engine MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2034 of 4133

GF54.30-P-3007A

Charge indicator lamp, exterior lamp failure

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

P54.30-0517-06

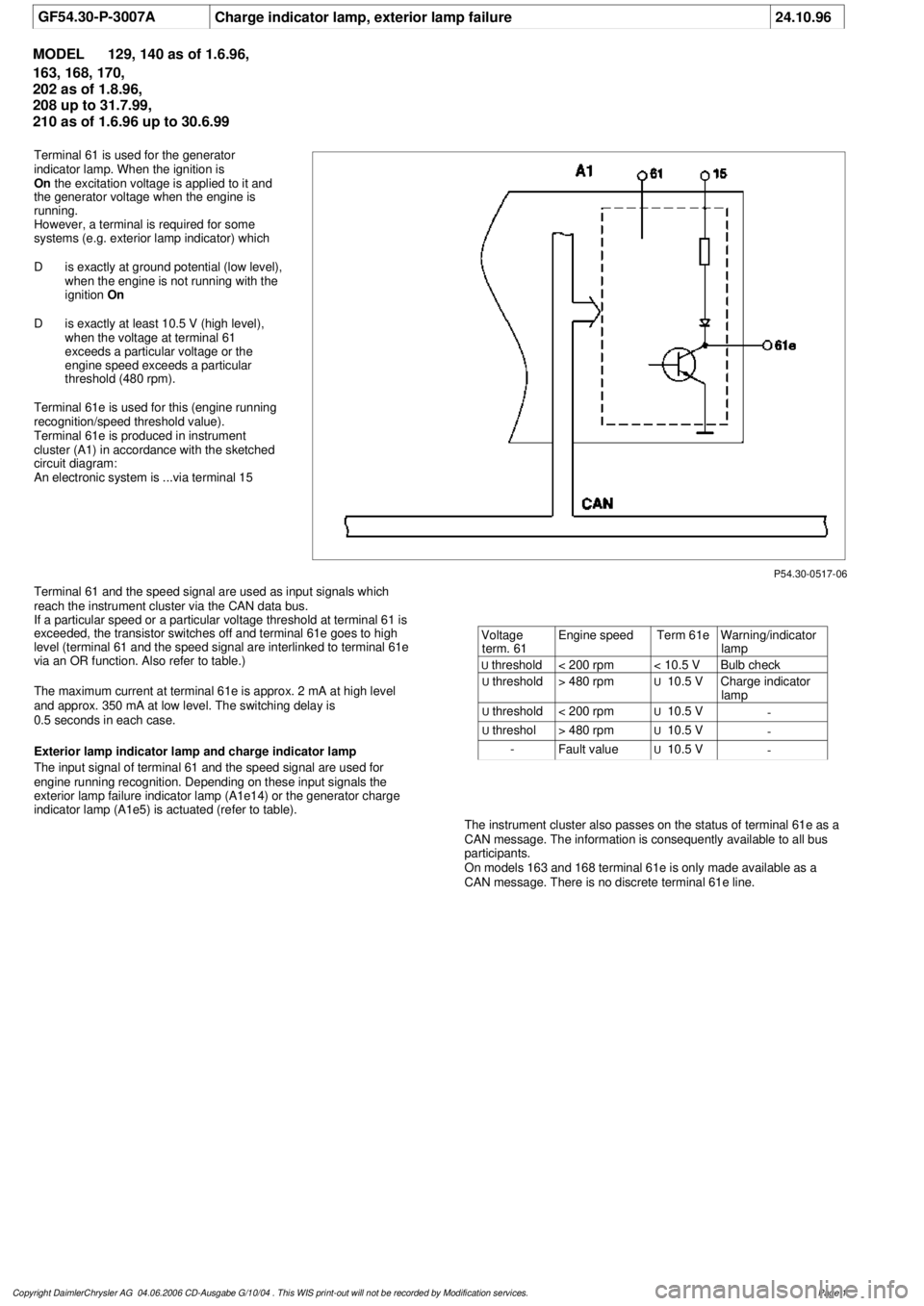

Terminal 61 is used for the generator

indicator lamp. When the ignition is

On

the excitation voltage is applied to it and

the generator voltage when the engine is

running.

