change wheel MERCEDES-BENZ ML320 1997 Complete Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1569 of 4133

4-channel power amplifier for vehicle loudspeakers

System interlinkage

The radio and navigation unit (A2/56) is provided with the following components for data exchange with

external digital components:

CAN (A1 -A2/56)

The radio and navigation unit (A2/56) is connected with the instrument cluster (A1) via a separate

CAN bus. The difference to the other CAN systems is indicated by the spelling CAN bus (A1-A2/56).

The CAN bus (A1-A2/56) allows the following functions:

Operation of the radio and navigation unit (A2/56)is also possible with the multifunction steering

wheel.

The multifunction display (A1/p13) in the instrument cluster (A1) can display navigation

information on the current operating status of the radio and navigation unit (A2/56) .

The connection to the CAN bus (A1-A2/56) is only realized on models 208 and 210. (Status 3/99)

Digital data bus (D2B)

Data can be exchanged between the external audio components, the telephone system and - if present -

the voice control system over the D2B bus. This allows control data as well as the actual audio signals

(e.g. music from CD changer) to be transferred.

The only additional D2B component presently possible is the CD changer (A2/6) (Status: 3/99)

K bus (diagnostic interface)

Data exchange is accomplished between the diagnostic interface and the hand-held tester (reading out

DTCs and actual values, ...).

The communication between the HHT and all other D2B components is accomplished over the radio

and navigation unit (A2/56) diagnostic interface.

Audio 30 APS, location of

componentsModel 163GF82.61-P-0002-01D

Model 168GF82.61-P-0002-01B

Model 170GF82.61-P-0002-01A

Model 208, model 210&.2.(GF82.61-P-0002-

01C)

Audio 30 APS block

diagramModel 163GF82.61-P-0002-02D

Model 168GF82.61-P-0002-02B

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:05 PMPage 74 © 2006 Mitchell Repair Information Company, LLC.

Page 1577 of 4133

The navigation processor recognizes the direction of motion (forward or reverse) from the reverse signal.

Direction in which vehicle is pointing

From the data of the gyrosensor and the sequence of the locations calculated with GPS the navigation

processor the calculates the direction in which the vehicle is pointing (compass direction).

The difference between calculated and actual distance traveled between two turning points is used for automatic

recalibration of the tire circumference (required due to tire wear).

Location finding errors during basic location finding

Rolling backwards without the reverse gear engaged is evaluated as forward motion, and may lead to an error in

the location finding.

Rolling with the ignition switched off or vehicle transportation also falsify map matching.

In both cases the deviation is automatically corrected by the navigation processor after receiving GPS data .

Calibration

Wheel calibration is not required following tire change.

GLOBAL POSITIONING SYSTEM LOCATION FINDING, FUNCTION - GF82.61-P-3007C

MODEL 163, 168, 170, 203.0 /2 /7, 208, 209.3 /4, 210 with CODE (353) Audio 30 APS

Basic representation of the GPS location finding shown on model 210

Global positioning system

location finding, function GF82.61-P-3007GI

Map-supported location

finding, function GF82.61-P-3008GI

Guidance, function GF82.61-P-3012GI

Radio and navigation

module, location/purpose/

design/function GF82.61-P-4109GI

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:05 PMPage 82 © 2006 Mitchell Repair Information Company, LLC.

