oil temperature MERCEDES-BENZ ML320 1997 Complete Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1116 of 4133

312 Technical termsEngine oil viscosity

Measurement for the inner friction (vis-

cosity) of the oil at different tempera-

tures. The higher the temperature an

oil can tolerate without becoming thin,

or the lower the temperature it can tol-

erate without becoming viscous, the

better the viscosity.

ESP

(E

lectronic S

tability Pr

ogram)

Improves vehicle handling and direc-

tional stability.

ETD

(E

mergency T

ensioning D

evice)

Device which deploys in certain frontal

and rear collisions exceeding the sys-

tem's threshold to tighten the seat

belts.

->SRSFSS

(F

lexible S

ervice S

ystem)

Service indicator in the speedometer

display that informs the driver when

the next vehicle maintenance service is

due.

Gear range

Number of gears which are available to

the automatic transmission for shifting.

The automatic gear shifting process

can be adapted to specific operating

conditions using the gear selector

lever.

GPS

(G

lobal P

ositioning S

ystem)

Satellite-based system for relaying

geographic location information to and

from vehicles equipped with special re-

ceivers. Employs CD or DVD digital

maps for navigation.GAWR

(G

ross A

xle W

eight R

ating)

The GAWR is the maximum permissible

axle weight. The gross vehicle weight

on each axle must never exceed the

GAWR for the front and rear axle indi-

cated on the certification label located

on the driver’s door pillar.

GVW

(G

ross V

ehicle W

eight)

The GVW comprises the weight of the

vehicle including fuel, tools, spare

wheel, installed accessories, passen-

gers and cargo. The GVW must never

exceed the GVWR, indicated on the

certification label located on the driv-

er’s door pillar.

