15.6.99

BT27.51-P-0002-01A

Additional dished washer in multi-plate set K2

TRANSMISSION 722.6## ## as of 1596205

as of 15.6.99

BT27.51-P-0003-01A

Center shift modified

TRANSMISSION 722.6

BT27.60-P-0001-01A

Deletion shift lock cable ignition lock to

transmission

TRANSMISSION 722.7 in MODEL

WDB168.### ## as of 548031 as of 10.1.01

BT27.60-P-0001-02A

Selector lever soldered

TRANSMISSION 722.6 as of 1.5.96

BT27.60-P-0002-01A

Deletion of lever for shift lock cable ignition

lock at transmission

TRANSMISSION 722.700 ## as of 0129631

as of 24.1.01, 722.701 ## as of 0132072 as

of 8.2.01

BT27.60-P-0003-01A

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3835 of 4133

SI18.00-P-0010A

Service Information: oil sludge

26.3.01

ENGINE

111 in MODELS 124, 163, 170, 202, 203, 208, 210

ENGINE

112 in MODELS 129, 163, 170, 202, 203, 208, 210, 220

ENGINE

112, 113 in MODEL 463

ENGINE

113 in MODELS 129, 163, 202, 208, 210, 215, 220

ENGINE

137 in MODEL 215, 220

ENGINE

166 in MODEL 168

Oil sludging in gasoline engines with ASSYST maintenance

system

Recently we have determined that time and time again oil

sludging occurs in gasoline engines with an ASSYST maintenance

system.

Oil sludging can lead to the following complaints:

D

engine oil consumption

D

engine smoke (white/blue)

D

influencing of oil level indicator

D

clogged oil filter, engine oil thickened like jelly

D

Check engine lamp illuminated

D

oil sludge visible during assembly job, e.g. in oil filter, in cylinder

head covers, condensation sludging

(engine 166) etc.

-----------------------------------------------------------------------------------------

The following list of causes may lead individually or as a combination

to engine oil sludging:

D

Crankcase ventilation inoperable, function orifices, bores,

passages in cylinder head cover, cylinder head, crankcase etc.

are mechanically sealed. A nonfunctioning crankcase

ventilation boosts loads on the engine oil through organic

nitrates. The risk of oil sludging increases.

The mechanical condition of the engine is always to be

checked, i.e. all engine oil drain orifices on the cylinder head

and crankcase and all crankcase ventilation ducts must be free

of obstacles. Crankcase breather lines may not be kinked.

Check the ventilation bores in the cylinder head covers.

-----------------------------------------------------------------------------------------

D

The engine oil used does not comply with the specifications in

Sheet 229.1 or 229.3 of the Specifications for Service Products.

The additive process, e.g. dirt-carrying capability, neutralization

capability and oxidation resistance as well as the quality of the

base stock influence sludging time.

Use of engine oils with best possible resistance to formation of

sludge, i.e. use only tested and approved engine oils (from

Sheet 229.1 or 229.3). The best protection is afforded by the

engine oils on Sheet 229.3, which fulfill more stringent

specifications with regard to preventing sludge and deposits

(see Sheet 221.0, page 11). These oils have a distinctly better

anti-sludge characteristic than other engine oils.

D

Sludging after adding a fuel or engine oil special additive.

Do not use fuel or engine oil special additives. More information

hereto is available on Sheet 219.0 of the Specifications for

Service products. Reference to customer not to use special

additives.

D

Engine oil change not performed according to ASSYST

specifications. At driven distances

exceeding > approx. 3000 km, engine oil sludging may occur.

-----------------------------------------------------------------------------------------

Comply with engine oil and filter change as under ASSYST

specifications. Observe remaining distance.

D

Fuel grade lies outside standard (regionally contingent). If

contaminated, deficient fuel is used, then engine oil sludging

may occur even where approved engine oil is used.

Operation with fuel, e.g. as under DIN EN 228. Clarify refueling

behavior of customer. If engine operation regional, is

temporarily possible with deficient oil only, then the startup

distance has to be individually reduced, i.e. the oil change

temporarily performed at an interval of, e.g. 10,000 km.