Page 1710 of 4133

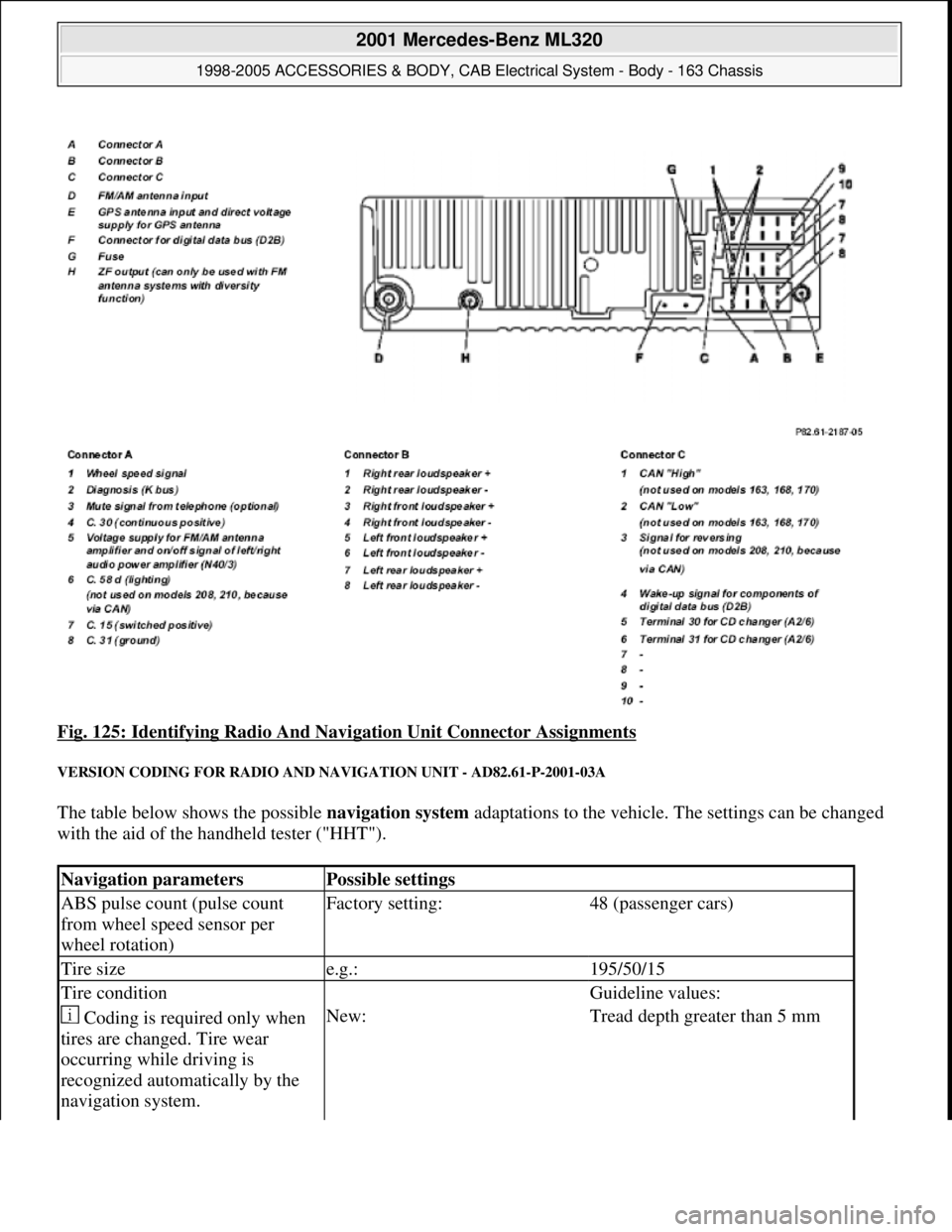

Fig. 125: Identifying Radio And Navigation Unit Connector Assignments

VERSION CODING FOR RADIO AND NAVIGATION UNIT - AD82.61-P-2001-03A

The table below shows the possible navigation system adaptations to the vehicle. The settings can be changed

with the aid of the handheld tester ("HHT").

Navigation parametersPossible settings

ABS pulse count (pulse count

from wheel speed sensor per

wheel rotation)Factory setting:48 (passenger cars)

Tire sizee.g.:195/50/15

Tire condition Guideline values:

Coding is required only when

tires are changed. Tire wear

occurring while driving is

recognized automatically by the

navigation system.New:Tread depth greater than 5 mm

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:08 PMPage 215 © 2006 Mitchell Repair Information Company, LLC.