Page 1131 of 4133

327 Index

I

Identification labels 292

Certification label 292

Vehicle identification number

(VIN) 292

Ignition 33

Immobilizer 83

Activating 54, 83

Deactivating 83

Indicator lamp

Adjustable steering column 253

Brake pad wear 254

Coolant 249

Front fog lamps 253

Low engine oil level 253

Indicators, additional

Speedometer display 256

Infant and child restraint systems 68

Installing 71

LATCH child seat mounts 72Information

About service and warranty 10

Button for Tele Aid* 177

Inside rear view mirror

Antiglare 126

Installing

Infant and child restraint systems 71

Wiper blades 273

Instrument cluster 24, 116, 313

Cleaning 238

Coolant temperature gauge 117

Display in the speedometer 117

Illumination 116

Lamps in 252

Outside temperature indicator 118

Instruments and controls see Cockpit 22

Integrated remote control

Erasing memory 185

Operating 185

Interior lighting 112Activating automatic control 113

Deactivating automatic control 113

Manual operation 113

Reading lamps 114

Interior storage spaces 164

Armrest 165

Cup holder 167

Glove box 164

Storage compartment in front of

armrest 165

Storage compartment under front pas-

senger seat* 164

Intermittent wiping 130

J

Jack 258

Jump starting 281

Page 1135 of 4133

331 Index

Oil

Adding 221

Consumption 218

Dipstick 218

Oil dipstick 221

Viscosity 312

One-touch gearshifting 120

Canceling gear range limit 120

Downshifting 120

Upshifting 120

Opening

Doors from the inside 90

Fuel filler flap 214

Fuel filler flap manually 263

Glove box 164

Hood 217

Liftgate 89, 91