However, a terminal is required for some

systems (e.g. exterior lamp indicator) which

D

is exactly at ground potential (low level),

when the engine is not running with the

ignition

On

D

is exactly at least 10.5 V (high level),

when the voltage at terminal 61

exceeds a particular voltage or the

engine speed exceeds a particular

threshold (480 rpm).

Terminal 61e is used for this (engine running

recognition/speed threshold value).

Terminal 61e is produced in instrument

cluster (A1) in accordance with the sketched

circuit diagram:

An electronic system is ...via terminal 15

Terminal 61 and the speed signal are used as input signals which

reach the instrument cluster via the CAN data bus.

If a particular speed or a particular voltage threshold at terminal 61 is

exceeded, the transistor switches off and terminal 61e goes to high

level (terminal 61 and the speed signal are interlinked to terminal 61e

via an OR function. Also refer to table.)

The maximum current at terminal 61e is approx. 2 mA at high level

and approx. 350 mA at low level. The switching delay is

0.5 seconds in each case.

Exterior lamp indicator lamp and charge indicator lamp

The input signal of terminal 61 and the speed signal are used for

engine running recognition. Depending on these input signals the

exterior lamp failure indicator lamp (A1e14) or the generator charge

indicator lamp (A1e5) is actuated (refer to table).

The instrument cluster also passes on the status of terminal 61e as a

CAN message. The information is consequently available to all bus

participants.

On models 163 and 168 terminal 61e is only made available as a

CAN message. There is no discrete terminal 61e line.

Voltage

term. 61

Engine speed

Term 61e

Warning/indicator

lamp

U

threshold

< 200 rpm

< 10.5 V

Bulb check

U

threshold

> 480 rpm

U

10.5 V

Charge indicator

lamp

U

threshold

< 200 rpm

U

10.5 V

-

U

threshol

> 480 rpm

U

10.5 V

-

-

Fault value

U

10.5 V

-

Copyright DaimlerChrysler AG 04.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2035 of 4133

2001-04 STARTING & CHARGING SYSTEMS

Generators & Regulators - 163 Chassis

IDENTIFICATION

CHASSIS & ENGINE IDENTIFICATION

DESCRIPTION

Bosch generators are available in various amp ratings depending on engine application. Voltage regulators are

transistorized and internal to generator. See GENERATOR APPLICATION

table.

GENERATOR APPLICATION

ADJUSTMENTS

DRIVE BELT ROUTING

For drive belt routing, see Fig. 1 . WARNING:Vehicles are equipped with air bag supplemental restraint system. Before

attempting any repairs involving steering column, instrument panel or

related components, see SERVICE PRECAUTIONS (or AIR BAG SAFETY

PRECAUTIONS) and DISABLING & ACTIVATING AIR BAG SYSTEM in

appropriate AIR BAG RESTRAINT SYSTEMS article.

NOTE: When the battery is disconnected, vehicle computer and memory system may

lose data. Driveability problems may exist until computer systems have

completed a relearn cycle.

Model (Year)ChassisEngine

ML55 AMG (2001-03)163.174113.981

ML320 (2001-02)163.154112.942

ML350 (2003-04)163.157112.970

ML430 (2001)163.172113.942

ML500 (2002-04)163.175113.965

ApplicationAmp Rating

V6115

V8150

NOTE: Vehicles have automatic belt tensioners. No adjustment is necessary.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:31 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

me

Saturday, October 02, 2010 3:20:35 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

Page 2037 of 4133

Fig. 1: Drive Belt Routing

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

TROUBLE SHOOTING

PRELIMINARY INSPECTION

Verify customer complaint by operating system. Visually inspect for obvious signs of mechanical and electrical

damage. Check generator belt tension and condition. Ensure that battery voltage is within specifications. Inspect

for blown fuses and damaged relays.

Verify ground connection integrity between engine, body, battery and generator. Check for damaged wiring

harnesses and/or switches. Check for a broken or partially broken wire inside insulation, which could cause

system malfunction but prove good in a continuity/voltage check with system disconnected. Ensure any

aftermarket electronic equipment is properly installed. If fault is found, repair as necessary. If no fault is found,

check for conditions that might cause an intermittent situation.

