oil temperature MERCEDES-BENZ ML320 1997 Complete Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1348 of 4133

The transmission oil temperature sens or (Y3/6b1) is connected in series with the starter lockout contact

(Y3/6s1). The temperature signal is tr ansmitted to the ETC control module (N 15/3) only the dry-reed contact of

the starter lockout contact (Y3/6s1) is closed.

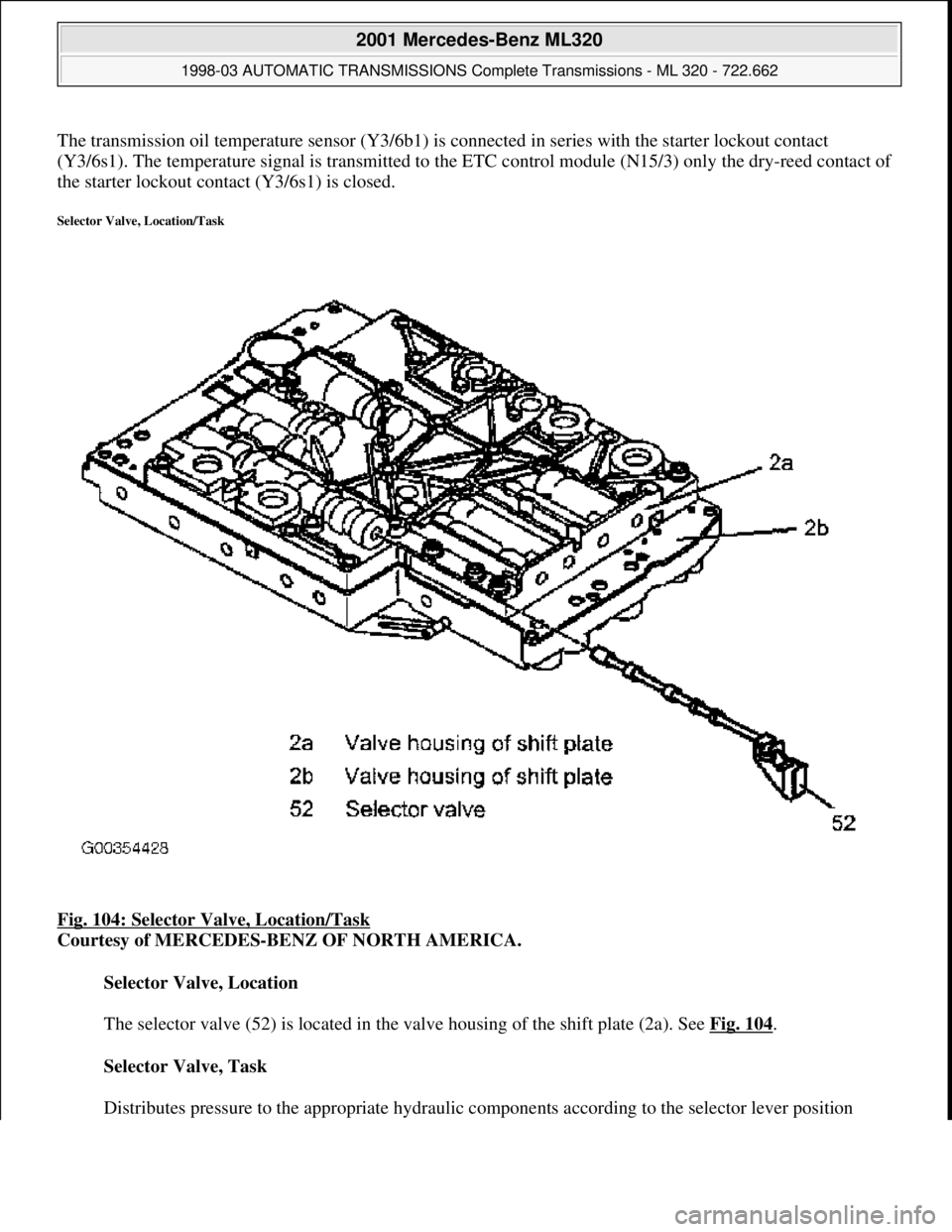

Selector Valve, Location/Task

Fig. 104: Selector Valve, Location/Task

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Selector Valve, Location

The selector valve (52) is located in th e valve housing of the shift plate (2a). See Fig. 104

.

Selector Valve, Task

Distributes pressure to the appropriate h

ydraulic components according to the selector lever position

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMI SSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:28 PMPage 179 © 2006 Mitchell Repair Information Company, LLC.

Page 1446 of 4133

Task

The ETC control module (N15/3) determines the instantaneous operating condition of the vehicle and controls

all gearshift sequences taking into account the ease of shifting and the driving situation. This involves receiving,

converting and transmitting various digital and analog signals. See Fig. 157

.