Liftgate from inside 91

Liftgate from outside 91

Rear quarter windows 146

Side windows 145Sliding/pop-up roof* 148, 265

Sliding/pop-up roof* in an

emergency 265

Storage compartment in front of

armrest 166

Storage compartment under passenger

seat 165

Windows 145

Opening and closing

Side windows 144

Operating

Garage door opener 185

Integrated remote control 185

Radio transmitters 211

Vehicle outside the USA and

Canada 13

Operating safety 17

Operator’s Manual 10

Ornamental moldings 236

Outside temperature indicator 118

Overdue service 233

Overhead control panel 29P

Paintwork 235

Panic alarm 75

Panic button on remote control 75

Parking and locking 53

Parking brake 47, 53

Engaging 53

Releasing 47

Parking lamps

Replacing bulbs 266, 267, 269

Replacing the bulbs 269

Switching on 107

Parktronic* 153, 313

Cleaning system sensor 237

Monitoring reach 154

Sensor cover 237

Switching off 156

Switching on 156

Warning indicators 155

Page 1240 of 4133

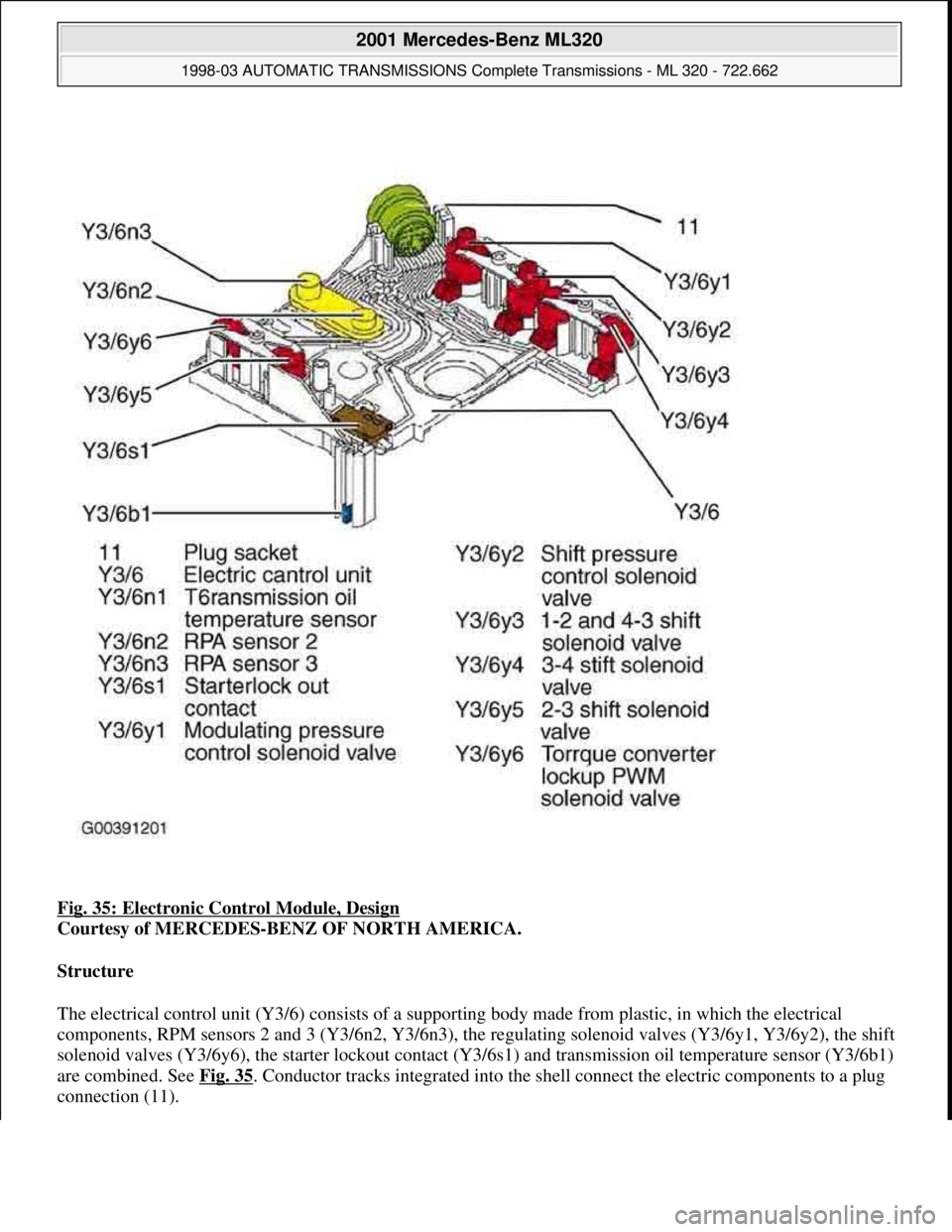

Fig. 35: Electronic Control Module, Design

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Structure

The electrical control unit (Y3/6) consists of a supporting body made from plastic, in which the electrical

components, RPM sensors 2 and 3 (Y3/6n2, Y3/6n3), the regulating solenoid valves (Y3/6y1, Y3/6y2), the shift

solenoid valves (Y3/6y6), the starter lockout contact (Y3/6s1) and transmission oil temperature sensor (Y3/6b1)

are combined. See Fig. 35

. Conductor tracks integrated into the shell connect the electric components to a plug

connection (11).