SERVICE PRECAUTIONS

BATTERY DISCONNECT/CONNECT

Disconnect Procedures

1. On vehicles not equipped with TELE AID, go to step 5 . Vehicles equipped with TELE AID, switch

TELE AID into service mode by turning ignition ON.

2. Turn ON telephone and enter code "*#4610#" on handset.

3. Confirm that "No Telematics Service" appears on handset with okay.

4. Turn OFF handset.

5. Turn OFF ignition.

6. Open hood and open snap fasteners (1) on dust filter housing. See Fig. 2

.

7. Remove dust filter housing (2) exposing battery.

8. If not using quiescent current retention unit, go to step 14 . If using quiescent current retention unit, go to

next step.

9. Connect quiescent current retention unit by switching on quiescent current retention unit (7) and then first

connecting positive terminal (8) and negative terminal (9) of retention unit to positive cable and battery

ground (W10). See Fig. 3

.

10. On vehicles equipped with TELE AID, remove luggage compartment cargo anchoring lugs and remove

floor paneling.

11. Remove screws (1). See Fig. 4

.

12. Dismantle cover from TELE AID control module (A35/8).

13. Disconnect connection coupling for back up battery and remove back up battery.

14. Disconnect ne

gative battery cable (1) and insulate terminal. See Fig. 5. NOTE: Numbers and letters in text refer to numbers and letters in figures.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:31 PMPage 3 © 2006 Mitchell Repair Information Company, LLC.

Page 2042 of 4133

3. Normalize side power windows. See NORMALIZING POWER WINDOWS .

4. Start engine and run at idle. Turn steering wheel from one lock position to the other to activate steering

angle sensor. Center steering wheel. Message "EI. STAB. PROGRAM GO TO GARAGE" should erase

from multifunction display panel.

5. If equipped, normalize tilting/sliding roof. See NORMALIZING TILTING/SLIDING ROOF

.

6. If equipped, normalize memory power seats, steering column and outside mirror if components are

installed. See NORMALIZING MEMORY POWER SEATS, STEERING COLUMN & OUTSIDE

MIRROR .

Normalizing Power Windows

1. Completely close each window with manual switch. Hold switch in closed position for .3 second.

2. Repeat procedure for each power window.

Normalizing Memory Power Seats, Steering Column & Outside Mirror

1. Using manual switch, move seat to each end position and hold for .3 second. Repeat procedure for each

switch except rear stop of backrest.

2. Repeat procedure for end positions of steering wheel and outside mirrors.

Normalizing Tilting/Sliding Roof

Open roof with SR switch until mechanical stop is reached. Continue to press switch for .5 seconds.

Setting Time

1. Use bottom left button on steering wheel to scroll through menus on instrument cluster to "Settings"

menu.

2. Move selection marker with + or - button to "Time" submenu.

3. Press up or down arrows to "Clock, hours" setting. Confirm selection marker is on the hour setting.

4. Press + or - to set hour. Press reset knob in instrument cluster to confirm.

5. Move selection marker with + or - button to "Time" submenu.

6. Press up or down arrows to "Clock, minutes" setting. Confirm selection marker is on the minutes setting.

7. Press + or - to set minute. Press reset knob in instrument cluster to confirm.

TESTING

If generator malfunctions, check for Diagnostic Trouble Codes (DTCs) in Motor Electronics Sequential Fuel

Injection (ME-SFI) system. See appropriate SELF-DIAGNOSTICS article in ENGINE PERFORMANCE. If

cause of generator malfunction is not engine performance related, replace generator.

RETRIEVING & ERASING DIAGNOSTIC TROUBLE CODES

NOTE: Before replacing any component that scan tool suggests are faulty, ensure that

all wiring connections and harness connectors are okay. Ensure that power and

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 8 © 2006 Mitchell Repair Information Company, LLC.

Page 2043 of 4133

RETRIEVING DIAGNOSTIC TROUBLE CODES

To retrieve codes using hand held tester, see Fig. 6 .

Fig. 6: Retrieving Codes Using Hand Held Tester

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

CLEARING DIAGNOSTIC TROUBLE CODES

Disconnecting vehicle battery will not erase codes. Follow scan tool equipment manufacturers instructions to

erase fault codes.