It receives operating data in the form of input signals from:

Starter Lock-Out Contact (Y3/6S1)

RPM Sensor 2 (Y3/6N2)

RPM Sensor 3 (Y3/6N3)

Transmission Oil Temperature Sensor (Y3/6B1)

In addition there is a connection via the engine compartment bus to the:

Instrument Cluster (A1)

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

The solenoid valves for the modulating and shift pressure and for the gear changes are actuated by the ETC

control module (N15/3).

The pressure required is calculated from all input signals, adjusted to the torque to be transferred. The following

information from other systems is then processed:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9):

Engine Torque

Engine Speed

Accelerator Pedal Position

Gear Shift

Engine Status

Electronic selector lever module control module (N15/5):

Kickdown Switch (S16/6)

Selector Lever Position P/N

Traction system control module (N47):

Transmission Ratio

Speeds

Instrument cluster (A1):

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:29 PMPage 277 © 2006 Mitchell Repair Information Company, LLC.

Page 1449 of 4133

The ETC control module (N15/3) determines the instantaneous operating condition of the vehicle and controls

all gearshift sequences taking into account the ease of shifting and the driving situation. See Fig. 158

. This

involves receiving , converting and transmitting various digital and analog signals.

Input Signals:

Starter Lock-Out Contact (Y3/6S1)

RPM Sensor 2 (Y3/6N2)

RPM Sensor 3 (Y3/6N3)

Transmission Oil Temperature Sensor (Y3/6B1)

Kickdown Switch (S16/6)

Gear Recognition Switch (S16/10)

Output signals:

Reverse/Parking Lock Valve

Input And Output Signals:

Datalink Connector (X11/4)

In addition there is a connection via the engine compartment bus to the:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

Traction System Control Module (N47)

Transfer Case Control Module (N78)

The solenoid valves for the modulating and shift pressure and for the gear changes are actuated by the ETC

control module (N15/3). The pressure required is calculated from all input signals, adjusted to the torque to be

transferred.

The following information from other systems is then processed:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9)

Reverse And Parking Lock Solenoids (Y66/1)

Selector Lever Position (P/N) to the Engine Control Module (ME-SFI) (N3/10) (only on detection of the

selector lever position "P" or "N" on the transmission range recognition switch (S16/10) and at the starter

interlock contact (Y3/6s1)).

Traction System Control Module (N47):

Wheel Speeds

Gear Shift

Traction Status

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:29 PMPage 280 © 2006 Mitchell Repair Information Company, LLC.

Page 1450 of 4133

Transfer Case Control Module (N78):

Position of Transfer Case (off-road or on-road ratio)

Engine Torque

Engine Speed

Accelerator Pedal Position

Gear Soft

Engine Status

The following information is output to other systems:

ME-SFI Control Module (N3/10) or CDI Control Module (N3/9):

Kickdown Switch (S16/6)

Engage Drive Mode

Traction System Control Module (N47):

Transmission Ratio

Speeds

Oil Level Control, Function

Operation - The oil level control system seals the opening between the oil gallery and gearset chamber so that

the rotating gearsets do not splash about in oil as the oil level rises. The oil level control reduces power loss and

prevents oil from being thrown out of the transmission housing at high oil temperatures.

Float, Location/Function

See SHIFT PRESSURE REGULATING VALVE, LOCATION/TASK/FUNCTION

.

Transmission Housing Breathing, Location/Task

See TRANSMISSION HOUSING BREATHING, LOCATION/TASK

.

Function Of Torque Converter Lockup Clutch Control

Operation

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:29 PMPage 281 © 2006 Mitchell Repair Information Company, LLC.

Page 1455 of 4133

See KICKDOWN SWITCH, LOCATION/TASK/DESIGN/FUNCTION MODEL 163 WITHOUT

TOUCH SHIFT.

Starter Lock-Out Contact, Location/Task/Design/Function

See STARTER LOCK

-OUT CONTACT, LOCATION/TASK/DESIGN/FUNCTION.

Temperature Sensor, Location/Task/Design/Function

See TEMPERATURE SENSOR, LOCATION/TASK/DESIGN/FUNCTION

.

Wheel Speed Sensor, Location/Task/Function

See WHEEL SPEED SENSOR, LOCATION/TASK/FUNCTION

.

Location/Task/Design/Function Of Oil Pump

See LOCATION/TASK/DESIGN/FUNCTION OF OIL PUMP

.

Kickdown Switch, Location/Task/Design/Function Model 163 Without Touch Shift

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:29 PMPage 286 © 2006 Mitchell Repair Information Company, LLC.