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 71 © 2006 Mitchell Repair Information Company, LLC.

Page 1243 of 4133

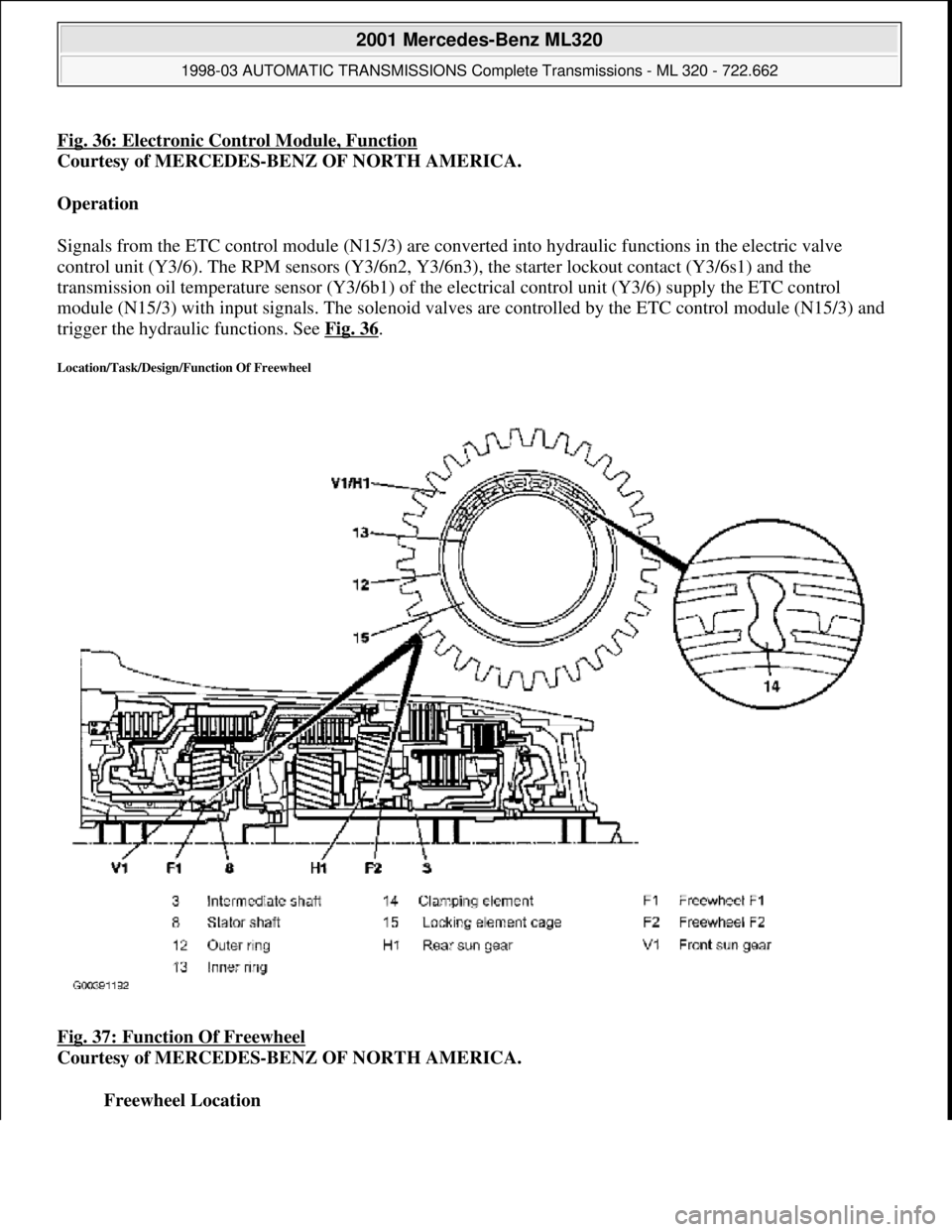

Fig. 36: Electronic Control Module, Function

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Operation

Signals from the ETC control module (N15/3) are conve rted into hydraulic functions in the electric valve