FAULT CODE DIAGNOSIS EQUIPMENT CONNECTION

To connect hand held tester scan tool to Mercedes-Benz data link connector, see Fig. 7 . To connect hand held

ground circuits are functioning properl

y. For circuit identification, see

appropriate WIRING DIAGRAM unde r ENGINE PERFORMANCE in SYSTEM

WIRING DIAGRAMS for vehicle being tested.

NOTE: For diagnostic equipment conn ections, see FAULT CODE DIAGNOSIS

EQUIPMENT CONNECTION .

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Gene rators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 9 © 2006 Mitchell Repair Information Company, LLC.

Page 2048 of 4133

Fig. 8: Connecting Hand Held Tester Scan Tool To OBD-II Data Link Connector

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

ON-VEHICLE TESTING

WIRING CONTINUITY

1. Connect voltmeter between generator B+ terminal and ground. Voltmeter should indicate battery voltage.

If battery voltage is not indicated, check battery and check wiring between generator and battery for

corrosion, loose terminals, etc.

2. Turn ignition on and ensure instrument cluster charge indicator light (battery symbol) comes on. If light

does not come on, check wiring between generator and warning light, including indicator bulb.

GENERATOR OUTPUT

1. Ensure connections at battery and generator are clean and tight. Ensure generator, engine and body are

properly grounded. Ensure generator drive belt is properly adjusted and in good condition.

2. Connect load tester/ammeter as per tester manufacturer's instructions. Connect voltmeter leads to battery

terminals. See Fig. 9

. Start engine and run at 2200 RPM for V6 or 2500 RPM for V8. Adjust load tester

to obtain maximum generator output. DO NOT allow voltage to drop to less than 12.7 volts.

3. Maximum generator output should be within a few amps of generator rated output stamped on generator.

If output is not within a few amps of generator rated output, check generator diodes. See DIODE TEST

.

Replace

generator as necessary.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 14 © 2006 Mitchell Repair Information Company, LLC.

Page 2050 of 4133

VOLTAGE REGULATOR CONTROL

1. Connect multimeter. See Fig. 10 . Ensure charge indicator light goes out when engine is idling and with

increasing engine speed up to 3000 RPM. Apply load to battery by turning on headlights and noting

reading after 2 minutes.

2. Voltage reading should be 13-14.5 volts. If voltage is not to specification, replace voltage regulator. See

VOLTAGE REGULATOR

under REMOVAL & INSTALLATION. If regulator is okay, replace

generator. See GENERATOR under REMOVAL & INSTALLATION.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 16 © 2006 Mitchell Repair Information Company, LLC.