Page 1547 of 4133

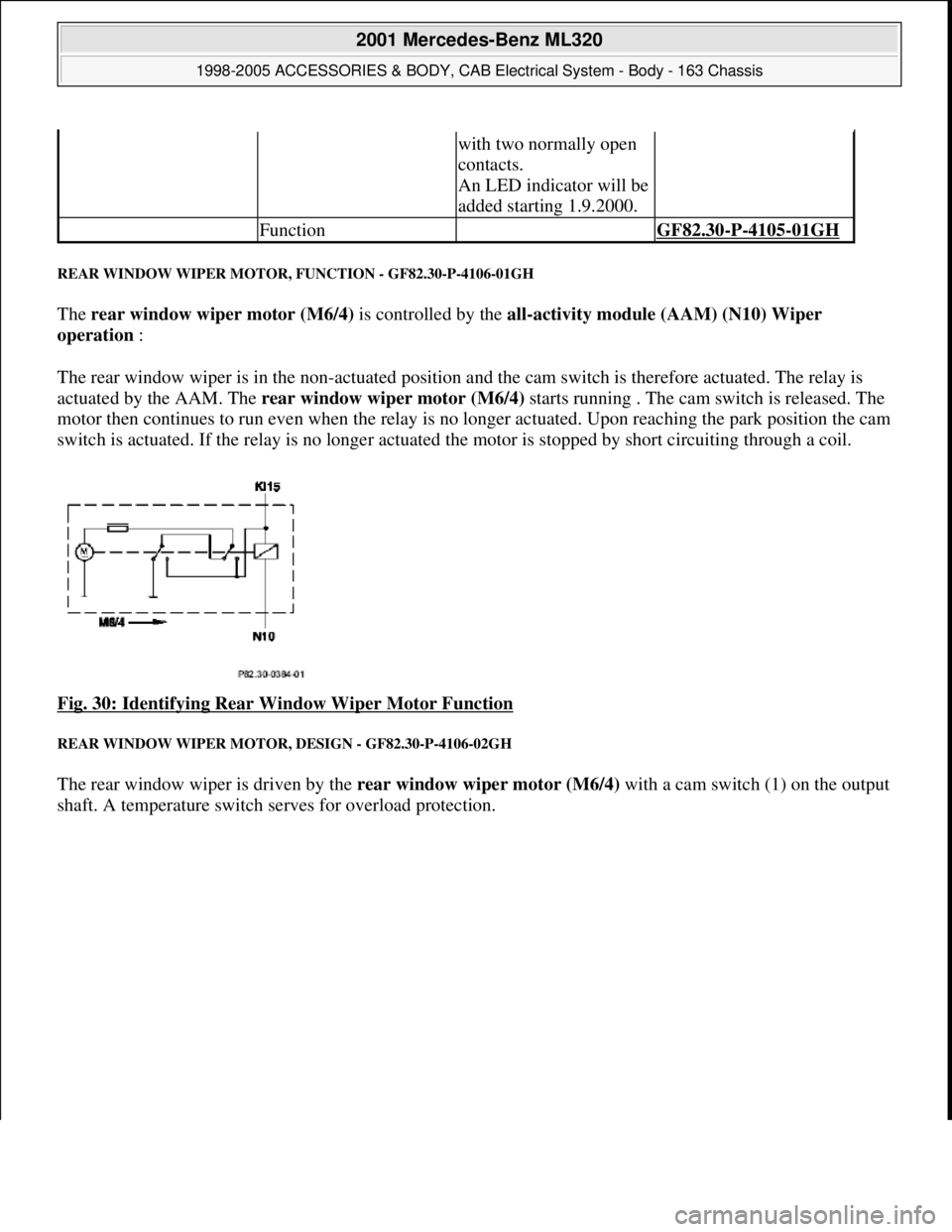

REAR WINDOW WIPER MOTOR, FUNCTION - GF82.30-P-4106-01GH

The rear window wiper motor (M6/4) is controlled by the all-activity module (AAM) (N10) Wiper

operation :

The rear window wiper is in the non-actuated position and the cam switch is therefore actuated. The relay is

actuated by the AAM. The rear window wiper motor (M6/4) starts running . The cam switch is released. The

motor then continues to run even when the relay is no longer actuated. Upon reaching the park position the cam

switch is actuated. If the relay is no longer actuated the motor is stopped by short circuiting through a coil.

Fig. 30: Identifying Rear Window Wiper Motor Function

REAR WINDOW WIPER MOTOR, DESIGN - GF82.30-P-4106-02GH

The rear window wiper is driven by the rear window wiper motor (M6/4) with a cam switch (1) on the output

shaft. A temperature switch serves for overload protection.

with two normally open

contacts.