Page 1830 of 4133

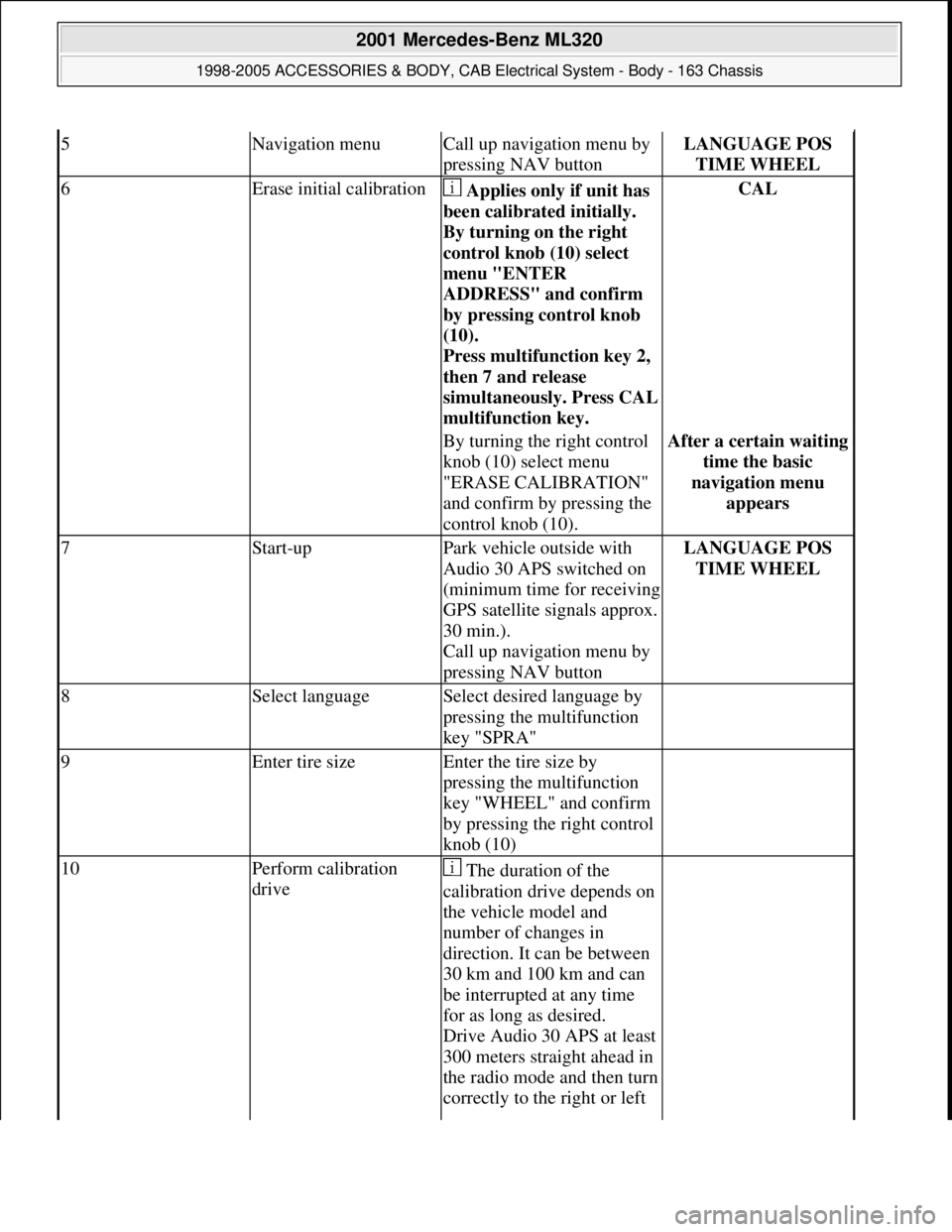

5Navigation menuCall up navigation menu by

pressing NAV buttonLANGUAGE POS

TIME WHEEL

6Erase initial calibration Applies only if unit has

been calibrated initially.

By turning on the right

control knob (10) select

menu "ENTER

ADDRESS" and confirm

by pressing control knob

(10).

Press multifunction key 2,

then 7 and release

simultaneousl

y. Press CAL

multifunction key.

CAL

By turning the right control

knob (10) select menu

"ERASE CALIBRATION"

and confirm by pressing the

control knob (10).After a certain waiting

time the basic

navigation menu

appears

7Start-upPark vehicle outside with

Audio 30 APS switched on

(minimum time for receiving

GPS satellite signals approx.

30 min.).

Call up navigation menu by

pressing NAV buttonLANGUAGE POS

TIME WHEEL

8Select languageSelect desired language by

pressing the multifunction

key "SPRA"

9Enter tire sizeEnter the tire size by

pressing the multifunction

key "WHEEL" and confirm

by pressing the right control

knob (10)

10Perform calibration

drive The duration of the

calibration drive depends on

the vehicle model and

number of changes in

direction. It can be between

30 km and 100 km and can

be interrupted at any time

for as long as desired.