Page 2052 of 4133

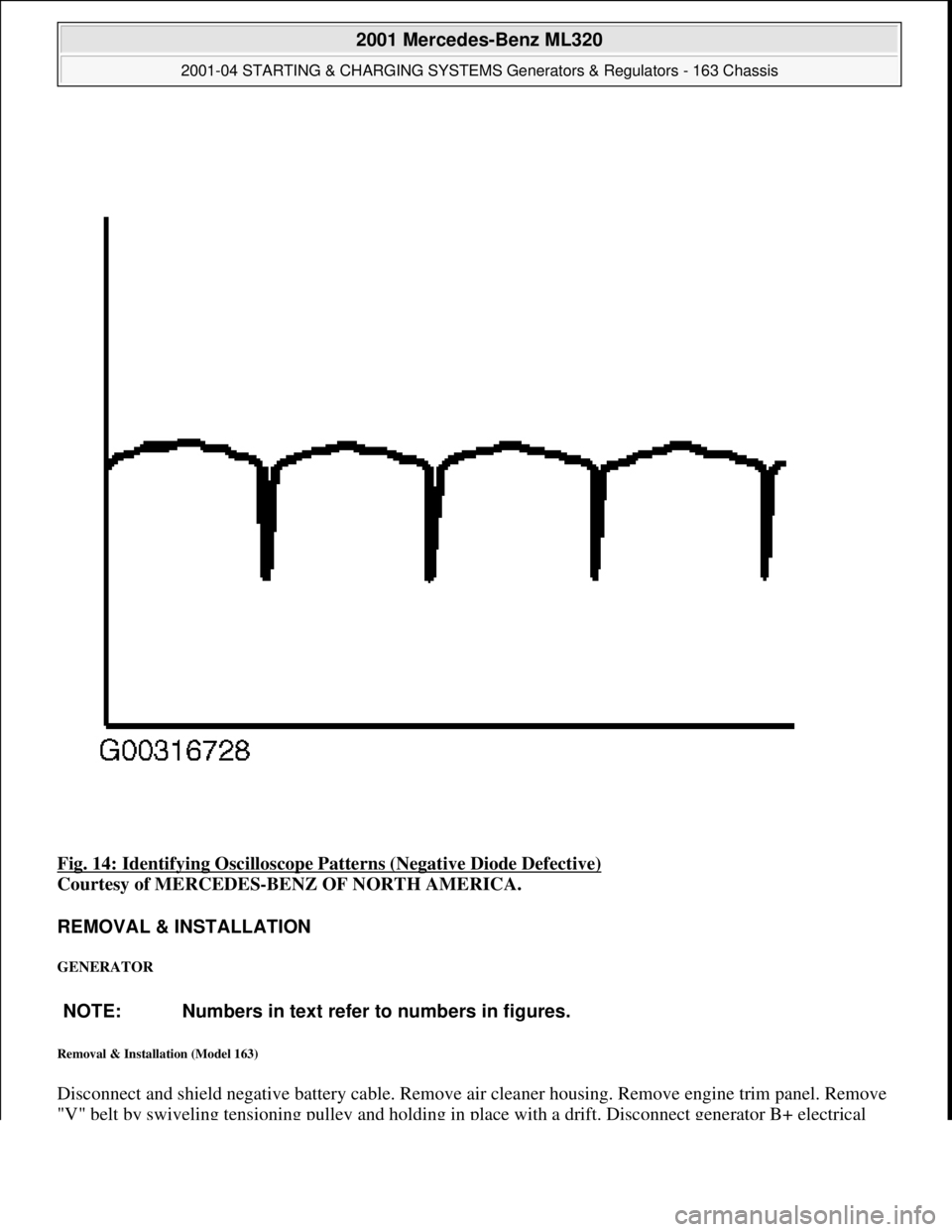

Connect DC clip-on probe from engine tester with oscilloscope to positive battery terminal. See Fig. 11. Start

engine. Switch on low beam. Access diode test at 3000 RPM. See Fig. 12

-Fig. 14 . Replace generator as

necessar

y.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 18 © 2006 Mitchell Repair Information Company, LLC.

Page 2056 of 4133

Fig. 14: Identifying Oscilloscope Patterns (Negative Diode Defective)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

REMOVAL & INSTALLATION

GENERATOR

Removal & Installation (Model 163)

Disconnect and shield negative battery cable. Remove air cleaner housing. Remove engine trim panel. Remove

"V" belt b

y swiveling tensioning pulley and holding in place with a drift. Disconnect generator B+ electrical

NOTE: Numbers in text refer to numbers in figures.

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 22 © 2006 Mitchell Repair Information Company, LLC.

Page 2066 of 4133

GF54.30-P-2004A

Control buttons, location/task

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 170

The instrument cluster has two control buttons which are on the left

or right next to the speedometer.

The

right control button

is used to adjust the time (refer to Owner's

Manual).

-----------------------------------------------------------------------------------------

The

left control button

is used

D

to regulate the instrument illumination

D

to activate the display illumination

D

to reset the trip odometer display

D

to operate the maintenance display (model 170 only bis 05.97)

D

to operate the Active Service System ASSYST (as of 06.97)

-----------------------------------------------------------------------------------------

n

Purpose/function of terminal 58d, instrument

display illumination

Engines 112, 113, 611 (engines with oil

sensor)

GF54.30-P-3008A

n

Electronic clock

GF54.30-P-3011A

n

Active Service System (ASSYST)

GF00.20-P-0003-01A

Operating instructions, resetting

Model 210 as of 01.03.97 with engines M111,

OM 602, OM 604, OM 605 and

OM 606

As of 06/97 models 129, 140, 170, 202 except

engines 112, 113, 611

(valid for engines with oil level switch)

GF00.20-P-0003-01B

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1