D

Radiator antifreeze penetration into engine oil, e.g. through an

internal engine leak (cylinder head gasket, casting porosity).

The engine oil sludges within a short period. The crankcase

ventilation clogs up and stops functioning. Condensation

sludging clogs up the oil separator cells

(engine 166).

Rectify coolant leakage. Clean all sludged engine parts, in

particular the crankcase ventilation parts. If the occurrence

repeats, and casting porosity is suspected, e.g. replace

crankcase.

-----------------------------------------------------------------------------------------

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3836 of 4133

Measures for slightly sludged engine:

Oil and filter change. Purge engine, i.e. normal engine operation

in neutral, or while driving, using oil from Sheet 229.3, 228.3, or

228.5. Drain off scavenging oil after purging process (approx. 1

hour). Repeat purging process if necessary. Refill using engine oil

from Sheet 229.3, or 229.1. The first oil change after clearing the

sludge should be performed after approx. 10,000 km or beforehand;

when doing so use engine oil from Sheet 229.3.

Measures for severely sludged engine:

Engines with severe oil sludging and caking onto engine parts

and into bores have to be dismantled and mechanically cleaned.

Tough sludge residue must not enter the clean side of the oil circuit,

as otherwise, e.g. the piston oil spray and the hydraulic

compensation elements may have their functionality impaired. Refill

using engine oil from Sheet 229.3, or 229.1.

The first oil change after sludging should be performed after approx.

10,000 km; when doing so use engine oil from

Sheet 229.3.

Warranty/goodwill regulations

If in combination with engine oil sludging a warranty/goodwill claim is

submitted, then a regular documentation of maintenance must be

presented. The ASSYST printout is to be filed carefully for further

reference.

Oil sludging in combination with an exceeded oil change interval, or

because of special additives in the fuel/engine oil are costs to be

borne by the customer.