Drive Audio 30 APS at least

300 meters straight ahead in

the radio mode and then turn

correctly to the right or left

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 335 © 2006 Mitchell Repair Information Company, LLC.

Page 2061 of 4133

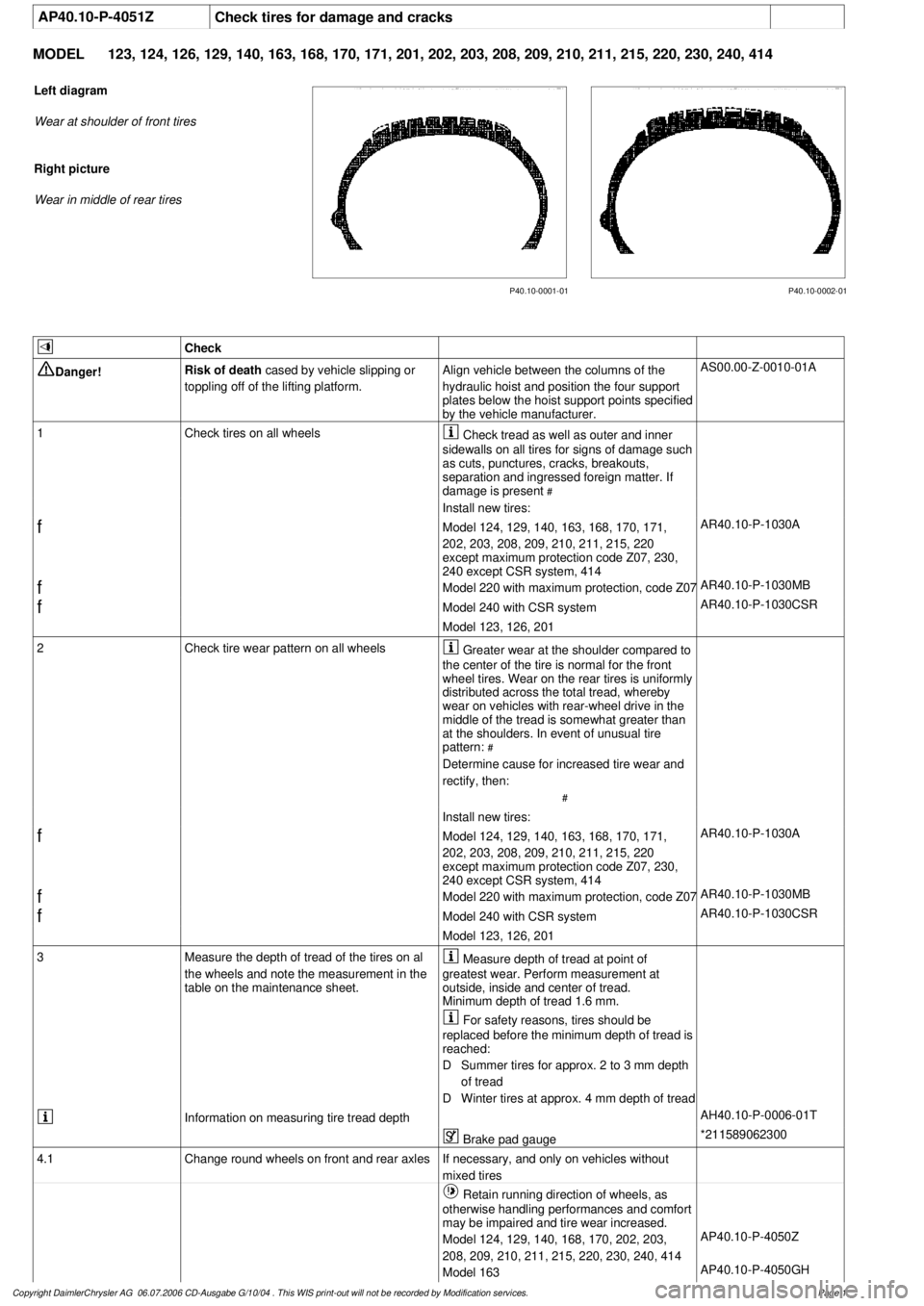

AP40.10-P-4051Z

Check tires for damage and cracks

MODEL

123, 124, 126, 129, 140, 163, 168, 170, 171, 201, 202, 203, 208, 209, 210, 211, 215, 220, 230, 240, 414

P40.10-0002-01

P40.10-0001-01

Left diagram

Wear at shoulder of front tires

Right picture

Wear in middle of rear tires

Check

Danger!