An LED indicator will be

added starting 1.9.2000.

Function GF82.30-P-4105-01GH

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:05 PMPage 52 © 2006 Mitchell Repair Information Company, LLC.

Page 2030 of 4133

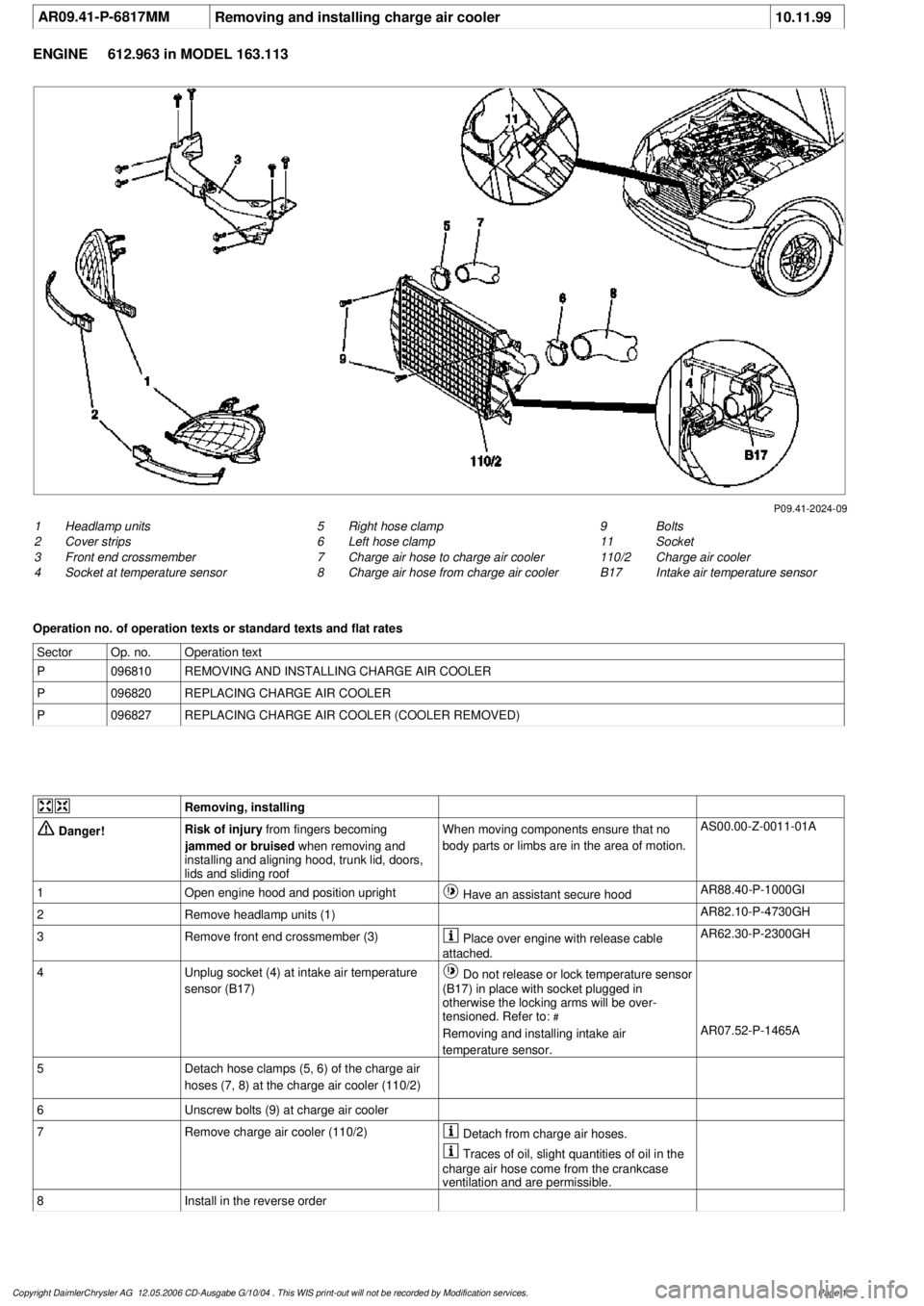

AR09.41-P-6817MM

Removing and installing charge air cooler

10.11.99

ENGINE

612.963 in MODEL 163.113

P09.41-2024-09

1

Headlamp units

2

Cover strips

3

Front end crossmember

4

Socket at temperature sensor

9

Bolts

11

Socket

110/2

Charge air cooler

B17

Intake air temperature sensor

5

Right hose clamp

6

Left hose clamp

7

Charge air hose to charge air cooler

8

Charge air hose from charge air cooler

Operation no. of operation texts or standard texts and flat rates

Sector

Op. no.