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3985 of 4133

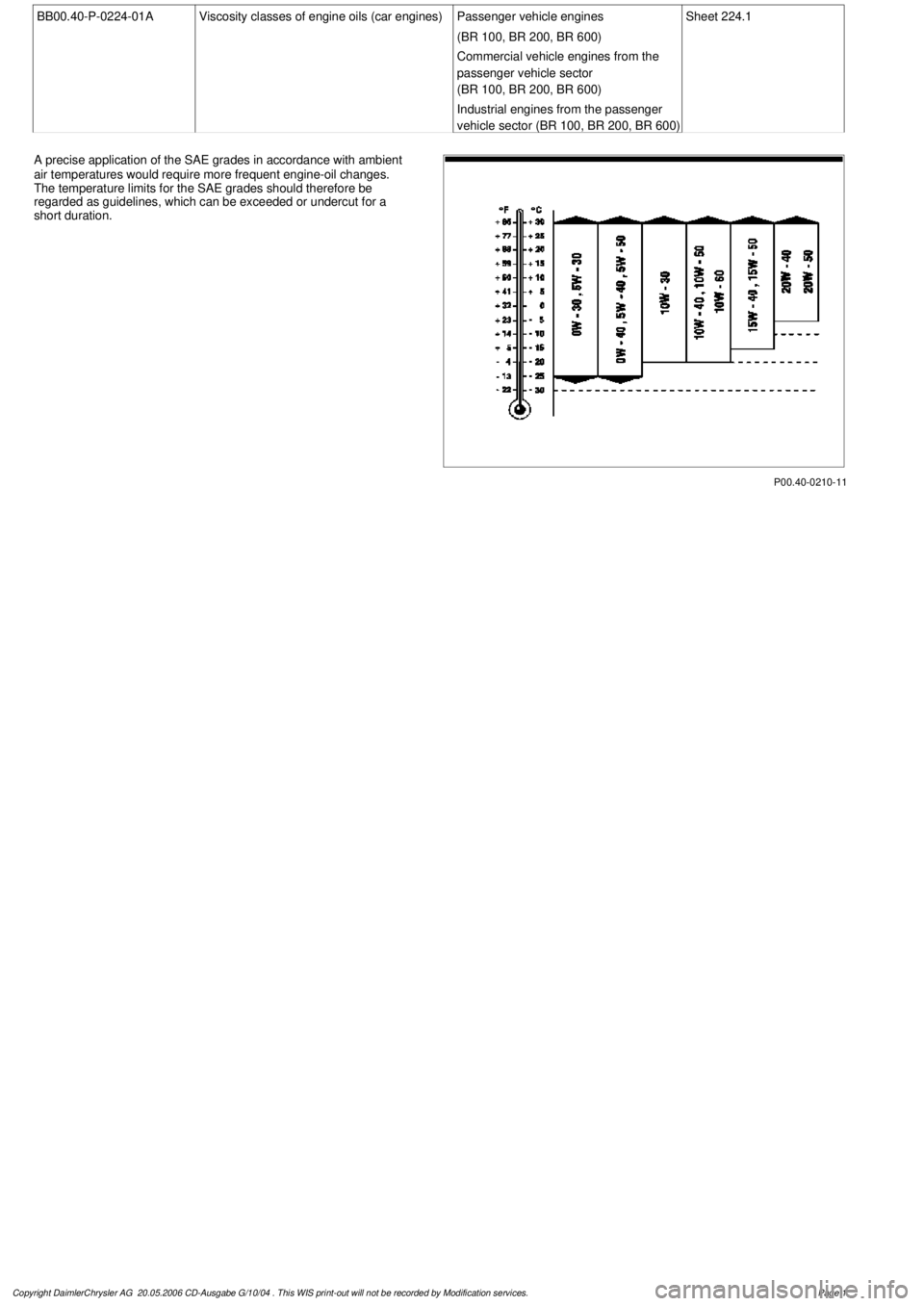

BB00.40-P-0224-01A

Viscosity classes of engine oils (car engines)

Passenger vehicle engines

(BR 100, BR 200, BR 600)

Commercial vehicle engines from the

passenger vehicle sector

(BR 100, BR 200, BR 600)

Industrial engines from the passenger

vehicle sector (BR 100, BR 200, BR 600)

Sheet 224.1

P00.40-0210-11

A precise application of the SAE grades in accordance with ambient

air temperatures would require more frequent engine-oil changes.

The temperature limits for the SAE grades should therefore be

regarded as guidelines, which can be exceeded or undercut for a

short duration.