Risk of death

cased by vehicle slipping or

toppling off of the lifting platform.

Align vehicle between the columns of the

hydraulic hoist and position the four support

plates below the hoist support points specified

by the vehicle manufacturer.

AS00.00-Z-0010-01A

1

Check tires on all wheels

Check tread as well as outer and inner

sidewalls on all tires for signs of damage such

as cuts, punctures, cracks, breakouts,

separation and ingressed foreign matter. If

damage is present

#

Install new tires:

f

Model 124, 129, 140, 163, 168, 170, 171,

202, 203, 208, 209, 210, 211, 215, 220

except maximum protection code Z07, 230,

240 except CSR system, 414

AR40.10-P-1030A

f

Model 220 with maximum protection, code Z07

AR40.10-P-1030MB

f

Model 240 with CSR system

AR40.10-P-1030CSR

Model 123, 126, 201

2

Check tire wear pattern on all wheels

Greater wear at the shoulder compared to

the center of the tire is normal for the front

wheel tires. Wear on the rear tires is uniformly

distributed across the total tread, whereby

wear on vehicles with rear-wheel drive in the

middle of the tread is somewhat greater than

at the shoulders. In event of unusual tire

pattern:

#

Determine cause for increased tire wear and

rectify, then:

#

Install new tires:

f

Model 124, 129, 140, 163, 168, 170, 171,

202, 203, 208, 209, 210, 211, 215, 220

except maximum protection code Z07, 230,

240 except CSR system, 414

AR40.10-P-1030A

f

Model 220 with maximum protection, code Z07

AR40.10-P-1030MB

f

Model 240 with CSR system

AR40.10-P-1030CSR

Model 123, 126, 201

3

Measure the depth of tread of the tires on al

the wheels and note the measurement in the

table on the maintenance sheet.

Measure depth of tread at point of

greatest wear. Perform measurement at

outside, inside and center of tread.

Minimum depth of tread 1.6 mm.

For safety reasons, tires should be

replaced before the minimum depth of tread is

reached:

D

Summer tires for approx. 2 to 3 mm depth

of tread

D

Winter tires at approx. 4 mm depth of tread

Information on measuring tire tread depth

AH40.10-P-0006-01T

Brake pad gauge

*211589062300

4.1

Change round wheels on front and rear axles

If necessary, and only on vehicles without

mixed tires

Retain running direction of wheels, as

otherwise handling performances and comfort

may be impaired and tire wear increased.

Model 124, 129, 140, 168, 170, 202, 203,

208, 209, 210, 211, 215, 220, 230, 240, 414

AP40.10-P-4050Z

Model 163

AP40.10-P-4050GH

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2523 of 4133

Fig. 3: Identifying Front Axle Components

Position in major assemblies compartment (left and right)

Fig. 4: Identifying RPM Sensor Connector

Modification notes

7.11.00Figure modified from 170 Nm to

200 NmValue in BA33.10-P-1001-01C changed

for Model 163*BA33.10-P-1001-

01C

Remove/install

Notes on self-locking nuts

and boltsAll modelsAH00.00-N-0001-01A

1Remove front wheels

Remove/install wheels,

rotate if necessaryAP40.10-P-4050GH

2Remove shock absorber AR32.25-P-0105GH

3Unplug speed sensor

connector (L6/1x1,

L6/2x1)

Risk of poisoning caused

by swallowing brake

fluid. Risk of injury

caused by brake fluid

coming into contact with

skin and eyes.Pour brake fluid only into

suitable and appropriately

marked containers. Wear

protective clothing and eye

protection when handling

brake fluid.AS42.50-Z-0001-01A

4Unscrew brake pipe from

brake hoseSeal off line connections

with plugs to prevent brake

fluid from running out.

Installation: The brake

hose must not be twisted

after tightening.

Brake fluid notesAll modelsAH42.50-P-0001-01A

Notes on installation of Model Series 163AH42.10-P-9406-01GH

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:21 PMPage 4 © 2006 Mitchell Repair Information Company, LLC.