Operation text

P

096810

REMOVING AND INSTALLING CHARGE AIR COOLER

P

096820

REPLACING CHARGE AIR COOLER

P

096827

REPLACING CHARGE AIR COOLER (COOLER REMOVED)

Removing, installing

Danger!

Risk of injury

from fingers becoming

jammed or bruised

when removing and

installing and aligning hood, trunk lid, doors,

lids and sliding roof

When moving components ensure that no

body parts or limbs are in the area of motion.

AS00.00-Z-0011-01A

1

Open engine hood and position upright

Have an assistant secure hood

AR88.40-P-1000GI

2

Remove headlamp units (1)

AR82.10-P-4730GH

3

Remove front end crossmember (3)

Place over engine with release cable

attached.

AR62.30-P-2300GH

4

Unplug socket (4) at intake air temperature

sensor (B17)

Do not release or lock temperature sensor

(B17) in place with socket plugged in

otherwise the locking arms will be over-

tensioned. Refer to:

#

Removing and installing intake air

temperature sensor.

AR07.52-P-1465A

5

Detach hose clamps (5, 6) of the charge air

hoses (7, 8) at the charge air cooler (110/2)

6

Unscrew bolts (9) at charge air cooler

7

Remove charge air cooler (110/2)

Detach from charge air hoses.

Traces of oil, slight quantities of oil in the

charge air hose come from the crankcase

ventilation and are permissible.