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3994 of 4133

AP40.10-P-4050GH

Remove/install wheels, rotate if necessary

15.7.97

MODEL

163

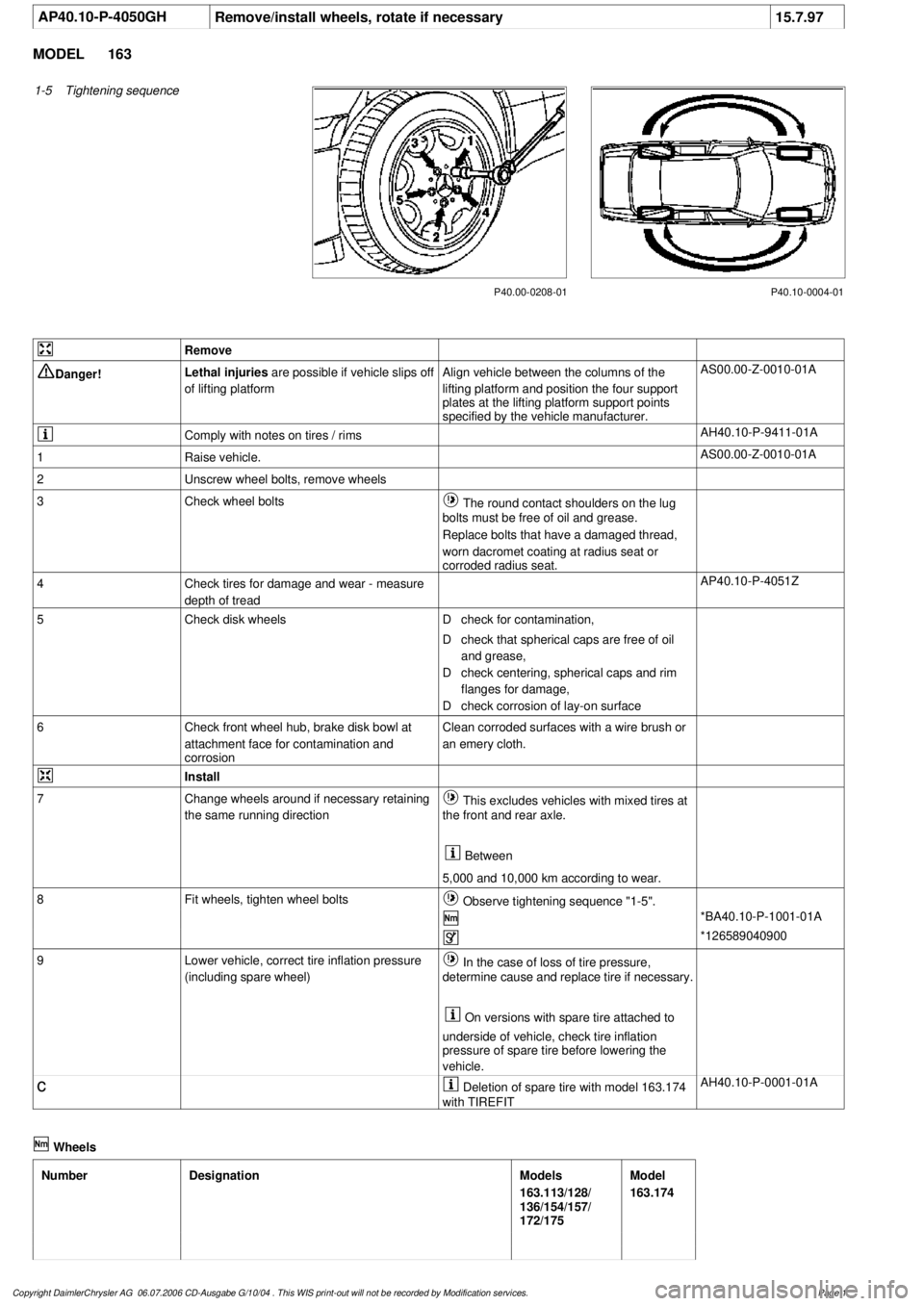

1-5

Tightening sequence

P40.10-0004-01

P40.00-0208-01

Remove

Danger!

Lethal injuries

are possible if vehicle slips off

of lifting platform

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

Comply with notes on tires / rims

AH40.10-P-9411-01A

1

Raise vehicle.

AS00.00-Z-0010-01A

2

Unscrew wheel bolts, remove wheels

3

Check wheel bolts

The round contact shoulders on the lug

bolts must be free of oil and grease.

Replace bolts that have a damaged thread,

worn dacromet coating at radius seat or

corroded radius seat.

4

Check tires for damage and wear - measure

depth of tread

AP40.10-P-4051Z

5

Check disk wheels

D

check for contamination,

D

check that spherical caps are free of oil

and grease,

D

check centering, spherical caps and rim

flanges for damage,

D

check corrosion of lay-on surface

6

Check front wheel hub, brake disk bowl at

attachment face for contamination and

corrosion

Clean corroded surfaces with a wire brush or

an emery cloth.

Install

7

Change wheels around if necessary retaining

the same running direction

This excludes vehicles with mixed tires at

the front and rear axle.

Between

5,000 and 10,000 km according to wear.

8

Fit wheels, tighten wheel bolts

Observe tightening sequence "1-5".

*BA40.10-P-1001-01A

*126589040900

9

Lower vehicle, correct tire inflation pressure

(including spare wheel)

In the case of loss of tire pressure,

determine cause and replace tire if necessary.

On versions with spare tire attached to

underside of vehicle, check tire inflation

pressure of spare tire before lowering the

vehicle.

c

Deletion of spare tire with model 163.174

with TIREFIT

AH40.10-P-0001-01A

Wheels

Number

Designation

Models

163.113/128/

136/154/157/

172/175

Model

163.174

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1