Page 2541 of 4133

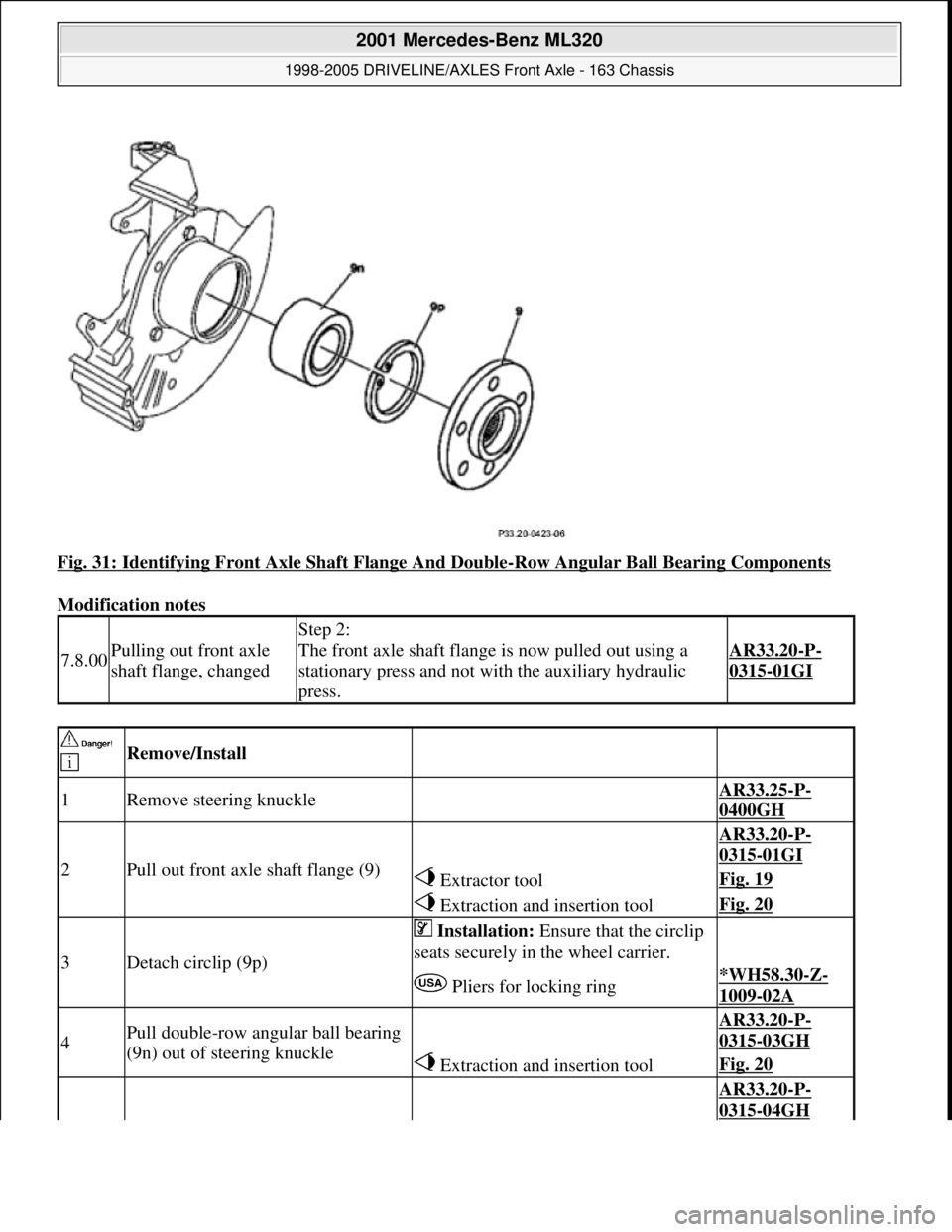

Fig. 31: Identifying Front Axle Shaft Flange And Double-Row Angular Ball Bearing Components

Modification notes

7.8.00Pulling out front axle

shaft flange, changed

Step 2:

The front axle shaft flange is now pulled out using a

stationary press and not with the auxiliary hydraulic

press.