8

Install in the reverse order

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2032 of 4133

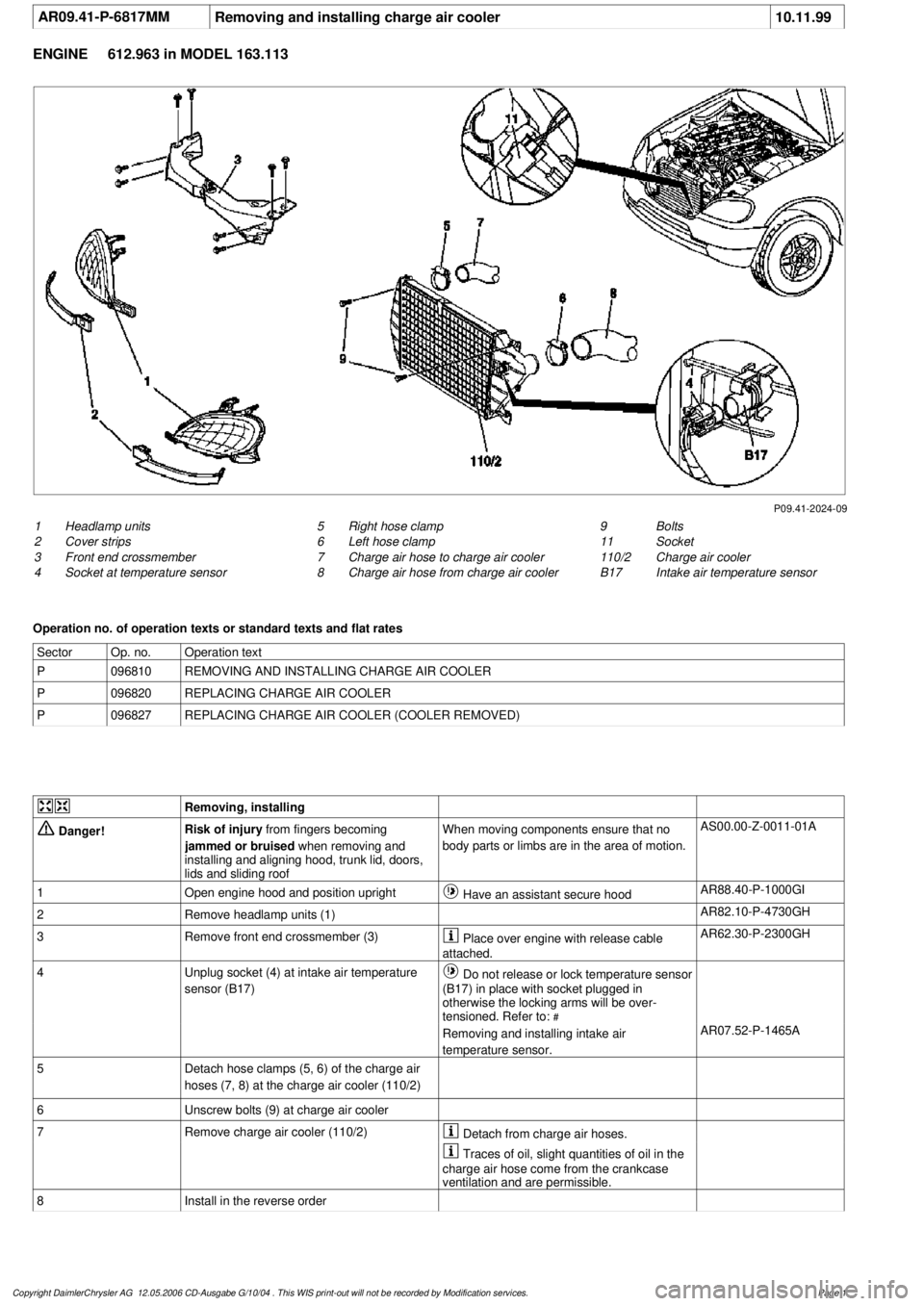

AR09.41-P-6817MM

Removing and installing charge air cooler

10.11.99

ENGINE

612.963 in MODEL 163.113

P09.41-2024-09

1

Headlamp units

2

Cover strips

3

Front end crossmember

4

Socket at temperature sensor

9

Bolts

11

Socket

110/2

Charge air cooler

B17

Intake air temperature sensor

5

Right hose clamp

6

Left hose clamp

7

Charge air hose to charge air cooler

8

Charge air hose from charge air cooler

Operation no. of operation texts or standard texts and flat rates

Sector

Op. no.

Operation text

P

096810

REMOVING AND INSTALLING CHARGE AIR COOLER

P

096820

REPLACING CHARGE AIR COOLER

P

096827

REPLACING CHARGE AIR COOLER (COOLER REMOVED)

Removing, installing

Danger!

Risk of injury

from fingers becoming

jammed or bruised

when removing and

installing and aligning hood, trunk lid, doors,

lids and sliding roof

When moving components ensure that no

body parts or limbs are in the area of motion.

AS00.00-Z-0011-01A

1

Open engine hood and position upright

Have an assistant secure hood

AR88.40-P-1000GI

2

Remove headlamp units (1)

AR82.10-P-4730GH

3

Remove front end crossmember (3)

Place over engine with release cable

attached.

AR62.30-P-2300GH

4

Unplug socket (4) at intake air temperature

sensor (B17)

Do not release or lock temperature sensor

(B17) in place with socket plugged in

otherwise the locking arms will be over-

tensioned. Refer to:

#

Removing and installing intake air

temperature sensor.

AR07.52-P-1465A

5

Detach hose clamps (5, 6) of the charge air

hoses (7, 8) at the charge air cooler (110/2)

6

Unscrew bolts (9) at charge air cooler

7

Remove charge air cooler (110/2)

Detach from charge air hoses.

Traces of oil, slight quantities of oil in the

charge air hose come from the crankcase

ventilation and are permissible.