control unit (Y3/6). The RPM sensors (Y3/6n2, Y3/6n3) , the starter lockout contact (Y3/6s1) and the

transmission oil temperature sensor (Y3/6b1) of the electrical cont rol unit (Y3/6) supply the ETC control

module (N15/3) with input signals. The solenoid valves are controlled by the ETC control module (N15/3) and

trigger the hydraulic functions. See Fig. 36

.

Location/Task/Design/Function Of Freewheel

Fig. 37: Function Of Freewheel

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Freewheel Location

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMI SSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 74 © 2006 Mitchell Repair Information Company, LLC.

Page 1247 of 4133

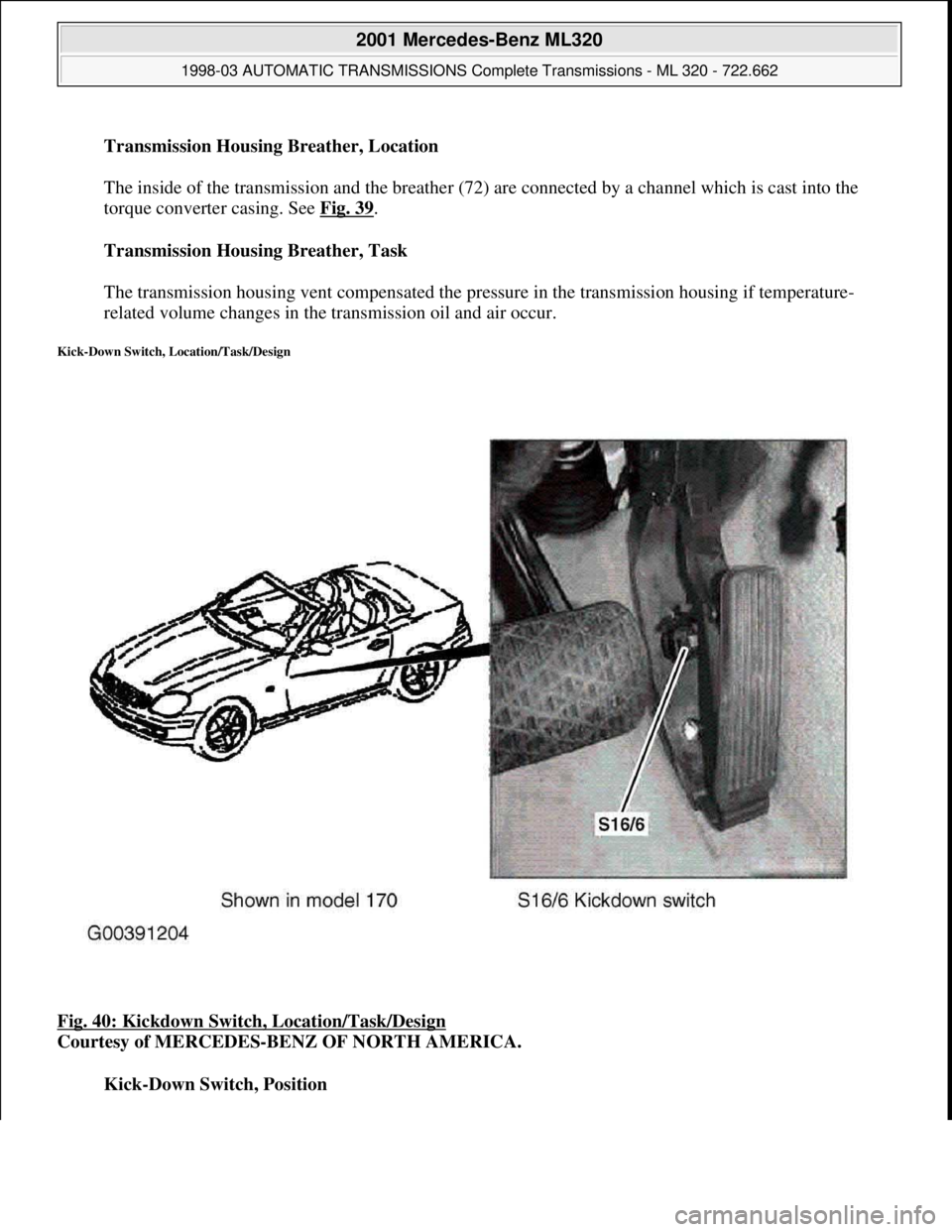

Transmission Housing Breather, Location

The inside of the transmission and the breather (72) are connected by a channel which is cast into the

torque converter casing. See Fig. 39

.

Transmission Housing Breather, Task

The transmission housing vent compensated the pressure in the transmission housing if temperature-

related volume changes in the transmission oil and air occur.

Kick-Down Switch, Location/Task/Design

Fig. 40: Kickdown Switch, Location/Task/Design

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Kick-Down Switch, Position

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 78 © 2006 Mitchell Repair Information Company, LLC.