AR33.20-P-

0315-01GI

Remove/Install

1Remove steering knuckle AR33.25-P-

0400GH

2Pull out front axle shaft flange (9)

AR33.20-P-

0315-01GI

Extractor toolFig. 19

Extraction and insertion toolFig. 20

3Detach circlip (9p)

Installation: Ensure that the circlip

seats securely in the wheel carrier.

Pliers for locking ring*WH58.30-Z-

1009-02A

4Pull double-row angular ball bearing

(9n) out of steering knuckle AR33.20-P-

0315-03GH

Extraction and insertion toolFig. 20

AR33.20-P-

0315-04GH

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 22 © 2006 Mitchell Repair Information Company, LLC.

Page 3056 of 4133

modification kit, code U47

except styling package, U49

Engine 612.963 in model 163.113 except

modification kit, code U47

except styling package, U49

Engine 628.963 in model 163.128 except

modification kit, code U47

except styling package, U49

AZ82.20-P-0001B Retrofit illuminated

door sill moldingModel 163.113/128/136/154/172/174/175AZ82.20-P-0001B

AZ82.64-P-

0001MA

Retrofitting CD

changerModel 163 as of 1.7.99 along with Audio

10 radio, Audio 30 or COMAND operating

and display unit and D2B fiber optic cableAZ82.64-P-

0001MA

AZ82.70-P-0002A Retrofitting

permanently

installed D-network

telephoneModel 163 up to 30.11.99 Permanently

installed Nokia 6081 telephoneAZ82.70-P-0002A

AZ82.70-P-0002C Retrofitting

permanently

installed D-network

telephoneModel 163 as of 1.12.99 up to 31.8.00

Telephone fixed installation Nokia 6090AZ82.70-P-0002C

AZ82.70-P-

0002GH

Retrofitting

permanently

installed D-network

telephoneModel 163 from 1.9.00 to 30.9.01 except

code 352a, COMAND operating and

display unit, fixed-installation Nokia 6090

telephoneAZ82.70-P-

0002GH

AZ82.70-P-0001A Retrofit D-network

cell phoneModel 163 up to 30.11.99 permanently

installed Nokia 3110 cell phoneAZ82.70-P-0001A

AZ82.70-P-0001D Retrofit D-network

cell phoneModel 163 as of 1.12.99 up to 31.8.00

Portable CTEL Nokia 3110AZ82.70-P-0001D

AZ82.70-P-

0001GH

Retrofit D-network

cell phoneModel 163 as of 1.10.01, only for D-

network portable CTELAZ82.70-P-

0001GH

AZ88.30-P-0002A Retrofitting outer

spare wheel holderModels 163.113/128/136/154/172/175,

except styling package, code U49AZ88.30-P-0002A

AZ82.60-P-0004A Retrofit vehicle

video systemModels 163.136 /154 /172 1A as of

145273, 163.136/154/172 1X as of 708319,

163.113/128/157/174/175 1# left-hand

drive vehicleAZ82.60-P-0004A

AZ82.60-P-0004BRetrofit vehicle

video systemModels 163.136 /154 /172 2A as of

145273, 163.136 /154 /172 2X as of

708319, 163.113/128 /157 /174 /175 2#

right-hand drive vehicleAZ82.60-P-0004B

AZ88.30-P-

0006GH

Retrofit side step barModels 163.113 /128 /136 /154 /172 /175,

except styling package, code U49AZ88.30-P-

0006GH

AZ88.30-P-

0005GHRetrofit protective

side moldingModels 163.113/128/136/154/172/175,

except styling package, code U49AZ88.30-P-

0005GH

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 411 © 2006 Mitchell Repair Information Company, LLC.

Page 3147 of 4133

low-viscosity base oils are not permitted. The kinematic viscosity at 100°C 2 must be at least 9.5 mm /s.

In hot zones, gear oils of SAE grade 90 are also permitted.

2.2 Alternative transmission lubricants for commercial vehicle synchromesh transmissions which are

operated with transmission oils as per sheets 235.1, 235.5.

If there are no gear oils according to Sheet 235.1 and 235.5 available, the following engine oils can also

be used as alternatives:

In a moderate climate, engine oils of SAE-grade 30 as per sheet 235.12

In tropical climate, engine oils of SAE-grade 40 as per sheet 235.12

2.3 Fully synthetic transmission oil, sheet 235.4

Completely synthetic gear oils are imperative for the Unimog manual transmission UG 3/40, UG 3/65 and

the PTO transmission -as of the vehicle end No. ...179909 -. Older vehicles can have their oils changed

from gear oils according to Sheet 235.1 to gear oils according to Sheet 235.4 when an oil change is due.