8

Install in the reverse order

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2068 of 4133

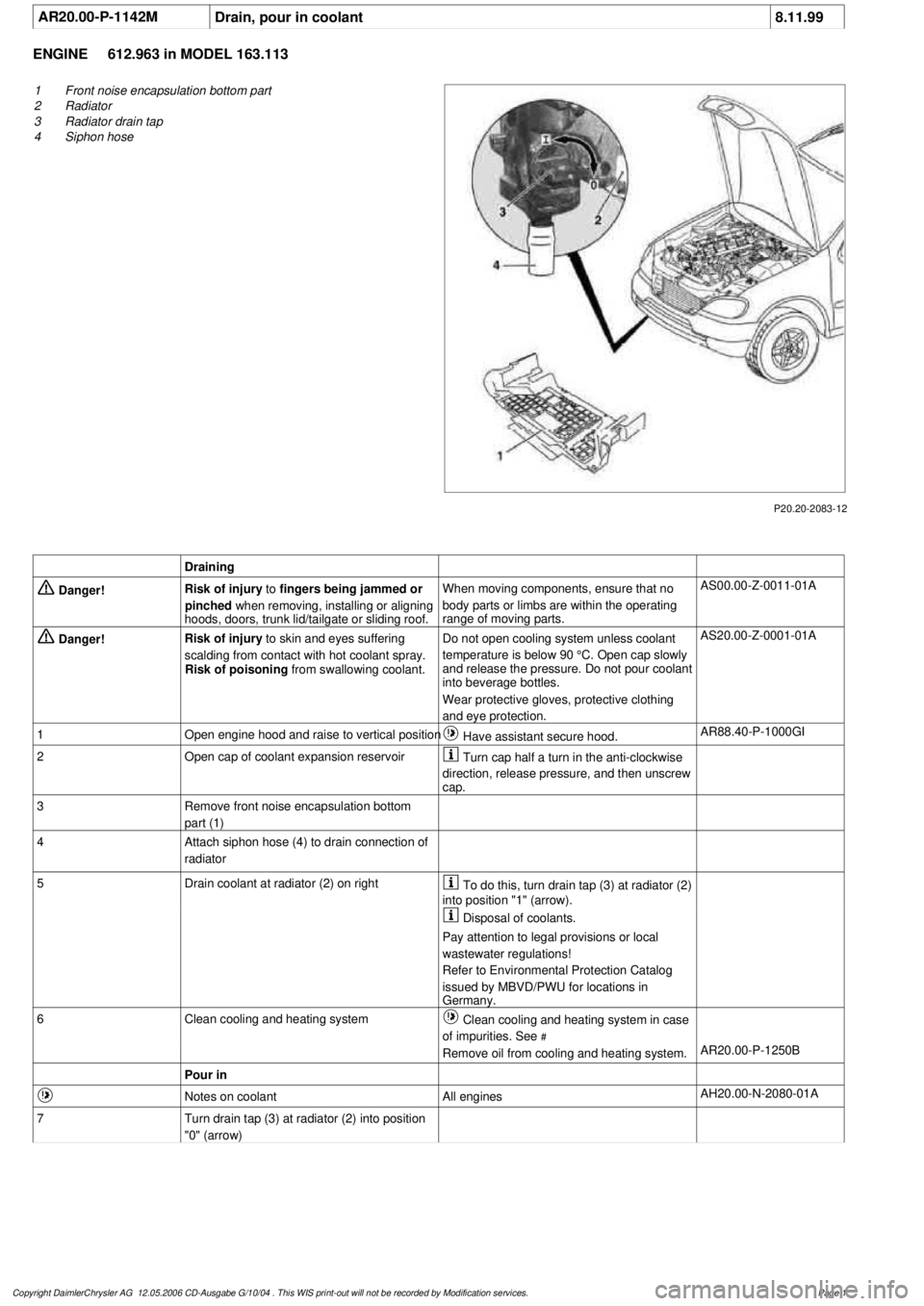

AR20.00-P-1142M

Drain, pour in coolant

8.11.99

ENGINE

612.963 in MODEL 163.113

P20.20-2083-12

1

Front noise encapsulation bottom part

2

Radiator

3

Radiator drain tap

4

Siphon hose

Draining

Danger!

Risk of injury

to

fingers being jammed or

pinched

when removing, installing or aligning

hoods, doors, trunk lid/tailgate or sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

Danger!

Risk of injury

to skin and eyes suffering

scalding from contact with hot coolant spray.

Risk of poisoning

from swallowing coolant.

Do not open cooling system unless coolant

temperature is below 90 °C. Open cap slowly

and release the pressure. Do not pour coolant

into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-0001-01A

1

Open engine hood and raise to vertical position

Have assistant secure hood.

AR88.40-P-1000GI

2

Open cap of coolant expansion reservoir

Turn cap half a turn in the anti-clockwise

direction, release pressure, and then unscrew

cap.

3

Remove front noise encapsulation bottom

part (1)

4

Attach siphon hose (4) to drain connection of

radiator

5

Drain coolant at radiator (2) on right

To do this, turn drain tap (3) at radiator (2)

into position "1" (arrow).

Disposal of coolants.

Pay attention to legal provisions or local

wastewater regulations!

Refer to Environmental Protection Catalog

issued by MBVD/PWU for locations in

Germany.

6

Clean cooling and heating system

Clean cooling and heating system in case

of impurities. See

#

Remove oil from cooling and heating system.

AR20.00-P-1250B

Pour in

Notes on coolant

All engines

AH20.00-N-2080-01A

7

Turn drain tap (3) at radiator (2) into position

"0" (arrow)