Page 1333 of 4133

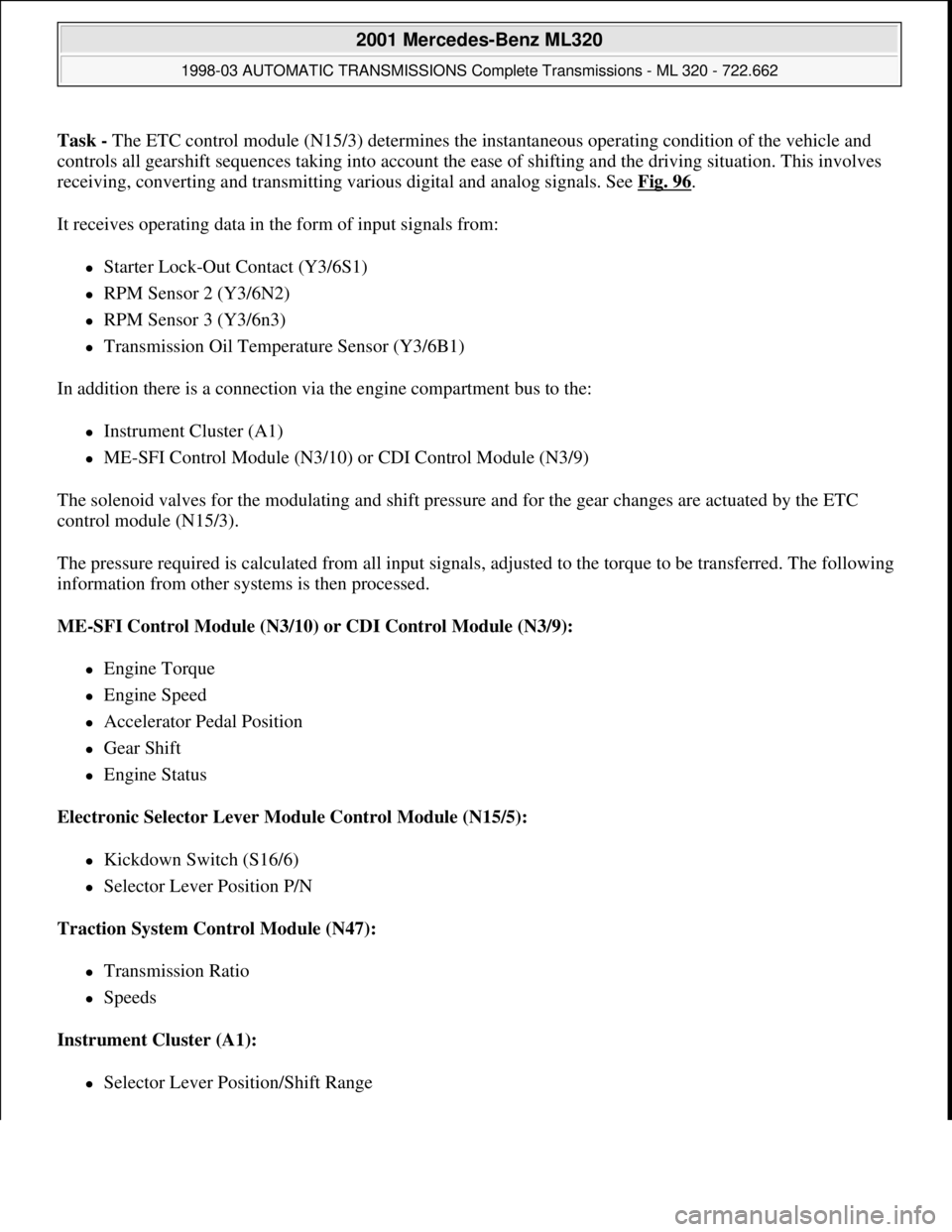

Task - The ETC control module (N15/3) determines the instantaneous operating condition of the vehicle and

controls all gearshift sequences taking into account the ease of shifting and the driving situation. This involves

receiving, converting and transmitting various digital and analog signals. See Fig. 96

.

It receives operating data in the form of input signals from:

Starter Lock-Out Contact (Y3/6S1)

RPM Sensor 2 (Y3/6N2)

RPM Sensor 3 (Y3/6n3)

Transmission Oil Temperature Sensor (Y3/6B1)

In addition there is a connection via the engine compartment bus to the:

Instrument Cluster (A1)

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

The solenoid valves for the modulating and shift pressure and for the gear changes are actuated by the ETC

control module (N15/3).

The pressure required is calculated from all input signals, adjusted to the torque to be transferred. The following

information from other systems is then processed.

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9):

Engine Torque

Engine Speed

Accelerator Pedal Position

Gear Shift

Engine Status

Electronic Selector Lever Module Control Module (N15/5):

Kickdown Switch (S16/6)

Selector Lever Position P/N

Traction System Control Module (N47):

Transmission Ratio

Speeds

Instrument Cluster (A1):

Selector Lever Position/Shift Range

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:27 PMPage 164 © 2006 Mitchell Repair Information Company, LLC.

Page 1335 of 4133

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Task - The ETC control module (N15/3) determines the instantaneous operating condition for the vehicle and

controls all gearshift sequences taking into account the ease of shifting and the driving situation. See Fig. 97

.

This involves receiving , converting and transmitting various digital and analog signals.

Input signals:

Starter Lock-Out Contact (Y3/6S1)

RPM Sensor 2 (Y3/6N2)

RPM Sensor 3 (Y3/6N3)

Transmission Oil Temperature Sensor (Y3/6B1)

Kickdown Switch (S16/6)

Gear Recognition Switch (S16/10)

Output signals:

Reverse/parking lock valve

Input and output signals:

Datalink connector (X11/4)

In addition there is a connection via the engine compartment bus to the:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

Traction System Control Module (N47)

Transfer Case Control Module (N78)

The solenoid valves for the modulating and shift pressure and for the gear changes are actuated by the ETC

control module (N15/3). The pressure required is calculated from all input signals, adjusted to the torque to be

transferred.

The following information from other systems is then processed:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

(Y66/1)

Selector lever position P/N to the engine control module (ME-SFI) (N3/10) (only on detection of the

selector lever position "P" or "N" on the transmission range recognition switch (S16/10) and at the starter

interlock contact (Y3/6s1)).

Traction system control module (N47):

Wheel speeds

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:27 PMPage 166 © 2006 Mitchell Repair Information Company, LLC.