The gear oils correspond to the ZF lubricant specifications TE-ML01 and TE-ML02 and are consequently

alternatives to the gear oils according to Sheet 235.1 in all synchronized ZF manual transmissions

installed in MB vehicles, with and without intarders. Furthermore, the approval extends to the MB

transfer case VG 2400 without oil cooler. Due to the favorable viscosity/temperature characteristics, a

good cold-shifting response and, due to the composition of the transmission oil, a good thermal/oxidative

stability of the oil at high transmission oil temperatures can be expected.

2.4 Transmission oils, sheet 235.5

The gear oils are approved for MB and ZF manual transmissions with steel/molybdenum synchronization,

MB and ZF transfer cases and corner gears.

The transmission oils have a low chlorine content as well as a potential for lower oil temperatures under

certain operating conditions.

2.5 Transmission oils, sheet 235.10

The partly synthetic gear oils are approved for the commercial vehicle manual transmission Model

G16/G28, for the passenger vehicle front-wheel-drive manual transmission SG 150/180 (A class) as well

as for all passenger vehicle in-line transmissions of the model series 717.4 as of transmission serial

number 7 340 241.

Due to the favorable viscosity/temperature characteristics, a very good cold-shifting response and, due to

the composition of the transmission oil, a good thermal/oxidative stability of the oil at high transmission

oil temperatures can be expected.

With regard to the use in passenger vehicle front-wheel drive manual transmissions/in-line transmissions,

which are also installed in cross-countr

y vehicles, the approved gear oil is usually only used in the event

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:56 PMPage 502 © 2006 Mitchell Repair Information Company, LLC.

Page 3176 of 4133

Because the brake fluid also absorbs moisture through the vent bore on the expansion reservoir, the wheel brake

cylinder and the brake hoses, the brake fluid has to be changed for safety reasons at regular intervals, best done

in the spring. When performing this change, make sure that the old fluid is also drained off the clutch system.

Generally, it is vital for the brake/clutch system to be completely drained before being filled with new fluid!

For the above-mentioned reasons, used brake fluid must not be used again.

The brake fluid is amber in color and thus can be easily confused with mineral products.

Therefore, brake fluids should always only be taken from original containers and stored separately from other

mineral oils and fluids.

When performing maintenance operations and repairs on brake parts, make sure that fuel, mineral oil, grease or

suchlike do not enter the brake system. Hydrocarbon-based materials will lead to swelling of the elastomers in

the brake and clutch system and - even in low concentrations - will suffice to cause total failure of the systems.

Only new brake fluid may be used as a rinsing and cleaning agent for the cylinders, lines and the expansion

reservoir of the hydraulic brake system.

Experience shows that before handling brake fluid, the hands must be cleaned and any oil and grease removed.

Brake fluid acts aggressively towards paint and color. In the event of any brake fluid spills or splashes, it must

be rinsed away immediately using copious amounts of water (do not rub it away).

Brake fluid disposal

When disposing of brake fluid, the relevant national specifications must be observed. It is advisable to try to

have the brake fluid disposed of as economic good; this is contingent on

Strict separation of used brake fluid from other materials;

Presence of a disposal channel, which justifies its classification as an economic good, i.e. a proper

alternate usage must be assured.

If this procedure is not possible, used brake fluid is to be disposed of together with any, e.g. paint residue,

solvents and suchlike. Any adding of used oil must be avoided, as it will result in difficulties, if the used oil is to

be recycled; in several countries this is prohibited by the legislators.

MISCELLANEOUS NOTES

NOTES ON SCRAPPING GAS-FILLED HYDRAULIC COMPONENTS - OS00.00-P-1000-01A

all

Unusable gas pressure dampers, spring accumulators, pressure reservoirs and impact absorbers have to be

depressurized before being scrapped according to the respective valid accident prevention regulations. These

safety measures are necessary because gas pressurized hydraulic parts can explode if heat is applied. A risk of

explosion is

given, e.g. when scrapping with cutting torches, smelting or if gas pressurized parts in landfills start

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 531 © 2006 Mitchell Repair Information Company, LLC.