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2075 of 4133

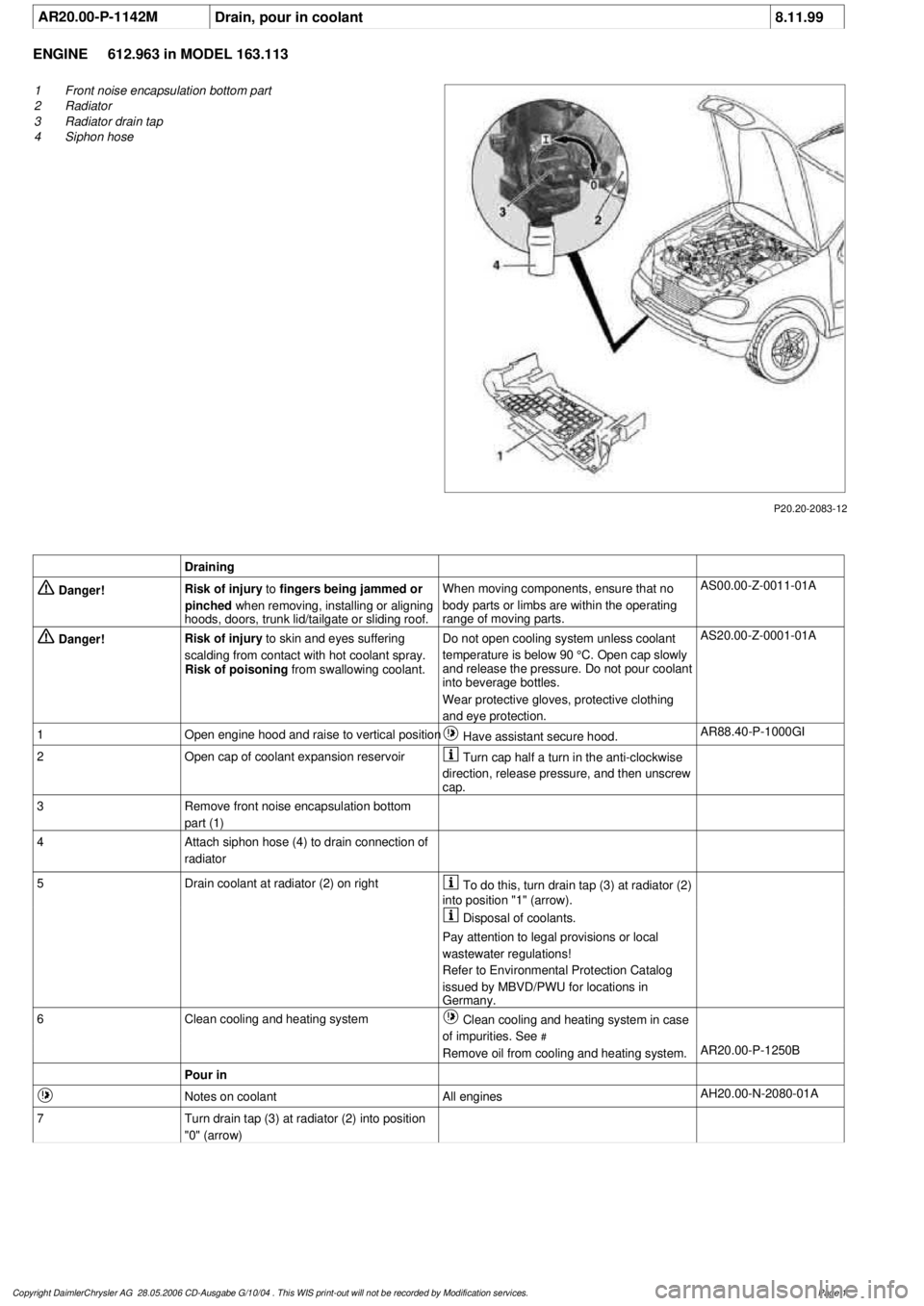

AR20.00-P-1142M

Drain, pour in coolant

8.11.99

ENGINE

612.963 in MODEL 163.113

P20.20-2083-12

1

Front noise encapsulation bottom part

2

Radiator

3

Radiator drain tap

4

Siphon hose

Draining

Danger!

Risk of injury

to

fingers being jammed or

pinched

when removing, installing or aligning

hoods, doors, trunk lid/tailgate or sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

Danger!

Risk of injury

to skin and eyes suffering

scalding from contact with hot coolant spray.

Risk of poisoning

from swallowing coolant.

Do not open cooling system unless coolant

temperature is below 90 °C. Open cap slowly

and release the pressure. Do not pour coolant

into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-0001-01A

1

Open engine hood and raise to vertical position

Have assistant secure hood.

AR88.40-P-1000GI

2

Open cap of coolant expansion reservoir

Turn cap half a turn in the anti-clockwise

direction, release pressure, and then unscrew

cap.

3

Remove front noise encapsulation bottom

part (1)

4

Attach siphon hose (4) to drain connection of

radiator

5

Drain coolant at radiator (2) on right

To do this, turn drain tap (3) at radiator (2)

into position "1" (arrow).

Disposal of coolants.

Pay attention to legal provisions or local

wastewater regulations!

Refer to Environmental Protection Catalog

issued by MBVD/PWU for locations in

Germany.

6

Clean cooling and heating system

Clean cooling and heating system in case

of impurities. See

#

Remove oil from cooling and heating system.

AR20.00-P-1250B

Pour in

Notes on coolant

All engines

AH20.00-N-2080-01A

7

Turn drain tap (3) at radiator (2) into position

"0" (arrow)

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1