Page 1346 of 4133

Courtesy of MECHANICS MONTHLY MAGAZINE

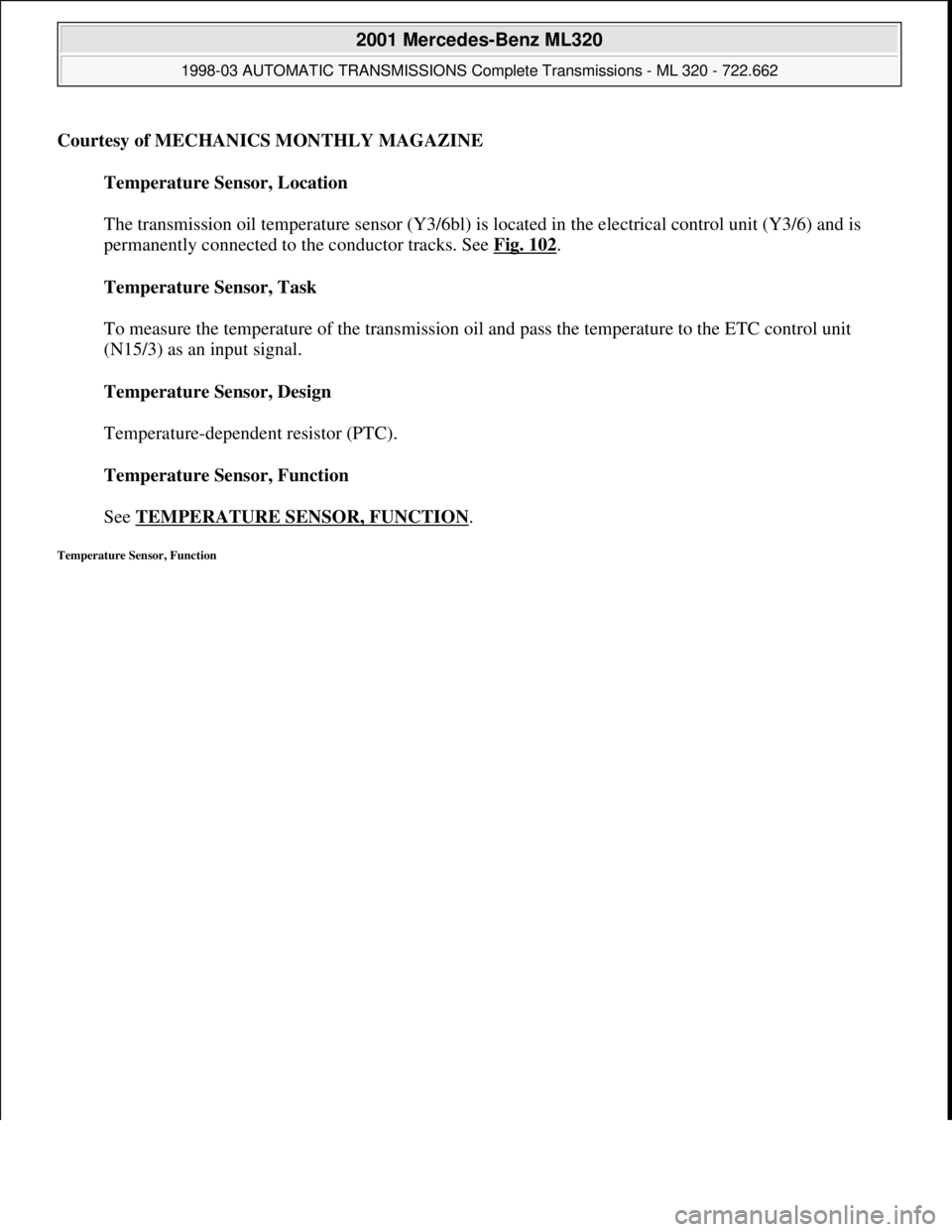

Temperature Sensor, Location

The transmission oil temperature sensor (Y3/6bl) is located in the electrical control unit (Y3/6) and is

permanently connected to the conductor tracks. See Fig. 102

.

Temperature Sensor, Task

To measure the temperature of the transmission oil and pass the temperature to the ETC control unit

(N15/3) as an input signal.

Temperature Sensor, Design

Temperature-dependent resistor (PTC).

Temperature Sensor, Function

See TEMPERATURE SENSOR, FUNCTION

.

Temperature Sensor, Function

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:28 PMPage 177 © 2006 Mitchell Repair Information Company, LLC.

Page 1347 of 4133

Fig. 103: Temperature Sensor, Function

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Operation

The temperature of the transmission oil has a major influence on the shift time and thus on the shift quality. It is

possible to optimize the gear shifts in all temperature ranges by detecting the oil temperature. See Fig. 103.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:28 PMPage 178 © 2006 Mitchell Repair Information Company, LLC.